When it comes to maintaining your trimming equipment, having a clear understanding of its various components is essential. This knowledge not only helps in identifying parts that may require replacement but also aids in enhancing the overall performance of your tool. By familiarizing yourself with the intricate layout of the mechanism, you can ensure efficient operation and longevity.

In this section, we will explore a detailed representation of the essential elements that comprise your device. Understanding how these components interact is crucial for effective troubleshooting and repair. With a comprehensive overview, you will be better equipped to manage maintenance tasks, ensuring that your equipment remains in optimal condition.

Whether you are a novice user or an experienced professional, recognizing the specific roles of each piece can significantly impact your trimming experience. By taking the time to delve into the construction and functionality, you pave the way for a more informed approach to care and usage.

Oregon PS250 Overview

This section provides a comprehensive look at a versatile cutting tool designed for efficient branch trimming and maintenance tasks. Ideal for both residential and professional use, this equipment is engineered to simplify tree care and enhance productivity in outdoor environments.

Key Features

- Lightweight design for ease of maneuverability

- Powerful motor for efficient cutting

- Adjustable length to reach higher branches

- User-friendly controls for effortless operation

Applications

- Perfect for maintaining trees and shrubs

- Ideal for clearing fallen branches after storms

- Useful for preparing firewood

- Great for landscaping projects

Key Features of the PS250

This section highlights the standout characteristics of the cutting tool, designed for efficiency and ease of use. The combination of innovative engineering and user-friendly features makes it a valuable addition to any garden maintenance toolkit.

Ergonomic Design

The tool boasts an ergonomic construction that reduces strain during prolonged use. Its lightweight frame ensures maneuverability, allowing users to reach high branches with minimal effort.

Powerful Performance

Equipped with a robust motor, this device delivers impressive cutting power. It can handle a variety of tasks, making it suitable for both residential and professional applications.

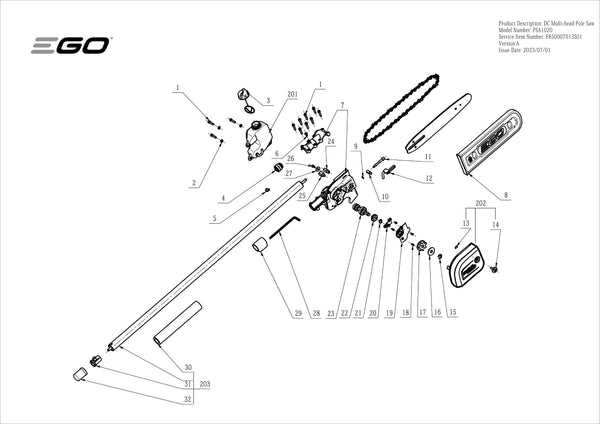

Understanding the Parts Diagram

The visual representation of components is essential for comprehending the assembly and functionality of any tool. By examining this schematic, users can identify each element’s role and how they interact to ensure optimal performance. This understanding can significantly enhance maintenance and troubleshooting efforts.

Components are usually labeled to facilitate easy identification, making it simpler to locate replacements or perform repairs. The arrangement often reflects the tool’s operational flow, highlighting critical connections that affect overall efficiency.

Familiarizing oneself with this visual guide empowers users to make informed decisions regarding repairs and upgrades. Knowledge of each segment’s purpose can lead to better care and prolonged lifespan of the equipment.

Common Issues with Pole Saws

When utilizing extended cutting tools, several challenges may arise, affecting performance and user experience. Understanding these frequent problems can help in maintaining efficiency and prolonging the lifespan of the equipment.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Overheating | Excessive heat emission, smoke | Allow cooling, check lubrication |

| Inconsistent cutting | Uneven results, difficulty | Sharpen or replace cutting blade |

| Vibration | Excessive shaking, discomfort | Tighten loose components, inspect balance |

| Power loss | Reduced effectiveness, stalling | Check fuel, clean air filter |

How to Maintain Your PS250

Regular upkeep of your cutting tool is essential for ensuring optimal performance and longevity. By following a few simple practices, you can enhance its efficiency and prevent potential issues. This guide outlines key maintenance steps that will keep your equipment running smoothly.

Begin by inspecting the tool before each use. Look for any signs of wear or damage, especially on the cutting mechanism. Ensure that all components are securely attached and functioning correctly. Cleaning the exterior and interior parts after each session will help remove debris and sap, which can hinder performance.

Sharpening the cutting edge is crucial for effective operation. A sharp edge not only increases efficiency but also reduces strain on the motor. Regularly check and replace any dull or damaged blades as needed.

Lubrication of moving parts is another vital aspect of maintenance. Applying the appropriate lubricant to specified areas will minimize friction and prolong the life of your tool. Always refer to the manufacturer’s guidelines for the recommended type and frequency of lubrication.

Finally, store your equipment in a dry, protected environment when not in use. This practice prevents rust and other forms of deterioration. By adhering to these maintenance tips, you can ensure your tool remains in peak condition, ready for your next task.

Tools Required for Repairs

When it comes to maintaining and fixing equipment, having the right tools is essential for effective and efficient repairs. This section outlines the necessary instruments that will help ensure a smooth and successful repair process, allowing users to tackle any issues with confidence.

Basic Hand Tools

To start, a variety of hand tools should be readily available. These include screwdrivers, wrenches, and pliers, which are fundamental for disassembling and reassembling components. Additionally, a utility knife can be useful for cutting through various materials during the repair process.

