In the realm of heating solutions, a comprehensive understanding of each element’s role is vital for optimal performance and maintenance. By exploring the intricate relationships among various components, one can enhance the efficiency and longevity of the entire system.

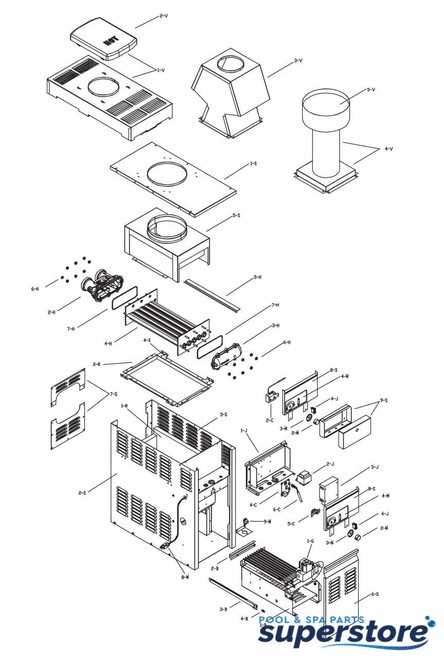

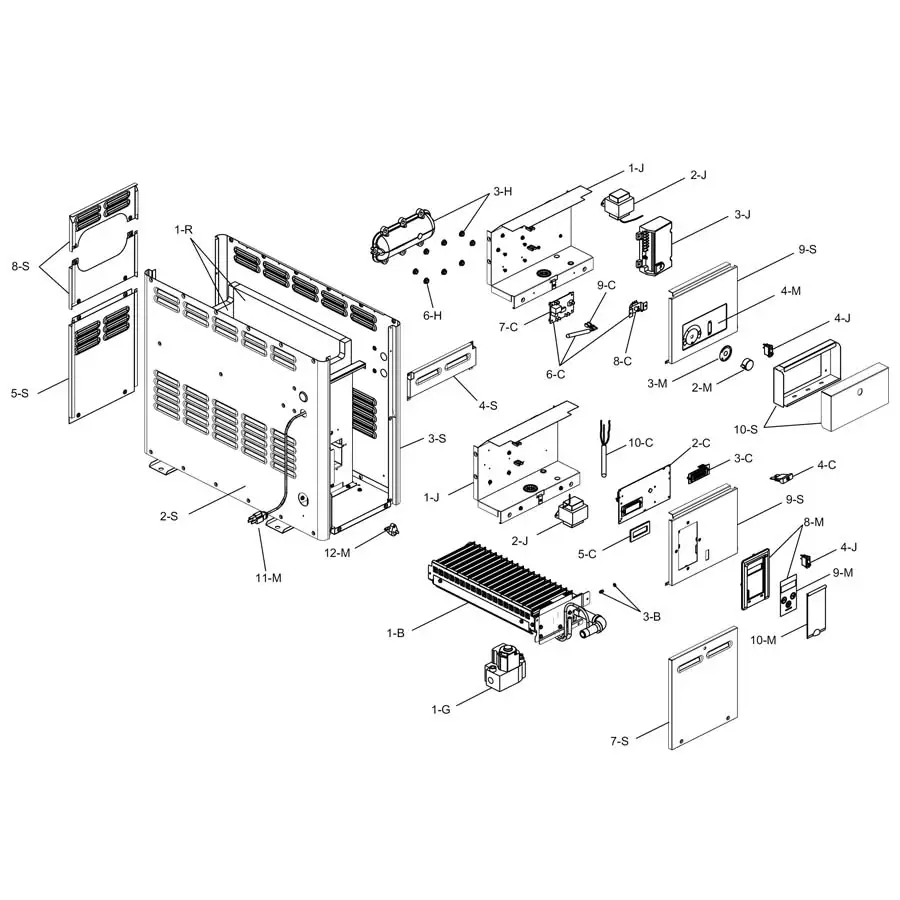

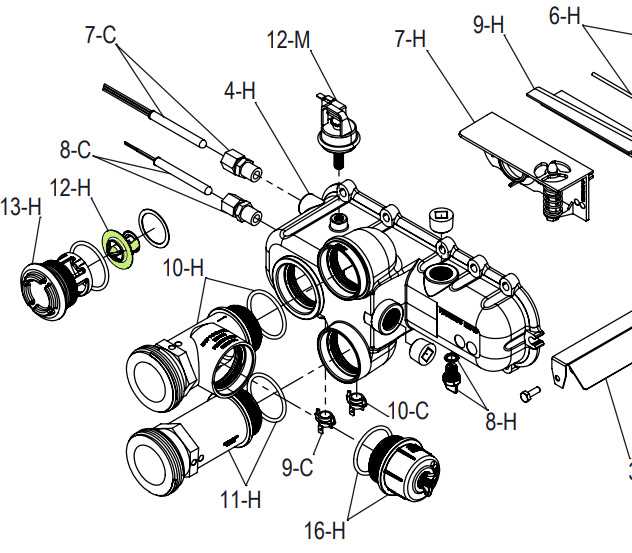

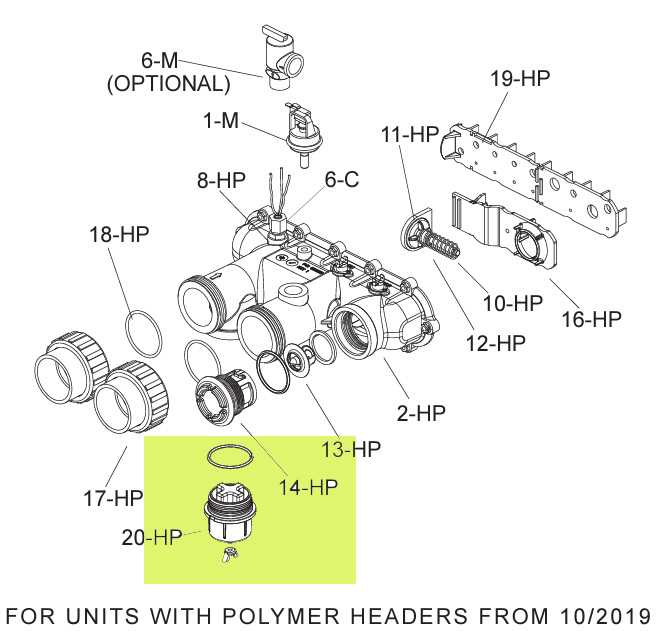

Visual aids serve as essential tools in grasping the complexity of these interconnected systems. They provide clarity, enabling technicians and enthusiasts alike to navigate through the specifics of assembly and function with ease.

Ultimately, this exploration aims to empower users with the knowledge necessary for informed decisions regarding repairs and upgrades. By delving into the details, one can ensure their system operates smoothly and effectively for years to come.

