In the world of construction and woodworking, the functionality of pneumatic equipment hinges on the precision of its individual elements. Familiarity with these components is crucial for maintaining performance and ensuring safety during operation. This section aims to illuminate the various features of a specific tool model, providing insights that can enhance both its usage and upkeep.

By delving into the intricate assembly of this particular device, users can gain a better understanding of its mechanics. Knowledge of each segment’s role not only aids in troubleshooting but also fosters a deeper appreciation for the engineering behind such equipment. Recognizing how these elements interact empowers operators to optimize their tool’s efficiency and longevity.

For enthusiasts and professionals alike, having access to a comprehensive overview of these critical parts is invaluable. Whether one is engaged in routine maintenance or preparing for repairs, this information serves as a foundational resource. As we explore the specifics of this tool’s configuration, it will become evident how essential these insights are for any user aiming to achieve the best results in their projects.

This section provides a comprehensive look at a popular tool known for its efficiency and reliability in various applications. Understanding its components and their functions is essential for maintenance and troubleshooting, ensuring optimal performance during operation.

Key Features of the Tool

The device boasts several important features that contribute to its effectiveness. Among them are precision-engineered elements that enhance functionality, making it suitable for both professional and DIY users. Familiarizing oneself with these features allows for better utilization of the tool.

Component Breakdown

Each element within the tool plays a crucial role in its overall operation. Below is a summary of the main components along with their functions:

| Component | Function |

|---|---|

| Housing | Protects internal mechanisms and provides structural integrity. |

| Trigger Mechanism | Controls the operation of the tool, allowing for precise usage. |

| Drive Cylinder | Facilitates the action that drives fasteners into materials. |

