The structure of any instructional representation serves as a crucial foundation for conveying complex information. By breaking down intricate concepts into easily digestible segments, learners can better grasp the underlying principles and relationships at play. This method enhances comprehension and retention, allowing for a more effective learning experience.

In exploring the various elements of such an illustration, one can appreciate how each section contributes to the overall coherence and functionality of the representation. Each component plays a vital role in linking ideas and facilitating a clear understanding of the subject matter.

Recognizing these individual elements can empower individuals to analyze and interpret instructional representations more effectively. As a result, learners can engage with the content in a deeper manner, ultimately fostering a more robust educational journey.

tags: Overview of Scaffold Diagrams”>

tags: Overview of Scaffold Diagrams”>

This section aims to provide a comprehensive outline for an article that delves into the various components and functionalities of a specific structure used for visual representation. Each element plays a crucial role in enhancing understanding and facilitating communication of complex information. Below is a detailed framework designed to explore these elements thoroughly.

- Introduction to Visual Frameworks

- Understanding the Core Elements

- Key Structural Features Explained

- The Role of Annotations in Clarity

- Hierarchy and Organization in Representation

- Interconnecting Relationships within the Framework

- Utilizing Color Coding for Enhanced Understanding

- Application of Legends and Keys

- Visual Balance and Composition Principles

- Common Mistakes in Representation

- Best Practices for Effective Design

- Future Trends in Visual Representation Techniques

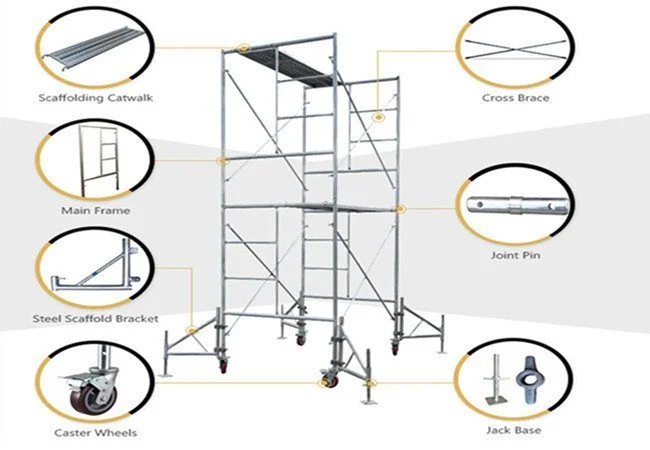

Key Components of Scaffolding

Understanding the essential elements that constitute a support framework is crucial for ensuring safety and efficiency during construction activities. These elements work together to create a stable environment for workers and materials, enabling the completion of projects at various heights and complexities.

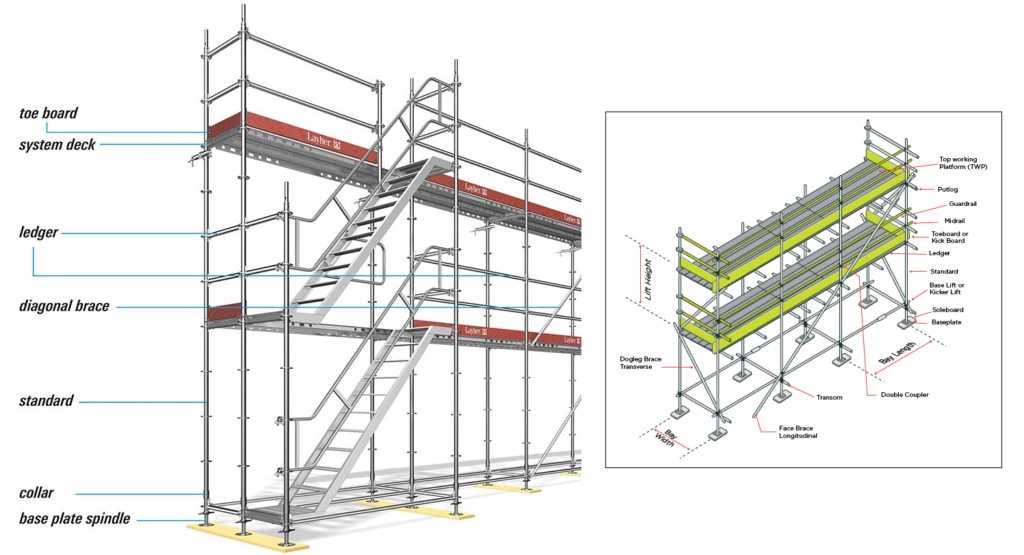

Structural Supports

Structural supports form the backbone of the entire assembly. These components bear the load and provide stability, ensuring that the framework can withstand the pressures exerted by both personnel and equipment. Their design must be robust and resilient to various environmental factors.

