Understanding the internal structure of a machine is essential for anyone looking to maintain or repair it effectively. A clear layout of its essential elements allows for precise identification and troubleshooting, making the task of addressing mechanical issues more manageable and efficient.

This article will offer insights into the arrangement and function of various segments within the equipment. By exploring how each unit interacts with others, you’ll gain a deeper appreciation of the device’s engineering, which can lead to more effective maintenance practices. Whether you are an experienced technician or a beginner, having a visual overview of key components will help streamline the entire process.

Moreover, this overview will delve into the essential elements that make up the structure, enabling users to recognize and locate specific items more easily. This clarity not only enhances your ability to diagnose problems but also supports the effective replacement of worn-out or defective sections, ensuring the equipment operates smoothly over time.

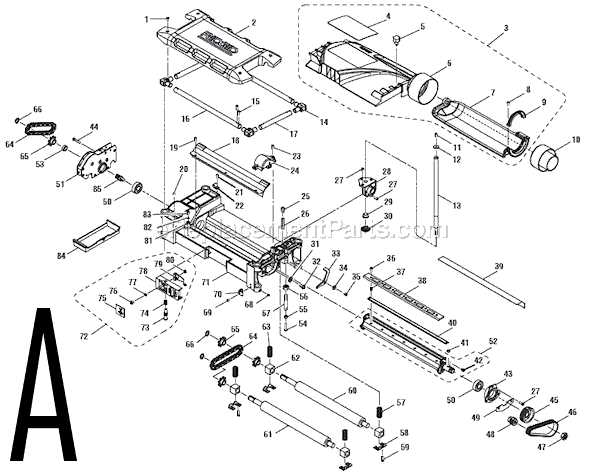

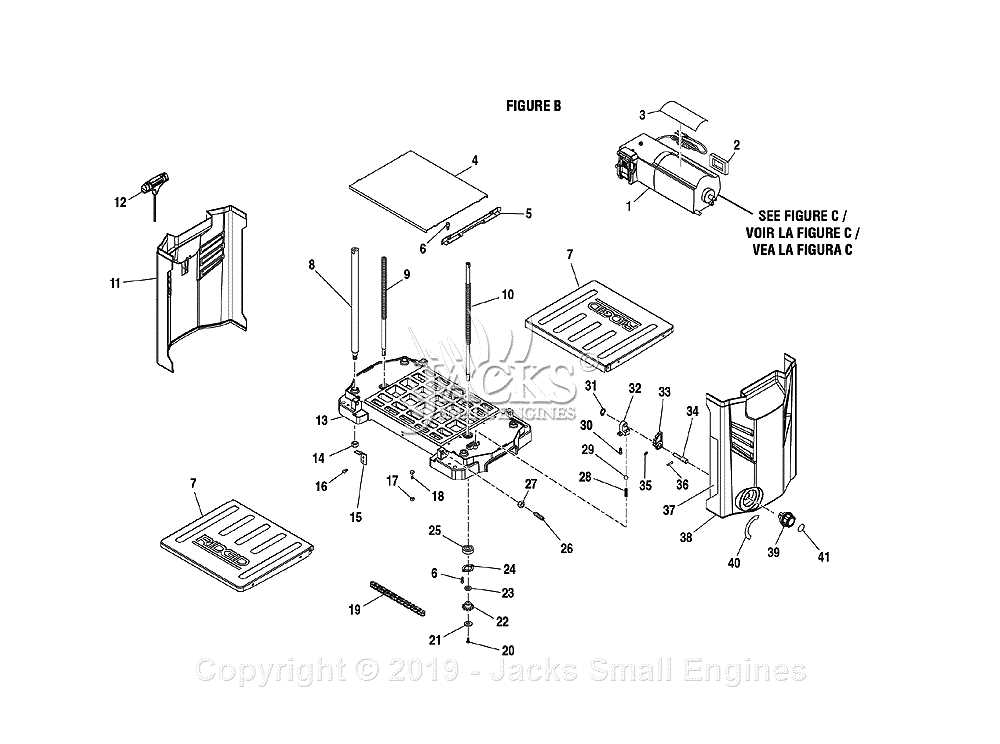

Overview of Ridgid R4331 Components

This section provides a comprehensive look at the essential elements that make up this versatile woodworking tool. Understanding the core components is key to ensuring proper operation, maintenance, and troubleshooting.

- Cutting Mechanism: The central element responsible for precise trimming and smooth finishes, designed to handle various types of wood surfaces with ease.

- Motor Assembly: The powerhouse driving the machine, enabling efficient and consistent performance across different tasks. It is engineered for durability and longevity.