| Magazine | Holds and feeds fasteners into the drive mechanism. |

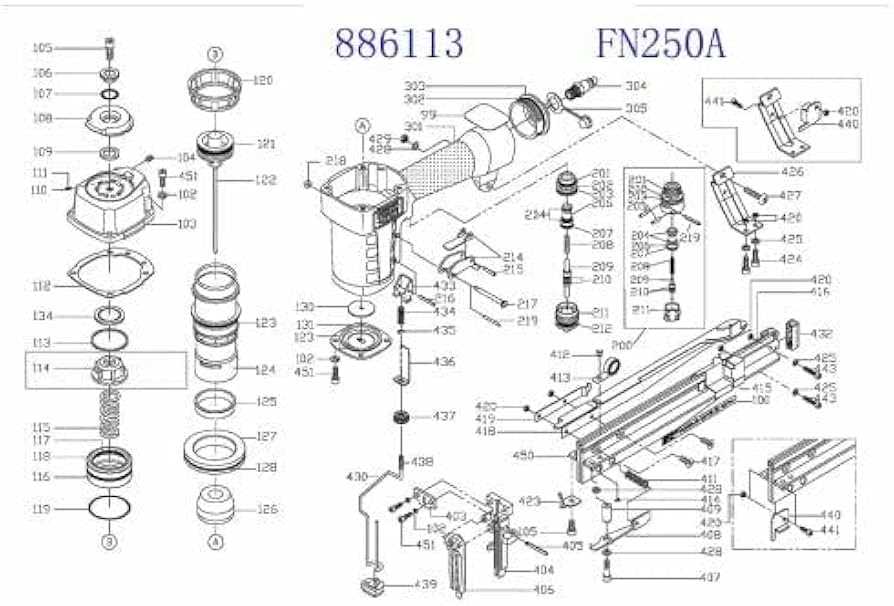

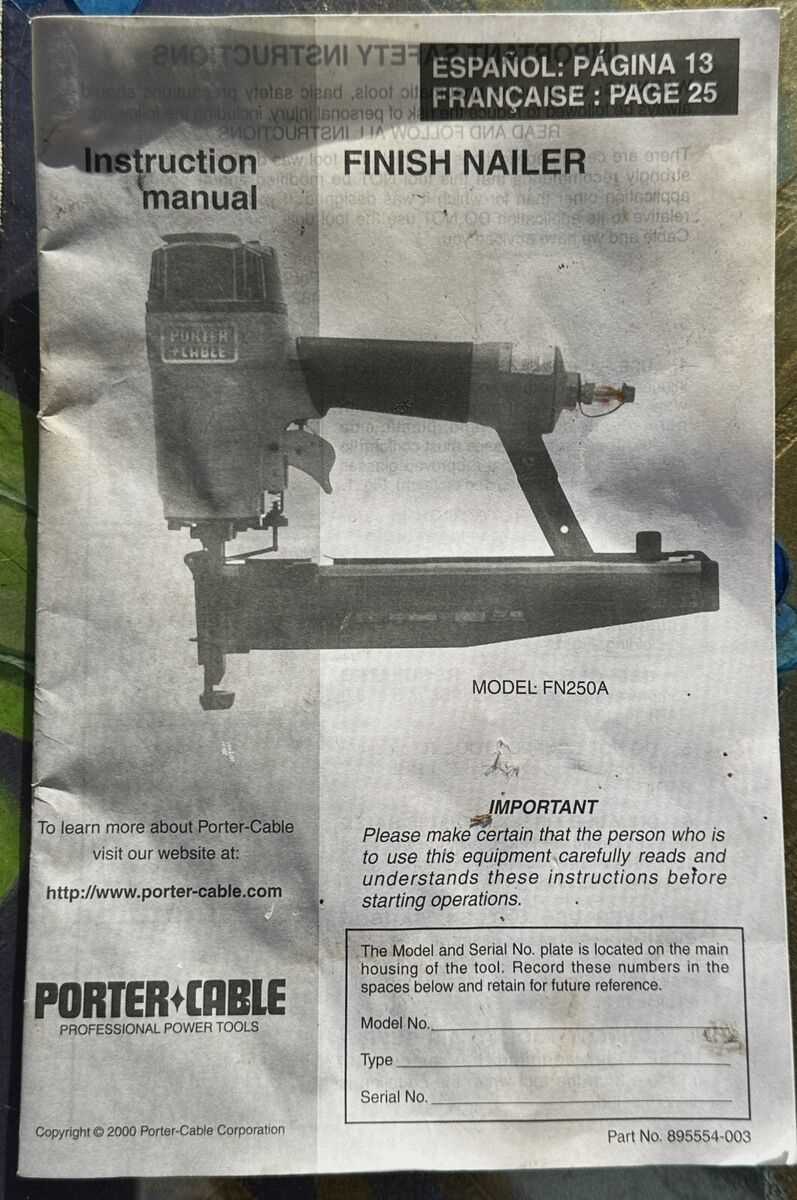

Key Features of the FN250A

The FN250A stands out for its remarkable design and functionality, making it a preferred choice among users seeking efficiency and reliability. Its innovative features enhance performance, ensuring seamless operation in various tasks.

| Feature | Description |

|---|---|

| Lightweight Design | The tool is designed for easy handling, reducing user fatigue during extended use. |

| Durable Construction | Manufactured with high-quality materials to withstand rigorous use in demanding environments. |

| Adjustable Depth Control | Allows for precise nail placement, accommodating various project requirements. |

| Quick Jam Release | Equipped with a mechanism that enables fast clearing of jams, minimizing downtime. |

| Ergonomic Grip | The handle is designed for comfort, promoting better control and stability during operation. |

Identifying Major Components

Understanding the primary elements of a tool is essential for effective maintenance and operation. This section highlights the key features that contribute to the overall functionality of the device, ensuring users can recognize and utilize them efficiently.

Key Features Overview

The main components play crucial roles in the device’s performance. Familiarity with these parts aids in troubleshooting and enhances the user experience. Recognizing each element’s function will help users operate the tool more effectively and extend its lifespan.

