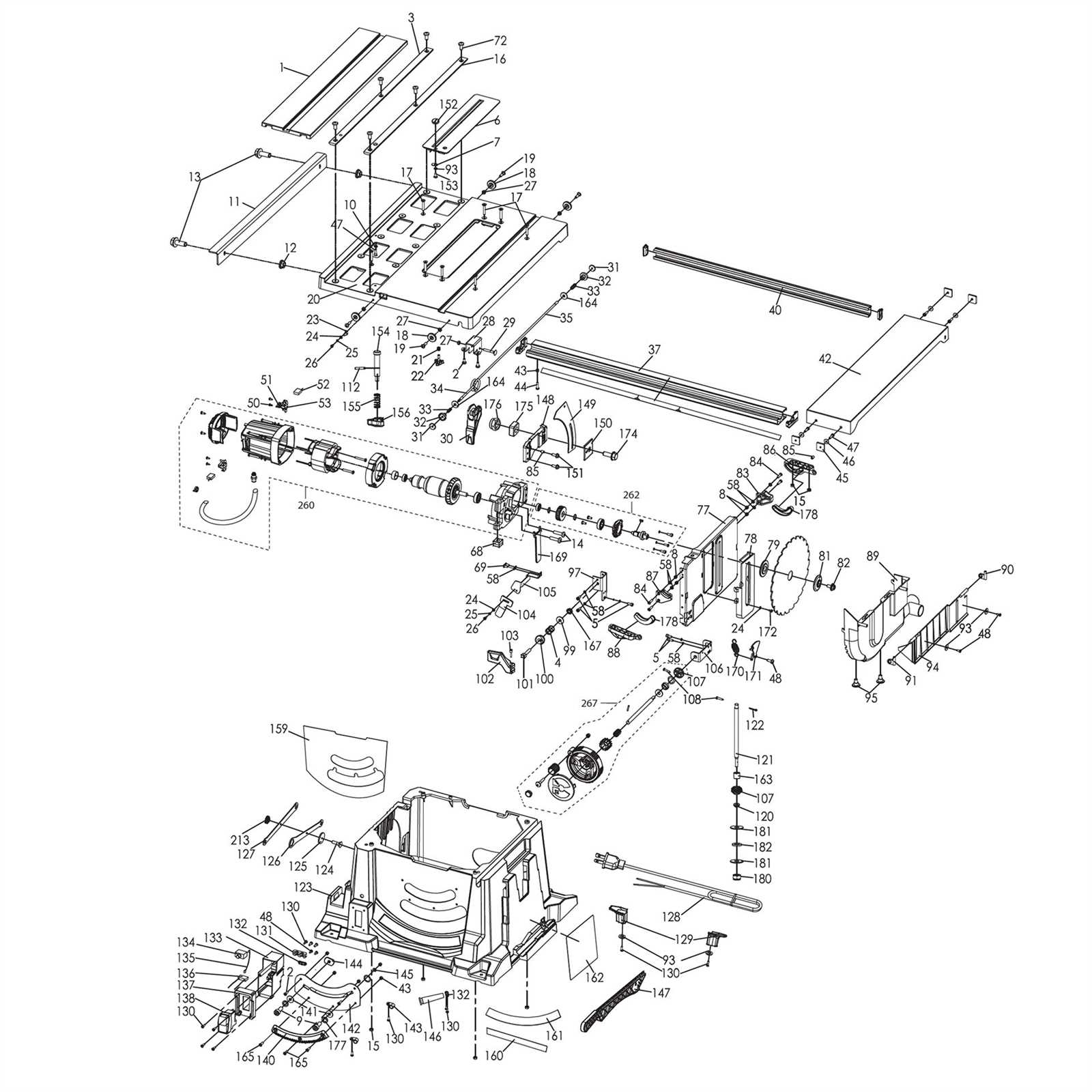

When it comes to machinery maintenance and repair, having a clear understanding of the internal structure and components is crucial. This section delves into the visual representations that illustrate the arrangement and function of various elements within a specific model of equipment. By analyzing these visual aids, users can gain insight into how each part interacts and contributes to the overall operation.

Utilizing these visual guides not only simplifies the identification of individual components but also enhances the troubleshooting process. Whether you are an experienced technician or a novice, familiarizing yourself with these representations can significantly improve your ability to maintain and repair machinery effectively. This knowledge empowers users to make informed decisions and tackle issues with confidence.

As we explore the intricacies of this particular model, we will highlight key features and provide essential information that will facilitate your understanding. Engaging with these resources will enable you to optimize your experience and ensure the longevity of your equipment.

