The operation of various lifting devices relies on a range of integral components that work in unison to ensure efficiency and safety. A comprehensive overview of these elements can greatly enhance one’s knowledge and facilitate better maintenance practices. This section delves into the fundamental aspects of these mechanisms, highlighting their importance in the overall functionality.

Each component plays a critical role in the performance of hoisting systems, from the initial engagement of the load to its final positioning. By familiarizing oneself with these elements, users can identify potential issues and make informed decisions regarding repairs and upgrades. This knowledge is invaluable for anyone involved in the operation or maintenance of such equipment.

Furthermore, understanding the configuration and relationship between these individual components can lead to improved operational efficiency. The interconnected nature of these elements emphasizes the need for a systematic approach to their inspection and upkeep. This exploration aims to provide clarity on these essential features, empowering users to optimize their lifting operations.

Understanding Windlass Mechanisms

At the core of many lifting and hauling systems lies a fascinating mechanism that combines simplicity and efficiency. This device is designed to manage heavy loads with ease, relying on a series of interrelated components to function smoothly. By transforming rotational motion into linear movement, it plays a crucial role in various applications, from marine settings to construction sites.

The primary function of this mechanism is to facilitate the movement of ropes or cables, allowing users to lift or lower objects with minimal effort. Its design often includes a cylindrical drum, around which the line is wound. When the drum rotates, it either gathers or releases the line, providing a powerful means of control over the load being manipulated.

Additionally, understanding the dynamics of this mechanism involves recognizing the importance of tension, friction, and torque. Each component contributes to the overall performance, ensuring that the system operates effectively under various conditions. This intricate balance of forces highlights the engineering prowess behind its creation and implementation.

Ultimately, a thorough grasp of this mechanism enhances not only operational efficiency but also safety, making it a vital element in many industries. By appreciating its complexities, users can maximize the potential of this ingenious tool, leading to improved productivity and reliability in their tasks.

