When it comes to maintaining an efficient heating system, comprehending the various elements that work together is crucial. A well-functioning heater relies on a combination of mechanisms that contribute to its overall performance. Each component plays a distinct role, ensuring that the unit operates smoothly and effectively.

Familiarity with these essential features can significantly enhance troubleshooting efforts and streamline maintenance procedures. By exploring the layout and relationships of these components, one can better appreciate how they interact to generate warmth. This knowledge is invaluable for homeowners and technicians alike, fostering a proactive approach to system care.

In this section, we will delve into a detailed overview of the key components, illustrating their functions and positions within the system. Understanding these elements will empower you to make informed decisions regarding repairs and replacements, ultimately promoting a more reliable and efficient heating experience.

Understanding the Payne Furnace Components

In the realm of heating systems, various elements work cohesively to provide warmth and comfort within a space. Each component plays a crucial role in ensuring efficiency and reliability. Familiarizing oneself with these elements can enhance maintenance efforts and improve overall performance.

Key Elements of the Heating System

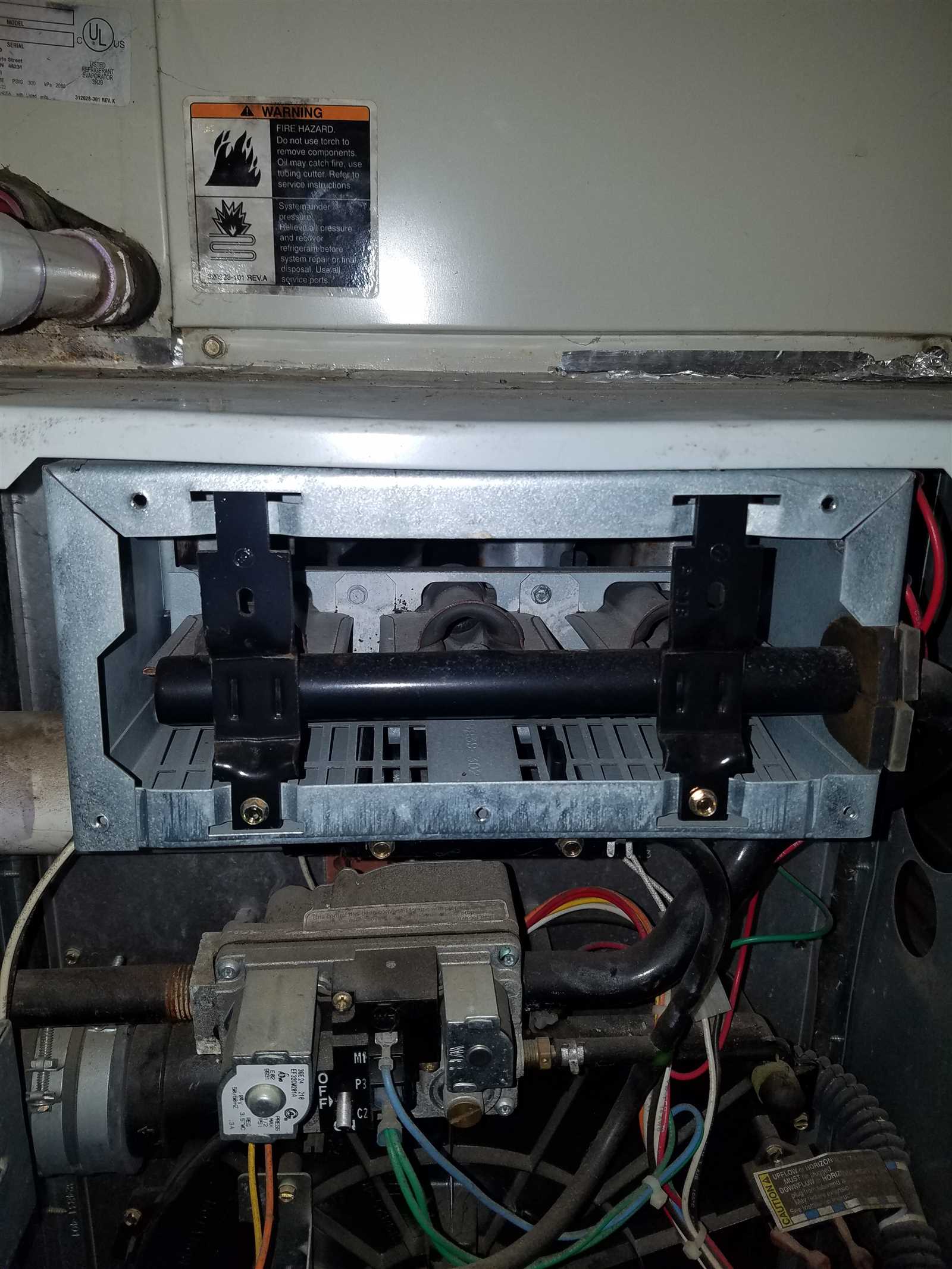

The central unit, often seen as the heart of the system, is responsible for generating heat. It operates alongside various mechanisms that facilitate airflow, control temperature, and ensure safety. Burners ignite fuel, while heat exchangers transfer warmth to circulating air. Additionally, fans help distribute heated air throughout the area, promoting an even temperature.

Importance of Regular Maintenance

Understanding these components is vital for effective upkeep. Regular checks on the ignitor, thermostat, and filters can prevent potential malfunctions. Proper attention to these aspects not only enhances the lifespan of the system but also contributes to energy efficiency, ensuring a cost-effective solution for heating needs.

Overview of Payne Furnace Functionality

This section provides a comprehensive understanding of how heating systems operate to ensure optimal indoor climate control. These systems utilize various components that work together seamlessly to produce and distribute warmth throughout a building.

The central mechanism typically relies on a heat source, which generates warmth through a combustion process or electrical elements. This heat is then transferred to air or water, depending on the design of the system. Efficient circulation of this heated medium is crucial, as it facilitates consistent temperature maintenance in living spaces.

Moreover, thermostatic controls play a vital role in regulating the temperature, enabling users to set desired levels. Safety features are also integrated into the system, ensuring reliable operation and minimizing risks associated with overheating or malfunctioning. Overall, the effectiveness of these systems is determined by their design and the quality of their components.