Understanding essential components for repair and maintenance is crucial for optimal performance and longevity. Regular checks can help identify worn or damaged elements that may require replacement to ensure smooth operation and prevent further issues.

| Component | Description | Purpose |

|---|---|---|

| Motor | The primary driving unit responsible for powering the machine. | Facilitates the main functions of the equipment. |

| Belt | A flexible loop that transmits power between rotating shafts. | Ensures efficient power transfer and operation. |

| Blade | The sharp tool used for cutting materials. | Enables precise and effective cutting action. |

| Table Surface | The flat area where materials are placed for cutting. | Provides stability and support during operation. |

| Guard | A safety feature that covers moving parts. | Helps protect users from accidental contact with dangerous areas. |

How to Access the Parts Diagram

To effectively navigate the components of your equipment, it is essential to understand how to locate its detailed illustrations. These visuals serve as a valuable resource for identifying individual elements and facilitating maintenance or repair tasks. By following a few straightforward steps, users can easily obtain the necessary reference materials.

Online Resources

Many manufacturers provide comprehensive online databases where you can find schematics. Simply visit the official website and navigate to the support or resources section. Enter the model number to access the relevant illustrations, which are often available in PDF format for easy viewing and printing.

User Manuals

Another effective way to find these visuals is through the user manual that accompanies your equipment. This document typically includes a section dedicated to visual references, helping you identify each component clearly. If the original manual is not available, it can often be downloaded from the manufacturer’s website.

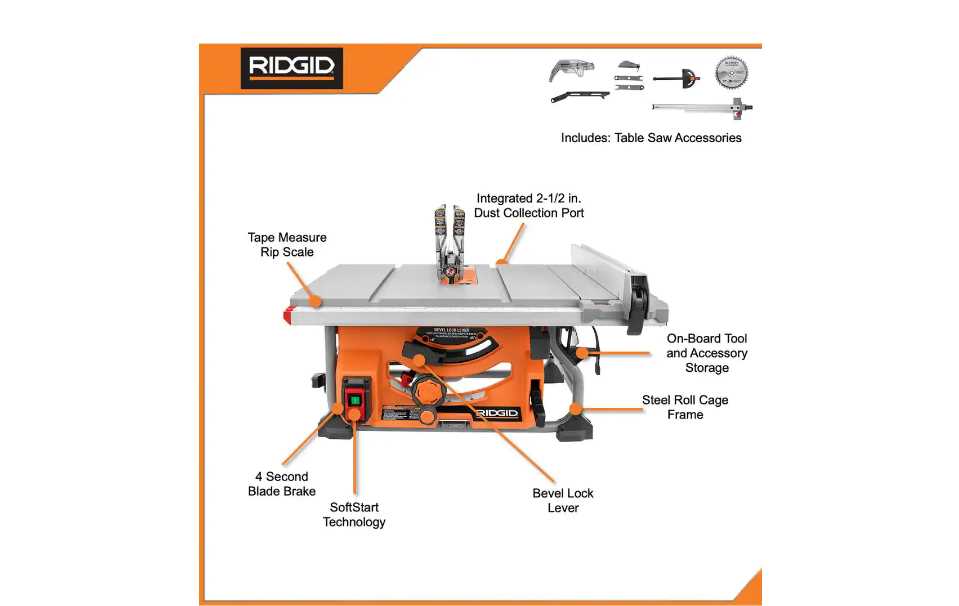

Identifying Components in the Diagram

Understanding the layout and elements of a technical representation is essential for effective maintenance and repair. Familiarizing oneself with the various parts depicted can significantly streamline the process of identifying issues and ensuring proper functionality. Each element is designed to play a specific role, contributing to the overall performance of the machinery.

| Component Name | Description |

|---|---|

| Base | The sturdy foundation that supports the entire assembly. |

| Motor | The driving force that powers the device, enabling operation. |

| Table Surface | The flat area where materials are placed for cutting or processing. |

| Guard | A safety feature that protects users from potential hazards during operation. |

| Adjustment Mechanism | A tool for fine-tuning settings to achieve desired results. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of any equipment. Proper care not only enhances performance but also prevents unnecessary wear and tear, ultimately saving time and resources. Below are some effective strategies to maintain optimal functionality and longevity.

Routine Cleaning

Keeping your equipment clean is crucial. Dust, debris, and residue can lead to malfunction and deterioration. Follow these steps:

- Use a soft brush to remove dust from surfaces.

- Wipe down components with a damp cloth to eliminate grime.

- Ensure all openings and vents are free from obstructions.