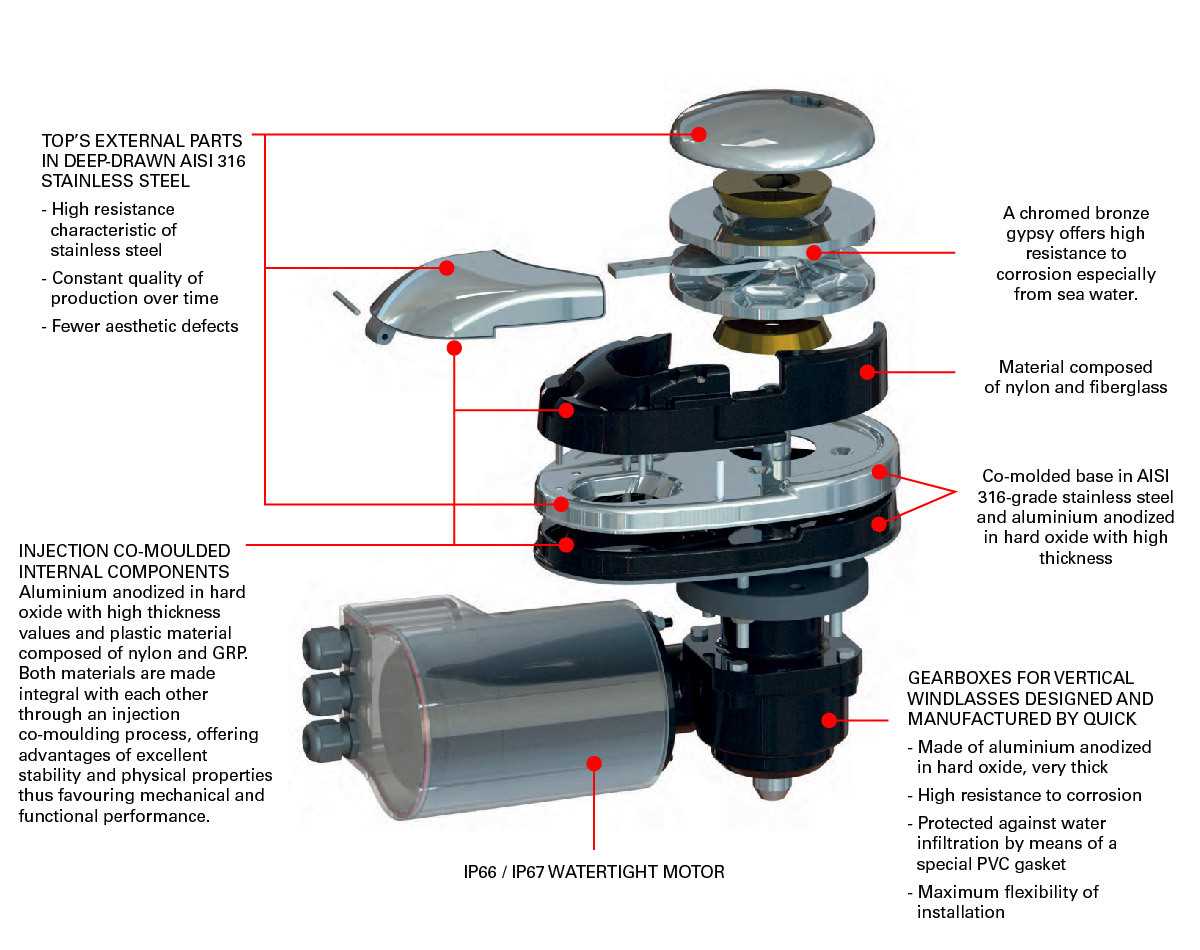

Key Components of a Windlass

Understanding the essential elements of this mechanical device is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring smooth functioning and durability.

Main Elements

- Drum: The central cylinder where the line is wound, enabling easy retrieval and deployment.

- Gear System: Transmits power and provides mechanical advantage for lifting heavy loads.

- Motor: Powers the device, either manually or electronically, depending on the model.

- Brake: Prevents uncontrolled descent of the line, ensuring safety during operation.

Additional Features

- Control Switch: Allows the operator to start and stop the mechanism with ease.

- Base Plate: Provides stability and supports the entire assembly.

- Clutch: Engages and disengages the drive mechanism for better control.

Familiarity with these crucial components enhances the overall efficiency and safety of using this device, leading to more successful operations.