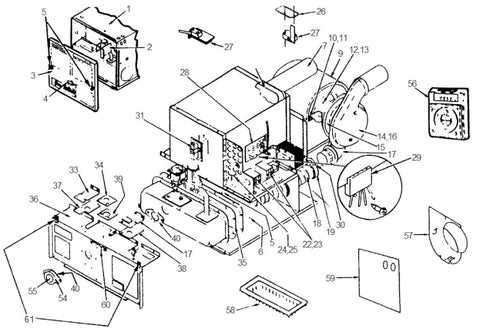

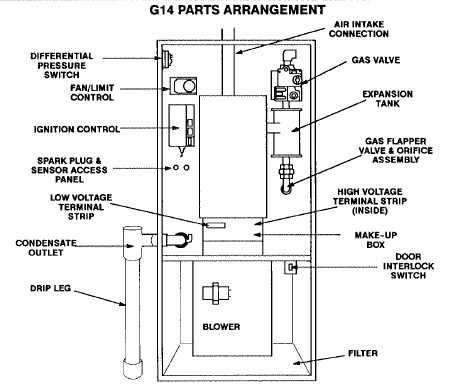

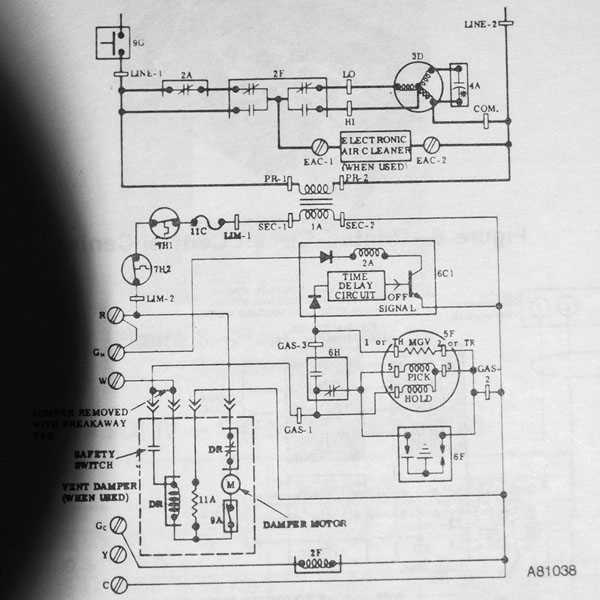

Key Elements in the Diagram

Understanding the essential components represented in a schematic is crucial for effective troubleshooting and maintenance. Each element serves a specific function, contributing to the overall efficiency and operation of the system. Recognizing these components will aid in identifying potential issues and facilitate repairs.

- Thermostat: This device regulates the temperature by controlling the heating mechanism based on the set preferences.

- Heating Elements: These components generate heat when electrical current passes through them, playing a vital role in warmth production.

