In the realm of home automation, robotic cleaners have become essential companions for maintaining a tidy environment. These devices, designed to navigate autonomously, require a clear understanding of their internal and external components to ensure optimal functionality. A well-organized visual representation can significantly enhance your ability to troubleshoot and maintain these machines effectively.

By familiarizing yourself with the various elements that constitute these cleaning appliances, you can better appreciate their engineering and design. Each component plays a vital role in the overall performance, and recognizing their arrangement will enable users to address issues and carry out necessary replacements with confidence.

Gaining insights into the configuration of these automated cleaners not only aids in resolving technical problems but also empowers you to make informed decisions regarding upgrades and enhancements. With the right knowledge at your disposal, you can maximize the efficiency and longevity of your cleaning device.

Key Parts of Roomba Robots

The efficiency of robotic vacuum cleaners relies heavily on their various essential components. Each element plays a crucial role in ensuring optimal performance, enhancing the user experience, and maintaining the device’s longevity. Understanding these fundamental sections helps users appreciate how their automated assistants function effectively.

Navigation and Sensors

Navigation systems enable autonomous movement, allowing devices to navigate different environments. Utilizing a range of sensory equipment, these systems can detect obstacles, avoid hazards, and map spaces for efficient cleaning paths.

Cleaning Mechanisms

The cleaning components consist of brushes and suction systems, which work together to remove dirt and debris from various surfaces. The combination of rotating brushes and powerful suction ensures that every corner of a room receives thorough attention.

How to Identify Each Part

Recognizing the components of a robotic vacuum can enhance your understanding of its functionality and maintenance. This knowledge enables users to troubleshoot issues effectively and perform necessary upkeep. Familiarizing yourself with each section will contribute to the overall efficiency of your device.

Key Components Overview

Each segment of the cleaning device serves a distinct purpose. From the brushes to the dustbin, understanding their roles will aid in optimal performance.

| Component | Description |

|---|---|

| Main Brush | This part is responsible for collecting debris and dirt from various surfaces. |