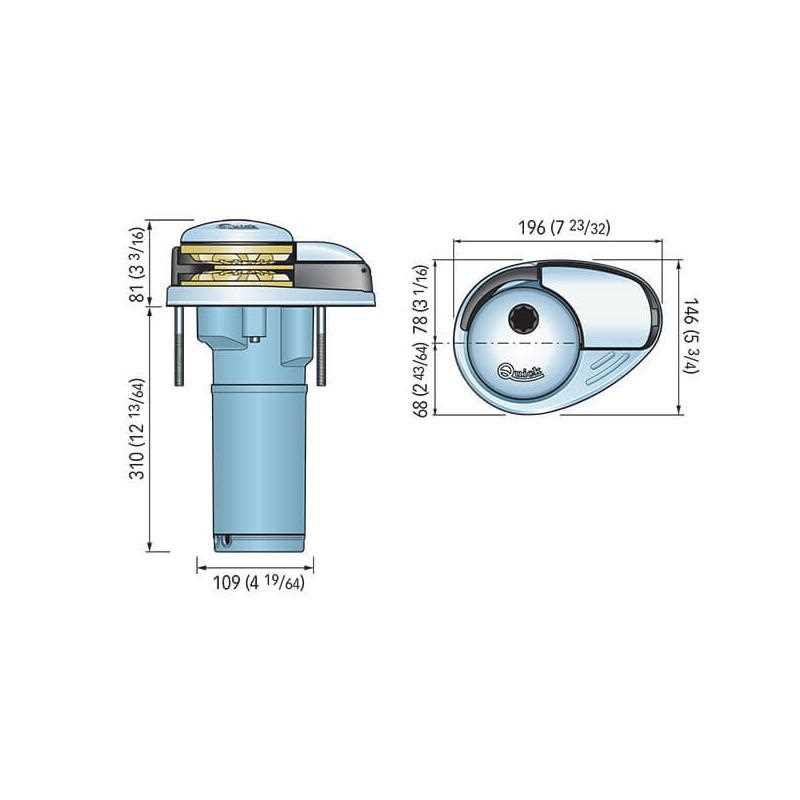

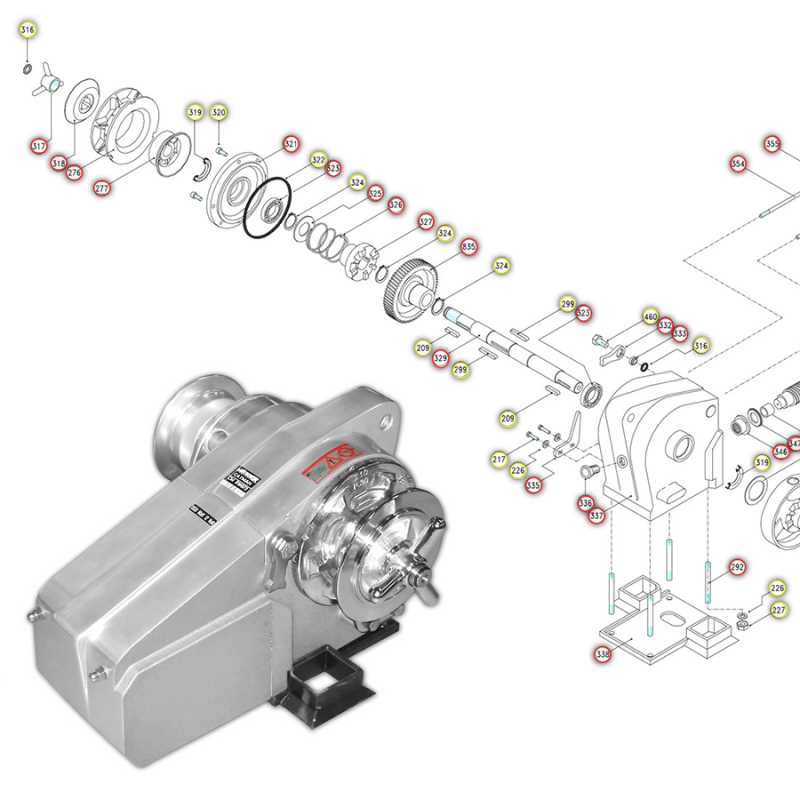

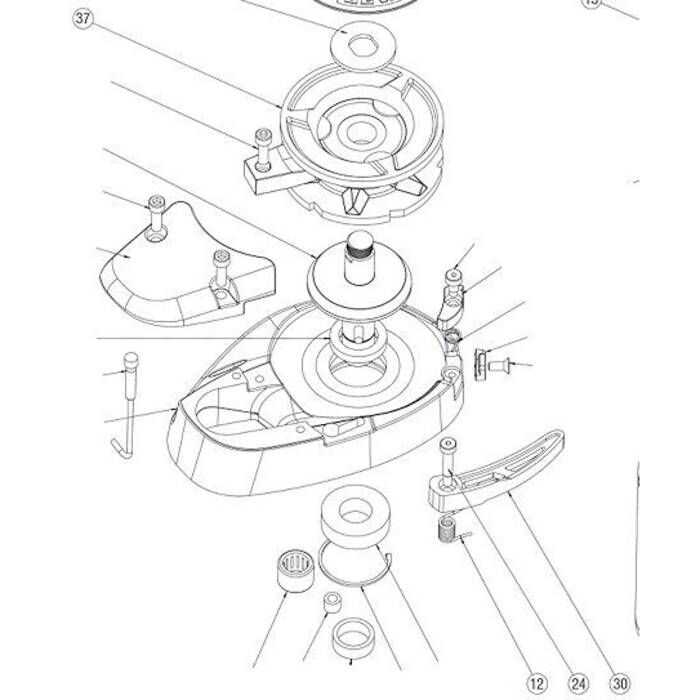

Diagram Overview: Quick Windlass Parts

This section presents a visual representation of the essential components found in the mechanical system. Understanding each element’s role is crucial for effective maintenance and operation.