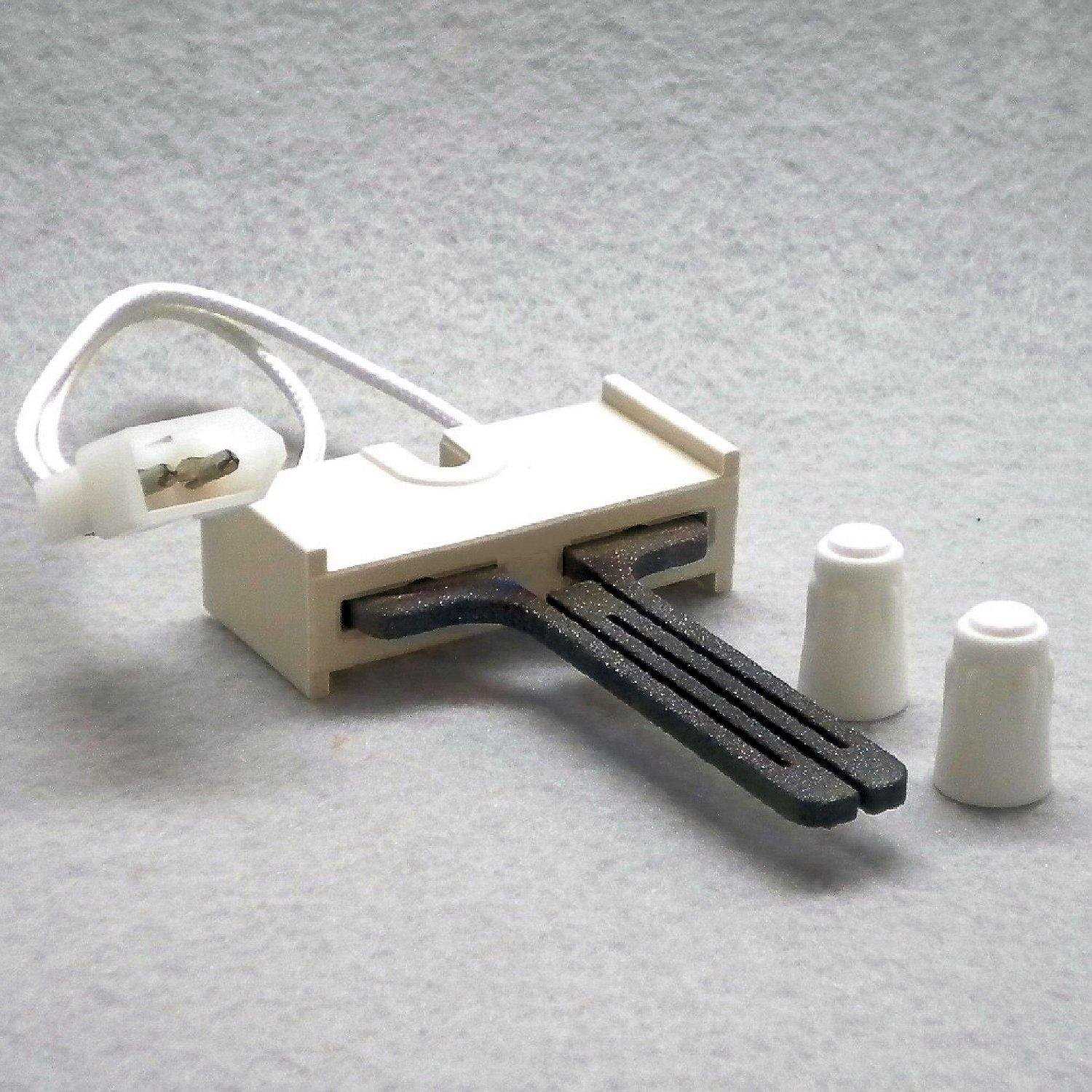

- Ignition System: Responsible for initiating the combustion process, ensuring that the heating elements activate as needed.