Platforming Systems

The platforming systems serve as the working surfaces for construction crews. These surfaces must be designed with careful consideration of both safety and functionality, offering a reliable area for workers to perform their tasks while minimizing the risk of accidents. Proper installation and maintenance of these platforms are vital to ensure a secure working environment.

Understanding Load-Bearing Elements

Load-bearing components play a crucial role in providing stability and strength to structures. These elements are designed to support various forces and loads, ensuring the overall integrity of the construction. Understanding their function and placement is essential for maintaining safety and durability in any build.

Key characteristics of these vital components include:

- Material Composition: The choice of materials significantly affects the load-bearing capacity.

- Design Geometry: The shape and size of elements determine their effectiveness in distributing weight.

- Connection Methods: How these components are joined influences the overall structural performance.

In construction, several types of load-bearing elements are commonly utilized:

- Columns: Vertical structures that transfer loads from above to the foundation.

- Beams: Horizontal elements that support loads and span across columns.

- Braces: Diagonal supports that provide additional stability and prevent lateral movement.

It is vital to consider the appropriate selection and configuration of these components to enhance structural resilience. Proper assessment and analysis ensure that they perform effectively under various conditions.

Functions of Vertical Supports

Vertical supports play a crucial role in providing stability and safety in construction and maintenance tasks. These structural elements are essential for ensuring that the entire framework remains upright and capable of bearing loads without compromising integrity.

The key functions of vertical supports include:

- Load Bearing: Vertical supports are designed to carry the weight of the structure above them, distributing the load evenly to prevent sagging or collapse.

- Stability: By providing a solid base, these components help maintain the overall balance of the framework, reducing the risk of tipping or shifting during use.

- Safety Enhancement: They create a secure environment for workers by preventing accidental falls and ensuring that the platform remains stable during operations.

- Facilitation of Access: Vertical supports allow for the installation of additional elements, such as ladders and platforms, enabling easy access to elevated areas.

In summary, vertical supports are vital for maintaining the safety, functionality, and reliability of any elevated work structure, making them indispensable in various applications.

Role of Horizontal Beams

Horizontal beams play a critical function in providing stability and support within construction frameworks. These structural elements are essential for distributing loads evenly across the entire assembly, ensuring safety and functionality during use.

By connecting vertical supports, they create a secure platform that allows workers to operate efficiently at various heights. The presence of these beams not only enhances the overall strength of the structure but also contributes to the ease of access and movement across the work area.

Moreover, they facilitate the attachment of additional components, such as guardrails and platforms, further increasing the safety measures for personnel. In summary, horizontal beams are indispensable in creating a cohesive and reliable framework that supports construction activities.

Importance of Diagonal Bracing

Diagonal bracing plays a crucial role in enhancing the stability and overall integrity of structural frameworks. It provides essential support that helps resist lateral forces, ensuring that the entire assembly remains secure during various operational conditions.

By incorporating diagonal elements, the risk of swaying or collapsing under unexpected loads is significantly reduced. This reinforcement is vital for maintaining safety standards and ensuring that workers can operate confidently within the structure.

Moreover, effective bracing contributes to the longevity of the framework by minimizing wear and tear over time. This, in turn, leads to reduced maintenance costs and extended usability, making it a wise investment for any construction project.

| Advantages of Diagonal Bracing | Description |

|---|---|

| Enhanced Stability | Provides resistance to lateral forces, reducing the likelihood of structural movement. |

| Increased Safety | Ensures a secure environment for workers by preventing potential collapses. |

| Cost Efficiency | Reduces maintenance needs and prolongs the life of the framework, saving money over time. |

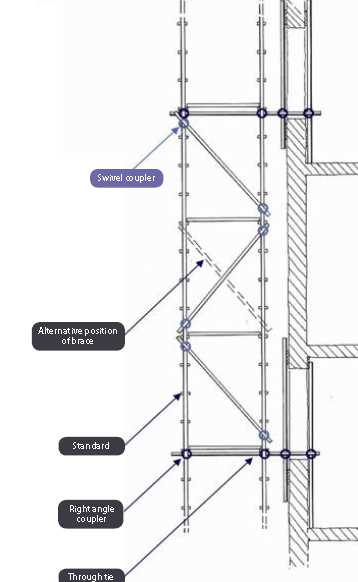

Connecting Parts in Scaffold Structures

The interconnection of various elements in elevated frameworks is crucial for ensuring stability and safety. This section delves into the methods and techniques utilized to join these components effectively, emphasizing their significance in maintaining the overall integrity of the construction.

