The intricate design of a transport vessel plays a vital role in its overall functionality and efficiency. Each component serves a specific purpose, contributing to the ship’s ability to navigate various waters while carrying significant loads. Gaining insight into this framework can enhance one’s appreciation for maritime engineering and its complexities.

By exploring the various sections of a freight vessel, one can better understand how these elements interact and support the entire system. Each segment is engineered to withstand the demands of the sea, ensuring that the vessel remains stable and operational under varying conditions. Knowledge of these features is essential for those involved in shipping, logistics, and maritime studies.

Furthermore, recognizing the significance of each area not only aids in operational tasks but also promotes safety practices among crews and support teams. Familiarity with the layout can lead to more efficient loading and unloading processes, ultimately improving performance. This exploration provides a foundational understanding that is crucial for anyone interested in maritime operations.

Understanding Cargo Ship Components

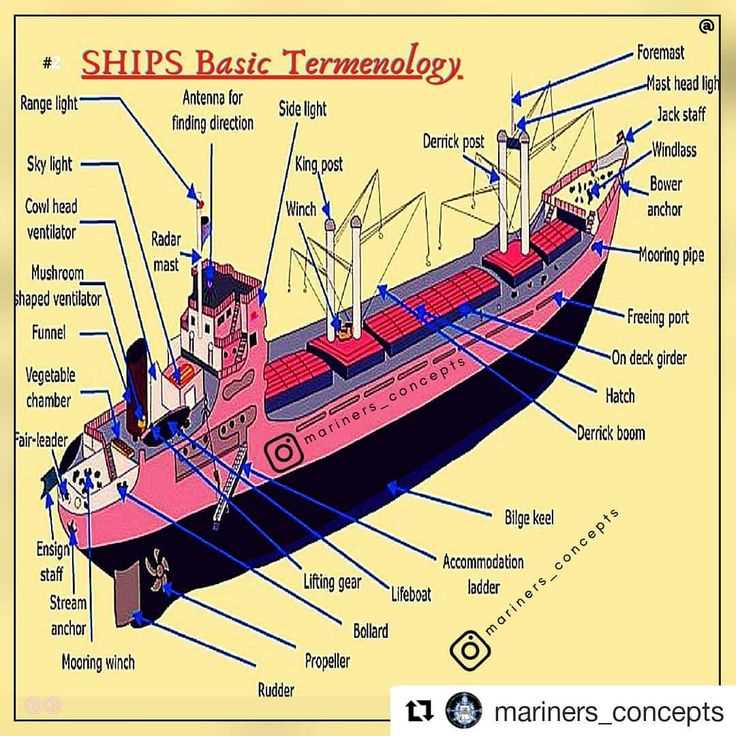

The intricate structure of marine vessels designed for transporting goods consists of various essential elements that contribute to their functionality and efficiency. Each component plays a crucial role in ensuring safe and effective movement across oceans and seas. A thorough comprehension of these elements is vital for understanding how these vessels operate and are maintained.

Main Structural Elements

- Hull: The watertight body of the vessel that provides buoyancy and structural integrity.

- Deck: The flat surface that covers the hull, where various activities take place.

- Superstructure: The part of the vessel above the main deck, housing the bridge and living quarters.

- Ballast Tanks: Compartments that can be filled with water or other materials to maintain stability.

Essential Systems and Equipment

- Propulsion System: The machinery that powers the vessel, including engines and propellers.

- Navigational Instruments: Tools and devices that assist in directing the vessel’s course.

- Cargo Handling Equipment: Mechanisms such as cranes and conveyor belts used for loading and unloading materials.

- Safety Equipment: Gear designed to ensure the safety of the crew and cargo, including lifeboats and fire extinguishers.

Hull Structure and Design

The hull serves as the foundation for any vessel, providing essential stability and protection against the elements. Its design is crucial for ensuring efficiency, safety, and performance in various maritime conditions. Understanding the key components and layout of the hull can enhance comprehension of its functionality and impact on overall navigation.

Key Components of Hull Design

Several integral elements contribute to the overall structure and effectiveness of the hull:

- Keel: The main structural element that runs along the bottom of the hull, providing stability and strength.

- Frames: Transverse members that shape the hull and support its outer skin.

- Shell plating: The outer surface that protects the internal components and maintains the vessel’s integrity.

- Deck: The upper surface that covers the hull, providing areas for operations and crew activities.