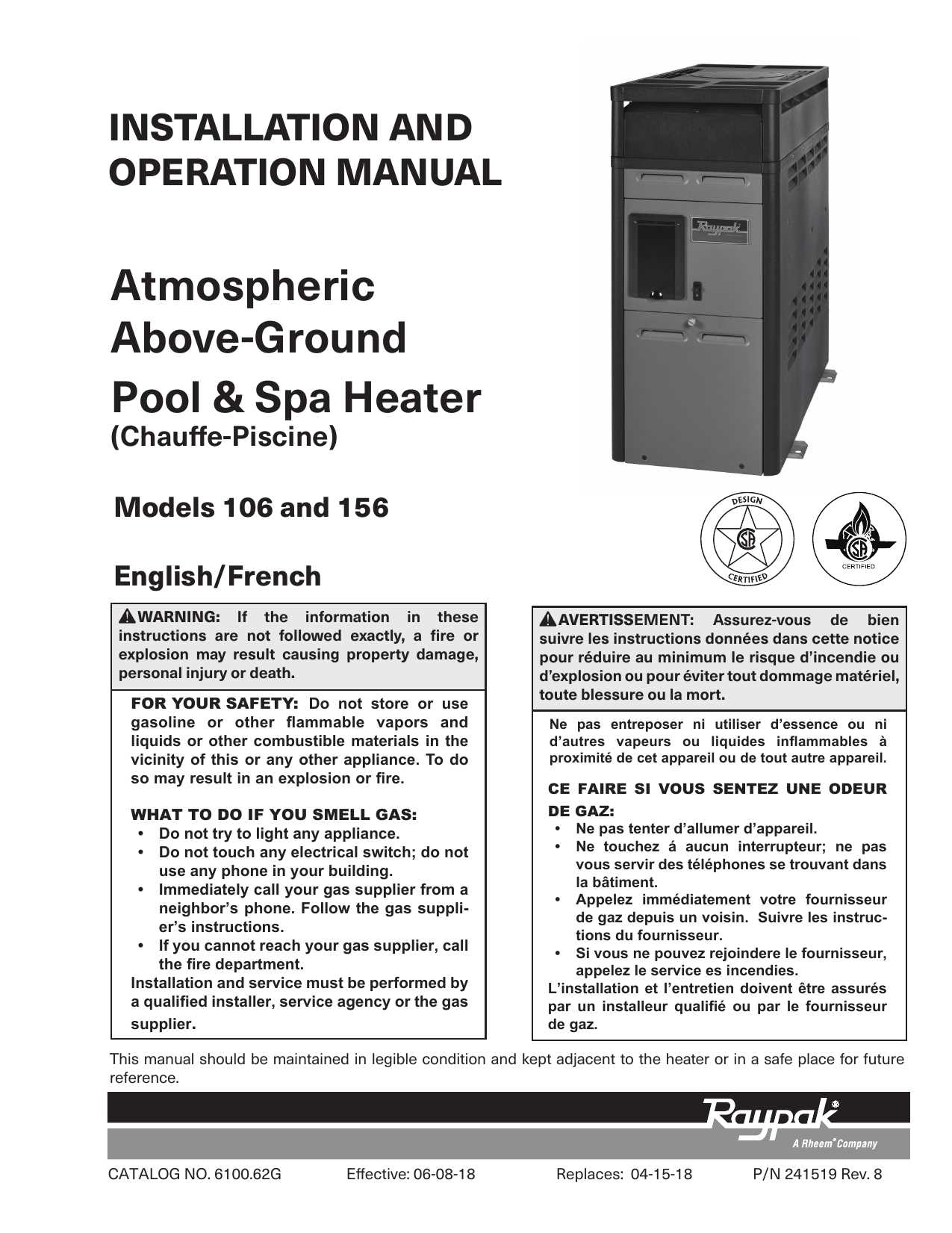

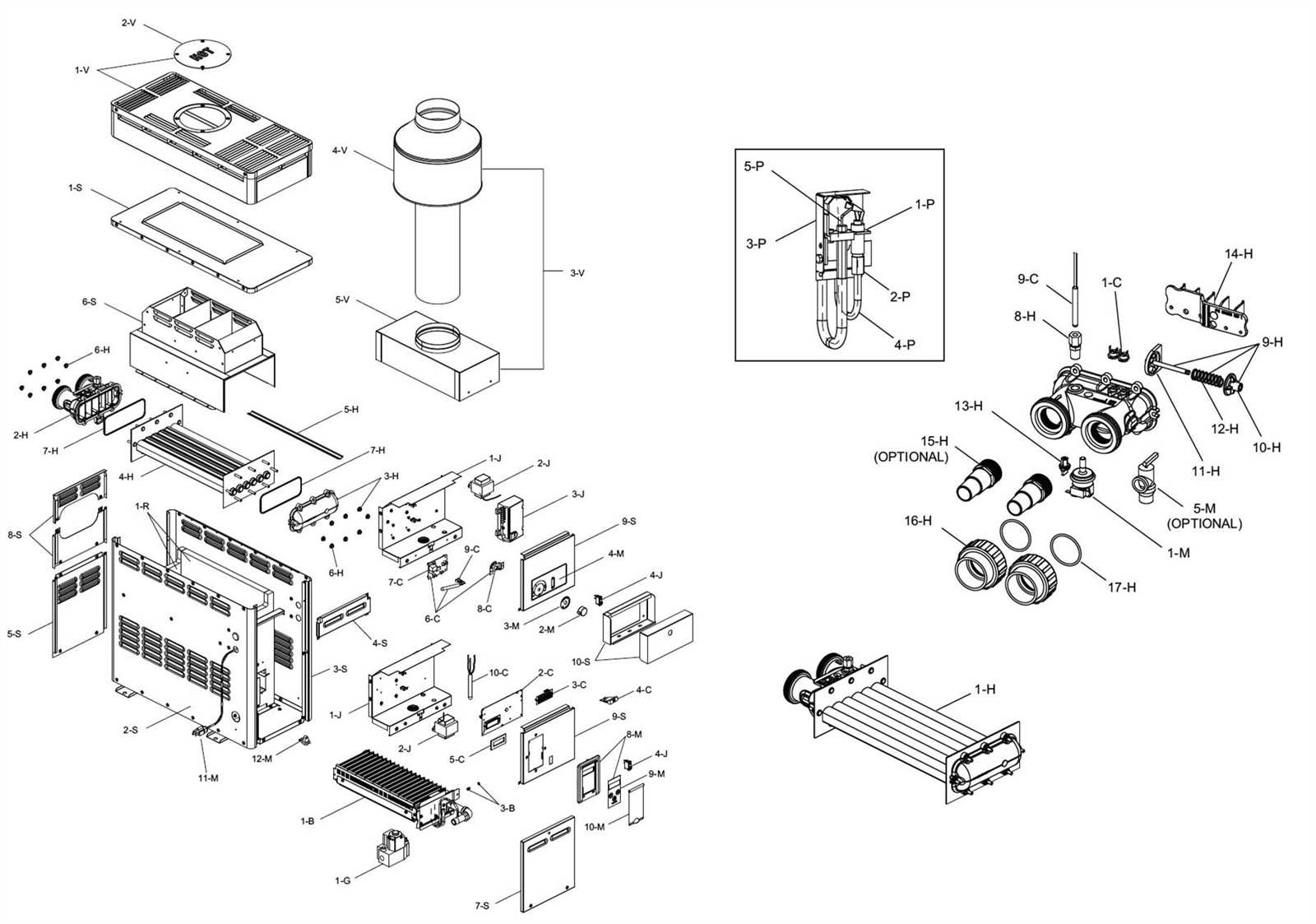

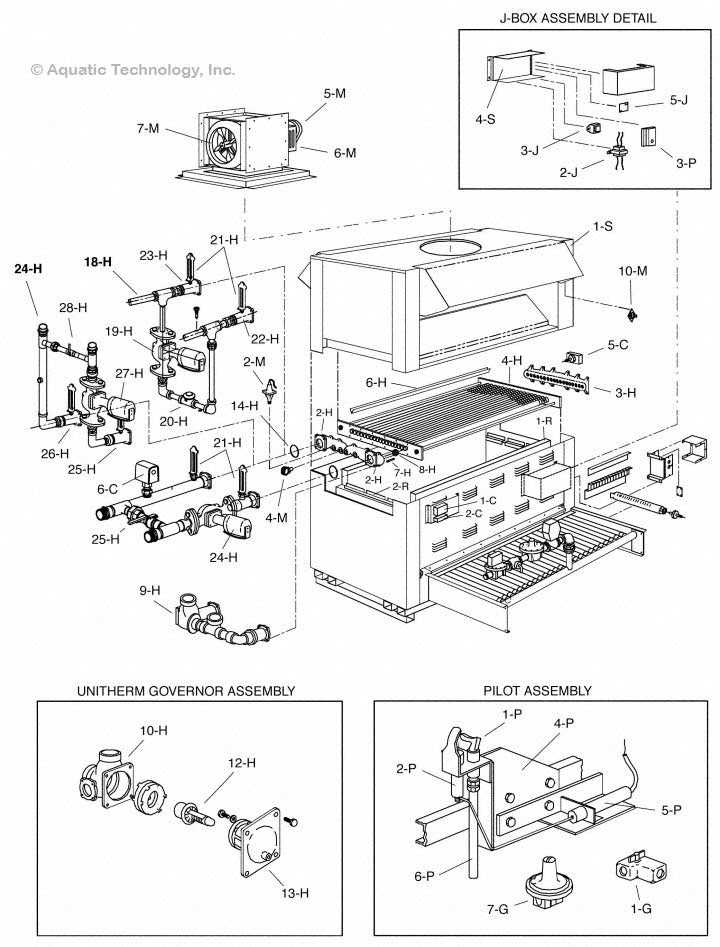

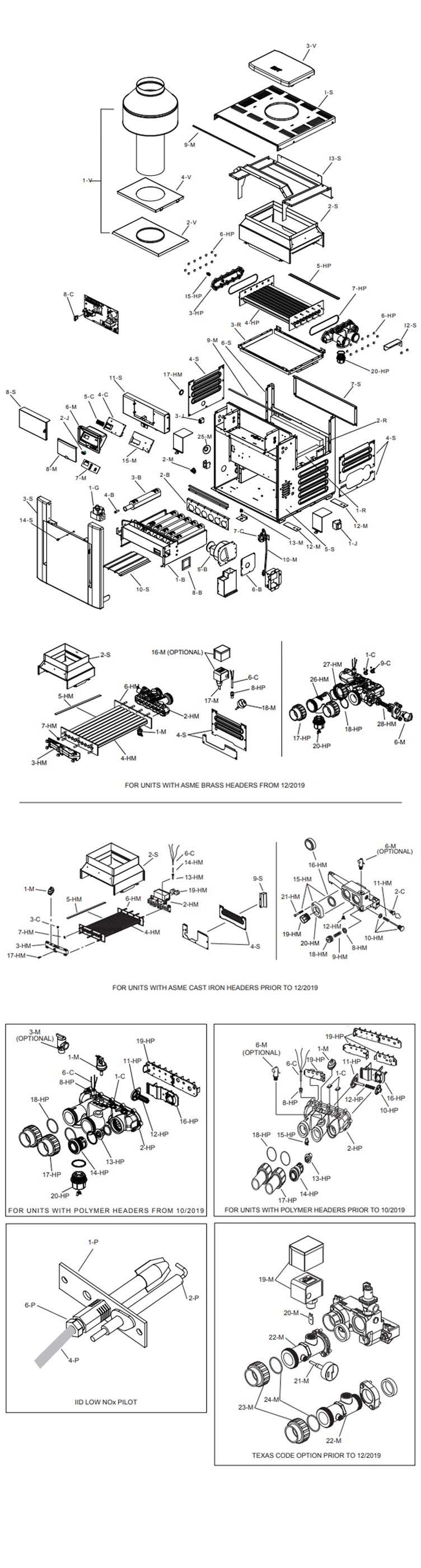

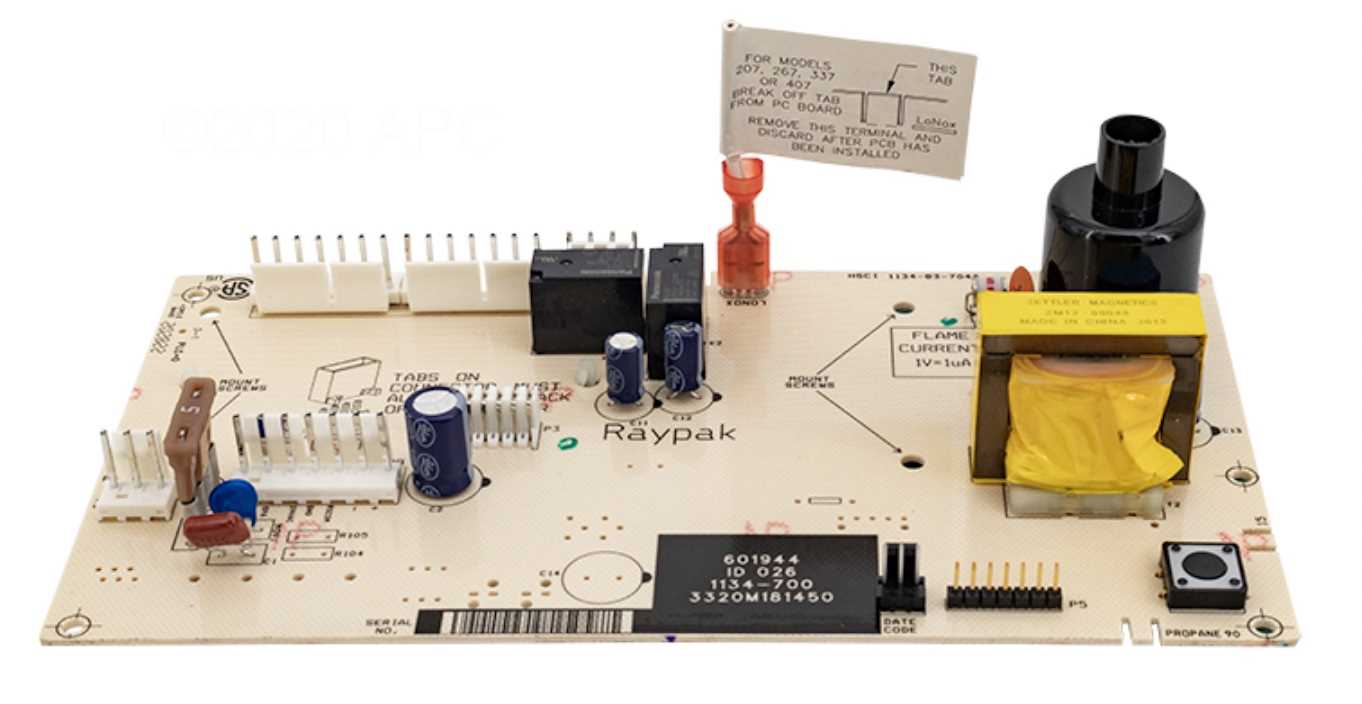

Understanding Raypak Parts Diagrams

This section aims to provide insight into the visual representation of components used in heating systems. These illustrations serve as essential tools for technicians and users, simplifying the identification and maintenance of various elements.

- Importance: Knowing the layout aids in troubleshooting and repairs.

- Components: Familiarity with individual items enhances understanding.

- Functionality: Visuals depict how each element interacts within the system.

To maximize the benefits of these representations, consider the following:

- Study each component’s role and placement.

- Utilize the visuals for quick reference during maintenance.

