In any mechanical system, grasping the layout and function of each element is essential for effective maintenance and repair. A comprehensive overview of these components allows individuals to troubleshoot issues efficiently and ensure optimal performance. This section aims to clarify the organization and interrelation of various machine elements, providing valuable insights into their operations.

Exploring the structure of these systems reveals intricate relationships among different units. Each segment plays a crucial role in the overall functionality, and recognizing how they connect can greatly enhance problem-solving skills. By familiarizing oneself with these intricacies, operators can make informed decisions regarding upkeep and repairs, ultimately prolonging the life of the machinery.

Various engine systems have become widely recognized for their durability and reliability in different applications. These power units, commonly found in a range of machinery, are valued for their versatility, adapting to both residential and industrial environments. Understanding the differences between these models can help users identify which one suits their specific needs best.

- Model A – Known for its compact design, this unit is often preferred in smaller installations where space is limited. It provides efficient performance without compromising power output.

- Model B – A mid-range option, this version strikes a balance between size and power. It is frequently used in both commercial and residential settings, offering a good combination of reliability an

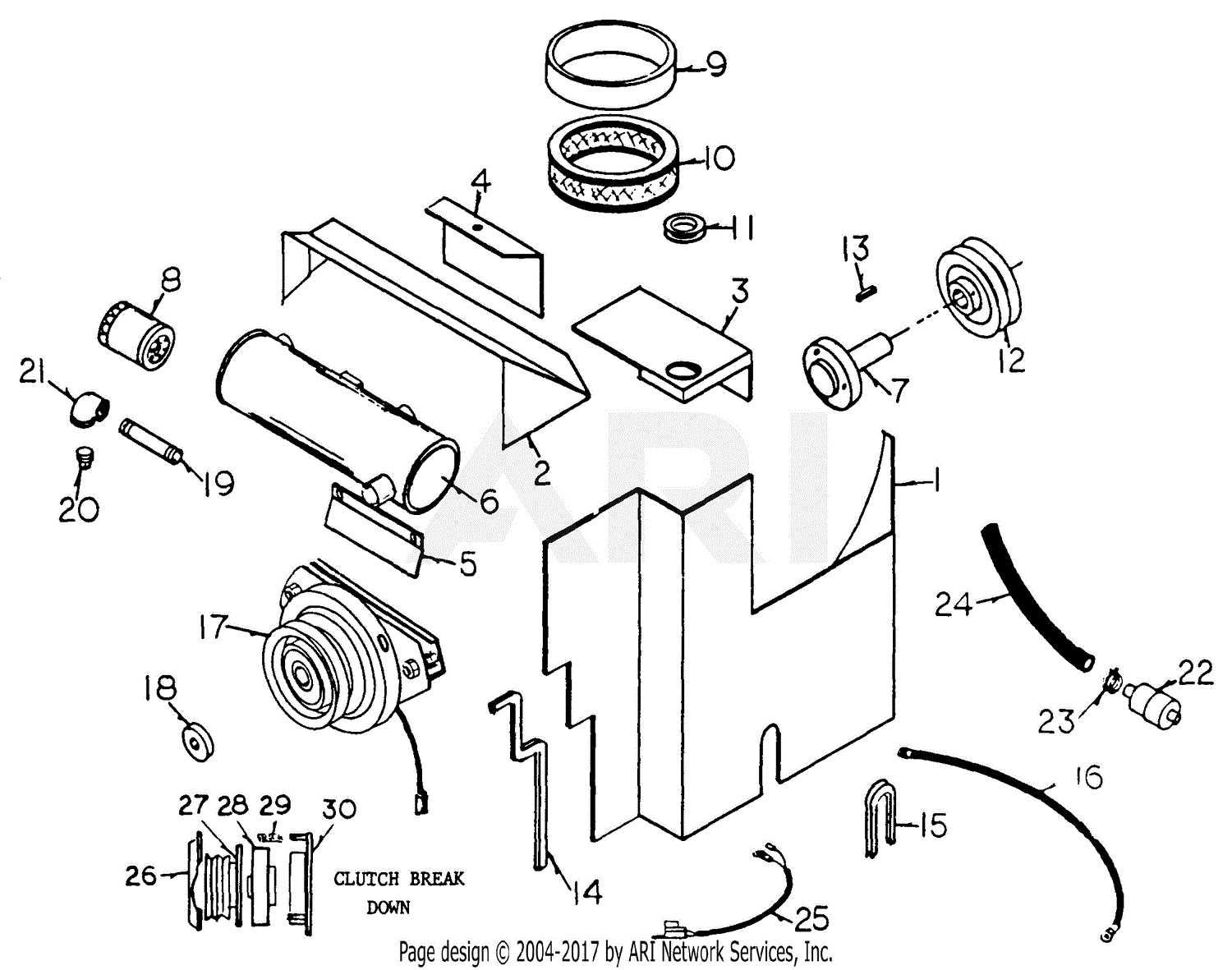

Components in Onan Generators

Power systems rely on various interconnected elements that ensure seamless operation and efficient energy production. Understanding the main components is essential for both maintenance and troubleshooting, as each element plays a crucial role in the functionality of the entire system.