- Adjustment Controls: These allow users to fine-tune settings, ensuring that each cut meets specific requirements. Precision and user-friendly adjustments are integral to the design.

- Safety Features: Include

Essential Parts for Optimal Performance

Maintaining smooth and efficient operation of any equipment requires understanding the crucial components that contribute to its functionality. Recognizing the key elements that play a vital role ensures that every task is completed with precision and reliability.

Among the core elements, focus should be given to the cutting assembly, as it influences the quality and consistency of the results. Regular inspection and upkeep of this area can prevent common issues and prolong the tool’s lifespan. Additionally, the drive mechanisms are central to the overall performance, ensuring steady and consistent movement during operation.

Properly maintained safety features also enhance the efficiency of the device, minimizing risks and ensuring safe use. Ensuring that these protective components are in good condition will not only protect the user but also contribute to the equipment’s long-term durability

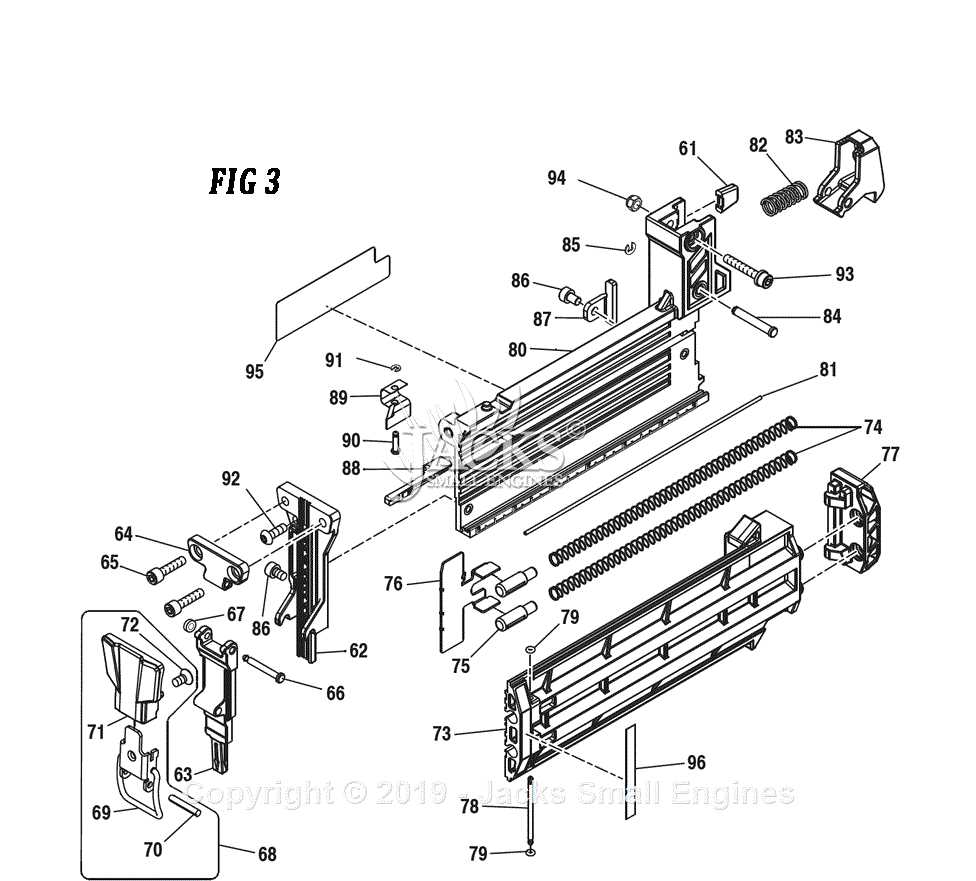

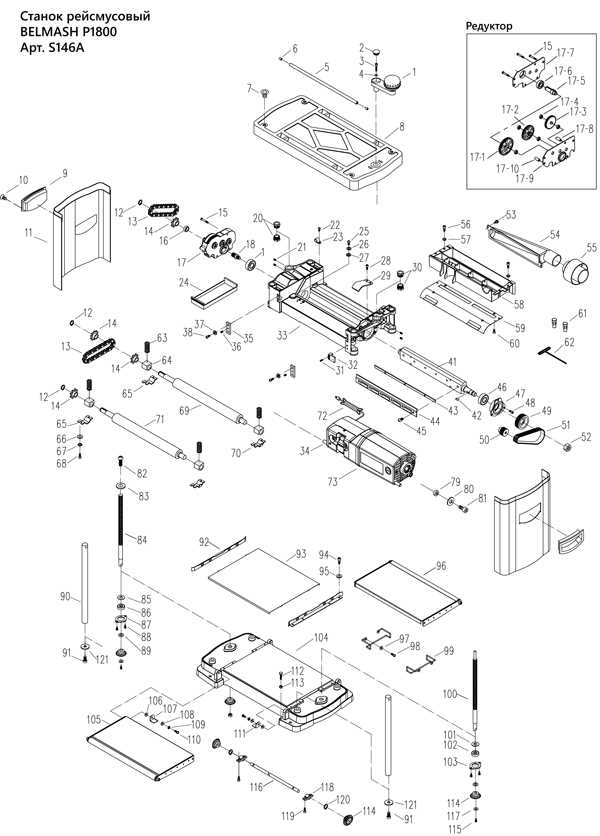

Detailed Breakdown of Major Components

In this section, we will explore the primary elements that constitute the device, providing a clear understanding of how each unit contributes to the overall operation. This overview aims to give a structured look at the essential mechanisms and their roles within the system, allowing for easier maintenance and troubleshooting.

Main Structural Elements

The core frame serves as the foundation, supporting all other units. This section covers the robust build and design features, ensuring stability during usage. Additionally, we will address how each component integrates seamlessly to form a cohesive unit.

Component Description Function Motor Assembly High-efficiency unit responsible for driving the device’s operation. Generates the necessary force to enable cutting or shaping tasks. How to Identify Key Parts

Understanding the essential components of your equipment is crucial for maintenance and troubleshooting. By familiarizing yourself with the layout and structure, you can easily pinpoint specific elements and ensure efficient operation. This section will guide you on how to recognize and locate important elements for better handling and upkeep.

Steps to Recognize Main Elements

- Begin by examining the overall structure and noting the primary sections. Often, each section is dedicated to a specific function, making it easier to identify.

