In the art of fabric creation, a structured device plays a crucial role in organizing and guiding the threads to produce intricate patterns. This apparatus is designed to ensure precision and efficiency in weaving, transforming raw materials into beautifully crafted textiles.

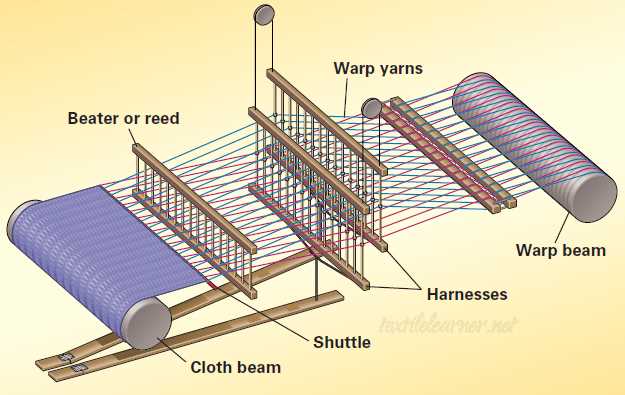

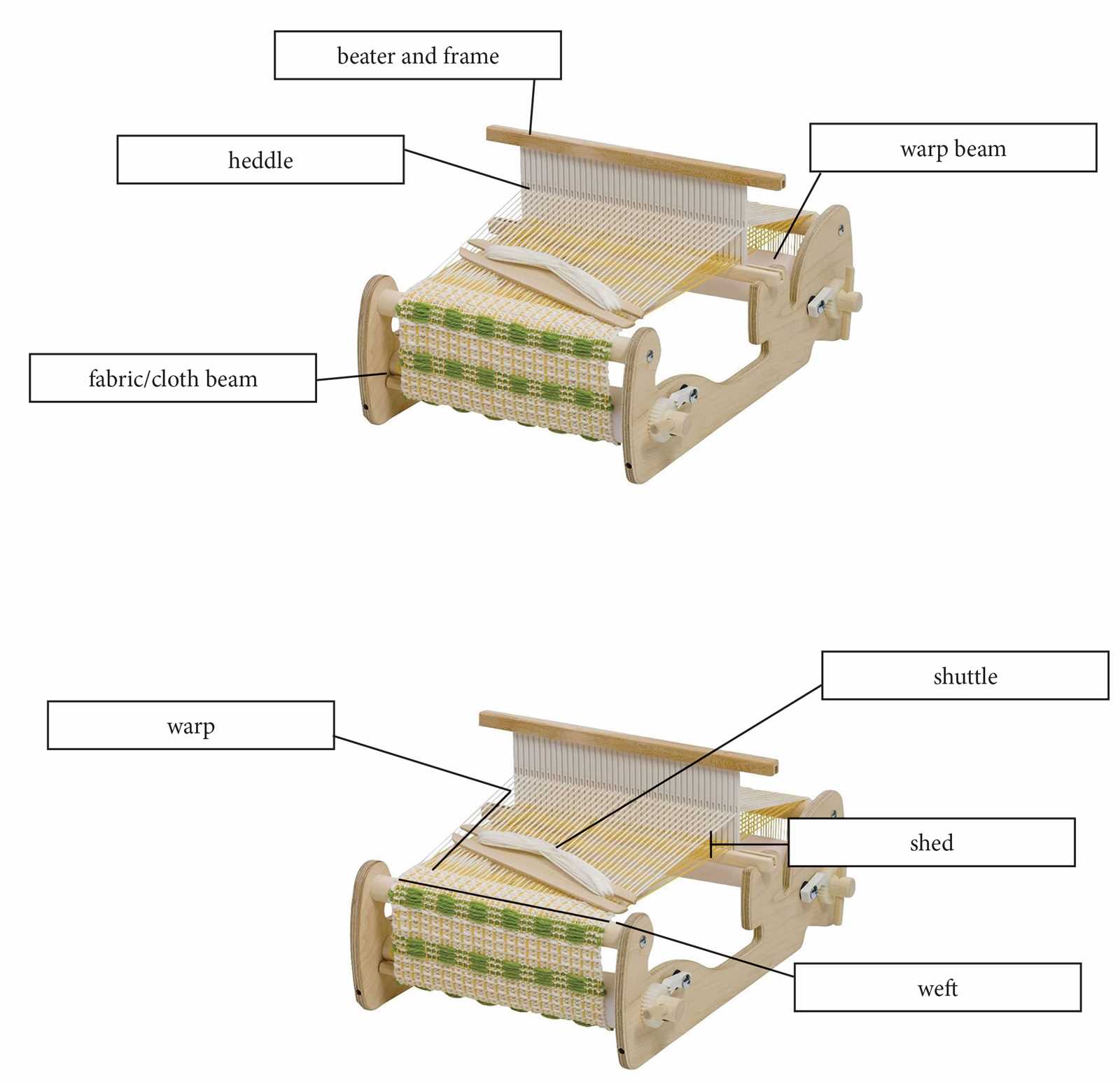

The mechanism at the heart of this process consists of several key components, each with a specific role in guiding and manipulating the threads. Understanding these elements is essential for anyone looking to master the technique of textile production, as they collectively influence the final outcome of the woven fabric.

