The intricate arrangement of elements within a device plays a crucial role in its overall functionality and performance. Understanding how these components interact can significantly enhance user experience and maintenance. This section aims to provide a comprehensive overview of the structure that supports efficient operation.

By examining the layout, individuals can gain insights into the various functions and relationships between different parts. This knowledge not only aids in troubleshooting but also assists in making informed decisions regarding upgrades and repairs. The visualization of these connections serves as a valuable resource for both enthusiasts and professionals alike.

Ultimately, a detailed exploration of this layout empowers users to appreciate the engineering behind their devices. Recognizing the importance of each element fosters a deeper understanding and encourages effective usage, ensuring that every feature is utilized to its fullest potential.

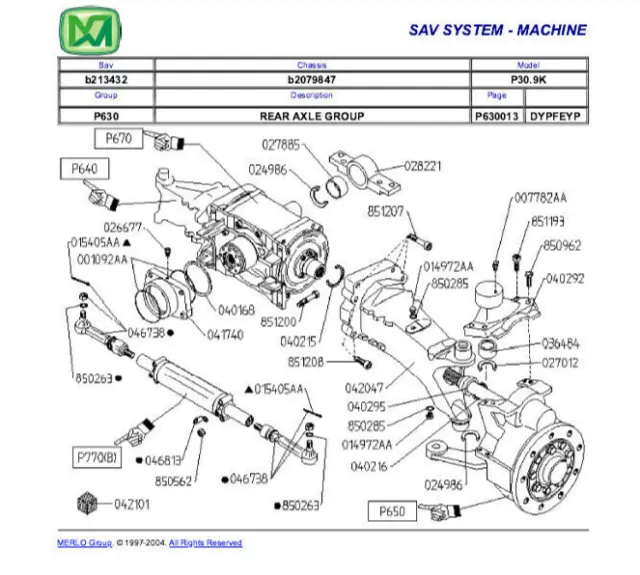

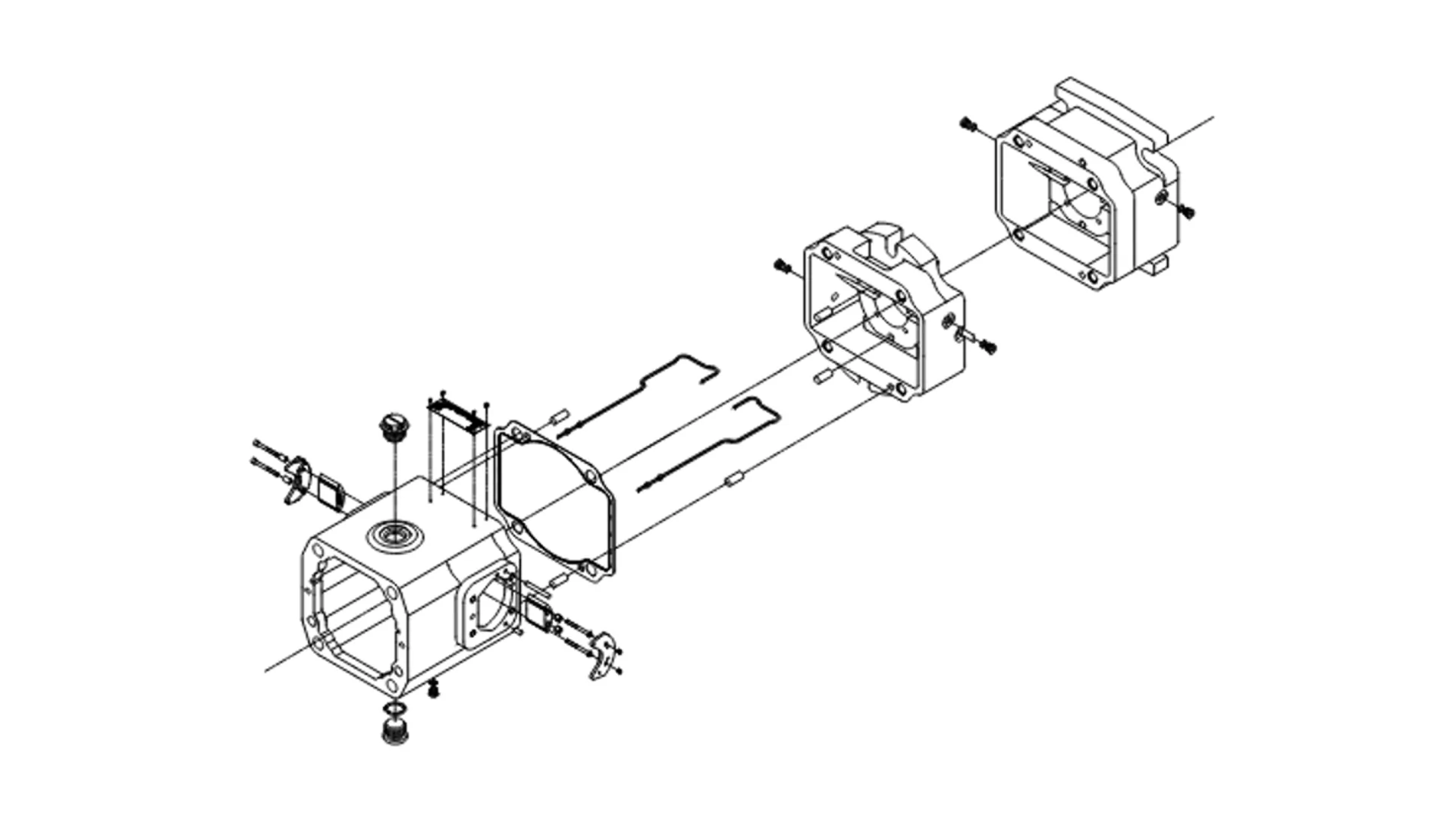

P30 Parts Diagram Overview

This section provides a comprehensive examination of the assembly components related to the discussed model. Understanding the layout and arrangement of various elements is crucial for effective maintenance and troubleshooting. By familiarizing oneself with the intricate details of each segment, users can enhance their operational knowledge and efficiency.

Understanding the Component Layout

The configuration of individual elements plays a significant role in the overall functionality of the device. Each section is meticulously crafted to serve a specific purpose, contributing to the seamless operation of the entire system. Recognizing how these pieces interconnect allows for better insights into the mechanisms at play.

Importance of Familiarity with Each Element

Having a clear grasp of each element’s role and location fosters improved handling during repairs or upgrades. When users are aware of the intricacies involved, they can address potential issues more effectively, ultimately prolonging the lifespan of the device. This knowledge empowers individuals to take informed actions when necessary.

Key Components of the P30

The central elements of any complex system play a crucial role in its functionality and efficiency. Understanding these fundamental components is essential for grasping how the system operates as a whole. Each part serves a specific purpose, contributing to the overall performance and reliability.

One significant element is the main housing, which provides structural integrity and protects internal mechanisms. Another critical component is the power unit, responsible for supplying energy to various functions, ensuring seamless operation. Additionally, the control interface allows users to interact with the system, enabling customization and efficient management.

Moreover, various sensors are integrated to monitor performance and provide feedback, enhancing the overall user experience. The communication module facilitates data exchange with other devices, allowing for advanced features and functionalities. Each of these elements is designed to work harmoniously, ensuring optimal performance and user satisfaction.