| Component | Description |

|---|---|

| Drum | The cylindrical element that holds the line or cable. |

| Motor | The power source that drives the mechanism. |

| Gearbox | Transmits power and modifies the speed of the drum. |

| Control Panel | Interface for operating the system. |

| Clutch | Allows for engagement and disengagement of the drive. |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the effective communication of complex systems. They serve as a visual language, allowing individuals to grasp intricate concepts quickly and efficiently. When every component is accurately represented, users can better understand the relationships and functions within the system.

Moreover, high-quality visuals are essential for maintenance and troubleshooting. They provide clear guidance, reducing the likelihood of errors during repairs or assembly. This is particularly vital in technical fields, where even minor mistakes can lead to significant issues.

| Benefits of Accurate Illustrations | Consequences of Poor Quality |

|---|---|

| Enhanced comprehension | Increased risk of errors |

| Efficient troubleshooting | Extended downtime |

| Improved training | Miscommunication among teams |

Ultimately, investing in detailed and accurate visual representations ensures that users can navigate complex tasks with confidence and clarity. This attention to detail fosters not only operational efficiency but also safety in various applications.

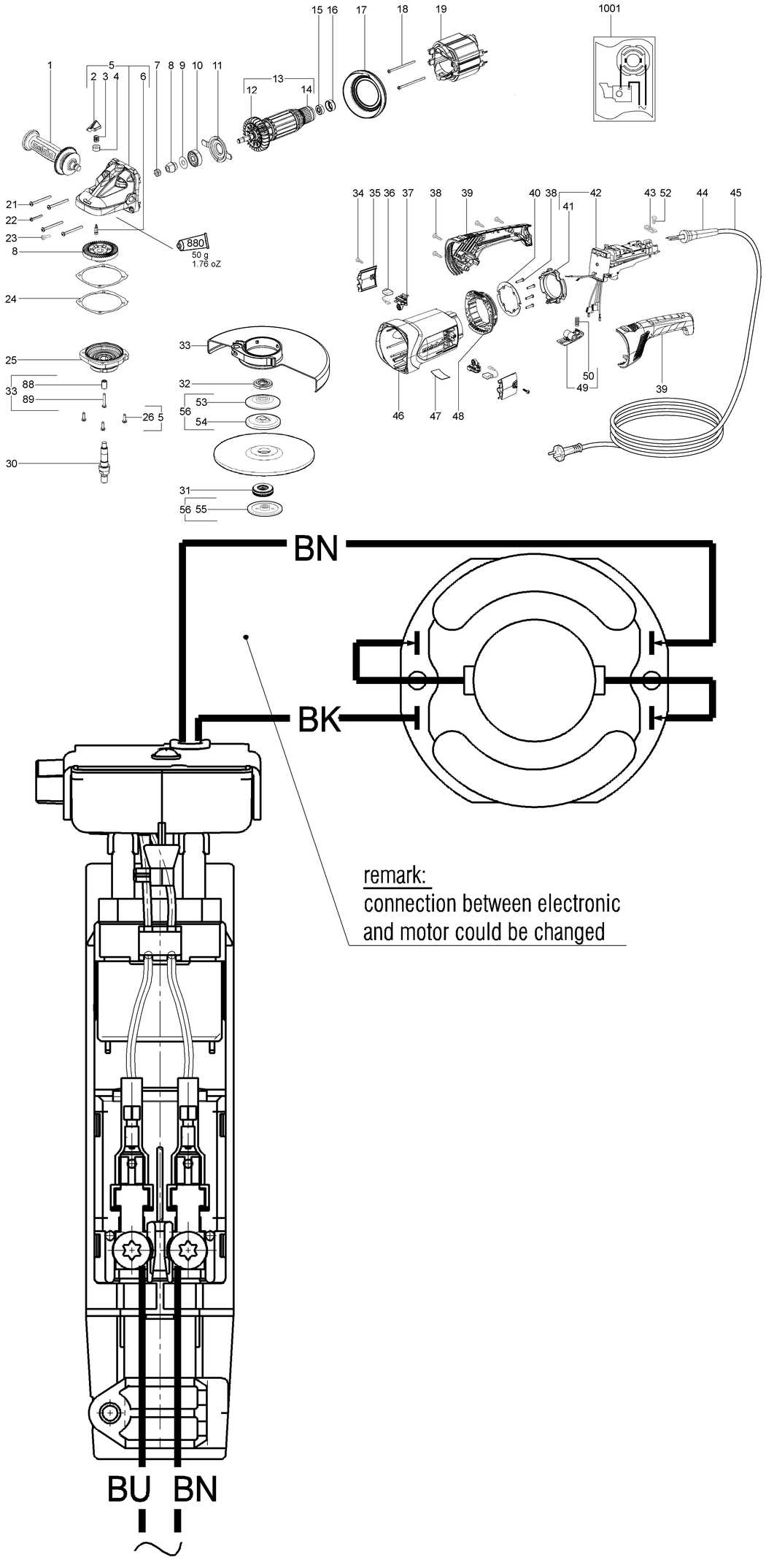

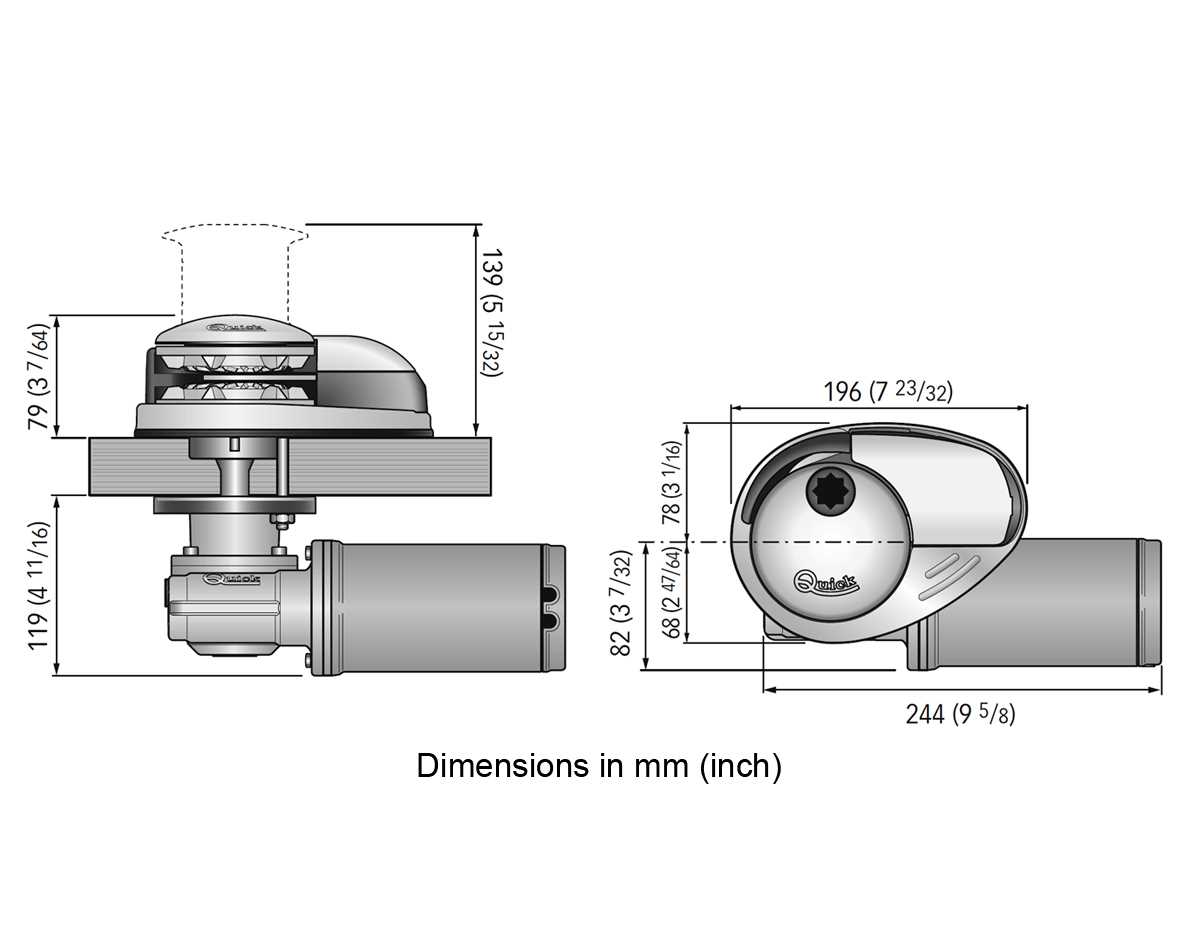

How to Interpret Windlass Diagrams

Understanding the layout and components of a lifting mechanism is essential for effective operation and maintenance. A schematic representation can simplify complex systems, allowing users to identify parts and their functions with ease. This knowledge is crucial for troubleshooting, repairs, and enhancing overall performance.