Each section of this tool operates in unison to achieve a harmonious flow, maintaining the tension and alignment necessary for creating even and consistent designs. By familiarizing oneself with these elements, one gains a deeper appreciation of how traditional craftsmanship meets technical expertise in the weaving process.

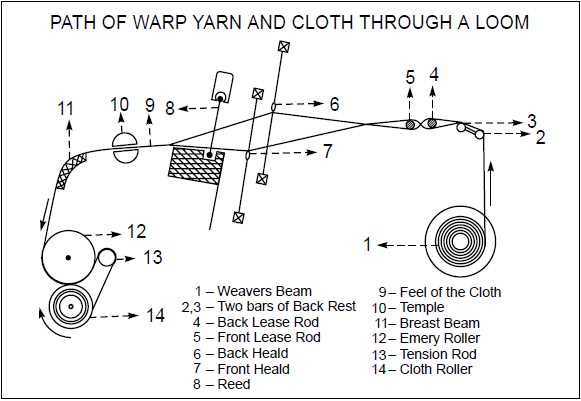

Identifying the Warp Thread Path

The arrangement of vertical fibers is fundamental to the structure’s overall design. Understanding how these threads interact within the setup is key to creating a balanced fabric pattern. By examining their placement and direction, one can gain insight into the tension and alignment that influence the weaving process.

Tracing the Route: To follow the course of these fibers, it’s important to note their origin at the starting point. Each thread is carefully positioned to ensure smooth progression through the guiding elements, establishing a stable base for further interlacing.

Ensuring Consistency: Maintaining a uniform path for the threads prevents distortions in the resulting textile. Even spacing and precise tension are crucial factors that contribute to the consistency of the final product.

The Role of the Weft in Weaving

The concept of the weft plays a crucial part in the process of interlacing threads to create fabric. It works in tandem with other components, contributing significantly to the fabric’s overall texture, strength, and appearance.

Understanding Weft Thread Movement

The weft threads run horizontally, crossing over and under the vertical fibers in a repetitive pattern. This action forms the foundation of the fabric’s structure, creating a stable network that holds the individual threads together.

Impact on Fabric Design

- Texture Variation: The type of thread used as the weft can greatly influence the feel and density of the final textile.

- Color Patterns: Different colored threads introduced into the weft create intricate designs and patterns within the material.

- Strength Enhancement: Using stronger or thicker weft threads can enhance the durability of the fabric, making it more resistant to wear and tear.

The role of the weft is essential in crafting diverse fabric styles, ensuring each piece not only holds together well but also possesses unique visual and tactile qualities.

Understanding the Loom’s Beater Function

The beater plays a crucial role in the weaving process, acting as a key element in securing each row of fibers into place. Its primary purpose is to ensure that the threads are consistently and tightly integrated, contributing to the overall quality and structure of the fabric.

Mechanism and Motion

The movement of this tool is straightforward yet essential, guiding the threads to align precisely with the rest of the fabric. The consistent action of this device helps maintain the pattern’s accuracy, supporting uniform texture and design throughout the weave.

Impact on Fabric Density

The influence of this component on fabric density is significant. By controlling the force applied to the fibers, it allows for adjustments in the material’s compactness. This precision in force application helps create textiles that vary from lightweight to dense, tailored to specific requirements.

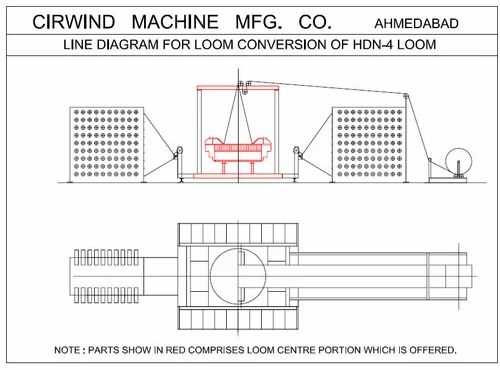

Shaft Mechanism Overview

The shaft system plays a crucial role in textile machinery, facilitating precise movement and control within the setup. Its function is essential to the overall operation, directly influencing the arrangement and structure during production.

Key Components of the Shaft System

This assembly typically consists of several segments that work in harmony to regulate movement. Each segment interacts smoothly with the others, ensuring that patterns are executed as intended, while maintaining accuracy and synchronization.

How the Shaft System Enhances Functionality

The integration of this system enhances the equipment’s versatility, allowing for intricate adjustments to be made efficiently. Its adaptability is a vital factor in achieving diverse configurations, making it an indispensable feature in advanced setups.

The Significance of the Heddle Frame

The heddle frame serves a critical role in the weaving process, influencing the movement and arrangement of threads. Its function directly impacts the quality and intricacy of the final pattern. Understanding its importance helps highlight the mechanism that drives thread manipulation.

- Thread Control: The heddle frame precisely guides the threads, creating an organized path for the design to develop.

- Pattern Creation: By lifting and lowering threads in specific sequences, it enables the formation of various intricate patterns.