Key Elements of the System

The structure of these power units includes several fundamental parts, each responsible for a specific function. These components work in harmony to produce, regulate, and distribute energy efficiently.

- Engine: The core of the power unit, responsible for driving mechanical force and converting it into electrical output.

- Alternator: This component generates electricity by converting mechanical energy from the

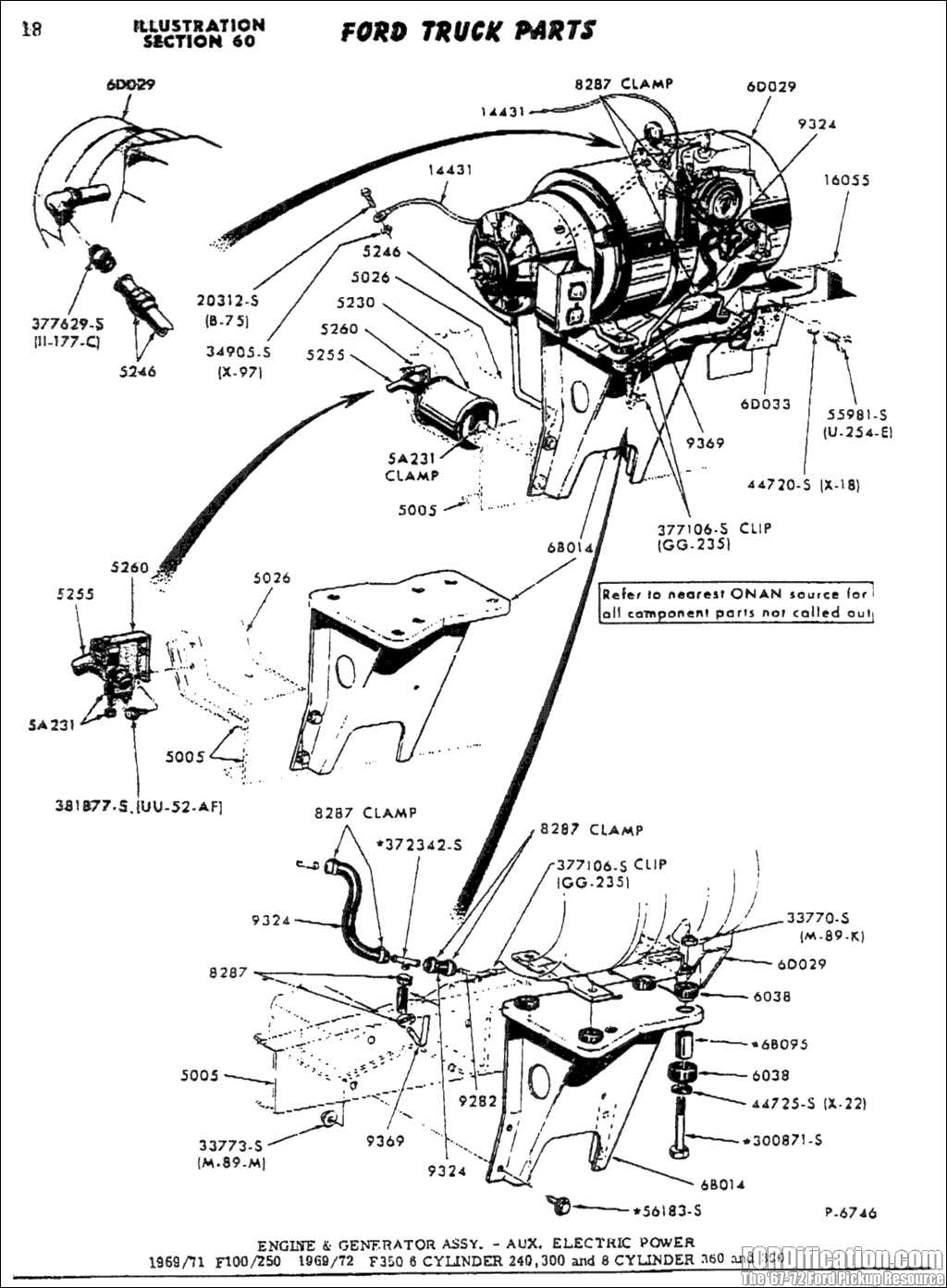

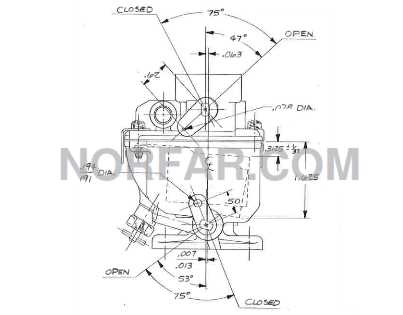

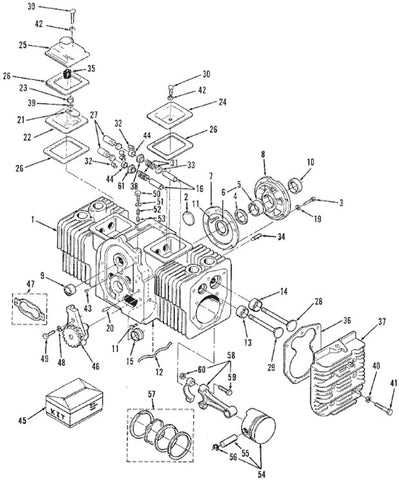

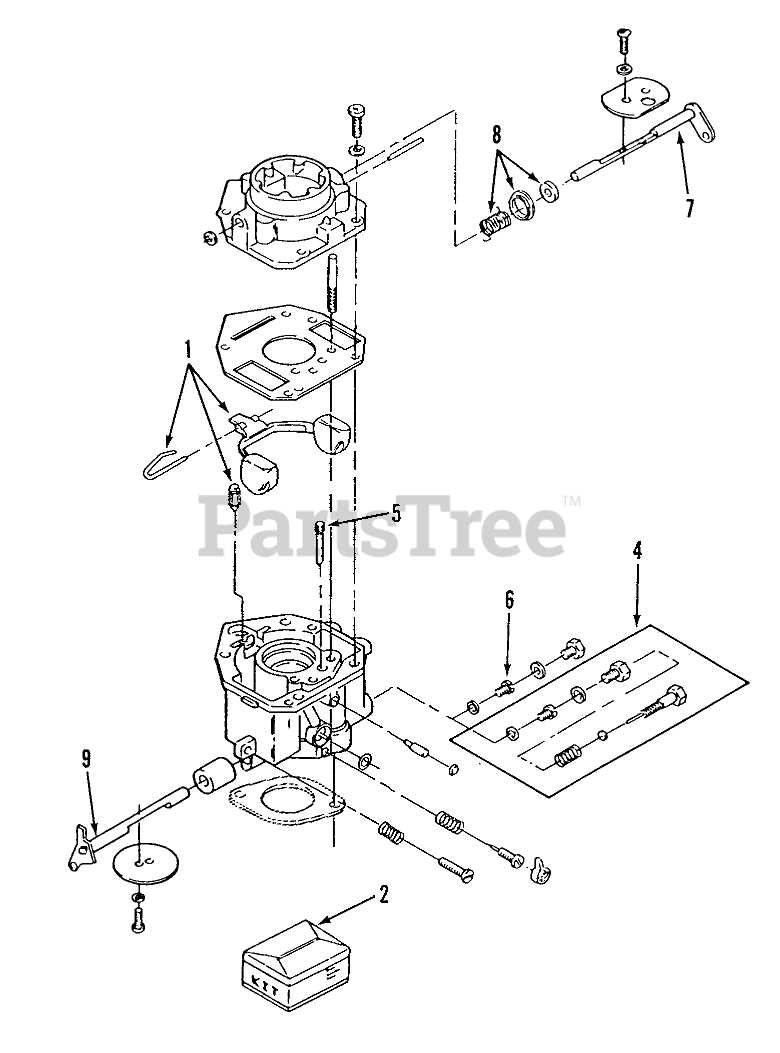

How to Read a Parts Diagram

Understanding visual breakdowns of mechanical components is essential when working with complex systems. These illustrations provide a detailed view of how individual elements are assembled and connected, making it easier to identify, replace, or repair specific sections of a system.

To effectively interpret these schematics, follow a systematic approach. First, familiarize yourself with the labels or numbers associated with each component. Next, cross-reference these with the accompanying legend or chart to learn more about each item’s function or specifications. Finally, pay attention to the order and orientation of each piece within the whole assembly.

