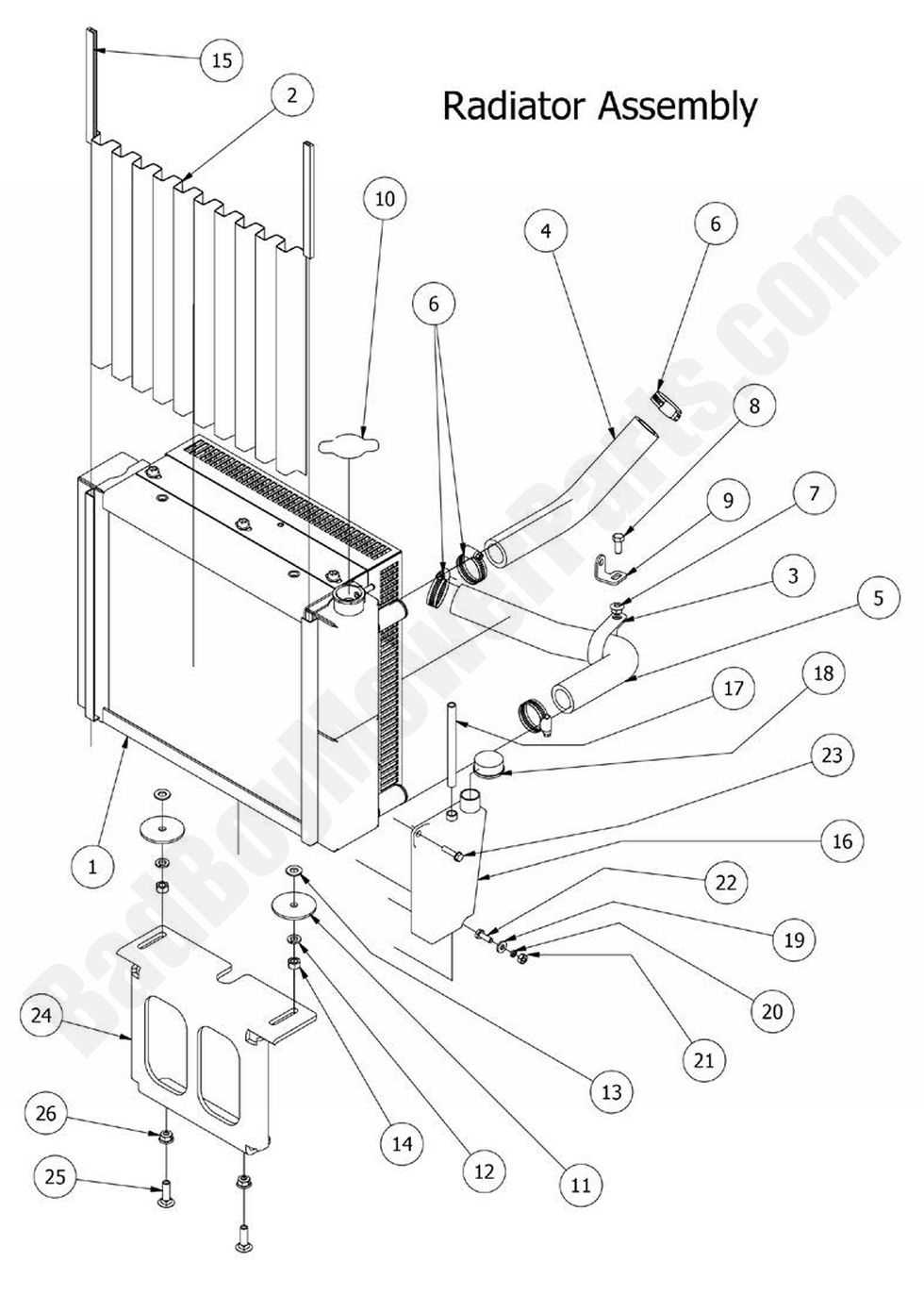

Key Functions of Radiator Elements

Various components within a heating system collaborate to ensure effective thermal regulation and optimal energy efficiency. Each element plays a crucial role in maintaining a stable and comfortable environment by managing the flow and distribution of heat.

