Understanding how various mechanical elements come together is essential for maintenance and improvements. Exploring the connections within these assemblies allows users to maintain efficiency, identify potential issues, and make modifications with precision. In this section, we delve into detailed visualizations that map out interconnected systems.

The focus is on key elements of an all-terrain machine. By breaking down its structure, users gain clarity on how individual units contribute to overall functionality. These insights are invaluable for enthusiasts seeking to enhance performance or perform repairs independently.

Each layout helps visualize the machine’s internal logic, highlighting where specific adjustments can be made. This clarity

Raptor 700 Parts Diagram Overview

This section provides a visual breakdown of essential components and their arrangement. It offers a clear way to understand how various elements fit together, ensuring smooth operation and maintenance.

- Engine system: Displays key elements that power the vehicle, such as cylinders and ignition modules.

- Suspension layout: Illustrates how shock absorbers and control arms contribute to a stable ride.

- Transmission assembly: Shows the interaction between gears, clutches, and axles for effective power delivery.

- Braking components: Highlights the arrangement of calipers, discs, and pads to ensure safe stopping.

- Electrical wiring:

Frame and Chassis Components

The frame and chassis form the structural core of the vehicle, providing strength, stability, and support for all other systems. These elements ensure the alignment of essential parts and contribute to the overall balance and handling during motion.

Frames are built to endure high levels of stress, acting as the main foundation to which all other components are attached. The durability and rigidity of the frame influence how well the vehicle withstands challenging conditions.

Chassis elements include the mounting points for suspension, steering systems, and other vital assemblies. Their design impacts performance by managing weight distribution and ensuring consistent contact with the surface, resulting in better control and maneuverability.

Engine and Transmission Layout

The layout of the engine and transmission focuses on the harmonious interaction between power generation and efficient transfer to the drivetrain. This section highlights the essential arrangement, ensuring smooth performance and optimal energy conversion during operation.

The engine is typically positioned to balance weight distribution, contributing to both stability and handling. Key components are arranged to allow effective cooling, minimizing heat buildup. The configuration ensures that the power generated by combustion is directed seamlessly into the transmission.

The transmission system is designed to translate engine output into controlled movement. Its placement aligns with the engine to reduce friction and wear, ensuring longevity. Whether automatic or manual, the system maintains smooth shifts, enhancing the overall riding experience.

Suspension System Breakdown

The suspension system plays a crucial role in ensuring smooth handling and stability on uneven terrain. It absorbs shocks from bumps, keeping the vehicle balanced and enhancing rider control under various conditions.

- Front Suspension: This section manages impacts from the front wheels, typically featuring independent shocks or dual arms for better maneuverability.

- Rear Suspension: It stabilizes the rear axle and absorbs more intense impacts, often using swing arms with single shock absorbers for optimal weight distribution.

- Adjustability: Many systems allow riders to fine-tune settings like compression and rebound, providing flexibility based on riding style or terrain type.

- Shock Absorbers: These components compress and rebound to dissipate kinetic energy from impacts.

Brake Assembly Details

The brake system plays a vital role in ensuring safety by effectively slowing down or stopping the vehicle. Understanding the components that work together within this system helps maintain reliable performance and ensures timely maintenance.

Main Components of the Brake Assembly

The assembly includes essential elements such as calipers, discs, pads, and hydraulic lines. Each part has a specific function, contributing to the smooth operation of the braking mechanism. Proper alignment and regular inspection of these components are necessary for consistent stopping power.

Common Issues and Maintenance Tips

Brake systems can experience wear over time, with signs such as squeaking sounds, reduced responsiveness, or fluid leaks. Replacing worn-out pads, checking the fluid level,

Electrical System Mapping

Understanding the intricacies of the electrical layout is crucial for maintaining and troubleshooting any all-terrain vehicle. A comprehensive mapping of the electrical components provides insights into their arrangement and interconnections, facilitating efficient diagnostics and repairs.

This section outlines the essential elements that make up the electrical system:

- Power source connections

- Wiring harness organization

- Control unit positioning

- Lighting and signaling configurations

- Safety features integration

By familiarizing oneself with these components, enthusiasts can better navigate potential issues, ensuring optimal performance and longevity of the vehicle. The following points highlight the importance of each aspect:

- Power Source Connections: Identifying the primary battery and its connection points aids in troubleshooting electrical failures.

- Wiring Harness Organization: A well-organized wiring harness reduces the risk of shorts and improves accessibility for repairs.

- Control Unit Positioning: Understanding where the main control unit is located can streamline diagnostic procedures.

- Lighting and Signaling Configurations: Proper mapping of lights and signals enhances visibility and safety during operation.

- Safety Features Integration: Familiarity with safety systems helps ensure the vehicle operates within safe parameters.

Ultimately, thorough knowledge of the electrical system promotes efficient maintenance and enhances the overall riding experience.