When analyzing such illustrations, begin by familiarizing yourself with common symbols and representations. Each element typically correlates with a specific function or component, making it easier to grasp the overall assembly. Pay attention to the connections and relationships between various parts, as these can indicate how they interact during operation.

| Symbol | Description |

|---|---|

| Circle | Represents a rotating component |

| Square | Denotes a fixed part or housing |

| Arrow | Indicates direction of movement |

| Line | Shows connection or pathway for force |

Once you have a grasp of the symbols, proceed to examine the layout systematically. Look for labels and notes that may provide additional context about each component. This can be particularly helpful in understanding specifications and operational requirements.

Lastly, practice interpreting various schematics to reinforce your understanding. Over time, this skill will become intuitive, enhancing your ability to work with complex systems efficiently.

Common Issues with Windlass Systems

Understanding the typical challenges that arise in marine hoisting mechanisms is crucial for maintaining optimal functionality. Frequent problems can lead to operational inefficiencies, requiring attention to ensure reliability.

Typical Problems

- Electrical failures: Inadequate power supply or wiring issues can disrupt operation.

- Mechanical wear: Components may suffer from fatigue over time, leading to decreased performance.

- Corrosion: Saltwater exposure can damage metal parts, necessitating regular inspections.

Maintenance Tips

- Regularly inspect all connections and wiring.

- Lubricate moving parts to prevent friction-related issues.

- Store the system properly when not in use to avoid environmental damage.