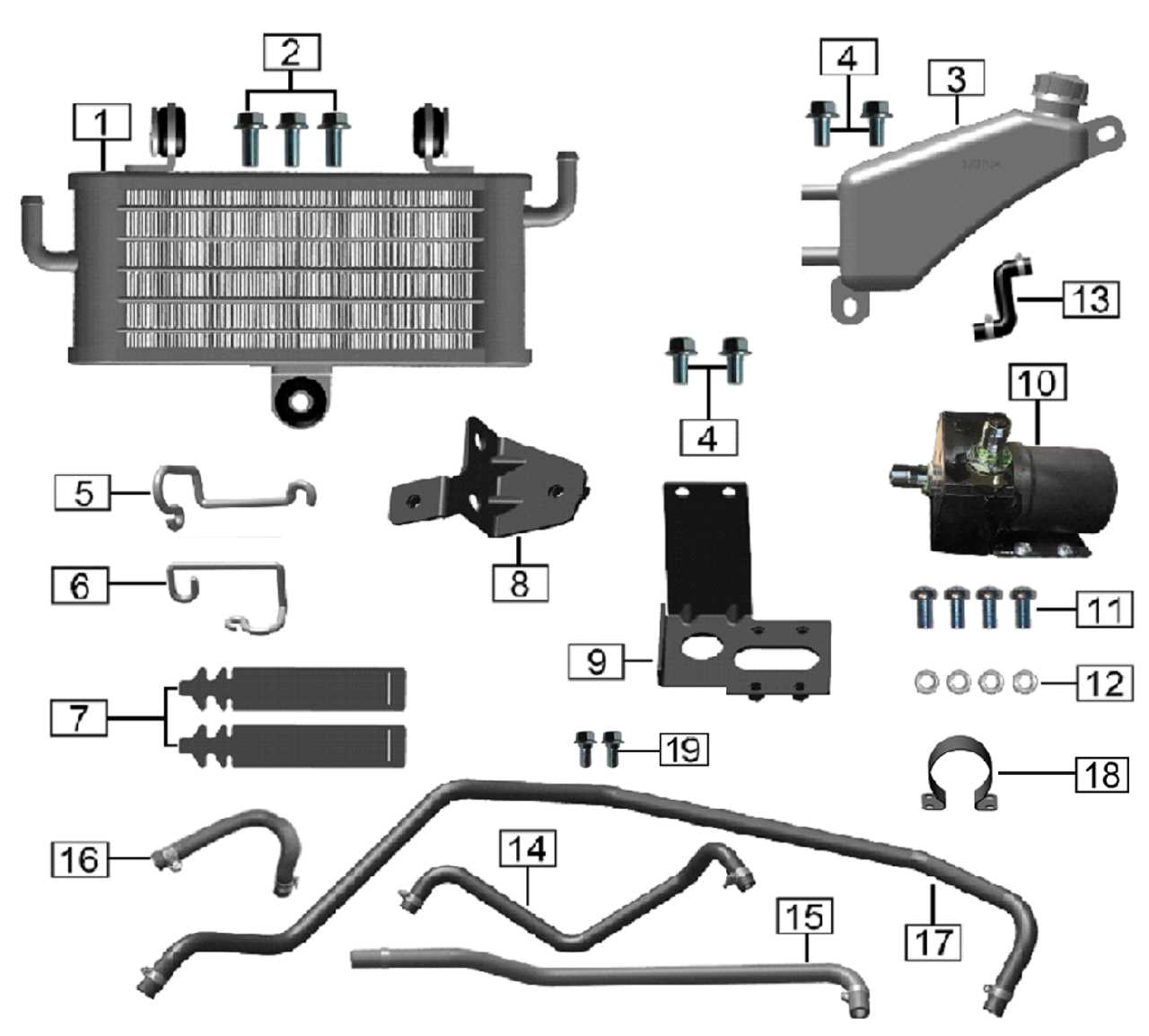

Heat Exchanger: This component is responsible for transferring thermal energy from one medium to another, facilitating the warming process. It enhances the overall performance by maximizing heat output while minimizing energy consumption.

Thermostatic Control Valve: This valve regulates the temperature by adjusting the flow of heated liquid. It ensures that the system functions at the desired temperature level, preventing overheating or inefficient operation.