- Refer to manufacturer manuals for detailed explanations.

By delving into these illustrations, users can develop a comprehensive grasp of their systems, ultimately improving efficiency and longevity.

Overview of Raypak Equipment Components

The intricate machinery used in heating systems consists of various essential elements that work in harmony to ensure optimal performance. Understanding these components is crucial for maintenance and efficient operation, allowing users to identify issues quickly and enhance longevity.

Heating Units: Central to the system, these devices provide the necessary warmth and are designed for durability and efficiency.

Pumps: Vital for circulating water throughout the system, these mechanisms ensure a steady flow and proper temperature distribution.

Controls: These units regulate the operation of the entire system, allowing for adjustments based on user preferences and environmental conditions.

Heat Exchangers: These components transfer heat effectively, maximizing energy use while minimizing waste.

Safety Features: Integral for preventing overheating and other hazards, these systems protect both the equipment and users from potential risks.

By delving into each of these components, users can gain a comprehensive understanding of their heating systems and ensure they operate at their ultimate potential.

Importance of Accurate Parts Identification

Correct identification of components is crucial for ensuring optimal functionality and longevity of any equipment. When each element is recognized with precision, it leads to effective maintenance, improved performance, and reduced downtime. This practice not only facilitates smooth operations but also enhances safety for users and operators alike.

Moreover, understanding the specific characteristics and roles of each component allows for timely replacements and repairs, preventing costly disruptions. Failure to accurately identify components can result in inappropriate substitutions, leading to malfunction or inefficiency. Therefore, maintaining a clear understanding of each element’s significance within the system is essential for sustaining operational integrity.

In addition, precise identification fosters a more informed approach to inventory management. It streamlines the procurement process and ensures that the right items are readily available when needed. This not only saves time but also reduces the risk of errors that could compromise the overall functionality of the system.

Common Raypak Models and Their Diagrams

This section explores various popular heating equipment models and their corresponding layouts. Understanding these configurations is essential for maintenance and repair, ensuring efficient operation and longevity of the systems. Each model features unique components that play a vital role in performance, making familiarity with these designs crucial for users and technicians alike.

Popular Models Overview

Here are some frequently encountered heating units and their characteristics:

| Model Name | Type | Key Features |

|---|---|---|

| Model A | Gas Heater | Compact design, high efficiency, suitable for residential use. |

| Model B | Electric Heater | Quick heating, easy installation, ideal for smaller spaces. |

| Model C | Commercial Unit | Robust build, high capacity, designed for large applications. |

Understanding Layouts

Familiarizing oneself with the layouts of these models facilitates efficient troubleshooting and repair. Each configuration presents distinct arrangements that require specific attention to ensure optimal function. Users should refer to the accompanying schematics for detailed information on individual components and their interconnections.

