In the world of construction and woodworking, efficient tools are essential for achieving high-quality results. Among these tools, a specific type of framing device stands out due to its remarkable performance and reliability. For both professionals and enthusiasts, understanding the intricate details of such equipment can enhance usability and maintenance.

To ensure optimal functioning, it is crucial to familiarize oneself with the various elements that comprise these tools. A comprehensive breakdown of these components not only aids in troubleshooting but also assists in making informed decisions regarding repairs and upgrades. By grasping how each segment interacts with others, users can improve their overall experience and extend the lifespan of their equipment.

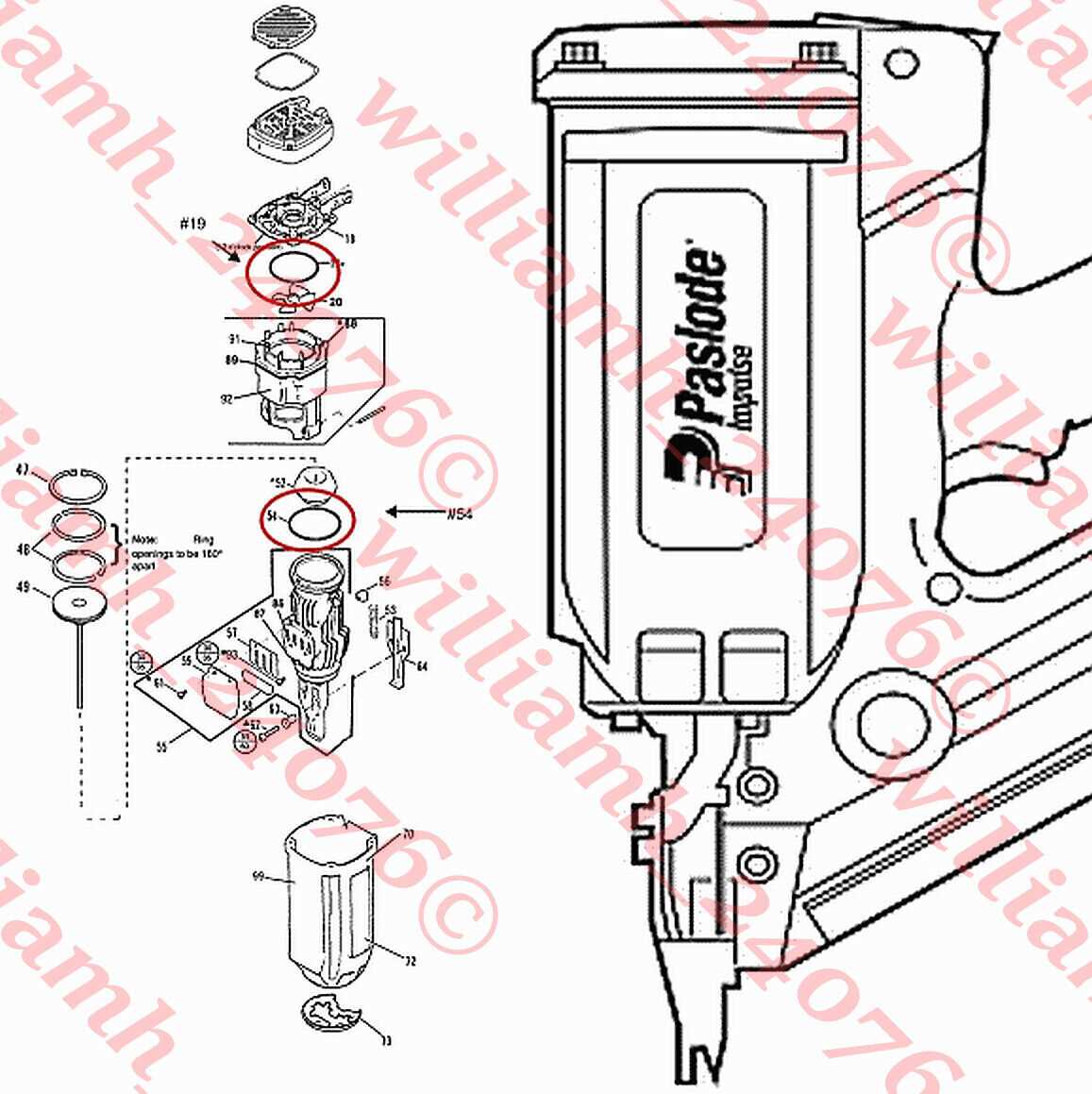