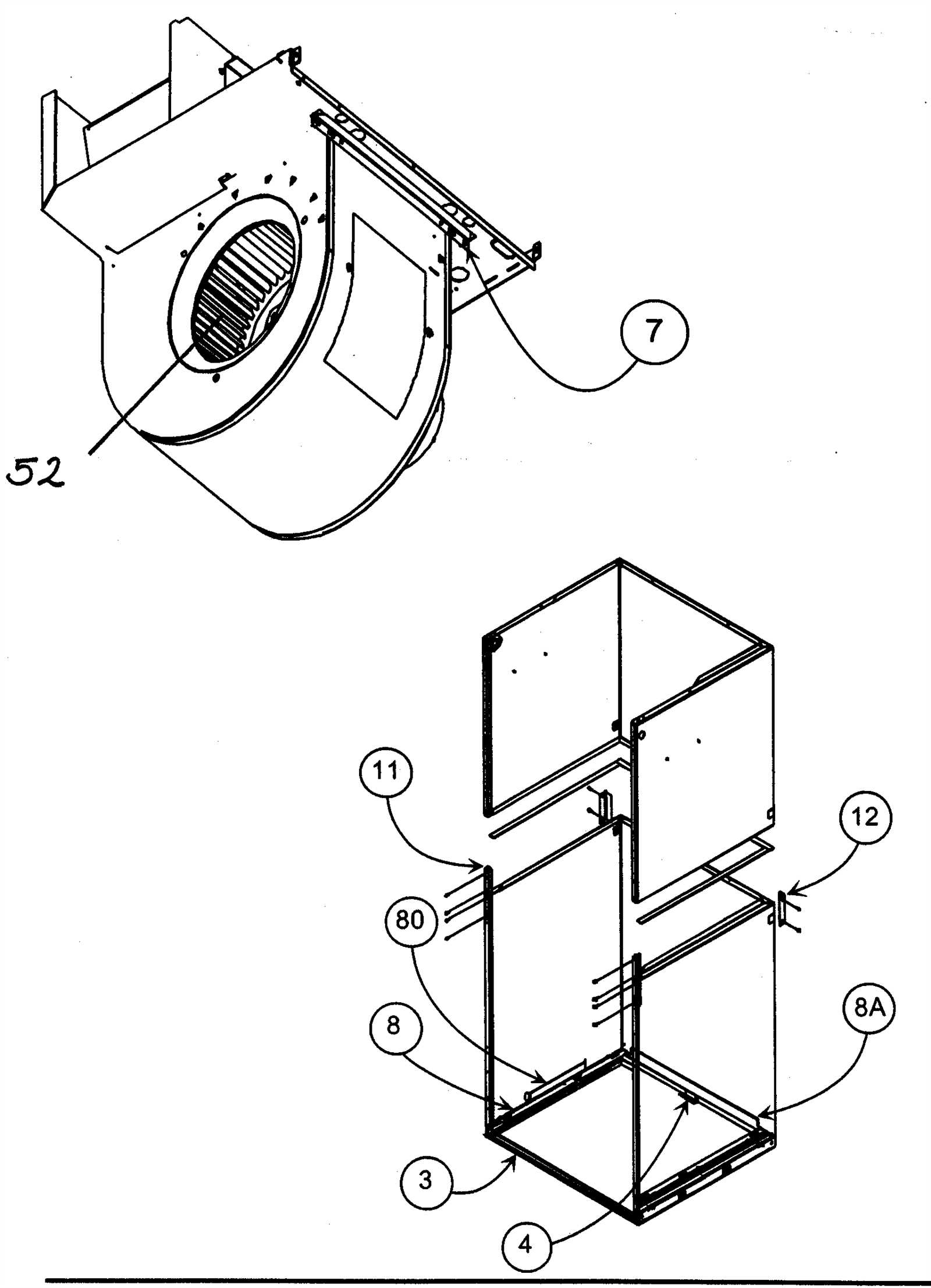

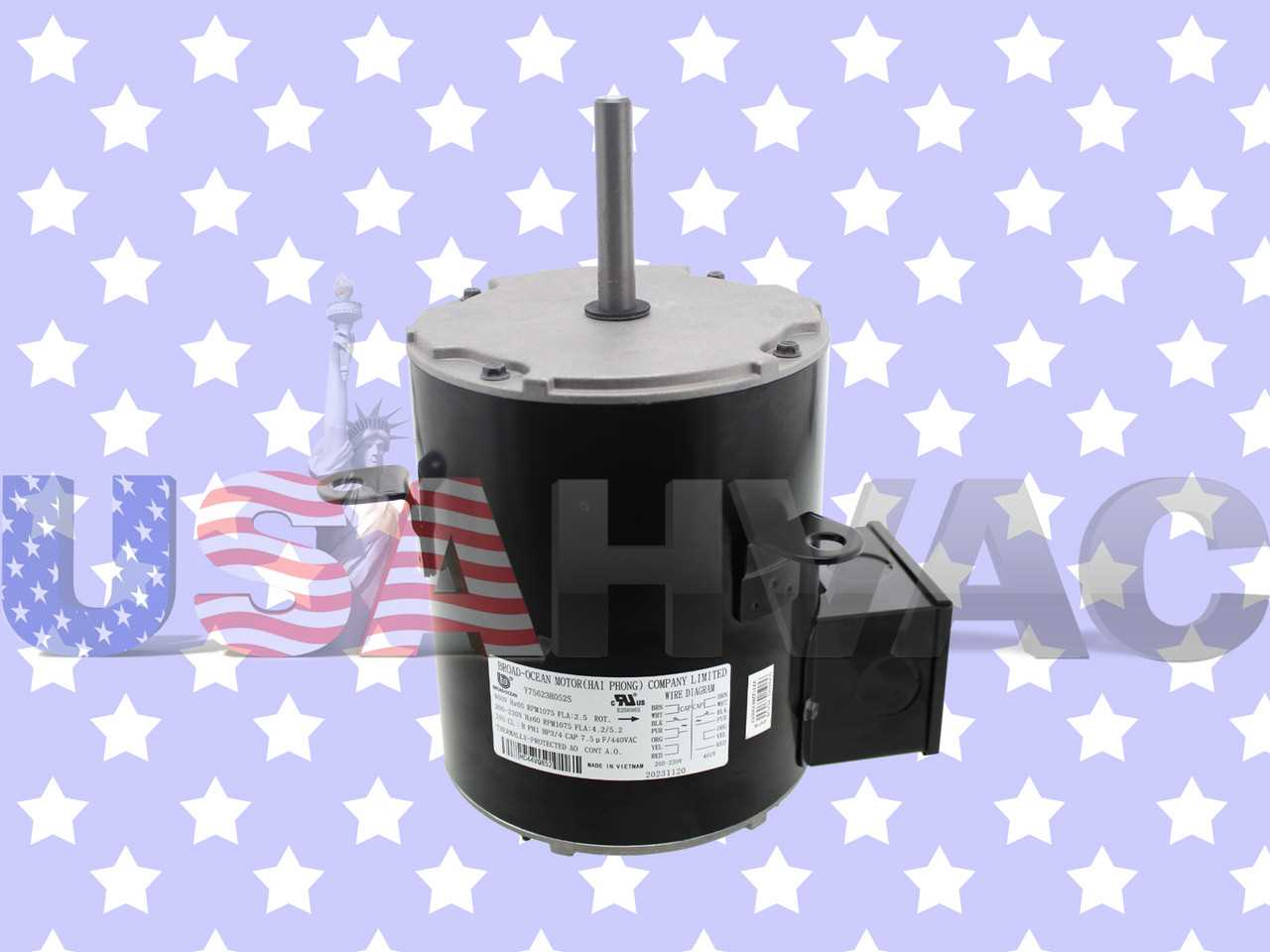

- Blower Motor: This part circulates warm air throughout the space, promoting even heat distribution.

- Limit Switch: A safety feature that prevents overheating by shutting down the system if temperatures exceed safe limits.

- Ventilation Ducts: Channels through which warm air is delivered to various areas, crucial for effective airflow.

Familiarizing oneself with these fundamental components can enhance the understanding of the overall functionality and support effective decision-making during maintenance or troubleshooting processes.

Importance of Proper Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of heating systems. It not only enhances efficiency but also prevents costly breakdowns and extends the lifespan of the equipment.

Neglecting maintenance can lead to a range of issues, from decreased efficiency to complete system failure. Routine inspections help identify potential problems early, allowing for timely repairs and adjustments that can save both time and money.