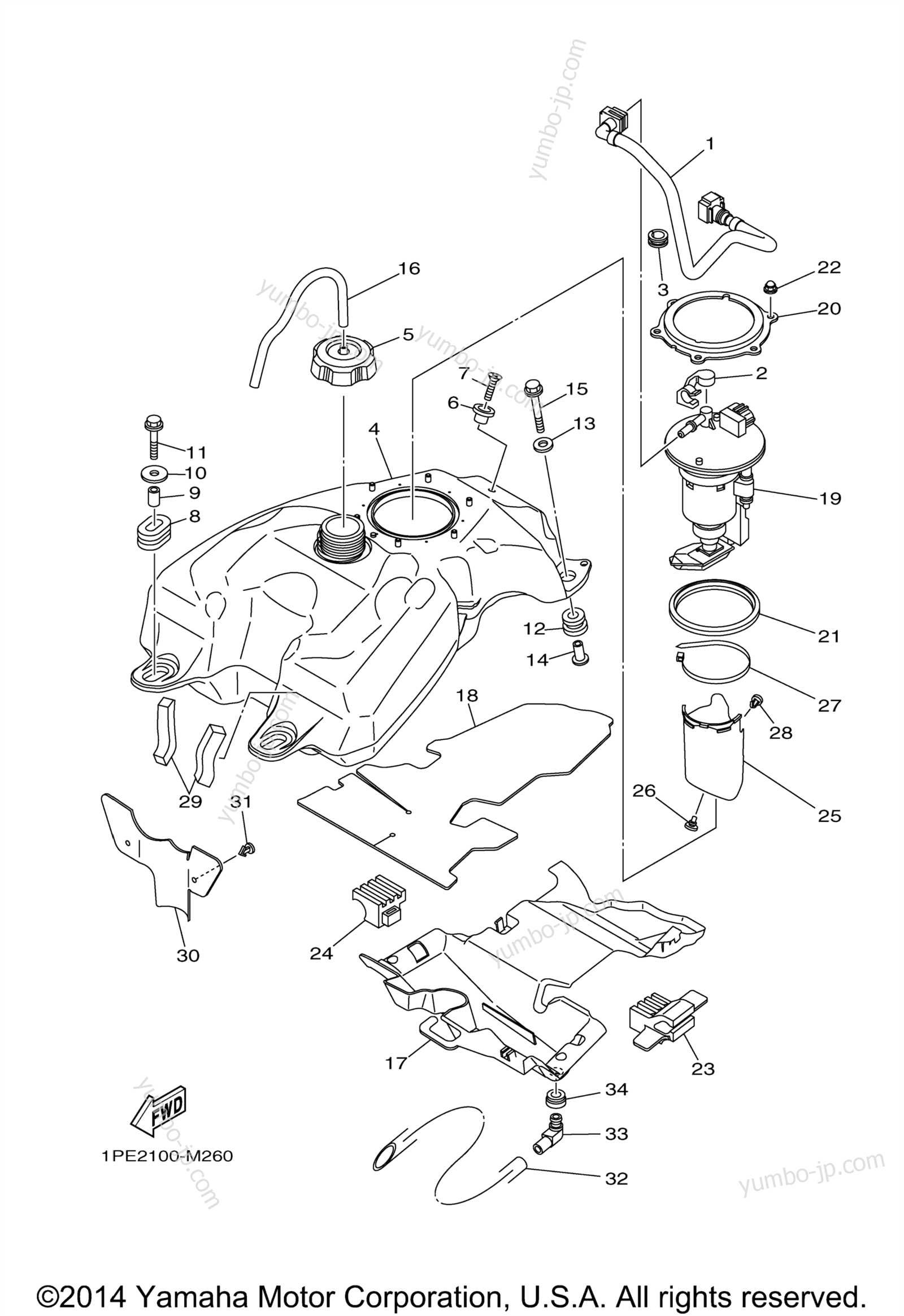

Fuel System Components

The fuel system plays a vital role in the overall performance and efficiency of any vehicle. This system is responsible for delivering the right amount of fuel to the engine, ensuring optimal combustion and power output. Various components work together seamlessly to achieve this, each with a specific function that contributes to the system’s overall effectiveness.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel until it is needed by the engine.

- Fuel Pump: Delivers fuel from the tank to the engine at the required pressure.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Injectors: Spray fuel into the engine’s combustion chamber for efficient mixing with air.

- Fuel Pressure Regulator: Maintains consistent fuel pressure within the system.

Functions of Each Component

- Fuel Tank: The initial storage point, ensuring a ready supply of fuel.

- Fuel Pump: Essential for maintaining the flow and pressure needed for efficient combustion.

- Fuel Filter: Protects the engine from damage caused by contaminants.

- Fuel Injectors: Critical for precise fuel delivery, enhancing performance and reducing emissions.