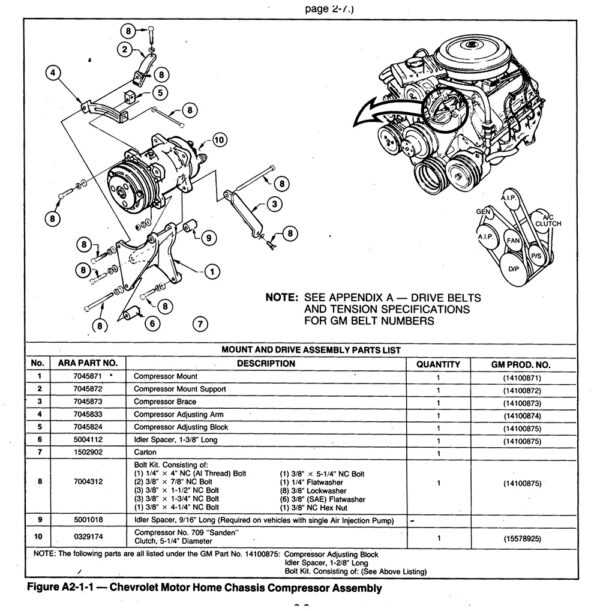

Understanding the P30 Engine Layout

The configuration of an engine plays a crucial role in its performance and efficiency. This section provides an overview of how various components interact within a specific engine setup, facilitating a better understanding of its functionality and design principles.

Key Components and Their Functions

Each engine is comprised of essential elements that work together to ensure smooth operation. Here are the primary components and their respective roles:

- Engine Block: The main structure housing various parts, providing stability and support.

- Cylinders: The chambers where fuel and air mix for combustion.

- Pistons: Move within the cylinders, converting fuel energy into mechanical energy.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion.

- Camshaft: Controls the opening and closing of the intake and exhaust valves.

Layout Considerations

Understanding the arrangement of these components is vital for diagnosing issues and enhancing performance. Key layout considerations include:

- Engine Orientation: Determines how the engine is mounted in relation to the vehicle chassis.

- Component Accessibility: Affects maintenance and repair procedures based on how easily parts can be reached.

- Weight Distribution: Impacts the vehicle’s handling and stability based on the engine’s position.

By comprehensively analyzing these aspects, one can appreciate the engineering behind a specific engine setup and its implications for vehicle dynamics.

P30 Electrical System Breakdown

The electrical framework of this model plays a crucial role in its overall functionality and performance. Understanding the components and their interactions is essential for diagnosing issues and ensuring optimal operation. Each element contributes to the efficient transmission of power and control signals throughout the system.

Power Distribution: The energy management unit serves as the heart of the electrical network, distributing electricity to various sections. It ensures that all components receive the necessary voltage levels to function correctly. Regular checks of this unit can prevent potential failures and enhance reliability.

Control Modules: These intelligent systems monitor and regulate various functions within the framework. They process information from sensors and execute commands to maintain performance. Any irregularities in these modules may lead to malfunctions, necessitating thorough inspections and potential recalibrations.

Wiring Harness: This intricate network connects all components, providing pathways for electrical signals. Proper routing and insulation are vital to prevent shorts and ensure durability. Maintenance of the wiring harness is essential, as wear and tear can lead to significant system failures.

Battery and Charging System: The energy storage unit is critical for starting the model and supporting electrical functions when the main power source is unavailable. Regular testing and maintenance of the battery and associated charging mechanisms can extend their lifespan and ensure reliable performance.

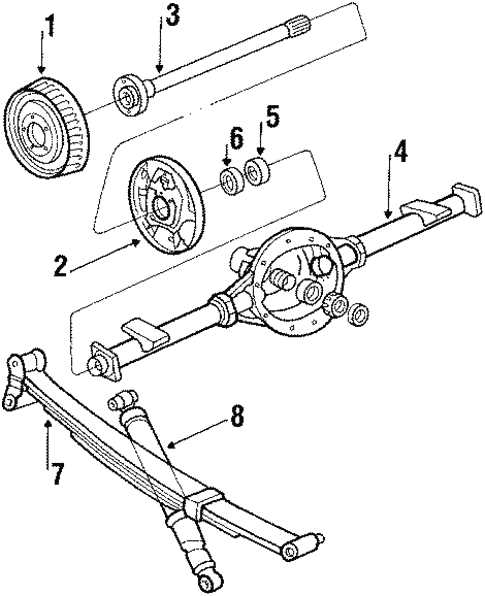

Detailed View of the P30 Suspension

This section offers an in-depth exploration of the suspension system, emphasizing its crucial role in enhancing vehicle performance and comfort. A well-designed suspension ensures optimal handling, stability, and ride quality, allowing for a smoother driving experience over various terrains.