Additionally, well-maintained systems operate more safely, reducing the risk of hazards such as carbon monoxide leaks or fire. Establishing a consistent maintenance schedule with qualified professionals ensures that all components function correctly and efficiently.

Overall, investing in proper care is a proactive measure that promotes reliable operation, reduces energy costs, and enhances comfort in living spaces.

Common Issues with Furnace Parts

Many homeowners encounter various challenges related to heating systems. These complications can arise from several components within the unit, leading to inefficiency and discomfort. Understanding these common problems can assist in troubleshooting and maintaining optimal performance.

One frequent issue is the accumulation of dirt and debris in the airflow channels, which can hinder circulation and reduce heating efficiency. Regular cleaning and maintenance can mitigate this problem.

Another common concern involves electrical malfunctions. Wiring problems or faulty connections may prevent the unit from operating correctly. It is essential to inspect electrical components periodically to ensure reliable functionality.

Thermostat inaccuracies can also cause significant disruptions in temperature regulation. If the device does not accurately sense the environment, it can lead to inconsistent heating throughout the space. Calibration or replacement may be necessary for accurate readings.

Finally, issues with ignition or pilot lights can hinder the startup process. If the ignition system fails, it can prevent the system from generating heat altogether. Ensuring that the ignition mechanism is clean and functional is vital for effective operation.

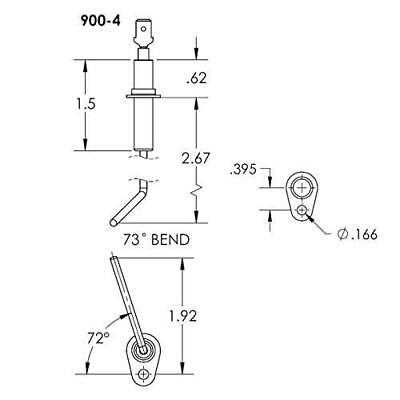

Identifying Components in the Diagram

Understanding the layout of key elements in an operational system is essential for effective maintenance and troubleshooting. This section provides insights into recognizing various components and their functions, aiding users in grasping the overall structure and functionality.