Coolant Channels: These pathways direct the flow of the thermal medium, allowing for uniform heat distribution throughout the system. They play a vital

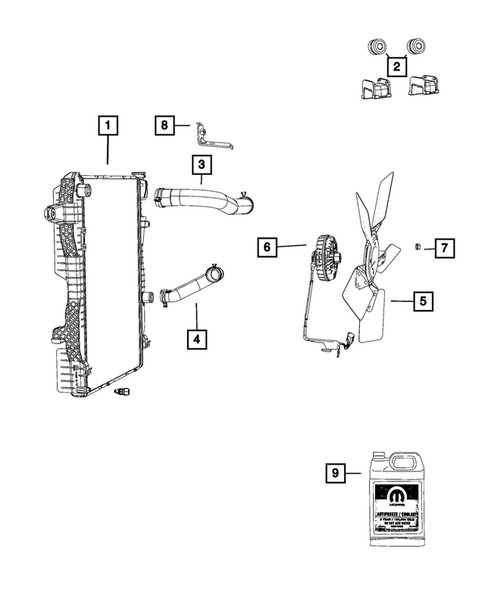

How Each Part Contributes to Cooling

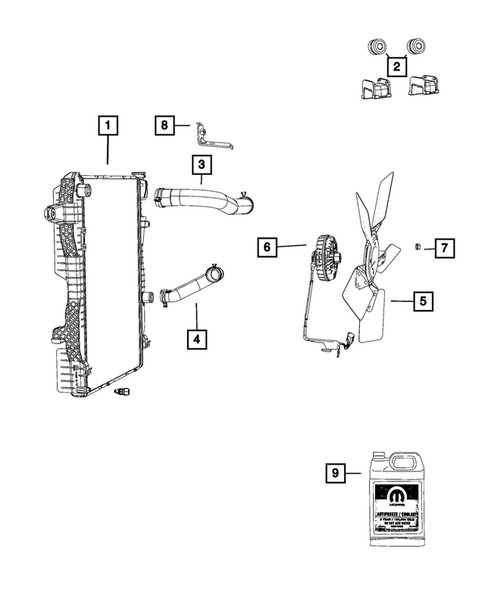

The cooling system is a crucial component in managing engine temperature, ensuring efficient operation and preventing overheating. Each element within the system works together to maintain an optimal thermal balance, enabling the transfer of heat away from the engine. This process is essential for keeping the motor running smoothly, regardless of external conditions.

The liquid circulation mechanism channels coolant through specific pathways, absorbing excess heat from the engine block. The fluid then travels through channels where heat dissipation occurs, aided by air flow. This exchange helps regulate temperatures, maintaining stability even under heavy loads.

Additional devices within the system assist in controlling the flow and pressure, ensuring that cooling remains consistent. Together, these components contribute to a seamless process of temperature regulation, providing long-lasting protection for the engine.