Maintenance Tips for Windlass Parts

Regular upkeep of marine equipment is essential for ensuring longevity and optimal performance. Neglecting maintenance can lead to costly repairs and diminished functionality, making proactive care crucial.

- Inspect all components regularly for signs of wear or damage.

- Clean moving parts to remove salt, dirt, and debris.

- Lubricate gears and bearings to prevent friction and corrosion.

- Check electrical connections and ensure they are secure and free from corrosion.

- Test the system periodically to ensure it operates smoothly under load.

By following these simple yet effective strategies, you can enhance the durability and reliability of your equipment, ensuring it performs at its best for years to come.

Upgrading Your Windlass Equipment

Enhancing your lifting gear can significantly improve efficiency and safety during operations. By selecting high-quality components and modernizing outdated equipment, you can ensure smoother performance and reduce the likelihood of malfunctions.

Choosing Quality Components

When upgrading, prioritize durable materials that withstand wear and tear. Investing in top-tier mechanisms can lead to long-term benefits and reduced maintenance costs. Consider brands known for reliability and innovation.

Integrating Advanced Technology

Incorporating the latest technology can elevate functionality. Features such as remote control systems or automated features can enhance convenience and control. Stay informed about emerging trends to maximize the ultimate potential of your lifting apparatus.

Safety Precautions When Using Windlasses

Ensuring safety during the operation of marine equipment is paramount to prevent accidents and injuries. Proper understanding and adherence to guidelines can significantly mitigate risks associated with handling such mechanisms.