Common Elements and Their Functions

Each element serves a specific purpose, contributing to the efficient operation of the entire setup. Familiarity with these components can help diagnose issues and facilitate repairs.

| Component | Description |

|---|---|

| Blower Motor | Responsible for circulating air throughout the system. |

| Heat Exchanger | Transfers heat from the combustion process to the air without mixing them. |

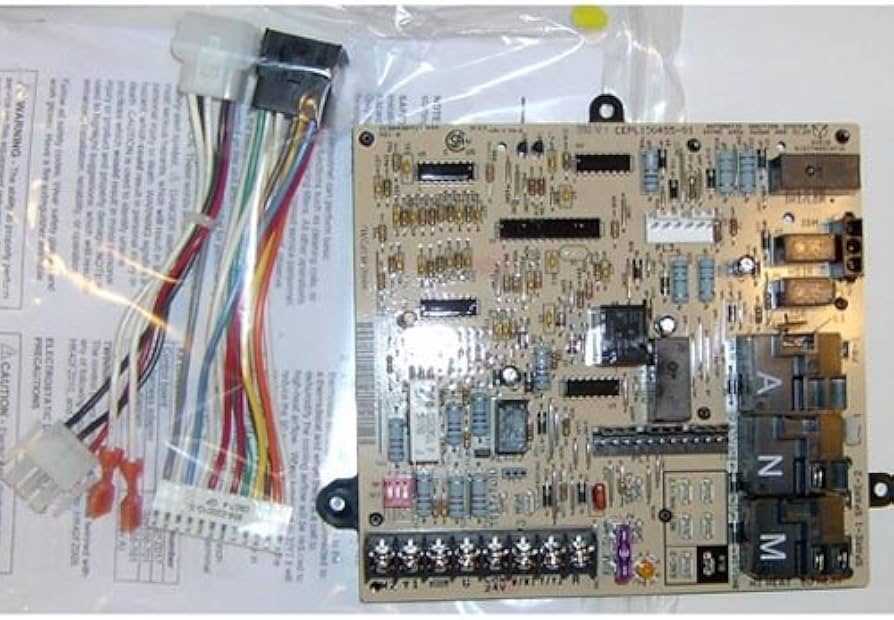

| Control Board | Acts as the brain of the system, regulating various functions and safety mechanisms. |

| Thermostat | Monitors the temperature and signals the system to turn on or off as needed. |

Visual Cues for Identification

Recognizing visual markers and common shapes can significantly aid in identifying each element. Familiarity with these cues enhances one’s ability to navigate and understand the layout effectively.

Replacement Parts and Their Costs

When it comes to maintaining a heating system, understanding the components that may require replacement is essential for ensuring optimal performance. Identifying these elements and their associated costs can help homeowners make informed decisions regarding repairs and upgrades.

Common Components Needing Replacement

- Blower Motor

- Ignition System

- Heat Exchanger

- Control Board

- Thermostat

Estimated Costs

The expense of acquiring new components can vary widely based on the type and complexity of the element. Below is a general overview of potential costs:

- Blower Motor: $150 – $500

- Ignition System: $100 – $300

- Heat Exchanger: $500 – $1,500

- Control Board: $100 – $400

- Thermostat: $50 – $200

Considering these factors can aid in budgeting for repairs and ensuring the system remains efficient throughout its lifespan.

Installation Tips for New Parts

When upgrading components in heating systems, careful attention to detail ensures optimal performance and longevity. Proper installation techniques not only enhance efficiency but also minimize the risk of future malfunctions. Here are some essential guidelines to follow during the replacement process.