- Look for labels or markings that highlight key areas. These markings are usually placed near critical areas to help with identification.

- Use the manual or a reference sheet to compare your observations. Diagrams and guides can simplify the process, showing where each component is located.

Common Features to Look For

Maintenance Tips for R4331 Components

Regular upkeep is essential to ensure smooth performance and longevity of various elements in your woodworking equipment. By adopting a consistent maintenance routine, you can prevent common issues, reduce wear and tear, and extend the lifespan of the unit. Below are some key practices to consider for effective upkeep.

Clean and Lubricate Regularly

Dust and debris can accumulate quickly, leading to blockages and reduced efficiency. It is crucial to clean all surfaces, especially around the cutting areas, to maintain optimal functionality. Applying high-quality lubricant to moving parts will minimize friction and ensure seamless operation.

Inspect and Tighten Connections

Over time, screws and bolts may loosen, affecting the stability of the unit. Regularly check all connections and tighten them as needed. Inspect for any signs of wear, such as cracks or rust, and replace faulty components to prevent more serious

Common Replacement Parts and Uses

In the realm of tool maintenance, understanding essential components and their functions is crucial for ensuring optimal performance and longevity. Various elements may require replacement over time due to wear and tear or damage from regular use. Familiarity with these components can aid users in making informed decisions when repairs are necessary.

Frequent Components for Replacement

Among the most commonly replaced items are blades and filters. Blades may become dull or chipped, reducing efficiency and increasing the risk of damage to the material being worked on. Filters, on the other hand, are essential for maintaining the cleanliness of the tool’s internal mechanisms, preventing dust and debris buildup that can hinder functionality.

Importance of Regular Maintenance

Ensuring the timely replacement of critical components not only enhances performance but also extends the life of the tool. Users should regularly inspect their equipment for signs of wear, such as decreased efficiency or unusual noises. By proactively addressing these issues, operators can prevent more significant problems down the line and maintain the reliability of their equipment.