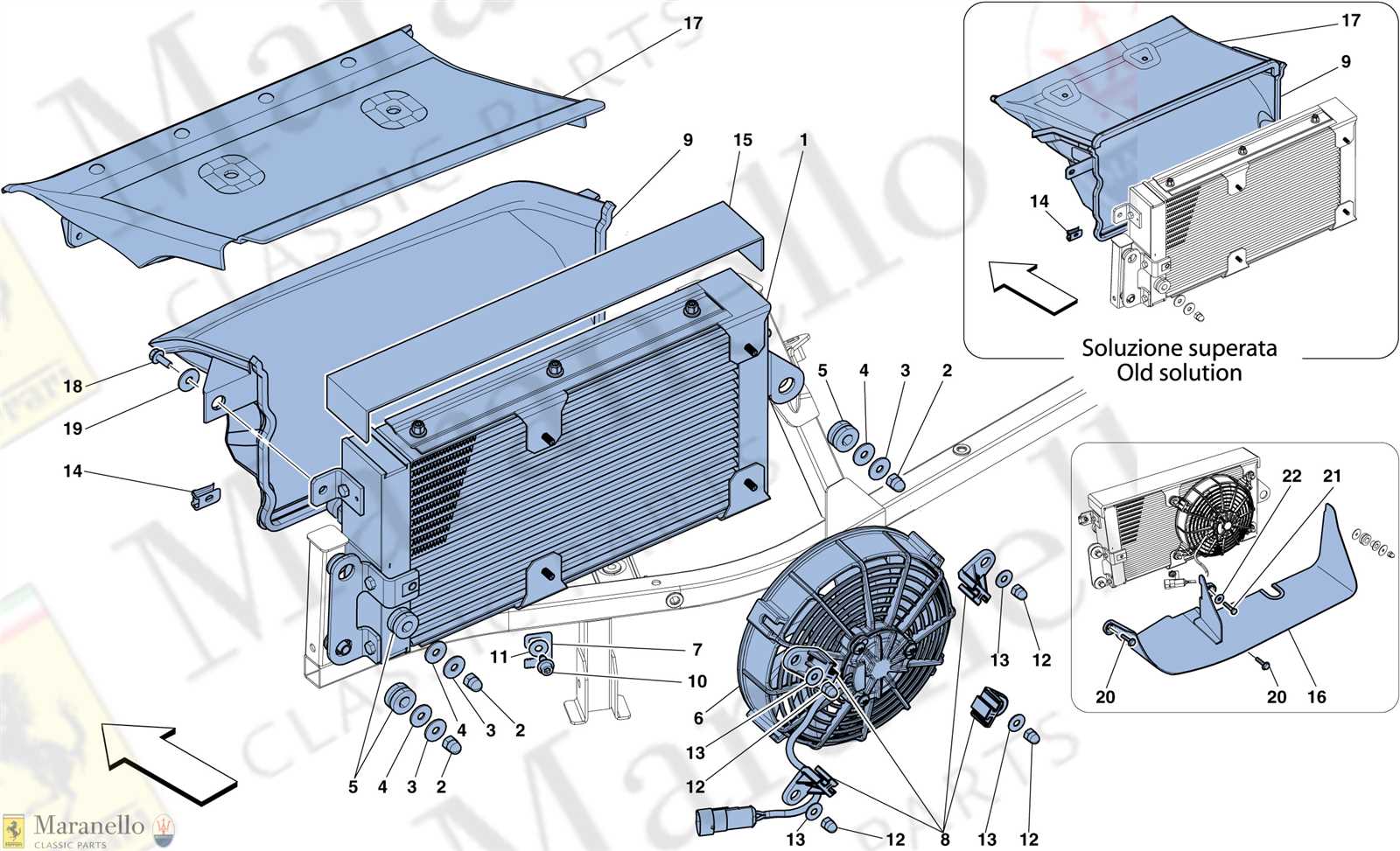

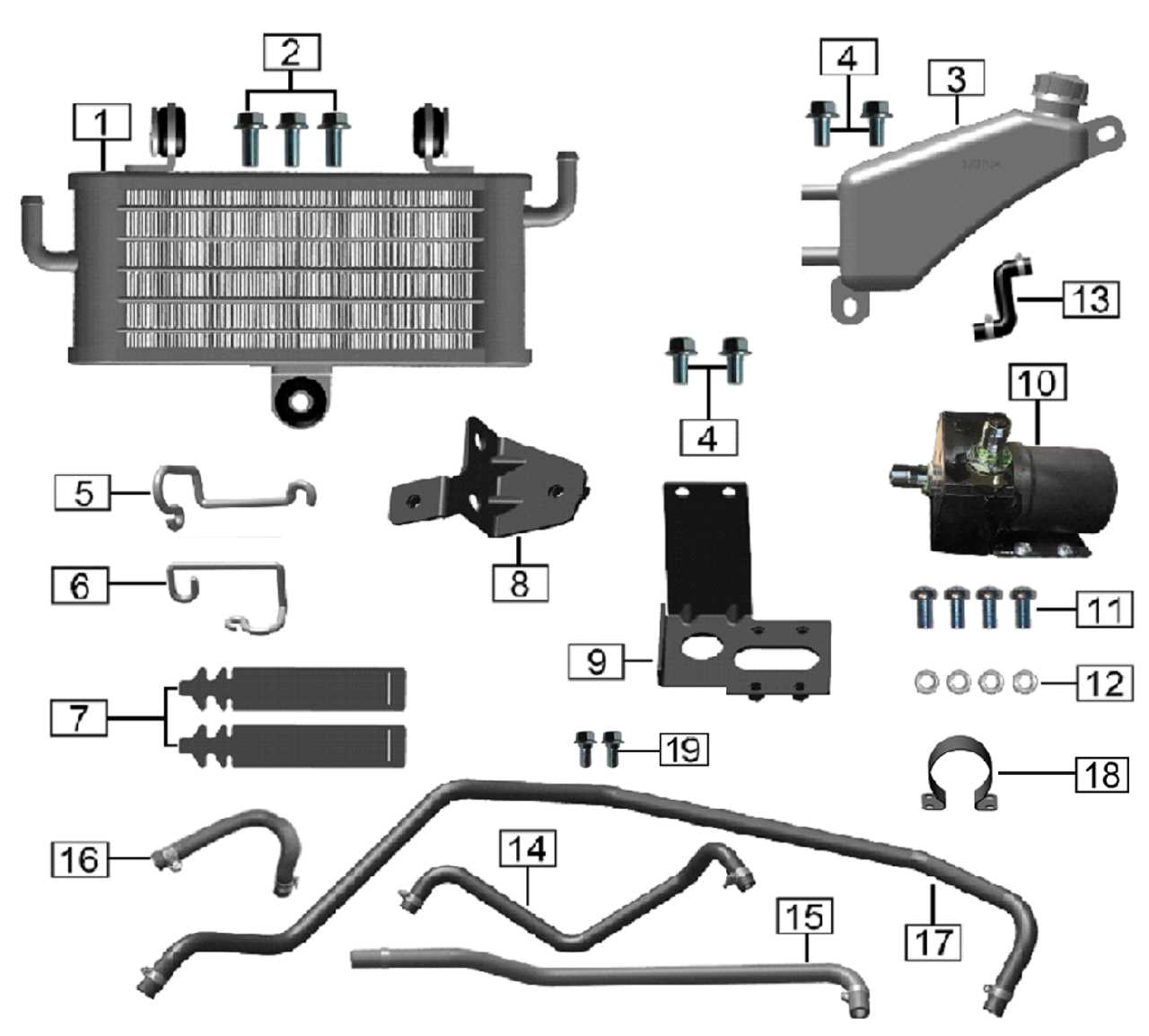

Identifying the Core of the Radiator

Understanding the essential component of this cooling system is crucial for maintaining the overall efficiency. The core plays a vital role in the process, acting as the central element responsible for heat exchange. Its structure, typically composed of multiple channels or tubes, allows for the circulation of a fluid that carries away heat, ensuring optimal performance.

To accurately recognize this component, focus on its placement and its unique design, which distinguishes it from other sections. The material used in its construction often provides clues, as it is selected to enhance thermal conductivity. By examining these features, you can effectively identify the main element responsible for regulating temperature within the system.