- Enhanced Efficiency: This component significantly boosts the weaving speed, making the process more streamlined and efficient.

Recognizing the significance of the heddle frame allows for a deeper appreciation of its role in shaping detailed designs and ensuring consistency throughout the weaving process.

Navigating Through the Reed Structure

The reed structure plays a crucial role in the weaving process, acting as a guide for the warp threads as they are woven together. Understanding its configuration helps weavers achieve precision in their work, ensuring that the fabric produced meets the desired specifications. By familiarizing oneself with the layout and functionality of this component, one can enhance both the quality and efficiency of the weaving process.

Understanding the Functionality

This element primarily serves to separate the warp threads and ensure that they remain evenly spaced during the weaving process. Its design allows for the smooth passage of the weft, facilitating a seamless integration of materials. Mastery of this structure enables artisans to produce fabrics that are not only visually appealing but also structurally sound.

Exploring Variations in Design

Different configurations of this structure can yield various results in the final fabric. By experimenting with diverse arrangements, weavers can influence the texture, pattern, and overall aesthetics of their creations. A thorough exploration of these variations can lead to innovative designs and improved techniques.

Tension Control and Its Importance

The ability to manage the tension within weaving mechanisms is crucial for achieving optimal results in fabric production. Proper regulation ensures that materials are handled efficiently, preventing defects and maintaining the integrity of the final product.

Maintaining the correct tension offers several advantages:

- Consistency: Even tension across the width of the fabric leads to uniformity in texture and appearance.

- Durability: Adequate control minimizes stress on fibers, enhancing the longevity of the finished textile.

- Precision: Accurate tension settings allow for intricate designs and patterns to be woven without distortion.

Without effective tension management, the production process can encounter various challenges, such as:

- Warp Breakage: Excessive tension can cause threads to snap, disrupting the workflow.

- Misalignment: Inconsistent tension may lead to uneven patterns, affecting the aesthetic quality.

- Fabric Defects: Poorly managed tension can create issues like puckering or wrinkling in the material.

In conclusion, controlling the level of tension is essential for producing high-quality textiles. It significantly impacts both the efficiency of the weaving process and the final characteristics of the fabric.

Exploring the Treadle System

The treadle mechanism is a fundamental component in the weaving process, playing a crucial role in the creation of intricate patterns and designs. This system allows the operator to control the lifting and lowering of various threads, facilitating the weaving of fabric with precision and artistry.

Understanding the Functionality

At its core, the treadle system operates through a series of interconnected components that work in harmony. When the treadle is pressed, it activates levers that correspond to specific threads, raising or lowering them as needed. This action enables the weaver to alternate between different sets of threads, creating complex designs and textures.

Components of the Treadle Mechanism

Various elements contribute to the efficient functioning of this system, including pedals, levers, and connecting rods. Each component has a unique role, ensuring seamless interaction between the weaver and the threads being manipulated.

| Component | Function |

|---|---|

| Pedal | Activates the entire system through foot pressure |

| Lever | Transfers motion from the pedal to the threads |

| Connecting Rod | Links pedals and levers for synchronized movement |

Weaving Techniques Using Shuttles

Shuttles play a crucial role in the art of weaving, allowing for the efficient interlacing of threads to create intricate patterns and designs. Various methods utilize these tools to achieve distinct textures and styles in fabric production. Understanding these techniques enhances the weaver’s ability to experiment and innovate in their craft.

Common Techniques

- Plain Weave: This foundational method alternates the horizontal and vertical threads, resulting in a simple yet durable fabric.

- Satin Weave: By floating threads over multiple intersecting threads, this technique produces a smooth surface with a lustrous finish.

- Twill Weave: Characterized by diagonal lines, this method creates a textured fabric that is both strong and flexible.

Advanced Techniques

- Jacquard Weaving: This intricate method employs programmable mechanisms to control individual threads, allowing for complex patterns.

- Overshot Weaving: Involves passing the shuttle over multiple threads, creating raised patterns on the surface of the fabric.

- Warp-Weighted Weaving: An ancient technique that uses weights to tension the warp threads, allowing for unique textures and structures.

Experimenting with these techniques can lead to innovative creations, pushing the boundaries of traditional fabric-making. Each method contributes to the overall aesthetic and functionality of the finished textile.

Combining Patterns with Dobby Bars

Integrating various designs can elevate the complexity and visual appeal of woven creations. By utilizing specialized mechanisms, artisans can efficiently manage multiple sequences and enhance the overall functionality of the weaving process. This approach allows for seamless transitions between different motifs, providing flexibility and creativity in the final outcome.

Dobby bars serve as a valuable tool in this endeavor, facilitating the control of various threads and patterns. By programming specific sequences, weavers can achieve intricate designs with precision. This capability not only saves time but also allows for experimentation with diverse patterns, making each project unique.

The ability to combine motifs through these mechanisms transforms the creative process. Artisans can explore a wider range of designs and easily adapt them to suit their artistic vision. This flexibility encourages innovation, enabling weavers to produce intricate textiles that capture attention and imagination.