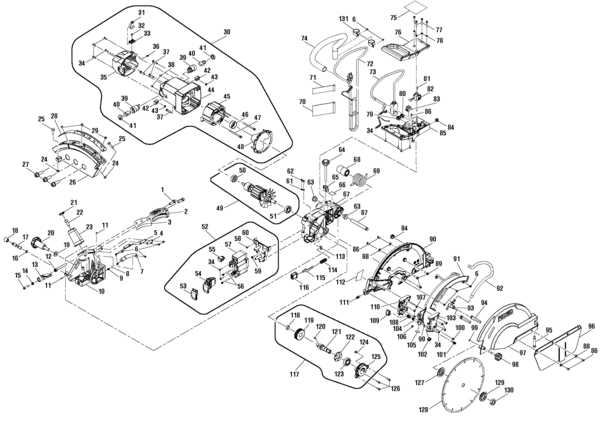

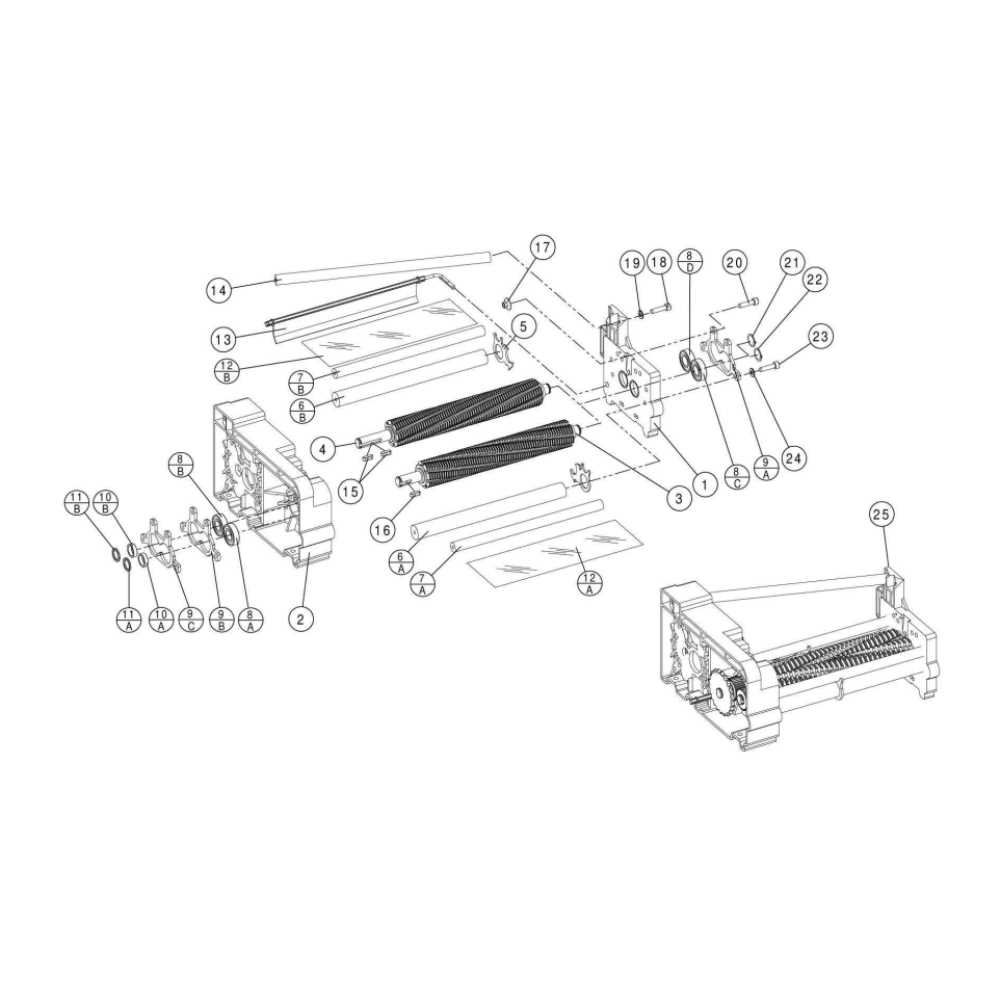

Understanding the Internal Mechanics

Delving into the inner workings of power tools reveals a complex interplay of components that ensure optimal functionality. Grasping how these elements collaborate can enhance maintenance and troubleshooting skills, leading to improved performance and longevity.

Key Components

- Motor: The driving force behind the tool’s operation, responsible for converting electrical energy into mechanical motion.

- Gear System: A series of gears that regulate the speed and torque, allowing for versatility in various tasks.

- Housing: The outer shell that protects internal parts while providing a framework for assembly.

- Trigger Mechanism: Enables user control over the tool’s activation and power levels.

Mechanics of Functionality

The synergy of these components dictates how effectively the tool performs its tasks. For instance, the motor’s power translates through the gear system, modulating speed based on the user’s input via the trigger. Proper alignment and maintenance of these parts are crucial to prevent wear and ensure seamless operation.

By understanding these foundational elements, users can better appreciate the craftsmanship behind their tools, leading to more informed usage and care.

Tools Required for Parts Assembly

When undertaking the task of assembling components, having the right tools on hand is crucial for ensuring efficiency and precision. The selection of equipment can significantly influence the ease of the assembly process and the overall quality of the final outcome. This section outlines essential implements that facilitate effective component assembly.