Step Description 1 Examine the visual layout of components. Identifying Spare Parts Quickly

Ensuring fast identification of replacement components is key to maintaining the efficiency of any mechanical system. Knowing how to locate the right elements within a complex assembly saves time and prevents unnecessary downtime. This guide will help streamline the process, allowing for quick and accurate selections without confusion.

Efficient Categorization

One of the most effective ways to speed up recognition is through organized categorization. By grouping similar elements together based on their function, location, or size, you can drastically reduce the time spent searching. Additionally, labels or codes associated with each group make identification straightforward.

Using a Visual Reference

A de

Maintenance Tips for Onan Units

Regular upkeep of power equipment ensures longevity and smooth operation, preventing unnecessary breakdowns. By following essential guidelines, users can extend the service life of their devices and maintain consistent performance.

Check Fluid Levels: One of the key steps in keeping your system functional is monitoring and replenishing all necessary fluids. This includes fuel, coolant, and oil, which are vital for the efficient running of your machine.

Filter Maintenance: Filters play a critical role in keeping your device free from harmful debris. Make sure to inspect air and oil filters regularly, replacing them when needed to avoid potential malfunctions.

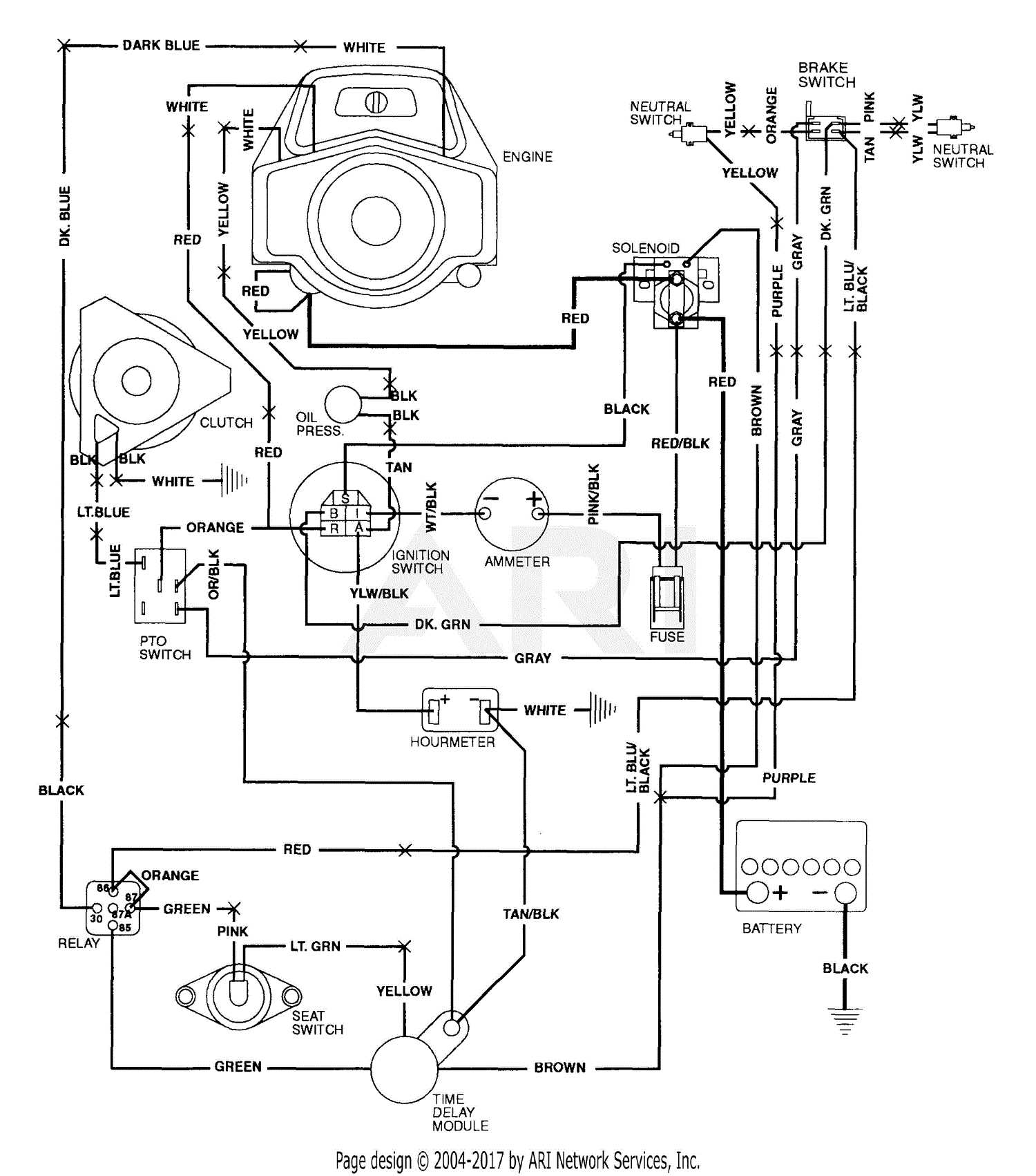

Inspect Electrical Connections: Over time, wires and connectors can loosen or become corroded. To prevent electrical issues, regularly check all connections and ensure they are secure and free of oxidation.