Maintenance Considerations

Regular inspection and maintenance of the major components are vital for optimal performance. Users should be aware of signs of wear and tear, as well as the appropriate care techniques for each part. This proactive approach ensures reliability and minimizes the risk of malfunction during use.

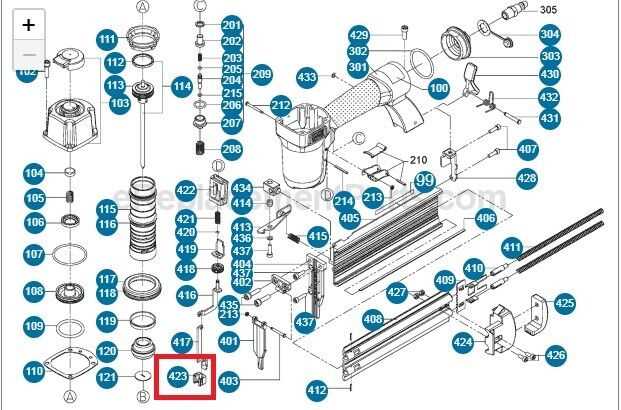

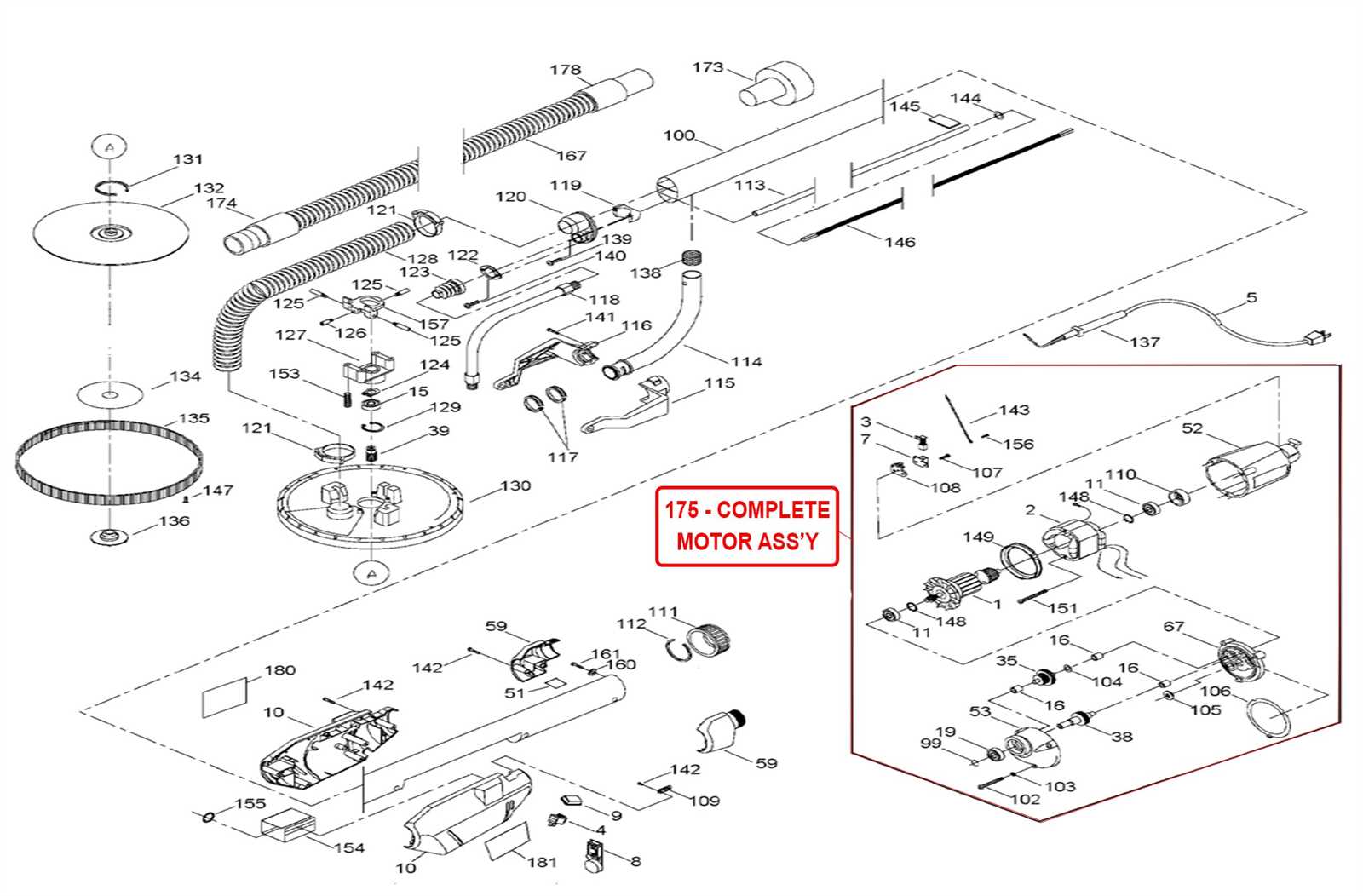

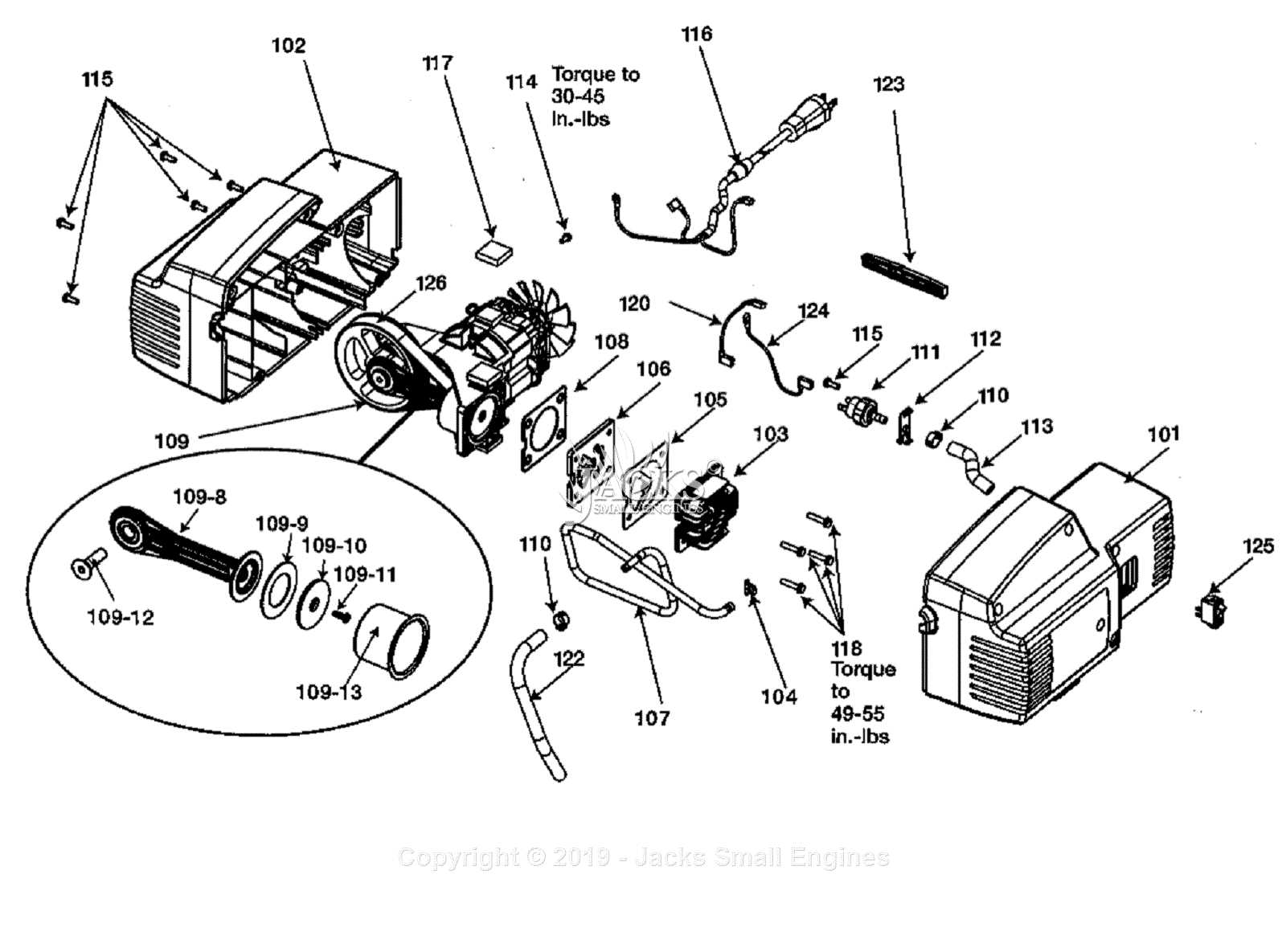

Understanding the Parts Diagram

The visual representation of components is essential for grasping the assembly and functionality of any mechanical device. Such illustrations serve as a valuable reference for identifying each element and understanding its role within the whole system. By familiarizing oneself with these representations, users can enhance their comprehension of how different pieces interact and contribute to the overall operation.

Key Elements of the Illustration

Each section within the illustration highlights various components, often labeled for easy identification. Recognizing these labels helps in comprehending the structure and function of each piece, ensuring that users can navigate the assembly with confidence. Moreover, understanding the arrangement of components facilitates troubleshooting and maintenance tasks.

Benefits of Using Visual References