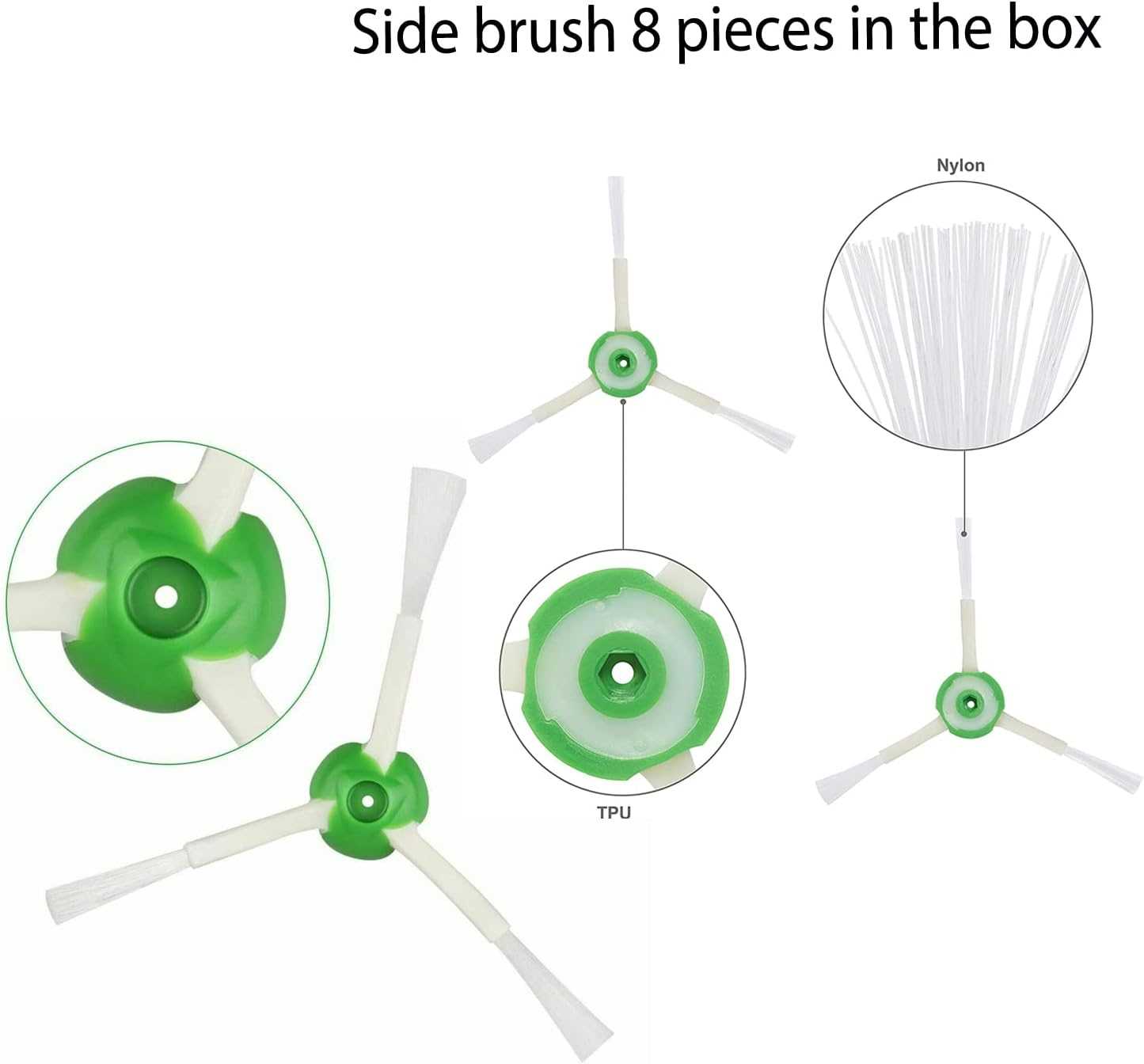

| Side Brush | It helps to sweep dirt from edges and corners, ensuring thorough cleaning. |

| Dustbin | This is where all collected dirt and particles are stored until emptied. |

| Filter | This component traps dust and allergens, improving air quality. |

| Charging Dock | This unit provides power to the vacuum, allowing it to recharge between cleaning sessions. |

Identifying Each Element

To ensure smooth operation, it’s essential to recognize when a component requires replacement or maintenance. Regular inspection of these segments can prevent malfunctions and prolong the lifespan of your device.

Importance of Regular Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of any automated cleaning device. By performing routine check-ups and maintenance tasks, users can enhance the efficiency of their equipment, preventing minor issues from escalating into significant problems.

Adhering to a consistent maintenance schedule offers numerous benefits:

- Improved Performance: Regular cleaning and inspections help maintain the device’s effectiveness in various cleaning tasks.

- Extended Lifespan: Proper care can significantly increase the operational life of the equipment, allowing for longer usage before replacement is necessary.

- Cost Savings: Investing time in maintenance can reduce the need for costly repairs and replacements in the long run.

- Enhanced Safety: Well-maintained devices are less likely to malfunction, minimizing the risk of accidents or damage to property.

In conclusion, committing to routine upkeep is a wise choice for anyone relying on automated cleaning technology. It ensures that the device continues to operate effectively and safely, ultimately providing a better cleaning experience.