Essential Equipment

To successfully complete assembly tasks, consider equipping yourself with the following implements:

Tool Purpose Screwdriver Set To tighten or loosen screws in various components. Wrench Set For fastening nuts and bolts securely. Pliers To grip and manipulate small parts effectively. Hex Key Set For assembling hexagonal screws and fasteners. Utility Knife To cut through packaging or materials as needed. Additional Considerations

In addition to the primary tools, having a reliable work surface and adequate lighting can enhance your assembly experience. Organizing your workspace will also help streamline the process, allowing you to focus on assembling components with confidence.

Step-by-Step Parts Installation Guide

This section provides a comprehensive approach to the installation of components in your tool. By following the outlined steps, you will ensure proper assembly and functionality, enhancing the overall performance of the device.

Step 1: Begin by gathering all necessary tools and components. Ensure you have a clean workspace to facilitate an efficient installation process.

Step 2: Carefully examine each element for any signs of damage or wear. This inspection will help identify any issues before proceeding with the installation.

Step 3: Refer to the provided instructions to locate the correct position for each component. It is crucial to follow the specified order to avoid complications.

Step 4: Align the components accurately and secure them in place using the appropriate fasteners. Ensure each part is tightly fitted to prevent any movement during operation.

Step 5: Once all elements are installed, perform a thorough check to confirm that everything is assembled correctly. Look for any loose fittings or misaligned parts.

Step 6: Finally, power on the tool to test its functionality. Monitor its performance and make any necessary adjustments to guarantee optimal operation.

Best Practices for Parts Replacement

Ensuring optimal performance of your equipment requires careful attention to the process of component substitution. By adhering to established guidelines, you can enhance the longevity and efficiency of your tools. This section outlines essential practices to follow when undertaking replacements, ensuring that your machinery operates smoothly and reliably.

First, always refer to the manufacturer’s specifications when selecting new components. Utilizing the correct size, type, and quality will guarantee compatibility and functionality. It is advisable to source replacements from reputable suppliers to avoid counterfeit or inferior products that could hinder performance.

Additionally, prior to initiating any replacement, conduct a thorough inspection of the entire assembly. Identifying other worn or damaged components can prevent future issues and save time and resources. Taking the time to clean the area before installation can also facilitate better adhesion and alignment, resulting in a more efficient repair.

During the installation process, follow step-by-step procedures to avoid errors. Utilize the appropriate tools for the task to ensure that components are fitted correctly without causing damage. Once the new component is in place, perform functionality tests to confirm that everything is operating as intended.

Finally, maintain a detailed log of any substitutions made, including dates and parts used. This record can provide valuable insights for future maintenance and help in identifying recurring issues. By following these best practices, you can enhance the reliability and performance of your equipment.

Troubleshooting Common Parts Issues

Maintaining equipment often involves addressing typical component challenges that can arise during operation. Understanding these frequent malfunctions can enhance performance and extend the lifespan of your device.

One of the first steps in resolving issues is to identify any signs of wear or damage. Inspecting each element thoroughly for cracks, loose connections, or abnormal sounds can provide valuable insights. If any parts appear compromised, replacing them promptly can prevent further complications.

Another common concern is the accumulation of debris or buildup that can hinder functionality. Regular cleaning and maintenance can mitigate these problems, ensuring smooth operation. If you notice performance degradation, consider disassembling the affected area to remove any blockages.

In some cases, improper installation may lead to operational difficulties. Verifying the correct assembly of each section is crucial. Referencing the manufacturer’s guidelines can help confirm that all components are installed properly.

Should you encounter persistent problems despite following these troubleshooting steps, seeking assistance from a professional may be necessary. They can offer expert advice and support to resolve any lingering issues effectively.

Frequently Asked Questions About Components

This section addresses common inquiries regarding various elements found in power tools. Understanding these components is essential for effective maintenance and operation.

- What are the essential elements in a power tool?

Key components typically include the motor, casing, switch, and attachments. Each part plays a crucial role in the functionality of the tool.

- How can I identify a malfunctioning part?

Look for signs such as unusual noises, overheating, or poor performance. If a specific component appears worn or damaged, it may need replacement.

- Are there compatible alternatives for original components?

Yes, many manufacturers offer compatible replacements. Ensure that the specifications match the original parts to maintain performance.

- How often should I replace components?

It varies based on usage. Regular inspection is recommended; replace parts as needed, especially those subjected to frequent wear.

- Where can I find replacement components?

Replacement parts can be sourced from authorized retailers, online marketplaces, or directly from manufacturers.