Components of the Suspension System

The suspension system comprises several key elements, each contributing to its overall functionality:

- Shock Absorbers: These components help control the impact and rebound movement of the vehicle’s springs, maintaining stability and comfort.

- Coil Springs: They support the weight of the vehicle while absorbing shocks from road irregularities.

- Control Arms: These link the chassis to the wheel assembly, allowing for smooth movement while maintaining alignment.

- Ball Joints: These provide flexible connections between various components, enabling movement while keeping them securely attached.

Functionality and Performance

The effectiveness of the suspension system directly influences the handling characteristics of the vehicle. Properly functioning components ensure:

- Improved traction on uneven surfaces.

- Enhanced steering response for better control.

- Reduced wear and tear on other vehicle parts by minimizing excessive movement.

Understanding these components and their roles helps in maintaining and optimizing vehicle performance for an enjoyable driving experience.

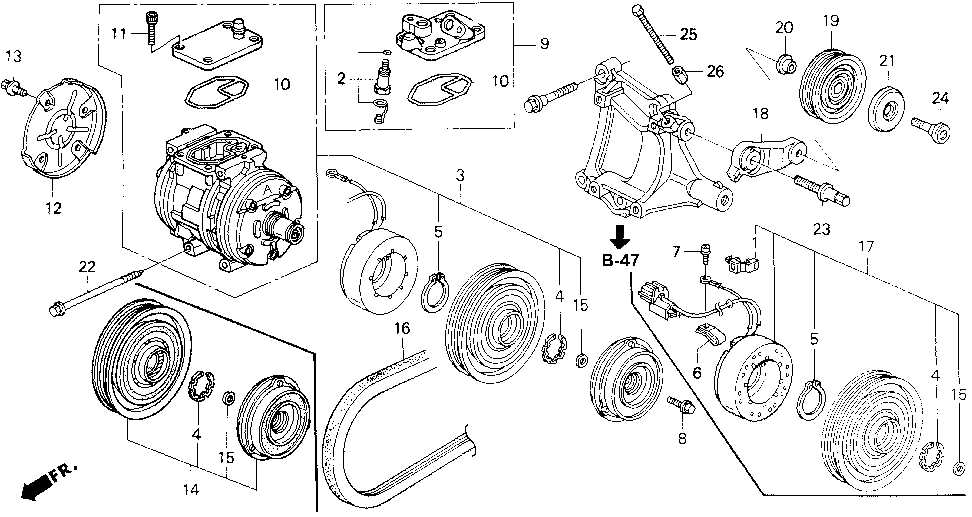

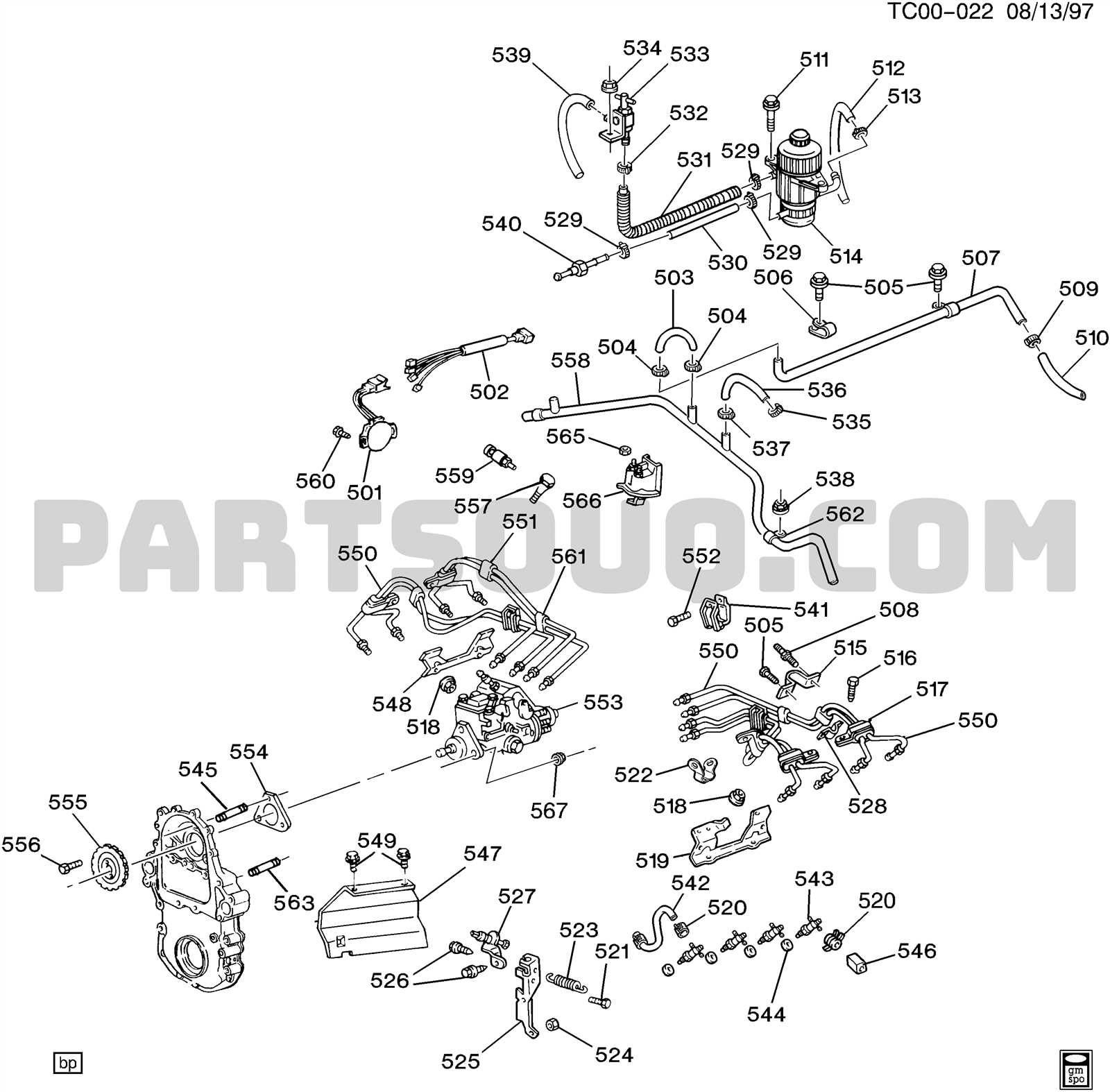

Transmission Components Explained

The transmission system of a vehicle plays a crucial role in converting engine power into motion. Understanding the various components within this system helps to grasp how vehicles achieve different speeds and power outputs while maintaining efficiency.

Key Components of the Transmission System

- Gears: Essential for altering the torque and speed, enabling the vehicle to adapt to various driving conditions.

- Shafts: These components transfer power between the engine and the wheels, ensuring smooth motion.