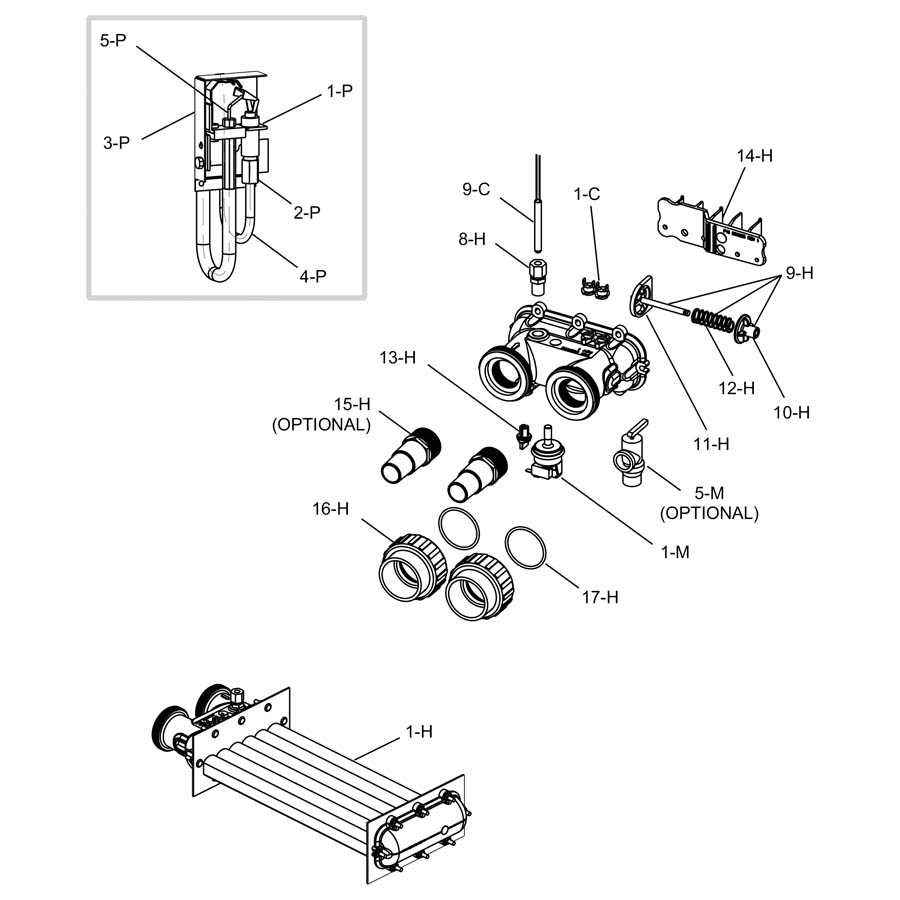

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will provide insights into deciphering these illustrations, ensuring you can identify and locate various elements with ease.

Key Elements to Look For

- Labels: Each component usually has a designation or label that describes its function.

- Numbers: Often, numerical references correspond to a list that provides further details.

- Connections: Arrows or lines indicate how parts interact with each other.

Steps to Interpret the Illustration

- Start by familiarizing yourself with the legend, if available.

- Identify the main components and their positions.

- Cross-reference with accompanying documentation to understand the purpose of each item.

- Take notes on any specific elements you may need to replace or inspect.

By mastering these techniques, you’ll ultimately enhance your ability to manage repairs and ensure optimal functionality of the system.

Essential Tools for Maintenance Tasks

Regular upkeep of equipment is crucial for optimal performance and longevity. To ensure efficiency in maintenance activities, having the right tools at your disposal is vital. These implements not only aid in executing repairs but also enhance safety and precision during the process.

Wrenches are fundamental for loosening and tightening various fittings. A good set of adjustable and socket wrenches will allow you to handle a wide range of tasks effectively.

Screwdrivers come in various types and sizes, making them indispensable for assembling and disassembling components. A quality set with both flathead and Phillips options ensures versatility.

Pliers serve multiple functions, from gripping and twisting wires to cutting materials. Investing in a few different styles, including needle-nose and locking pliers, can enhance your toolkit significantly.

Multimeters are essential for diagnosing electrical issues. These devices measure voltage, current, and resistance, providing critical information for troubleshooting problems.

Safety gear, such as gloves and goggles, should never be overlooked. Protecting yourself while performing maintenance tasks is paramount to prevent injuries and ensure a safe working environment.

Having these essential tools readily available can streamline maintenance efforts and contribute to the overall reliability of your equipment.

Identifying Replacement Parts Quickly

When it comes to maintaining heating systems, recognizing the right components efficiently can save time and reduce frustration. Understanding the layout and function of each element allows for swift identification and replacement, ensuring optimal performance of the system.

Steps for Quick Identification

- Gather necessary documentation, including manuals and specifications.

- Inspect the unit thoroughly to locate any visible identifiers or labels.

- Utilize online resources to cross-reference components with descriptions.

Tips for Effective Identification

- Keep a record of previous replacements for future reference.

- Familiarize yourself with common issues related to each component.

- Join online forums or communities for additional support and information.

Where to Find Raypak Diagrams Online

Accessing visual representations of components can significantly enhance the understanding and maintenance of heating systems. Various online resources provide users with detailed schematics that are essential for troubleshooting and repairs. Here’s where you can find these invaluable resources.

Official Manufacturer Websites

The most reliable source for comprehensive schematics is the official website of the manufacturer. These sites often provide downloadable resources that include maintenance guides and detailed illustrations of different models. Always ensure that you are looking at the latest version for the most accurate information.

Online Forums and Community Groups

Dedicated forums and community groups can be treasure troves of shared knowledge. Enthusiasts and professionals often upload useful documents and images. Participating in these communities can also allow you to ask specific questions and get assistance from experienced users.

| Resource Type | Description |

|---|---|

| Manufacturer Site | Official documents, updates, and model-specific guides. |

| Forums | User-contributed resources, troubleshooting tips, and community support. |

| Online Retailers | Some sellers provide product details and diagrams for items they sell. |

| Social Media Groups | Active discussions and shared resources among users. |

Tips for Ordering Raypak Parts

When it comes to acquiring essential components for your heating equipment, a systematic approach can save time and ensure you receive the correct items. Here are some helpful suggestions to streamline the ordering process.