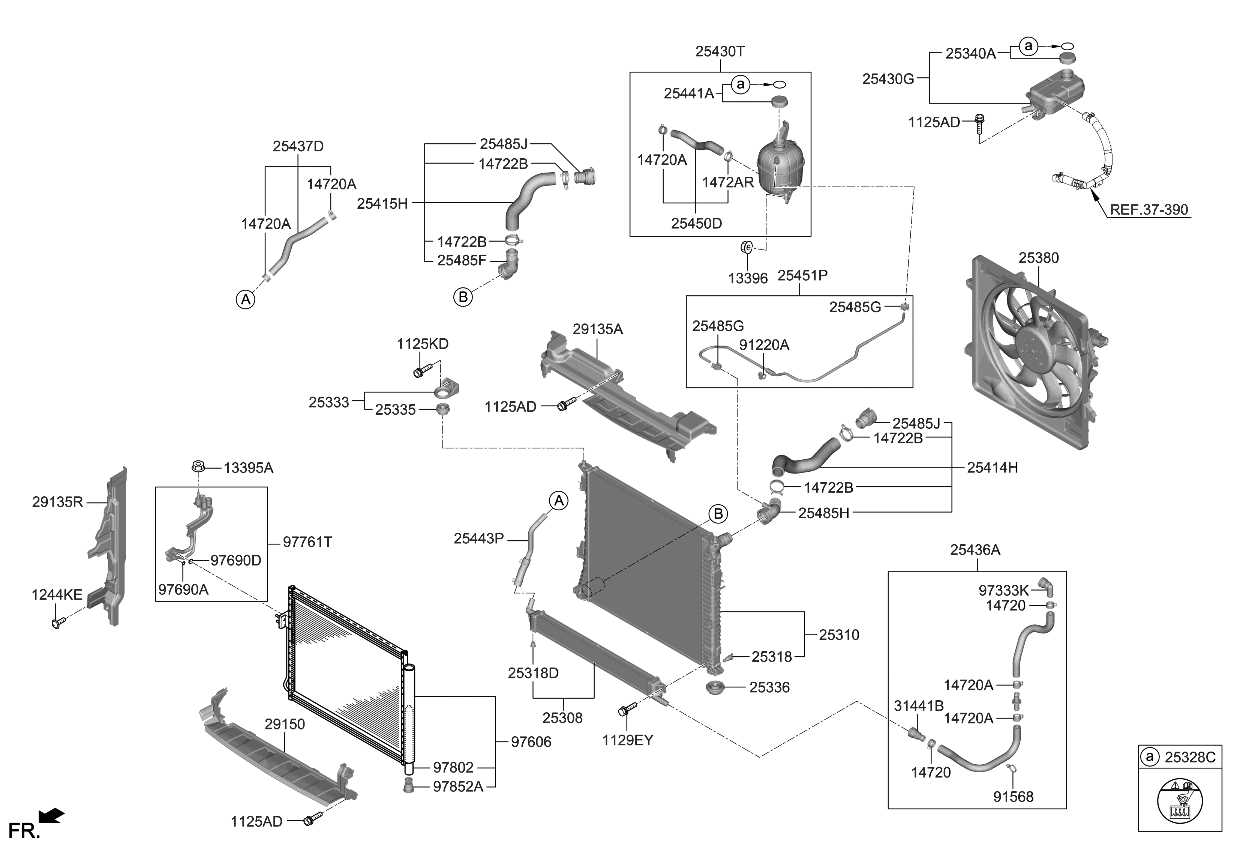

The Role of the Core in Heat Dissipation

The core serves as a crucial component in the process of removing excess thermal energy from a system. Its design and functionality directly influence how effectively heat is managed, ensuring optimal performance and longevity of the associated mechanisms.

Functionality and Design

The core’s design is tailored to maximize surface area, facilitating efficient heat transfer. Key attributes include:

- Material Composition: The choice of materials affects thermal conductivity, impacting heat absorption and dissipation.

- Structural Configuration: Fins and channels within the core enhance airflow, promoting better heat exchange.

- Size and Shape: Variations in dimensions can optimize the cooling efficiency based on the specific requirements of the system.

Importance in Overall System Efficiency

An effective core is vital for maintaining the equilibrium of temperature within a mechanical setup. It contributes to:

- Enhanced Performance: By preventing overheating, it allows for smoother operation of machinery.

- Increased Longevity: Effective heat management reduces wear and tear, extending the lifespan of components.

- Energy Efficiency: Improved heat dissipation minimizes energy consumption, leading to cost savings over time.