- Clutches: Vital for engaging and disengaging the engine from the transmission, allowing for smooth gear shifts.

- Synchronizers: Help in matching the speed of the gears during shifts, preventing grinding and ensuring smooth transitions.

- Fluid System: Transmits hydraulic pressure needed for the operation of automatic transmissions, ensuring proper functionality.

Functionality and Importance

Each component within the transmission system has a specific role that contributes to the overall functionality. The interplay between gears, shafts, and clutches allows for efficient power delivery, while synchronizers and the fluid system enhance performance and longevity. Understanding these elements is essential for proper maintenance and troubleshooting.

Exploring the P30 Brake System

The braking mechanism in vehicles is crucial for safety and performance. Understanding the components and their functions can greatly enhance maintenance and troubleshooting efforts. This section delves into the intricacies of the braking assembly, highlighting its essential elements and their roles.

Functionality and Components are vital in ensuring that the stopping power is reliable. The main elements include the brake pads, calipers, and rotors, each contributing to the overall effectiveness of the system. The pads create friction against the rotors, which helps slow down or stop the vehicle.

Maintenance Tips are essential for ensuring optimal performance. Regular inspections and timely replacements of worn-out parts can prevent potential failures. Additionally, keeping the braking fluid at appropriate levels and checking for leaks can prolong the lifespan of the entire system.