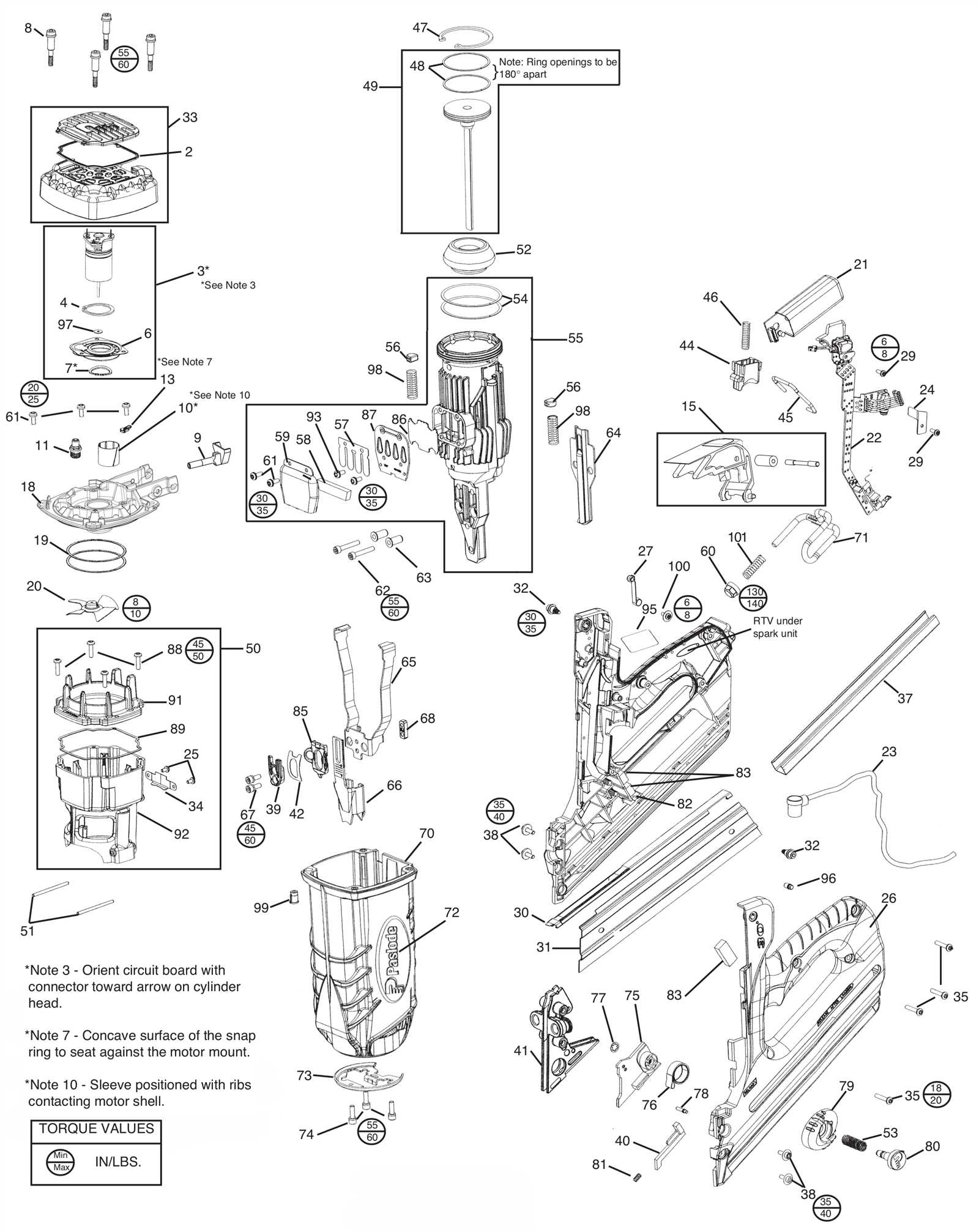

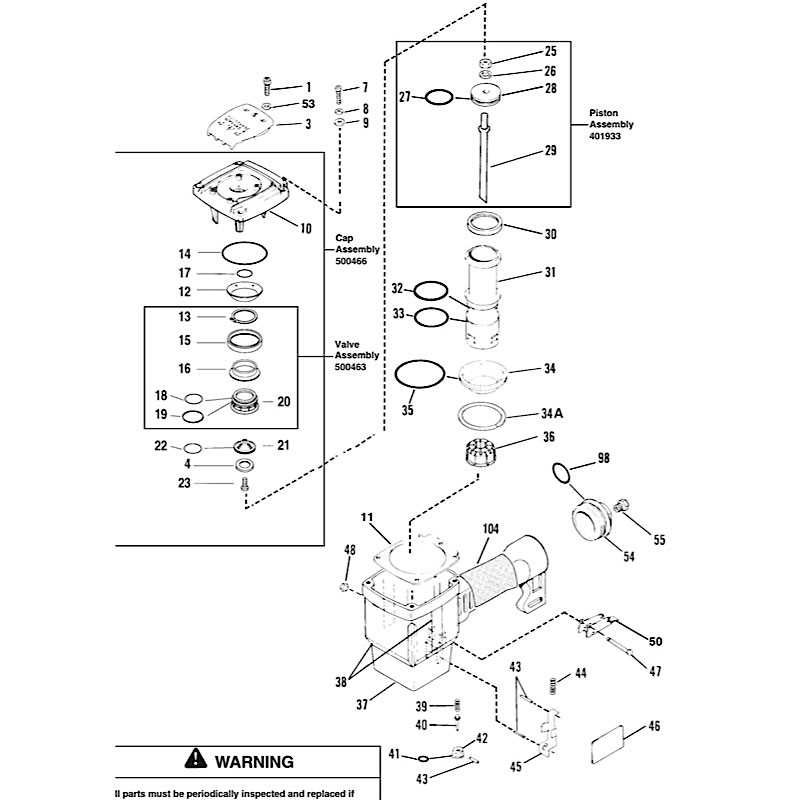

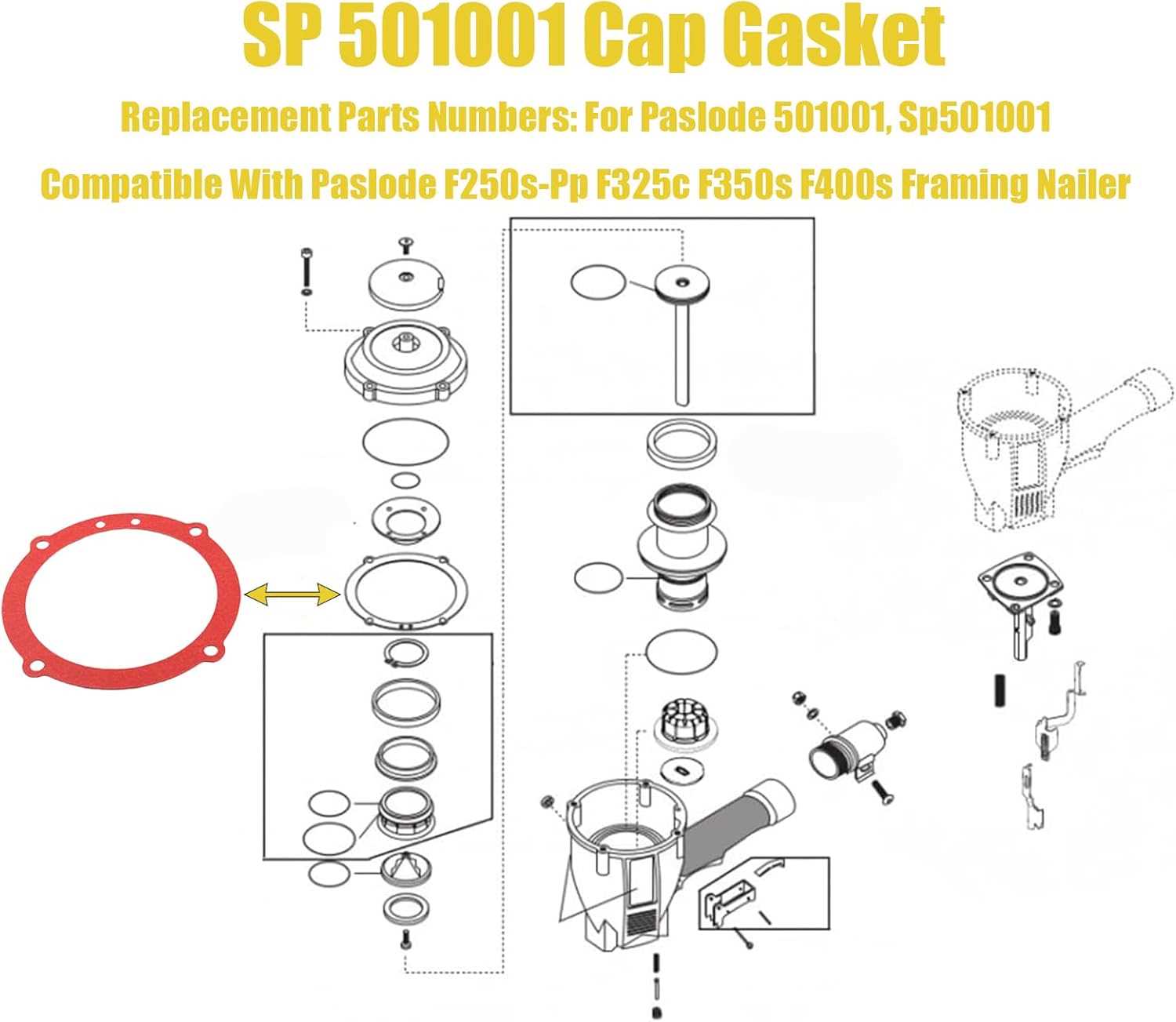

In this guide, we will explore a visual representation that showcases the assembly of the device, highlighting each significant part and its role. This will serve as a valuable resource for anyone looking to deepen their knowledge and ensure that their tool operates at peak performance.

Understanding the Paslode PF350S

This section aims to explore the key features and functionalities of a popular fastening tool designed for professionals. By examining its design and performance, users can gain insights into how this equipment enhances efficiency in various applications.

The tool is engineered for reliability, ensuring consistent operation in demanding environments. Its construction allows for ease of handling while providing powerful performance, making it suitable for both seasoned contractors and DIY enthusiasts.

Additionally, understanding the internal mechanisms and components is essential for proper maintenance and troubleshooting. Familiarity with these elements can ultimately lead to enhanced longevity and optimal performance, making any project smoother and more effective.

Key Components of the PF350S

This section explores the essential elements that make up the tool, focusing on their functions and significance in ensuring optimal performance.

- Power Source: The primary mechanism that drives the tool, providing the necessary energy for operation.

- Trigger Mechanism: Responsible for initiating the action, allowing for precise control during use.

- Magazine: Holds the fasteners, facilitating quick and efficient loading for continuous use.

- Motor Assembly: Converts energy into mechanical motion, ensuring consistent delivery of fasteners.

- Housing: The outer shell that protects internal components while providing a comfortable grip.

Understanding these key components allows users to delve into the functionality and maintenance of the tool, ultimately enhancing its lifespan and effectiveness.

Importance of Parts Diagrams

Understanding the components of any complex machinery is essential for efficient maintenance and repair. Visual representations of these elements serve as valuable tools for users, providing clarity and insight into assembly and function.

Enhancing Maintenance Efficiency

- Facilitates quick identification of components.

- Streamlines troubleshooting processes.

- Reduces downtime during repairs.