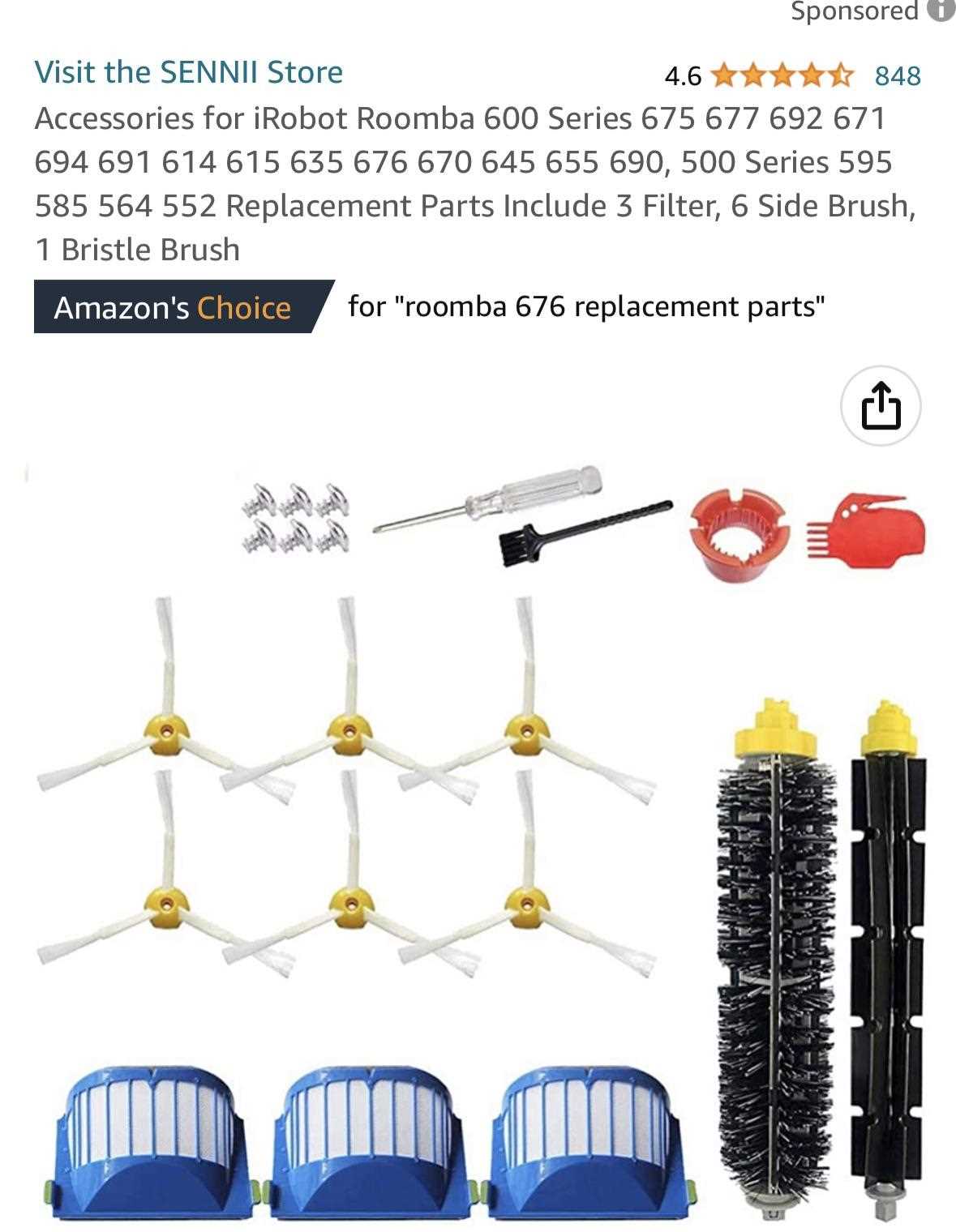

Common Replacement Parts Overview

Maintaining the efficiency of automated cleaning devices often requires replacing certain components. Understanding the commonly needed elements can help users ensure their appliances operate at peak performance. This section outlines the key components that may need attention over time, allowing for informed decision-making regarding replacements.

Essential Components

Several elements play crucial roles in the functionality of automated cleaning units. Below are the primary components that frequently require replacement due to wear and tear:

| Component | Function | Replacement Frequency |

|---|---|---|

| Brushes | Agitate and lift dirt and debris | Every 3-6 months |

| Filters | Trap dust and allergens | Every 1-3 months |

| Batteries | Power the device | Every 1-2 years |

| Wheels | Enable movement across various surfaces | As needed |

Impact of Regular Maintenance

Regular attention to these components can significantly enhance the overall effectiveness and longevity of automated cleaning devices. Timely replacements not only maintain optimal performance but also contribute to a better cleaning experience for users.

Tools for DIY Repairs

Undertaking repairs on household devices can be a rewarding experience, allowing individuals to save money and gain a deeper understanding of their appliances. To successfully carry out these repairs, having the right tools at your disposal is essential. This section explores various instruments that can enhance your repair efforts, making the process smoother and more efficient.

Essential Tools for Maintenance

When tackling repairs, certain instruments are fundamental for efficient and effective maintenance. Screwdrivers of various sizes and types are necessary to open device casings and access internal components. Pliers are invaluable for gripping, twisting, and cutting wires, while wrenches help tighten or loosen bolts securely. Additionally, a multimeter can be instrumental in diagnosing electrical issues, ensuring you identify problems accurately.

Specialized Repair Equipment

For more complex tasks, having specialized equipment can make a significant difference. Heat guns are useful for softening adhesives, while soldering irons enable you to connect electronic components effectively. Investing in a toolkit that includes these specialized items can prepare you for a wider range of repairs, enhancing your ability to restore functionality to various devices.

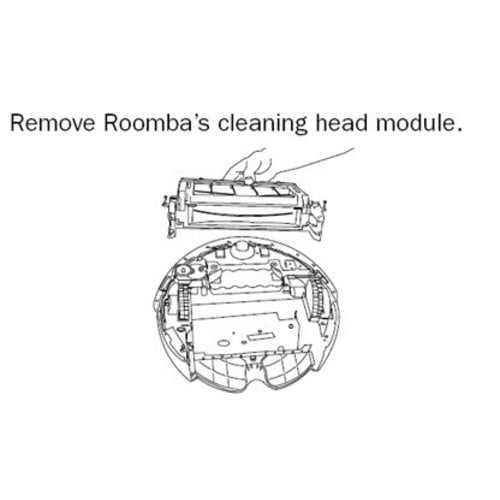

Assembly Process of Roomba

The assembly procedure of robotic vacuum cleaners involves several critical steps that ensure proper functionality and performance. Understanding these steps is essential for anyone looking to maintain or repair their automated cleaning device effectively.