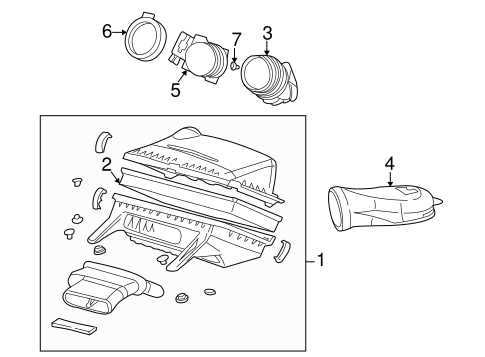

How the P30 Fuel System Operates

The functionality of a fuel delivery mechanism is crucial for ensuring optimal performance in any automotive engine. This system is responsible for transporting the necessary energy source from the tank to the engine, where it is mixed with air and ignited. Understanding the components and their roles can help in diagnosing issues and improving efficiency.

Key Components of the Fuel Delivery Mechanism

At the heart of the fuel delivery process are several key components, including the fuel pump, filter, injectors, and pressure regulator. The pump draws fuel from the tank and sends it through the filter, which removes impurities that could harm the engine. The injectors then atomize the fuel, allowing for an efficient combustion process. Finally, the pressure regulator ensures that the fuel is delivered at the correct pressure, maintaining the optimal air-fuel mixture for combustion.

Operation and Efficiency

When the engine starts, the fuel pump activates, generating a flow of fuel that travels through the system. This flow is carefully controlled to match the engine’s demands, ensuring that it receives the right amount of fuel at all times. Efficient operation of this system not only enhances engine performance but also contributes to fuel economy, reducing emissions and saving costs in the long run.

Cooling System Diagram of the P30

The cooling mechanism is crucial for maintaining optimal operating temperatures within various systems. It involves several components working together to dissipate heat efficiently and ensure the longevity and performance of the unit.

At the core of this mechanism lies a network of interconnected elements that facilitate the transfer of heat away from the engine or core components. This process typically includes a radiator, which cools the fluid, and a pump, responsible for circulating this fluid throughout the system. Additionally, thermal sensors play a vital role in monitoring temperature levels, triggering adjustments as needed to prevent overheating.

Proper maintenance and understanding of this mechanism can significantly impact performance. Regular inspections and timely replacements of any worn components are essential to ensure that the cooling system operates at peak efficiency, ultimately enhancing the overall reliability of the unit.

P30 Exhaust System Layout

The exhaust system plays a crucial role in ensuring optimal performance and efficiency of a vehicle. It is designed to direct harmful gases away from the engine and reduce emissions, contributing to a cleaner environment. Understanding the configuration of this system is essential for proper maintenance and troubleshooting.

Components of the Exhaust Arrangement

Key elements of the exhaust setup include the manifold, catalytic converter, muffler, and tailpipe. Each component serves a distinct purpose in the overall functionality. The manifold collects exhaust gases from the engine cylinders and channels them towards the catalytic converter, where harmful substances are transformed into less harmful emissions.

Flow Dynamics and Maintenance

The layout of the exhaust system is engineered to promote efficient gas flow, minimizing backpressure. Regular inspection and maintenance of the components are vital to prevent leaks and ensure longevity. Utilizing quality materials and following manufacturer guidelines will aid in maintaining the system’s integrity and performance.

Steering Mechanism Components

The steering system is a critical aspect of any vehicle, responsible for directing movement and ensuring stability while in operation. It comprises several key elements that work together to facilitate smooth maneuverability and control.

The primary components of the steering mechanism include:

- Steering Wheel: The main interface for the driver, allowing for the control of the vehicle’s direction.

- Steering Column: Connects the steering wheel to the mechanism, transmitting the driver’s input.

- Gearbox: Converts the rotational motion of the steering wheel into linear motion for the steering linkage.

- Linkage System: Comprises rods and joints that connect the gearbox to the wheels, enabling movement.

- Power Assist Unit: Provides additional force to ease steering effort, enhancing driver comfort.

Understanding the individual roles of these components is essential for diagnosing issues and performing maintenance on the steering system.