- Fuel Pressure Regulator: Plays a key role in achieving optimal engine performance by controlling the pressure of the fuel supply.

Cooling System Parts

The efficiency of an engine is significantly influenced by its ability to manage heat. A well-functioning cooling system is essential for maintaining optimal operating temperatures, preventing overheating, and ensuring longevity. This section focuses on the key components that work together to regulate temperature and enhance performance.

One of the primary elements in this system is the radiator, which dissipates heat from the coolant before it re-circulates back into the engine. The water pump plays a crucial role by moving coolant throughout the system, ensuring consistent temperature control. Additionally, hoses and thermostats are vital for directing the flow of coolant and regulating its temperature, respectively.

Furthermore, fans assist in cooling the radiator when additional airflow is needed, particularly during low-speed operation. Each component works in harmony to create an efficient cooling cycle, ultimately supporting the overall performance and reliability of the engine.

Handlebars and Control Layout

The arrangement of the steering mechanism and associated controls is essential for ensuring an optimal riding experience. This section explores the design and functionality of the handlebar setup, focusing on how it contributes to rider comfort and control. Understanding the layout can enhance the overall handling and maneuverability of the vehicle.

Component Description Handlebars Provide grip and control for steering while accommodating the rider’s posture. Throttle Control Regulates engine power and speed, allowing precise acceleration. Brake Lever Enables the rider to slow down or stop the vehicle, crucial for safety. Clutch Lever Facilitates smooth shifting and control over power delivery. Switches and Controls Includes lights, horn, and other essential functions easily accessible from the handlebars. A well-thought-out arrangement ensures that all controls are within reach, allowing for quick adjustments and enhancing rider confidence while navigating various terrains.

Exhaust System Structure

The exhaust system plays a crucial role in the overall performance and efficiency of an engine. It is designed to guide exhaust gases away from the engine, reducing harmful emissions and enhancing the engine’s sound profile. Understanding the components and their interactions within this system is essential for maintaining optimal functionality.

At its core, the exhaust assembly comprises several key elements, including the header, catalytic converter, muffler, and exhaust pipes. The header collects exhaust gases from the engine cylinders and channels them into the rest of the system. Following this, the catalytic converter processes these gases to minimize pollutants before they exit into the environment.

The muffler is another significant component that helps to reduce noise produced by the engine. By using internal baffles and chambers, it dampens the sound waves generated during the combustion process. Finally, the exhaust pipes transport the treated gases from the muffler to the rear of the vehicle, ensuring efficient expulsion and preventing back pressure that could hinder performance.

Each part of the exhaust assembly must work in harmony to achieve the desired results. Regular inspection and maintenance are vital to ensure that all components function effectively, preventing any potential issues that could arise from wear or damage. Understanding this structure not only aids in troubleshooting but also assists enthusiasts in making informed modifications to enhance performance.

Tires and Wheels Assembly

The assembly of tires and wheels is a crucial component of any off-road vehicle, impacting both performance and safety. Properly designed wheels and high-quality tires enhance traction, stability, and overall handling. Understanding the intricacies of this assembly can significantly improve your riding experience and extend the life of your equipment.

Components of the Assembly

The primary elements involved in the assembly of wheels and tires include:

- Tires: The rubber components that provide grip and shock absorption.

- Wheels: The metal rims that support the tires and provide attachment points for other components.

- Valves: Essential for maintaining air pressure within the tires.

- Hubs: Connect the wheels to the vehicle’s axle, allowing for rotation.

Assembly Process

Assembling tires and wheels involves several key steps:

- Begin by inspecting the wheels for any signs of damage or wear.

- Install the tire onto the wheel, ensuring it is properly seated.

- Inflate the tire to the recommended pressure for optimal performance.

- Attach the wheel to the hub using the appropriate fasteners.

- Finally, conduct a thorough check to ensure all components are securely in place.

Body Panels and Covers

The exterior components of an all-terrain vehicle play a crucial role in its overall aesthetic and functionality. These elements not only enhance the visual appeal but also provide necessary protection to the internal mechanisms from debris and environmental factors. Understanding the various types of body panels and covers can help enthusiasts maintain their vehicles effectively and ensure they remain in optimal condition.

Types of Exterior Components

Different types of exterior components serve distinct purposes, ranging from protection to style enhancement. Familiarizing oneself with these variations can aid in selecting the right components for specific needs.

Component Type Function Material Fenders Protects wheels and reduces mud splatter Plastic or fiberglass Side Panels Enhances aesthetics and provides protection Polyethylene or ABS plastic Front and Rear Covers Protects internal components and adds style Metal or composite materials Footwells Prevents dirt and water accumulation Rubber or molded plastic Importance of Maintenance

Regular inspection and maintenance of these exterior components are essential for prolonging the lifespan of the vehicle. Keeping these parts clean and free from damage not only ensures optimal performance but also maintains the visual appeal of the vehicle.