Types of Connections

Several methods can be employed to unite the structural elements, each with its own advantages and applications. Below is a table summarizing the primary connection techniques:

| Connection Method | Description | Advantages |

|---|---|---|

| Welding | A method that fuses components using heat to create a solid bond. | Provides high strength and permanence. |

| Bolting | Utilizes bolts to secure pieces together, allowing for easier assembly and disassembly. | Offers flexibility and can be easily adjusted. |

| Clamping | Involves the use of clamps to hold components in place temporarily. | Facilitates quick adjustments during setup. |

Importance of Proper Connections

Establishing robust connections between components is essential to prevent structural failures. Each method must be chosen based on the specific requirements of the project, including load-bearing capacity and environmental factors. Attention to detail in these connections contributes significantly to the overall performance and longevity of elevated structures.

Types of Platform Systems

Various types of support frameworks exist to enhance safety and efficiency in construction and maintenance tasks. Each system is designed to cater to specific needs, ensuring workers can operate securely and effectively at different heights and environments.

Modular Platforms offer flexibility and can be easily adjusted to accommodate different project requirements. These systems are constructed from interlocking components, allowing for quick assembly and disassembly.

Suspended Platforms are typically used for high-rise buildings and structures, where they hang from a support system above. This type allows for easy access to elevated areas while providing a stable working environment.

Mobile Platforms are equipped with wheels or casters, making them easy to maneuver. These systems are particularly useful for tasks that require frequent relocation, enhancing productivity on site.

Fixed Platforms are permanently installed and designed for long-term use. They provide a stable working area and are often used in industrial settings where regular access is required.

Understanding the different types of support structures is essential for selecting the most suitable system for a given project, promoting both safety and efficiency.

Safety Features in Scaffold Design

Ensuring a secure working environment is paramount in any construction framework. Various elements are incorporated to enhance stability and minimize hazards for personnel involved in elevated tasks. By focusing on specific characteristics, designers can create structures that protect users and promote efficient workflows.

Stabilizing Components

Effective support systems are essential for maintaining balance. Features such as braces and outriggers play a crucial role in preventing tipping and swaying. Additionally, the integration of non-slip surfaces contributes to improved footing, reducing the likelihood of accidents.

Load Management

Careful consideration of weight distribution is vital for safety. Structures must be designed to accommodate varying loads, ensuring that no single point is overburdened. This is achieved through strategic placement of supporting elements and regular inspections to verify integrity.

Inspection Points for Stability

Ensuring a secure and reliable structure during use is crucial for safety. Various factors contribute to the overall firmness of a construction framework, and routine evaluations are essential. Identifying key areas to assess helps in maintaining integrity and preventing potential hazards.

| Inspection Point | Description |

|---|---|

| Base Support | Check the ground conditions and ensure that the foundation is level and stable. |

| Vertical Elements | Inspect the upright components for any signs of bending or damage that may compromise stability. |

| Cross Bracing | Ensure that diagonal supports are securely fastened and free from wear or deformation. |

| Horizontal Beams | Verify that the horizontal members are adequately secured and positioned to bear loads. |

| Connections | Examine all joints and connections for tightness and integrity to prevent movement. |

Materials Used in Scaffold Construction

When it comes to the construction of elevated platforms, the selection of appropriate materials is crucial for ensuring safety, stability, and efficiency. Various substances are utilized to form the structure, each offering unique benefits tailored to specific needs.

Common materials employed in the creation of these systems include:

- Steel: Known for its strength and durability, steel is often the primary choice for framework components. Its ability to support heavy loads makes it ideal for industrial applications.

- Aluminum: Lightweight and resistant to corrosion, aluminum is frequently used in portable structures. This material enhances mobility while maintaining adequate strength.

- Wood: Traditionally utilized for temporary platforms, wood offers a cost-effective solution. However, it requires proper treatment to withstand environmental factors.

- Plastic composites: Increasingly popular for their lightweight nature and resistance to weathering, these materials provide a modern alternative to traditional substances.

Each of these materials contributes to the overall functionality and safety of elevated working environments. Proper assessment of the construction needs will guide the selection process, ensuring that the chosen materials align with the specific demands of the project.

Assembly Techniques for Efficiency

Optimizing the assembly process is crucial for achieving high productivity and minimizing errors in construction and design projects. By implementing effective methods, teams can enhance their workflow, reduce downtime, and ensure that all components are aligned and functioning correctly.

One key approach is to utilize modular systems that allow for quick assembly and disassembly. This flexibility enables workers to adapt to changing requirements and site conditions efficiently. Additionally, pre-fabricating components off-site can save significant time and labor during on-site assembly, as teams can focus on integrating these parts seamlessly.

Incorporating advanced tools and technologies, such as digital measurement devices and collaborative software, can further streamline the assembly process. These innovations facilitate accurate alignment and provide real-time feedback, allowing for immediate adjustments and reducing the likelihood of costly mistakes.

Moreover, training personnel in best practices for assembly not only enhances their skills but also fosters a culture of safety and efficiency. Encouraging teamwork and open communication among members can lead to improved problem-solving and a smoother workflow throughout the assembly process.