Specialized Equipment

Beyond basic tools, some specialized equipment may be necessary. A torque wrench is vital for applying the correct amount of force to fasteners, ensuring components are secured properly. Moreover, a multimeter can assist in diagnosing electrical issues, making it an invaluable tool for any repair enthusiast.

Identifying Replacement Parts

Understanding the components of your cutting tool is essential for maintaining its performance and longevity. When it comes time to replace a specific element, knowing how to identify the correct substitute can make the process smoother and more efficient.

Start by consulting the user manual to familiarize yourself with the various components and their functions. This document often contains illustrations that can help you pinpoint the part you need to replace. Additionally, examining the damaged component closely can reveal part numbers or distinguishing features that will assist in your search for a suitable replacement.

Consider reaching out to customer support or visiting local retailers specializing in outdoor equipment, as they can provide valuable insights and recommendations for finding the right match for your tool. Keeping a record of the components you’ve replaced over time can also aid in future maintenance and ensure optimal performance.

Assembly Instructions for PS250

This section provides a comprehensive guide for assembling the device effectively and safely. Following these instructions will ensure optimal performance and longevity of the equipment.

Before beginning the assembly process, ensure that you have all necessary components and tools at hand. The following steps outline the procedure:

- Begin by laying out all the components on a flat surface for easy access.

- Refer to the instruction manual for a complete list of required tools.

- Identify the main components and their respective functions:

- Engine unit

- Extension shaft

- Cutting attachment

- Safety gear

After assembly, perform a quick inspection of the device to confirm that everything is properly secured before usage.

Safety Precautions When Using

Ensuring safety during operation is crucial for avoiding accidents and injuries. Proper precautions help protect both the user and bystanders while enhancing overall efficiency.

General Safety Guidelines

- Always wear appropriate personal protective equipment, including gloves, goggles, and hearing protection.

- Inspect the tool before use to ensure all components are secure and in good condition.

- Maintain a clear work area free of obstacles and bystanders.

- Stay focused and avoid distractions while operating the equipment.

Operational Safety Measures

- Follow the manufacturer’s instructions for starting and stopping the tool.

- Use both hands to maintain control during operation.

- Never attempt to reach above shoulder height; use a ladder or platform instead.

- Keep the cutting area clear and avoid cutting branches that are too large or unstable.

Best Practices for Storage

Properly storing your equipment is crucial to ensuring its longevity and optimal performance. Adhering to specific guidelines can prevent damage and deterioration, allowing you to maintain its effectiveness over time.

Clean Before Storing

Before placing your tools away, it’s essential to clean them thoroughly. Removing dirt, debris, and sap not only enhances appearance but also prevents corrosion and build-up that can hinder functionality.

Choose an Appropriate Location

Select a dry, temperature-controlled area for storage. Exposure to extreme conditions can lead to rust and degradation. Utilizing protective coverings can also safeguard against dust and moisture.

Remember: Regular maintenance checks during storage will ensure your equipment remains in peak condition for future use.

Where to Buy Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. Whether you need to replace worn-out elements or upgrade your tools, knowing where to source these items is essential for maintaining efficiency.

There are several reliable options available for acquiring the necessary components:

| Source | Description | Advantages |

|---|---|---|

| Online Retailers | Websites dedicated to tool supplies often offer a wide selection of components. | Convenience and competitive pricing. |

| Local Hardware Stores | Neighborhood shops frequently stock popular components for immediate access. | Quick purchases and local support. |

| Manufacturer’s Website | Directly purchasing from the maker can ensure compatibility and authenticity. | Guaranteed quality and specific fit. |

| Specialty Tool Shops | Stores focusing on specific tools may have specialized components that are hard to find. | Expert advice and unique options. |

By exploring these avenues, you can effectively locate the necessary components to keep your equipment in optimal condition.

Customer Reviews and Feedback

This section presents insights and evaluations from users regarding their experiences with the product. Customer feedback is invaluable as it highlights the strengths and weaknesses observed during usage, helping potential buyers make informed decisions.

Positive Experiences

Many users have expressed satisfaction with the performance and efficiency of the equipment. They appreciate its reliability and the ease with which it tackles various tasks. Users often note that the functionality exceeds their expectations, particularly in handling challenging cutting jobs.

Areas for Improvement

While the majority of feedback is positive, some customers have mentioned areas where enhancements could be beneficial. Common suggestions include improved instructions for assembly and maintenance, as well as a desire for additional accessories to be included in the package. Addressing these concerns could further elevate the user experience.

Comparing PS250 with Other Models

This section focuses on the evaluation of one particular model in relation to similar tools available on the market. Understanding the differences in features, performance, and user experiences can help users make informed decisions when selecting the right equipment for their needs.

Performance and Efficiency

When comparing this model with others, performance and efficiency stand out as crucial factors. Many alternatives offer varying power outputs and cutting capabilities, which can significantly affect how well they handle different tasks. Users often find that certain models excel in heavy-duty jobs while others may be better suited for lighter, more precise work.

Design and Usability

The design and usability of these tools also play an essential role in user satisfaction. Some models feature ergonomic designs that enhance comfort during extended use, while others may prioritize lightweight structures for ease of handling. Ease of maintenance is another aspect that varies across different options, impacting long-term usability.