Supporting User Knowledge

- Increases familiarity with the equipment.

- Promotes safer handling and usage.

- Encourages informed decision-making during replacements.

Common Issues with Paslode Tools

Tools designed for fastening applications are essential in construction and woodworking. However, like any equipment, they can encounter a variety of problems that hinder performance and efficiency. Understanding these common challenges can help users troubleshoot effectively and maintain their tools for optimal operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Jamming | Fasteners fail to feed or get stuck | Check for debris, clean the magazine, and ensure proper loading |

| Inconsistent Firing | Tools misfire or fire intermittently | Inspect air pressure levels, clean the trigger mechanism, and replace worn seals |

| Battery Issues | Tool fails to power on or has reduced runtime | Charge the battery fully, inspect for damage, and consider replacement |

| Pneumatic Leaks | Loss of power or pressure | Check hoses and fittings for wear, tighten connections, and replace damaged parts |

| Overheating | Tool becomes excessively hot during use | Allow for cooling periods, avoid prolonged use, and ensure adequate ventilation |

How to Use the Diagram Effectively

Understanding how to utilize a technical illustration can significantly enhance your repair or assembly experience. Such visuals provide crucial insights into the components and their relationships, making troubleshooting and maintenance tasks more manageable.

Here are some steps to make the most out of the visual representation:

- Familiarize Yourself with the Layout: Before diving into the details, take a moment to understand the overall structure of the image. Identify the major sections and how they relate to one another.

- Identify Key Elements: Look for labels and numbers that correspond to specific items. Knowing which part is which is essential for effective navigation.

- Refer to the Legend: If the illustration includes a legend or key, use it to decode symbols and color codes that may represent different types of components.

To ensure a smooth process, consider these additional tips:

- Cross-Reference with Manuals: Use the technical guide alongside the illustration for a more comprehensive understanding of assembly or repair procedures.

- Make Notes: As you study the image, jot down any questions or points of confusion. This will help you focus on specific areas that need further research.

- Use High-Quality Copies: Ensure that the illustration is clear and legible. Poor-quality images can lead to misinterpretation of crucial details.

By following these strategies, you can effectively navigate and utilize the visual guide to enhance your project efficiency and accuracy.