Proactive care will help avoid costly repairs

Where to Find Replacement Parts

Finding the right components for equipment maintenance is essential for ensuring long-term functionality. Whether you’re looking for internal mechanisms or external accessories, knowing where to search for quality replacements is key to avoiding potential issues down the road.

Online stores are a popular and convenient option, offering a wide range of compatible items for different models and needs. Many websites also provide detailed descriptions, which help you make informed decisions.

For those who prefer a more hands-on approach, local suppliers and specialized stores can be ideal for checking the condition of items before purchasing. These locations often provide expert advice, which can be invaluable in identifying the right solutions for your machinery.

Lastly, consulting authorized service centers ensures that you are getting original components, which are often backed by warranties. These centers can also provide installation

Understanding Wiring Diagrams

Wiring diagrams are essential tools used to visually represent electrical circuits. They help users comprehend the connections and relationships between different components in a system. By reading these illustrations, individuals can trace the flow of electricity, identify connections, and understand how various elements interact within the circuit.

Symbols and Their Meanings

Each wiring diagram uses standard symbols to represent electrical components, making it easier to follow. Understanding these symbols is key to interpreting the diagram correctly. Common symbols may include switches, wires, and power sources, each depicted in a simplified format to avoid confusion.

- Lines represent the wires that connect components.

- Switches are often drawn as break

Visual References for Repairs

When working on equipment maintenance, having clear visual aids can greatly enhance the repair process. These resources provide a visual breakdown of components, allowing technicians to quickly identify and understand the structure of the system. Using visual references ensures that each element is correctly placed and handled during the repair process, reducing the chance of errors.

In addition, these visual tools can help troubleshoot specific issues, making it easier to locate problem areas. Whether it’s for routine maintenance or complex fixes, having access to such resources can streamline the entire workflow and improve efficiency.

Integrating Diagrams in Troubleshooting

Visual aids play a vital role in diagnosing technical issues, providing a clear reference for identifying problems quickly and efficiently. By combining schematic representations with practical knowledge, technicians can streamline their workflow and minimize potential errors during the repair process. These tools are particularly useful for those unfamiliar with a system, offering a structured approach to understanding its components and connections.

Benefits of Visual Aids

The use of schematics offers several advantages, including enhanced clarity, reduced troubleshooting time, and the ability to pinpoint specific issues without the need for extensive guesswork. This method helps prevent misinterpretations and provides a solid foundation for accurate diagnostics, particu

Best Practices for Diagram Use

Understanding visual representations can greatly enhance efficiency when working with technical systems. These visuals simplify complex processes, helping users quickly identify key elements and their functions. Applying effective strategies ensures that users maximize the potential of these resources while minimizing errors and misunderstandings.

Clear Labeling and Structure

A well-organized visual guide should always be clearly labeled. Each component should have distinct identifiers, and the layout should follow a logical flow that is easy to interpret. This helps to quickly locate the necessary elements and reduces the time spent on identifying details. Consider using a table for additional clarity, providing direct references to specific elements and their descriptions.

Component Description Resources for Further Learning

For those seeking to deepen their understanding of machinery and its components, numerous valuable materials are available. Engaging with various educational tools can enhance knowledge and practical skills related to maintenance and repair.

Books and Manuals: A wide range of literature covers technical aspects, providing insights into functionality and troubleshooting techniques. Reference manuals can offer step-by-step guidance and detailed explanations of different systems.

Online Courses: Many platforms offer structured courses that delve into equipment operation and servicing. These courses often include videos, quizzes, and interactive content to facilitate learning.

Forums and Communities: Participating in online forums can connect enthusiasts and professionals, allowing for the exchange of experiences and solutions. Engaging in discussions can broaden perspectives and enhance practical knowledge.

Videos and Tutorials: Video platforms host numerous tutorials that visually demonstrate repairs and maintenance tasks. These resources can be particularly helpful for visual learners who benefit from seeing processes in action.

Workshops and Seminars: Attending local workshops or seminars can provide hands-on experience and direct interaction with experts. Networking opportunities at these events can also lead to valuable insights and resources.