- Bulbous bow: An extension at the front that reduces resistance and improves fuel efficiency.

Design Considerations

Several factors must be taken into account during the design process:

- Hydrodynamics: The shape of the hull must minimize drag and optimize flow to enhance speed and efficiency.

- Material selection: Choosing appropriate materials is vital for durability, weight reduction, and maintenance.

- Stability: The design must ensure that the vessel remains balanced under various loading conditions.

- Regulatory compliance: Adhering to maritime standards and safety regulations is essential for operational approval.

Through careful planning and innovation, the hull’s design significantly influences the vessel’s performance and operational capabilities, reflecting advancements in maritime engineering.

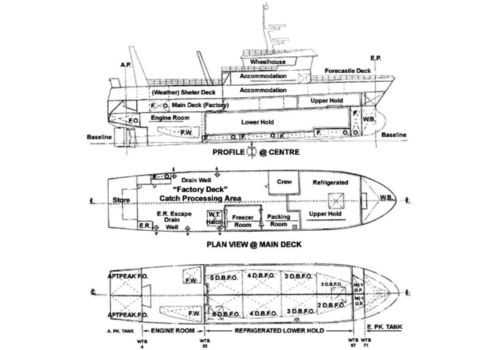

Types of Cargo Holds

The design and structure of storage areas on maritime vessels play a crucial role in the efficient transportation of goods. These compartments vary in size, shape, and functionality, catering to different types of freight. Understanding the various kinds of these storage spaces is essential for optimizing loading and unloading processes, ensuring safety, and maintaining the integrity of the transported items.

Common Types of Storage Areas

- General Cargo Holds: Versatile spaces used for a wide range of items, typically equipped to handle various shapes and sizes.

- Tank Holds: Specifically designed for liquid transport, these areas are lined with materials that prevent leakage and contamination.

- Reefer Holds: Refrigerated sections used for perishable goods requiring temperature control during transit.

- Container Holds: Designed to accommodate standardized containers, optimizing loading efficiency and securing cargo during voyages.

- Heavy Lift Holds: Reinforced spaces built to handle oversized and heavy items, ensuring structural integrity and safety.

Specialized Storage Solutions

- Ventilated Holds: Equipped with airflow systems to prevent moisture buildup, ideal for transporting items sensitive to humidity.

- Open Holds: Exposed areas allowing for easy loading and unloading of bulk materials such as coal or grain.

- Multi-Purpose Holds: Flexible spaces that can be adapted for various cargo types, enhancing the vessel’s versatility.

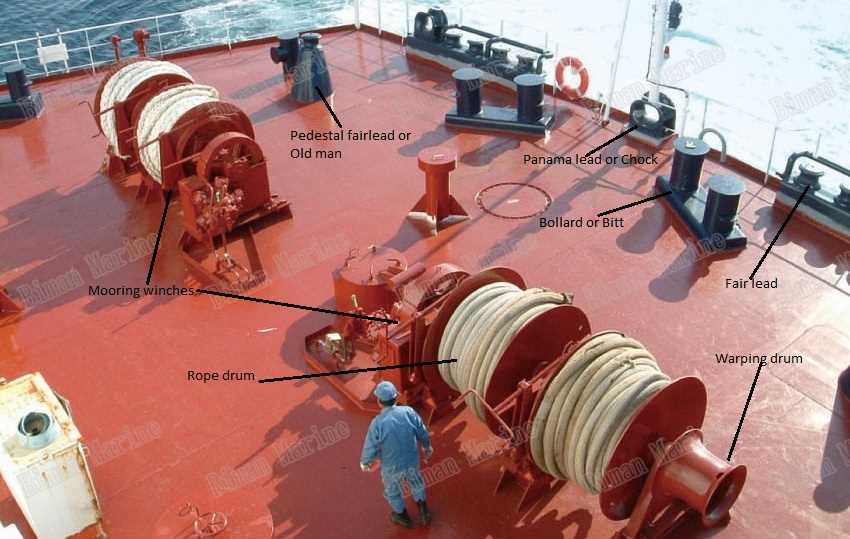

Deck Equipment Overview

The deck area of a vessel is equipped with various tools and systems that facilitate loading, unloading, and overall functionality. These mechanisms play a crucial role in ensuring smooth operations and safety during transit. Understanding the layout and purpose of each element is essential for efficient management and maintenance.