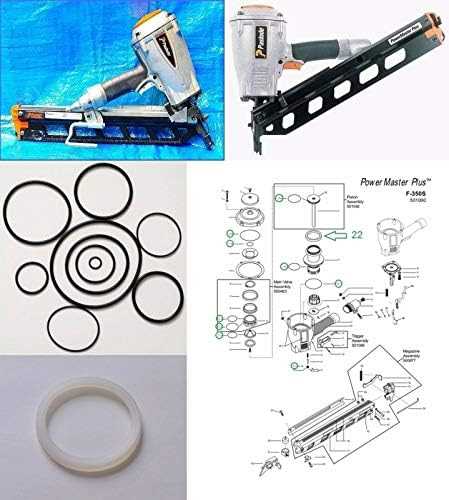

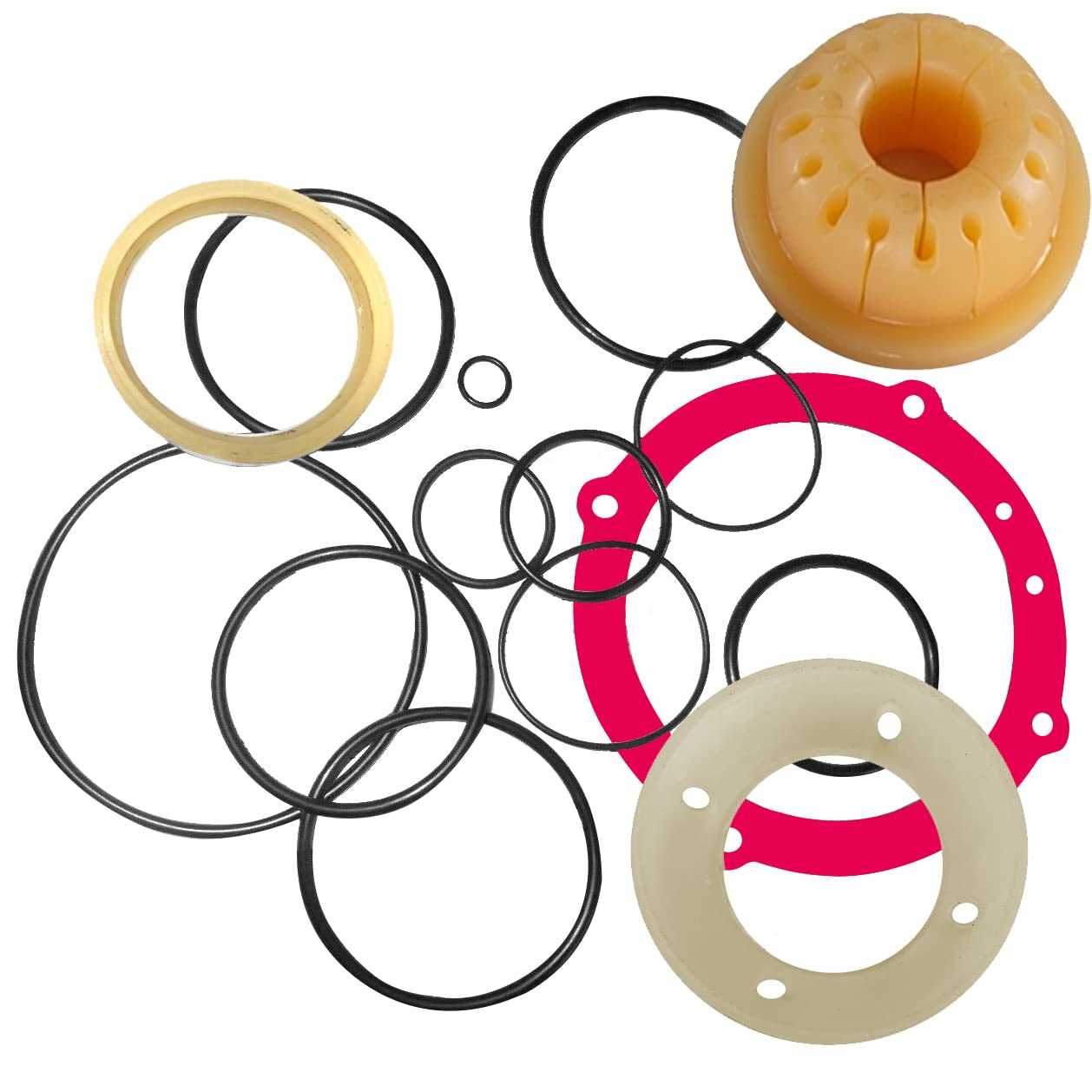

Ordering Replacement Parts Online

In today’s digital age, acquiring components for tools and equipment has never been easier. The online marketplace offers a vast selection of options, allowing users to find exactly what they need with just a few clicks. Whether for maintenance or repair, understanding how to navigate these platforms is crucial for a successful purchase.

Finding Reliable Sources

When seeking out new components, it’s essential to choose trustworthy suppliers. Look for websites that specialize in tool accessories and offer detailed product descriptions. User reviews can provide valuable insights into the quality and service reliability of these vendors.

Ensuring Compatibility

Before making a purchase, confirm that the item matches your specific model requirements. Utilize the manufacturer’s specifications or consult online resources to delve into compatibility issues. This attention to detail will help ensure your repairs are effective and long-lasting.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of any tool or device. Regular maintenance not only ensures optimal performance but also helps prevent unexpected breakdowns. By adhering to a systematic care routine, you can maintain efficiency and extend the life of your equipment.

| Tip | Description |

|---|---|

| Clean Regularly | Remove debris and dust after each use to prevent clogs and damage. |

| Inspect Components | Regularly check for wear and tear, replacing any damaged parts promptly. |

| Lubricate Moving Parts | Use appropriate lubricants to reduce friction and enhance functionality. |

| Store Properly | Keep the equipment in a dry, temperature-controlled environment to avoid corrosion. |

| Follow Manufacturer Guidelines | Adhere to the maintenance schedule and recommendations provided in the manual. |

Implementing these strategies will help ensure your tools operate smoothly and efficiently for years to come. Regular attention to maintenance pays off by avoiding costly repairs and replacements.