Utilizing visual references significantly streamlines the repair and assembly process. It provides clarity on how parts fit together and aids in the identification of any missing or damaged components. This proactive approach not only saves time but also minimizes the risk of errors during reassembly or repairs.

| Component | Description |

|---|---|

| Element A | Defines the primary function of the system. |

| Element B | Supports the stability and alignment of the main structure. |

| Element C | Connects various parts, allowing for movement and operation. |

Maintenance Tips for Longevity

To ensure the extended lifespan of your equipment, regular upkeep is essential. Proper maintenance not only enhances performance but also prevents potential issues that could arise from neglect.

Start by keeping the device clean and free of debris. Regularly inspect all components for signs of wear or damage. Cleaning the exterior and interior with appropriate tools can prevent buildup that affects functionality.

Lubrication is another key factor in maintaining efficiency. Applying the right lubricant to moving parts helps reduce friction and wear, which can prolong the operational life of the equipment.

Additionally, follow the manufacturer’s guidelines for any specific maintenance schedules. Staying attentive to recommended service intervals can help catch problems early and ensure optimal performance.

Lastly, store the device in a dry, temperature-controlled environment to prevent damage from humidity and temperature fluctuations. Proper storage practices contribute significantly to the longevity of your equipment.

Common Issues and Solutions

Every tool may encounter problems over time, leading to inefficiencies and frustrations. Understanding these common challenges and their solutions can enhance the longevity and performance of your equipment. Here are some typical issues faced by users and effective strategies to resolve them.

Frequent Challenges

- Inconsistent performance

- Difficulty in operation

- Excessive noise during use

- Parts not functioning as intended

Effective Solutions

-

Check for Blockages: Ensure that all pathways are clear and free from debris. Regular maintenance can prevent clogs that hinder performance.

-

Inspect for Wear and Tear: Examine components for signs of damage. Replacing worn parts can significantly improve functionality.

-

Lubricate Moving Parts: Applying appropriate lubricants can reduce friction and noise, leading to smoother operation.

-

Consult the Manual: Referring to the user guide can provide insights into troubleshooting and maintenance specific to your model.

Replacement Parts Availability

Access to quality components is essential for maintaining the efficiency and longevity of your equipment. When repairs or replacements are necessary, it’s important to ensure that suitable alternatives are readily obtainable.