Preparation Before Installation

Before beginning the installation, gather all necessary tools and ensure that you have the correct components. Always consult the manufacturer’s manual for specifications and installation procedures. Additionally, turning off the power supply and ensuring the area is clean and free of debris will facilitate a smoother installation process.

Step-by-Step Installation Process

Follow these steps to successfully install new components:

| Step | Description |

|---|---|

| 1 | Remove the old component carefully, taking note of the connections and mounting points. |

| 2 | Inspect the surrounding area for any signs of wear or damage that may need attention. |

| 3 | Install the new component, ensuring that all connections are secure and aligned properly. |

| 4 | Restore power to the system and perform a test run to check for any issues. |

Following these steps will help ensure a successful installation, leading to improved efficiency and reliability in your heating system.

How to Read the Diagram

Understanding a schematic representation can significantly enhance your ability to troubleshoot and maintain your heating system. This section will guide you through the essential steps to interpret such illustrations effectively.

Follow these key points to make sense of the layout:

- Identify Symbols: Each symbol in the representation corresponds to a specific component or function. Familiarize yourself with these symbols to understand what each part does.

- Follow the Lines: The lines connecting the symbols indicate how different elements are linked. Trace these connections to see how the system operates as a whole.

- Check Labels: Look for labels that provide additional information about each component, such as model numbers or specifications. These can be crucial for replacement or repair.

- Refer to the Legend: Most representations include a legend or key that explains the symbols used. This is an essential reference that can clarify any uncertainties.

- Analyze Flow Direction: Pay attention to arrows or indicators showing the flow of air or energy. Understanding the direction helps in diagnosing potential issues.

By mastering these elements, you can efficiently navigate and interpret the representation, leading to more informed maintenance decisions.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both personal safety and equipment longevity. Proper precautions must be taken to minimize risks associated with electrical and mechanical components. Familiarizing oneself with safety guidelines will help prevent accidents and injuries during repair procedures.

Personal Protective Equipment

Wearing appropriate protective gear is crucial when handling equipment. Items such as safety goggles, gloves, and non-slip footwear should be utilized to safeguard against potential hazards. This gear acts as a barrier between the technician and any harmful elements, enhancing safety during repair activities.

Power Supply and Ventilation

Before beginning any maintenance work, it is imperative to disconnect the power source to prevent electric shock. Additionally, ensuring adequate ventilation in the workspace is vital, especially when dealing with combustion-related components. This practice helps to reduce the risk of inhaling harmful fumes and maintains a safe working atmosphere.

Resources for Parts and Support

When maintaining heating systems, having access to reliable resources is essential for ensuring optimal performance and longevity. This section provides guidance on where to find components and assistance for various models, helping users keep their systems running smoothly.

Authorized Dealers and Retailers

Certified distributors offer a wide range of components and accessories for heating units. These retailers are equipped with knowledgeable staff who can assist with product selection and provide valuable advice on maintenance. Checking the manufacturer’s website for a list of authorized sellers can simplify the process of locating the right items.

Online Resources and Forums

The internet hosts numerous platforms where users can exchange information and seek support. Online communities and forums dedicated to heating systems provide a wealth of knowledge, including troubleshooting tips, installation guides, and recommendations for specific components. Utilizing these resources can enhance understanding and facilitate effective repairs.

Frequently Asked Questions

This section addresses common inquiries related to heating systems and their components. Here, you’ll find valuable information that can help users understand various aspects of their equipment, troubleshooting techniques, and maintenance tips.

What should I do if my heating system is not functioning properly?

If your heating apparatus is not operating as expected, first ensure that it is receiving power. Check the thermostat settings and make sure they are correctly adjusted. If the issue persists, it may be necessary to inspect the system for blockages or faults in the internal components.

How often should I perform maintenance on my heating unit?

Regular upkeep is essential for optimal performance. It is advisable to conduct a thorough inspection and service at least once a year. This ensures that any potential issues are identified early, keeping the system efficient and prolonging its lifespan.