Differences Between PF350S Models

Understanding the variations among different versions of a particular tool can significantly impact performance and usability. Each iteration may include enhancements or modifications designed to improve efficiency, durability, or user experience. This section delves into the distinct features and specifications that differentiate these models.

Model Specifications

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 5.5 lbs | 6.0 lbs | 5.8 lbs |

| Power Source | Gas | Electric | Battery |

| Max Depth | 2.5 inches | 2.0 inches | 2.5 inches |

| Price | $299 | $349 | $319 |

Performance Enhancements

Each version incorporates different technologies aimed at boosting operational capabilities. Users may find that certain models offer improved firing speed, enhanced battery life, or better ergonomics, which cater to diverse working environments. Evaluating these distinctions can aid in selecting the most suitable option for specific needs.

Visualizing Parts for Easy Repairs

Understanding the various components of a tool can significantly simplify the repair process. By creating a visual representation of each element, users can quickly identify issues and streamline maintenance. This approach fosters a more intuitive understanding, enabling effective troubleshooting and enhancing the overall efficiency of repairs.

Benefits of Visual Representation

A graphical layout provides clarity and eliminates confusion during the repair process. Users can easily match components with their respective functions, reducing the likelihood of errors. This visual aid not only saves time but also enhances the user’s confidence in performing repairs independently.

Enhancing Repair Skills

Utilizing visual guides cultivates better repair skills over time. As individuals become more familiar with the layout and functions of different elements, their ability to diagnose and resolve issues improves. This mastery ultimately leads to greater satisfaction and success in maintaining their tools.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining equipment efficiency and longevity. Regular inspection can help detect issues before they lead to significant malfunctions or costly repairs.

Common Signs of Deterioration

- Visible damage or cracking on surfaces

- Unusual sounds during operation

- Decreased performance or efficiency

- Frequent need for adjustments or repairs

Steps to Assess Condition

- Perform routine visual inspections to check for obvious damage.

- Listen for abnormal noises when the equipment is in use.

- Monitor performance metrics over time to identify declines.

- Keep a log of maintenance and repairs to track patterns.

Understanding Warranty Policies

Warranty policies play a crucial role in consumer satisfaction and product reliability. They outline the manufacturer’s commitment to quality and the support available to users when issues arise. Knowing these guidelines can enhance the overall experience with the product.

Key Features of Warranty Policies

- Duration: Typically specifies how long the warranty is valid.

- Coverage: Details what parts and services are included.

- Exclusions: Lists any conditions or damages not covered.

- Claim Process: Explains the steps to take when making a warranty claim.

Benefits of Understanding Warranty Policies

- Enhanced product longevity through proper maintenance.

- Peace of mind knowing that support is available.

- Informed decision-making when purchasing tools.

Expert Resources for Tool Users

For enthusiasts and professionals alike, having access to reliable information is essential for effective tool management and maintenance. A variety of resources can empower users to enhance their understanding of equipment functionality, troubleshoot issues, and improve overall performance.

Online Communities provide a wealth of shared experiences and advice. Joining forums or social media groups dedicated to specific tools can connect users with seasoned experts who offer invaluable insights and practical tips.

Instructional Videos are another fantastic resource. Platforms like YouTube host numerous channels that demonstrate proper usage, maintenance techniques, and repairs. These visual aids can simplify complex processes and help users follow along step by step.

User Manuals are often overlooked but serve as crucial references. These documents detail specifications, safety precautions, and maintenance schedules that can prolong the lifespan of any tool.

Manufacturer Websites frequently offer downloadable resources such as manuals, FAQs, and troubleshooting guides. Regularly visiting these sites can keep users informed about the latest updates and enhancements.

By utilizing these expert resources, tool users can elevate their skills, ensuring they make the most of their equipment and maintain it in peak condition.