Anchoring systems are vital for securing the vessel during mooring or at rest. They consist of anchors, chains, and windlasses, which work together to maintain stability against currents and winds.

Winches are used for handling heavy loads, providing the necessary power to pull or release ropes and cables. They are essential for lifting equipment, adjusting sails, and managing cargo handling operations.

Fenders are protective devices that absorb the impact during berthing, safeguarding both the vessel and the dock. They come in various shapes and materials, ensuring durability and efficiency.

Deck cranes offer the flexibility to load and unload cargo directly from the quay or other vessels. Their design allows for precise movement and positioning, streamlining operations and minimizing the risk of accidents.

Overall, the equipment situated on the deck is integral to the successful operation of any vessel, contributing to safety, efficiency, and reliability during maritime activities.

Navigational Instruments and Systems

The effective operation of maritime vessels heavily relies on advanced tools and technology designed for precise positioning and navigation. These devices facilitate safe travel across vast waters, ensuring that navigators can determine their location, direction, and speed with high accuracy. A well-integrated system enhances situational awareness and assists in making informed decisions during voyages.

Gyrocompasses play a crucial role by providing reliable heading information based on the Earth’s rotation, while radar systems help in detecting other vessels and land obstacles, contributing to collision avoidance. Additionally, Global Navigation Satellite Systems (GNSS), including GPS, offer accurate location data, which is vital for route planning and navigation.

Furthermore, automatic identification systems (AIS) enhance maritime safety by enabling vessels to share information such as position, speed, and course with one another. Integrating these instruments not only improves navigation but also supports compliance with international regulations and safety protocols.

To optimize performance, navigators must regularly maintain and calibrate these systems, ensuring they function correctly under various conditions. Ultimately, the combination of these advanced navigational tools and systems empowers maritime professionals to navigate the seas confidently and efficiently.

Propulsion and Power Systems

This section explores the critical mechanisms responsible for generating the necessary force and energy to drive marine vessels. Understanding these systems is essential for grasping how large vehicles navigate through water effectively.

The propulsion systems typically include engines and propellers, which convert fuel into kinetic energy, enabling movement through the water. Different types of engines, such as diesel or gas turbines, are utilized based on efficiency, power requirements, and operational conditions.

Power generation is equally crucial, as it supplies energy for various onboard systems, from navigation to living quarters. These systems often consist of generators and auxiliary machinery, ensuring a steady power supply for both propulsion and onboard operations.

Integration of advanced technologies, such as electric propulsion and hybrid systems, is becoming more prevalent, enhancing efficiency and reducing environmental impact. These innovations contribute to improved performance and sustainability in maritime operations.

Ballast Systems and Management

The effective regulation of water weight within a vessel is crucial for maintaining stability and safe navigation. These systems play a pivotal role in adjusting the balance of the vessel according to varying conditions and cargo loads. Proper management ensures optimal performance and enhances safety on the water.

Components of Ballast Systems

- Water Ballast: Utilizes water stored in designated tanks to achieve the desired weight distribution.

- Ballast Pumps: Facilitate the intake and discharge of water, allowing for rapid adjustments based on operational needs.

- Valves and Piping: Control the flow of water to and from ballast tanks, ensuring efficient management of weight.

- Monitoring Systems: Provide real-time data on water levels, pressure, and overall ballast status.

Management Strategies

- Regular Inspections: Conduct frequent checks on ballast systems to ensure they are functioning properly and free from leaks.

- Automated Controls: Implement systems that automate ballast management, enhancing accuracy and responsiveness.

- Training Personnel: Ensure crew members are well-trained in operating ballast systems and understanding their importance.

- Environmental Considerations: Monitor the impact of ballast water management on marine ecosystems, adhering to regulations to prevent pollution.

Safety Features on Cargo Ships

The maritime industry prioritizes the protection of crew members, cargo, and the environment. Vessels are equipped with various mechanisms and protocols designed to enhance security during operations. These features not only address potential hazards but also ensure compliance with international regulations and standards.