- Identify the Model: Always check the model number of your equipment. This information is crucial for selecting compatible components.

- Consult the Manual: Refer to the user manual for your device. It often contains detailed information on the required components and specifications.

- Check for Updates: Manufacturers sometimes release updated versions of components. Verify that you are ordering the latest version to ensure optimal performance.

Before placing your order, consider the following:

- Compare Prices: Look at multiple suppliers to find competitive pricing. Don’t forget to factor in shipping costs.

- Read Reviews: Investigate feedback from other customers regarding the reliability of the supplier. This can help you avoid potential issues.

- Ask Questions: If you’re uncertain about compatibility or specifications, reach out to customer service for clarification.

By following these tips, you can enhance your ordering experience and ensure that your heating system remains in peak condition.

Understanding Warranty and Returns Policies

When it comes to purchasing equipment or components, knowing the terms of guarantees and return options is crucial for customer satisfaction. These policies provide essential information on how to handle potential issues and ensure that buyers feel secure in their investments.

Warranties typically cover specific aspects of a product’s performance and durability, giving consumers peace of mind. Understanding the key elements of these assurances can help users navigate their rights and obligations effectively.

- Duration: The length of the warranty period can vary significantly. Be sure to check the time frame for coverage.

- Coverage: It’s important to know what is included in the warranty. Some may cover parts, while others may also include labor.

- Exclusions: Familiarize yourself with what is not covered, such as damage from misuse or unauthorized repairs.

Returns policies also play a vital role in consumer confidence. Understanding these terms ensures that you can return or exchange products when necessary.

- Time Limit: Most return policies specify a period during which returns can be made. This timeframe can vary, so always check before making a purchase.

- Condition: Items usually need to be in their original condition and packaging. Understanding these requirements can save time and frustration.

- Refund Process: Be aware of how refunds are processed, including potential restocking fees or store credit options.

By grasping the details of warranties and return policies, consumers can make informed decisions and enhance their overall purchasing experience.

Common Issues and Troubleshooting Steps

When it comes to maintaining heating systems, several frequent problems can arise, often leading to decreased efficiency or functionality. Understanding these common challenges and knowing how to address them can help ensure optimal performance and longevity of the equipment.

Frequent Problems

One of the most typical issues involves inadequate heating. This may be attributed to a variety of factors, including thermostat malfunctions, low water levels, or blocked pipes. Another common concern is unusual noises, which can indicate loose components or buildup of sediment within the system. Lastly, the presence of error codes can signal electrical or operational failures, necessitating prompt attention.

Troubleshooting Steps

To tackle inadequate heating, first check the thermostat settings and ensure they are correct. Inspect the water level and clear any obstructions in the pipes. For unusual sounds, examine all accessible components for tightness and look for any signs of blockage. If error codes appear, consult the user manual to decipher their meanings and follow recommended actions. Regular maintenance and prompt troubleshooting can significantly enhance the performance of the heating system.

Maintaining Your Raypak Equipment Effectively

Proper upkeep of your heating apparatus is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns and costly repairs. By following a systematic approach, you can keep your equipment running smoothly and efficiently throughout its lifespan.

Key Maintenance Practices

- Regular Inspections: Conduct periodic checks for any signs of wear or damage.

- Cleaning Components: Keep essential parts free from debris and build-up to ensure proper functionality.

- Check Fluid Levels: Monitor and maintain appropriate levels of coolant or other necessary fluids.

- Test Safety Features: Ensure that all safety mechanisms are operational to prevent accidents.

- Schedule Professional Servicing: Engage a qualified technician for annual inspections and servicing.

Benefits of Regular Upkeep

- Enhanced Efficiency: Regular maintenance helps your system operate at peak performance.

- Increased Lifespan: Well-maintained equipment lasts longer, saving you money in the long run.

- Improved Safety: Routine checks minimize the risk of hazards associated with malfunctioning units.

- Cost Savings: Preventative care reduces the likelihood of costly repairs and energy waste.

Community Resources for Raypak Users

Finding reliable support and information can significantly enhance the experience of those utilizing heating systems. A variety of community-driven platforms exist to share insights, troubleshoot issues, and discuss best practices.

- Online Forums: Engage with fellow users to exchange tips and solutions.

- Social Media Groups: Join dedicated pages where enthusiasts share experiences and advice.

- YouTube Channels: Explore tutorials and guides to better understand your equipment.

- Local Meetups: Participate in gatherings to connect with others in your area.

- Resource Libraries: Access documents, manuals, and maintenance tips provided by users.

Utilizing these resources can help users delve into their systems and maximize their efficiency.