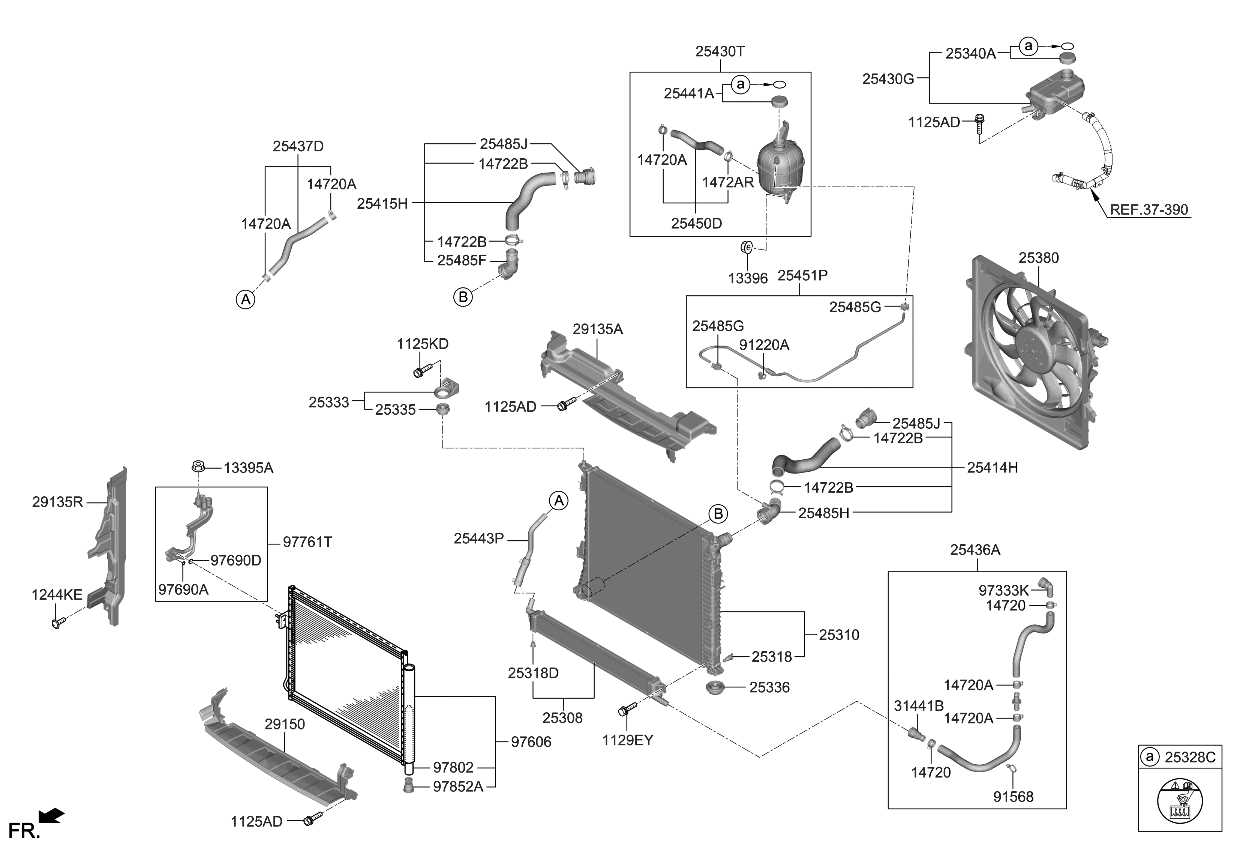

Radiator Tank and Its Importance

The tank serves a crucial role in the cooling system of a vehicle, ensuring optimal temperature regulation. This component not only houses the coolant but also facilitates its circulation throughout the engine. Proper functioning of the tank is vital for maintaining the overall efficiency of the thermal management system.

Significance of the Tank: The tank is essential for containing the coolant, which absorbs excess heat generated by the engine. Without a reliable container, the cooling fluid would escape, leading to overheating and potential damage to the engine components. Furthermore, the tank’s design allows for expansion and contraction of the fluid, accommodating temperature fluctuations during operation.

Maintenance Considerations: Regular inspection of the tank for leaks, cracks, or corrosion is imperative to ensure its longevity and functionality. Addressing any issues promptly can prevent costly repairs and enhance the performance of the entire cooling system.

Understanding the Function of Radiator Tanks

The tanks within cooling systems play a crucial role in managing temperature and ensuring efficient operation. These components are designed to contain the fluid responsible for heat dissipation, allowing the system to maintain optimal performance under varying conditions.

Essentially, the tanks serve as reservoirs for coolant, providing a space for fluid to expand and contract as temperatures fluctuate. This function is vital for preventing overheating and ensuring that the entire mechanism operates smoothly. Moreover, the construction of these tanks is engineered to withstand high pressures, contributing to the overall durability and reliability of the system.

In addition to their primary role in fluid storage, these tanks often feature additional elements that enhance performance. For instance, some designs include integrated fittings that facilitate the connection of hoses and other components, streamlining the overall assembly. Understanding the significance of these tanks is essential for maintaining an efficient cooling system.

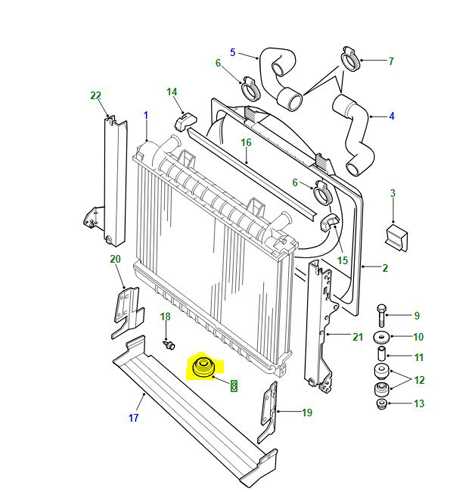

Explanation of Cooling Fins

Cooling fins play a crucial role in enhancing heat dissipation in various thermal management systems. Their design and arrangement significantly influence the efficiency of heat exchange processes. Understanding the function and structure of these components is essential for optimizing performance in applications ranging from automotive to industrial machinery.