Regular Inspections

Frequent examinations can identify potential issues before they escalate. Consider the following:

- Check for any signs of wear or damage on moving parts.

- Examine electrical connections for corrosion or fraying.

- Monitor fluid levels and replenish as needed.

Proper Storage

Storing equipment correctly is vital for preventing deterioration:

- Keep in a dry, temperature-controlled environment.

- Avoid exposure to extreme temperatures or humidity.

- Utilize covers to protect against dust and contaminants.

By following these maintenance practices, you can significantly enhance the durability and efficiency of your equipment, ensuring it remains in excellent condition for years to come.

Ordering Replacement Parts Efficiently

Acquiring new components for machinery can often feel overwhelming, especially when aiming to maintain optimal performance. Understanding the process of obtaining these essential items is crucial for any user. Streamlining this experience not only saves time but also ensures that repairs are conducted without unnecessary delays.

Identifying Necessary Components

Before making a purchase, it’s important to clearly identify the specific components required. Referencing the equipment’s manual can provide insights into the essential elements needed for replacement. Additionally, keeping a list of the components in question can facilitate quicker transactions when contacting suppliers.

Choosing Reliable Suppliers

Selecting trustworthy vendors plays a pivotal role in acquiring quality replacements. Look for suppliers that specialize in providing high-quality components for your type of machinery. Reading reviews and seeking recommendations can help ensure that the chosen source is reputable and offers prompt service. Moreover, verify that they provide a return policy in case the components are not a suitable fit.

Installation Guide for New Parts

This section provides essential instructions for the effective installation of new components in your equipment. Proper assembly and setup are crucial for ensuring optimal performance and longevity of your device. Follow the guidelines outlined below to facilitate a smooth installation process.

Preparation Steps

Before beginning the installation, gather all necessary tools and ensure that you have a clear workspace. Refer to the specific requirements for the components you are working with, including any manufacturer recommendations. Additionally, it is advisable to review any existing manuals or documentation that may assist you during the installation.

Step-by-Step Installation Process

Start by carefully removing the old components, taking note of their arrangement for reference. Once cleared, position the new parts according to the designated locations. Ensure that all connections are secure and follow any specific alignment instructions provided. After assembly, conduct a thorough inspection to confirm that everything is correctly installed before powering on the device.

Troubleshooting Common Issues

When working with power tools, encountering problems is a common experience. Understanding potential issues can help users effectively address and resolve them. This section will explore typical challenges and provide guidance on identifying and fixing these situations to ensure optimal performance.

Common Problems and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Tool not starting | Power supply issue | Check the power cord and outlet. Ensure the tool is plugged in. |

| Inconsistent operation | Worn components | Inspect internal parts for wear and replace if necessary. |

| Excessive vibration | Unbalanced blade | Ensure the blade is properly installed and balanced. |

| Overheating | Blocked ventilation | Clean any dust or debris from ventilation openings. |

Upgrading Your Ridgid R4512

Improving your woodworking equipment can significantly enhance performance and functionality. Whether you are looking to increase precision, efficiency, or safety, there are various modifications and enhancements you can consider. By upgrading components or incorporating new accessories, you can tailor your machine to better meet your needs.

Enhancing Performance

One way to boost the effectiveness of your tool is by upgrading the motor or blade. A higher-quality blade can provide cleaner cuts, while a more powerful motor can handle tougher materials with ease. Additionally, consider adding a fence system that offers better accuracy and adjustability.

Improving Safety Features

Safety should always be a priority in any workshop. Installing guards, improved dust collection systems, or anti-kickback devices can make a significant difference in preventing accidents. Investing in high-quality accessories not only enhances safety but also contributes to a more efficient work environment.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components associated with various equipment. Understanding these elements is essential for maintenance and efficient operation. Below are some typical questions and their answers to assist users in navigating their concerns.

- What should I do if a component is missing?

If you find that a specific element is not included, it’s advisable to check the packaging thoroughly. Should the issue persist, contacting the supplier or manufacturer directly is recommended for further assistance.

- How can I determine if a component is compatible?

Compatibility can usually be verified through the product manual. It’s also beneficial to consult with customer service or check online resources for specific model information.

- Are replacement components readily available?

Most manufacturers offer replacement elements, which can often be found through authorized dealers or online marketplaces. It’s important to ensure that you are purchasing from reputable sources.

- What are the signs that a component needs replacement?

Common indicators include unusual noises, difficulty in operation, or visible wear and tear. If you notice any of these symptoms, it’s best to examine the element closely for potential replacement.

These questions represent just a portion of the inquiries that users may have. For any additional concerns or specific issues, further research or professional consultation may be necessary.