Numerous suppliers offer a wide range of replacements for various models. It is advisable to research and compare options to find the best fit for your specific needs. Checking with authorized dealers or reputable online retailers can help you secure authentic items that meet the necessary standards.

Additionally, exploring forums and user groups can provide insights into the availability of specific components. Engaging with fellow enthusiasts often leads to valuable recommendations on where to source reliable alternatives.

How to Use the Diagram Effectively

Understanding technical illustrations is crucial for successful repairs and maintenance. These visuals serve as valuable guides, providing clarity on component placement and functionality. By familiarizing yourself with the layout and design of these representations, you can enhance your ability to troubleshoot and assemble devices efficiently.

Familiarize Yourself with Symbols and Labels

Begin by identifying the various symbols and labels used in the visual representation. Each element typically has a specific meaning that indicates its role within the overall assembly. Knowing these definitions can significantly reduce confusion during repairs, ensuring you understand how each part interacts with others.

Follow a Systematic Approach

When using the illustration, adopt a step-by-step method. Start by locating the components you wish to examine or replace. Then, trace their connections and relationships to adjacent parts. This structured approach will streamline your repair process, minimize errors, and help you maintain an organized workflow.

Tools Needed for Repairs

To effectively conduct maintenance and restoration on your equipment, it is essential to gather the appropriate instruments. Having the right tools not only facilitates the repair process but also ensures that tasks are executed efficiently and safely.

Here is a list of essential tools that will assist you during the repair procedure:

- Wrench set: Useful for loosening and tightening various fasteners.

- Screwdriver set: Essential for removing and replacing screws of different sizes and types.

- Pliers: Handy for gripping, twisting, and cutting wire or small components.

- Socket set: Provides a range of sizes for tackling nuts and bolts.

- Measuring tape: Important for precise measurements and adjustments.

- Utility knife: Versatile tool for cutting materials and trimming edges.

- Multimeter: Useful for testing electrical connections and diagnosing issues.

By assembling these tools, you will be well-prepared to tackle any repairs with confidence and ease.

Safety Precautions During Repairs

When undertaking maintenance or fixing machinery, prioritizing safety is crucial. Proper precautions not only protect the individual performing the repair but also ensure the longevity of the equipment. Familiarity with the necessary safety measures can prevent accidents and promote a secure working environment.

Essential Safety Guidelines

Before starting any repair tasks, it is vital to follow specific guidelines to minimize risks:

| Guideline | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and appropriate footwear to shield against injuries. |

| Disconnect Power Source | Ensure that the equipment is unplugged or disconnected from its power source to prevent accidental activation. |

| Work in a Well-Ventilated Area | Perform repairs in an area with adequate ventilation to avoid inhaling harmful fumes or dust. |

Post-Repair Safety Checks

After completing repairs, it is important to conduct safety checks before using the equipment again. Verify that all components are securely reassembled and that no tools are left behind in the work area. A thorough inspection can prevent future malfunctions and enhance user safety.

Comparing with Other Models

When evaluating different tools within the same category, it is essential to analyze their features, specifications, and overall performance. Understanding how various models stack up against each other can assist consumers in making informed decisions based on their unique needs and preferences.

In this comparison, we will highlight key aspects that differentiate several models in the market:

- Performance: Each tool may vary in power output and operational speed, impacting its efficiency for specific tasks.

- Build Quality: The durability and materials used in construction can influence longevity and reliability under frequent use.

- Weight and Ergonomics: Heavier models may offer more stability, while lighter options can enhance maneuverability and reduce fatigue during prolonged operation.

- Maintenance Requirements: Different designs may entail varying levels of upkeep, affecting user experience over time.

- Accessory Compatibility: Availability and interchangeability of attachments can broaden functionality and enhance versatility.

By carefully considering these factors, users can identify which model aligns best with their operational needs, ultimately leading to greater satisfaction and productivity.