Key Safety Mechanisms

Modern vessels incorporate a range of essential systems to mitigate risks and enhance safety. These include fire suppression systems, life-saving equipment, and navigation aids. Understanding these mechanisms is crucial for maintaining a safe operating environment.

| Safety Feature | Description |

|---|---|

| Fire Suppression Systems | Automatic and manual systems to extinguish fires and prevent damage. |

| Life Rafts | Inflatable rafts that provide a means of escape in emergencies. |

| Life Jackets | Personal flotation devices ensuring buoyancy for individuals in distress. |

| Emergency Alarms | Alerts crew members to potential dangers and necessary actions. |

| Navigation Systems | Advanced technology to assist in safe maneuvering and collision avoidance. |

Regulatory Compliance

Adhering to international regulations is vital for operational safety. Organizations establish guidelines that vessels must follow, ensuring all safety features are effectively implemented and maintained. Regular inspections and drills are conducted to prepare the crew for emergency situations and uphold safety standards.

Cargo Handling Mechanisms

The efficient management of goods during transportation is crucial in maritime operations. Various systems and devices are employed to facilitate the loading, unloading, and storage of merchandise, ensuring seamless workflow and safety. These mechanisms are designed to optimize space and enhance productivity while adhering to safety standards.

Modern transportation vessels utilize a range of equipment to streamline these processes. From cranes and conveyor belts to specialized lifting gear, each component plays a vital role in the overall efficiency of operations. Understanding these mechanisms helps in appreciating their significance in enhancing operational performance.

| Type of Mechanism | Description | Advantages |

|---|---|---|

| Cranes | Used for lifting heavy loads, often found on the docks or attached to the vessel. | High lifting capacity and versatility for various load types. |

| Conveyor Belts | Mechanical systems that transport items across different heights and distances. | Efficient transfer of goods, reducing manual labor and time. |

| Forklifts | Motorized vehicles designed to lift and move items within storage areas. | Enhanced maneuverability in tight spaces and improved handling of loads. |

| Hydraulic Lifts | Devices that use hydraulic power to raise and lower cargo. | Ability to lift heavy items with minimal physical effort. |

| Automated Guided Vehicles (AGVs) | Robotic systems used for transporting goods within warehouses or ports. | Increased efficiency and reduced human error in handling. |

Electrical Systems and Wiring

Effective electrical systems are crucial for the functionality and safety of marine vessels. These systems enable various operations, from navigation and communication to powering essential equipment. A well-designed network ensures that energy is distributed efficiently, supporting both routine activities and emergency protocols.

At the core of these systems lies the intricate wiring network, which must withstand the harsh marine environment. Conductors are typically insulated to prevent corrosion and damage from moisture, ensuring longevity and reliability. Proper installation techniques are essential to minimize the risk of electrical faults that could lead to significant issues.

Power distribution panels play a vital role in managing the flow of electricity throughout the vessel. They serve as the central hub for controlling and monitoring electrical circuits, making it easier to manage energy consumption. Regular maintenance and inspections of these panels are necessary to ensure optimal performance and to identify potential problems before they escalate.

Moreover, safety measures such as circuit breakers and fuses are integrated into the electrical framework. These components are designed to protect against overloads and short circuits, thereby safeguarding both the crew and the vessel’s infrastructure. Understanding the layout and functionality of these systems is essential for effective troubleshooting and repair.

In conclusion, a robust electrical network is fundamental to the operational integrity of any marine vessel. By ensuring proper installation, maintenance, and adherence to safety standards, the reliability of these systems can be significantly enhanced, contributing to a safer and more efficient maritime experience.

Communication Equipment and Technologies

The efficient exchange of information is crucial in maritime operations. Modern vessels rely on advanced systems to ensure that all crew members and stakeholders remain connected, allowing for seamless navigation, safety, and coordination. This section delves into the essential tools and technologies that facilitate communication in a marine environment.

Types of Communication Technologies

Various technologies are employed to maintain connectivity at sea. These include traditional radio systems, satellite communication, and internet-based solutions. Each type has unique features that cater to different operational needs, enabling reliable communication in challenging conditions.

Importance of Reliable Communication

Maintaining effective communication enhances safety protocols, operational efficiency, and emergency response. It allows for real-time updates on weather conditions, navigational hazards, and other critical information. The integration of advanced technologies significantly reduces the risk of miscommunication and ensures that all parties are informed promptly.

| Technology Type | Functionality | Advantages |

|---|---|---|

| VHF Radio | Short-range communication | Reliable and easy to use |

| SATCOM | Global communication coverage | High reliability in remote areas |

| GSM | Cellular communication | Widely accessible in coastal areas |

| Internet-based Systems | Data exchange and messaging | Supports a wide range of applications |