Functionality and Design

The primary purpose of cooling fins is to increase the surface area available for heat transfer. By maximizing exposure to air or liquid coolant, they facilitate efficient thermal conduction away from the source of heat. Typically made from materials with high thermal conductivity, these elements are often arranged in a manner that promotes airflow, allowing for effective cooling.

Impact on Performance

Effective cooling fins can dramatically improve the overall efficiency of a thermal system. The design parameters, including spacing, thickness, and shape, can be tailored to specific applications to ensure optimal heat dissipation. Properly designed cooling surfaces not only enhance the longevity of components but also contribute to energy efficiency and performance stability.

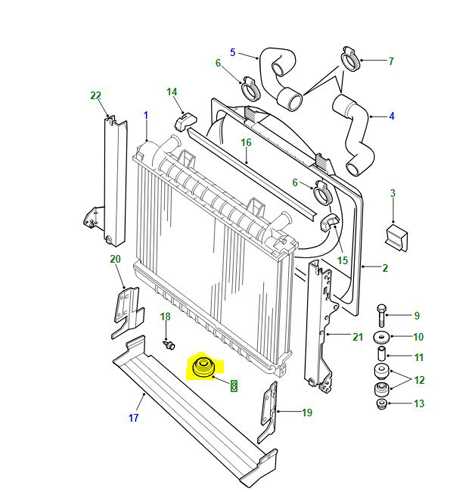

How Cooling Fins Enhance Performance

Cooling fins play a vital role in improving the efficiency of heat exchange systems. By increasing the surface area available for heat dissipation, these components help maintain optimal operating temperatures in various applications. Their design and arrangement significantly influence the overall effectiveness of thermal management solutions.

Enhanced Heat Dissipation: The primary function of cooling fins is to facilitate the rapid transfer of heat away from critical components. This process is essential in preventing overheating, which can lead to performance degradation or even failure. By maximizing airflow and promoting convection, these elements ensure that excess heat is effectively removed.

Material Considerations: The choice of materials for cooling fins can greatly impact their performance. Lightweight metals, such as aluminum, are commonly used due to their excellent thermal conductivity and corrosion resistance. Additionally, the fin’s surface finish can be optimized to enhance heat transfer capabilities.

Design Variations: Different configurations and shapes of cooling fins can be employed to suit specific needs. For instance, some designs may prioritize compactness, while others focus on maximizing exposure to air. Understanding the application’s requirements allows for the selection of the most effective design to boost efficiency.

Conclusion: Ultimately, the integration of cooling fins into thermal systems is crucial for maintaining performance and longevity. Their ability to enhance heat dissipation not only supports optimal functionality but also contributes to the reliability of the entire system.

The Role of the Inlet and Outlet Pipes

The functionality of a heating system heavily relies on the efficiency of its entry and exit conduits. These components serve as vital pathways for the flow of heated fluid, ensuring that warmth is effectively distributed throughout a designated area. Their design and placement significantly impact the overall performance of the system, affecting both heat transfer and circulation.

Understanding the Inlet Pipe

The entry conduit is crucial for introducing heated fluid into the system. Its diameter and positioning play a significant role in determining how well the fluid can circulate. A well-designed inlet allows for optimal flow rates, reducing the likelihood of blockages and maintaining a steady temperature within the system.

The Importance of the Outlet Pipe

Conversely, the exit conduit is essential for removing cooled fluid from the system. Its role is to ensure that the heat transfer process remains efficient by allowing the cooler fluid to exit and making way for warmer fluid to enter. Properly functioning exit conduits help maintain consistent temperature levels, ultimately leading to enhanced comfort and energy efficiency.

| Pipe Type |

Function |

Impact on System |

| Inlet Pipe |

Introduces heated fluid |

Optimizes flow and reduces blockages |

| Outlet Pipe |

Removes cooled fluid |

Maintains temperature consistency |