Prior to Operation

Inspect Equipment: Always perform a thorough check of the machinery before use. Look for any signs of wear, damage, or loose components. A well-maintained system is crucial for safe operation.

During Operation

Stay Clear of Moving Parts: Keep hands, feet, and loose clothing away from any active elements. Awareness of surroundings and maintaining a safe distance from the equipment will enhance safety for all involved.

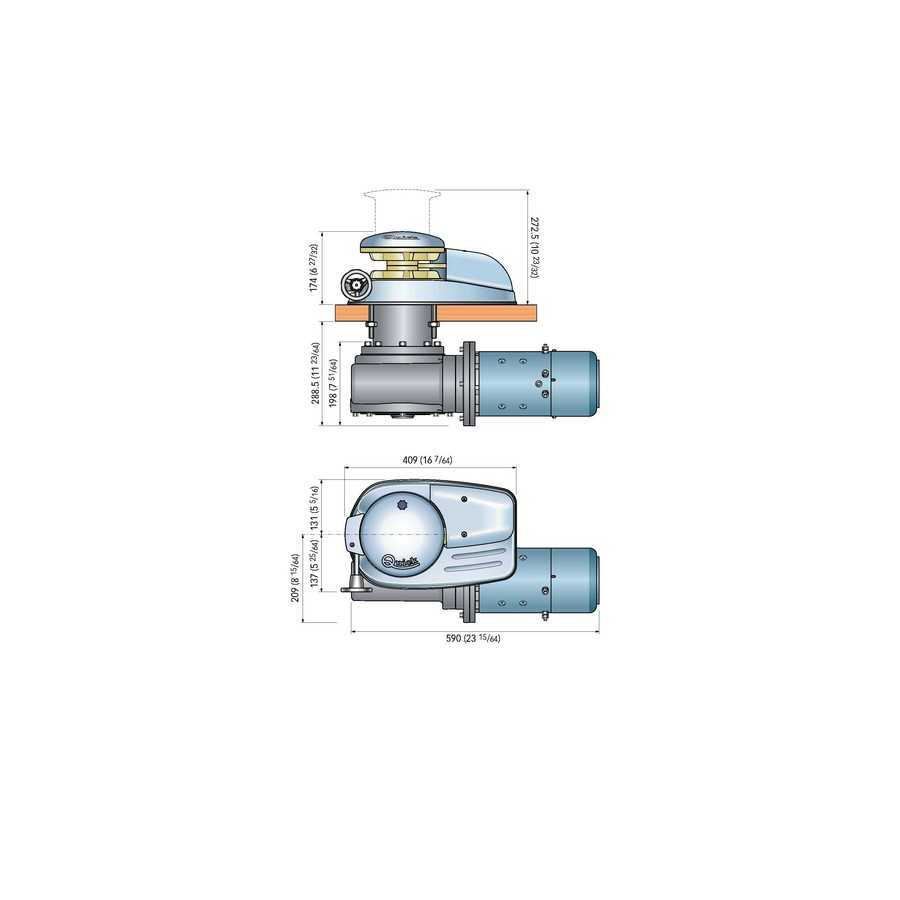

Choosing the Right Windlass for You

Selecting the appropriate equipment for managing your anchor is essential for a seamless experience on the water. Various factors come into play, including size, weight, and the specific needs of your vessel. Understanding these elements will help ensure that you make an informed choice tailored to your unique requirements.

First, consider the size of your boat and the type of anchor you plan to use. The equipment must be compatible with the weight and dimensions of your anchor to function effectively. Additionally, assess your usage frequency–if you frequently anchor, investing in a more robust and efficient model might be wise.

Next, evaluate the power source. Manual or electric options are available, each with its own benefits. Electric models tend to offer greater convenience and ease of use, while manual versions can be more reliable in remote situations.

Lastly, delve into the features available. Some devices come with advanced functionalities like remote controls or integrated safety mechanisms, enhancing usability and security. By weighing these considerations, you’ll arrive at the ultimate choice that enhances your maritime adventures.