Key Stages in the Assembly

- Preparation: Gather all necessary components and tools required for the assembly process.

- Component Inspection: Check each part for defects or damages before proceeding.

- Structural Assembly: Begin by assembling the main body and attaching the chassis components.

- Electrical Connections: Connect wires and sensors carefully, ensuring all connections are secure.

- Final Assembly: Attach outer casings and secure all screws to complete the assembly.

Post-Assembly Considerations

After the assembly is completed, it is crucial to perform several tests to verify that the device operates as intended. These checks can include:

- Running the unit to ensure it moves and navigates correctly.

- Testing the charging system to confirm it properly powers the device.

- Verifying that all sensors are functioning and responding to obstacles.

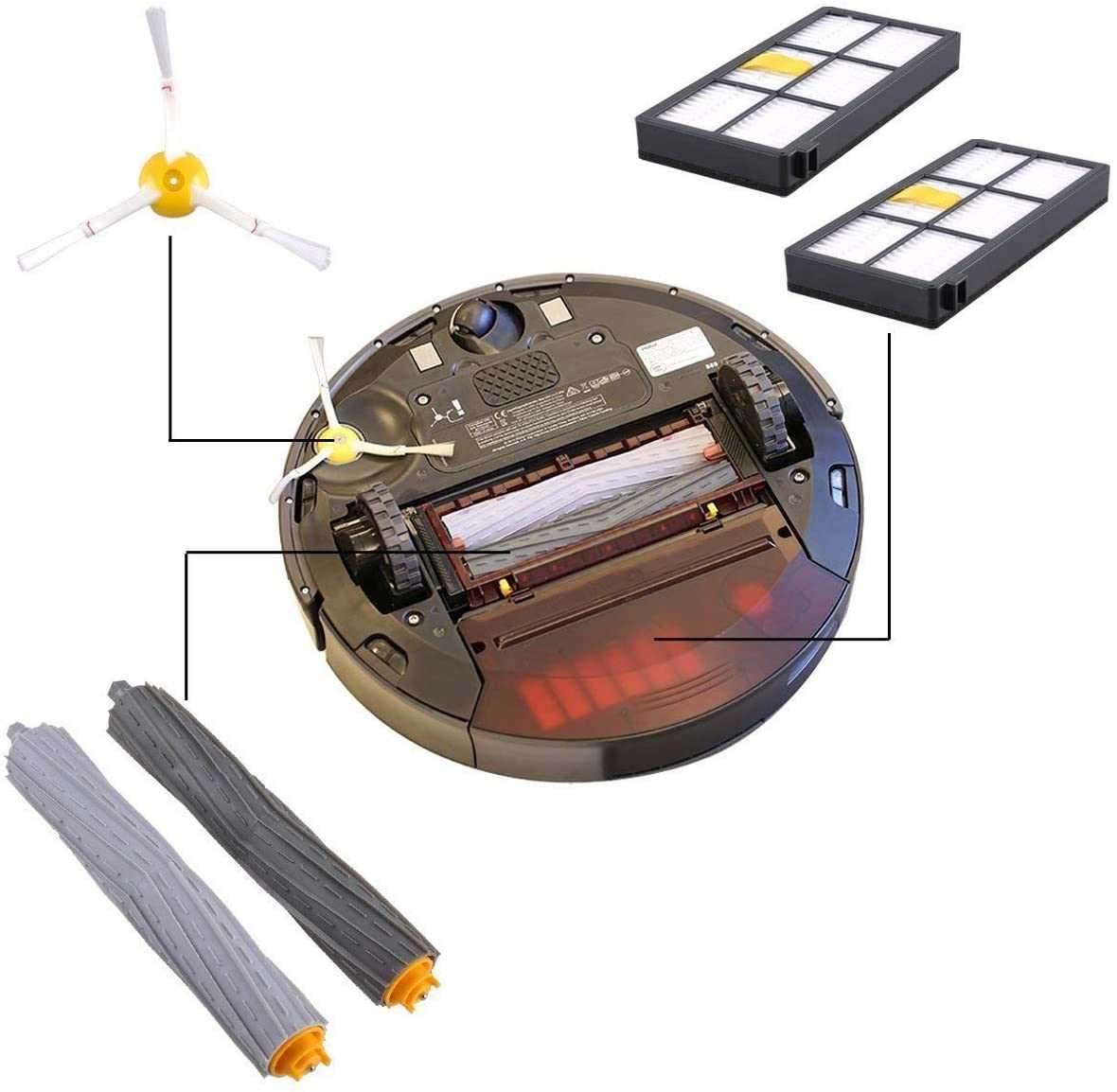

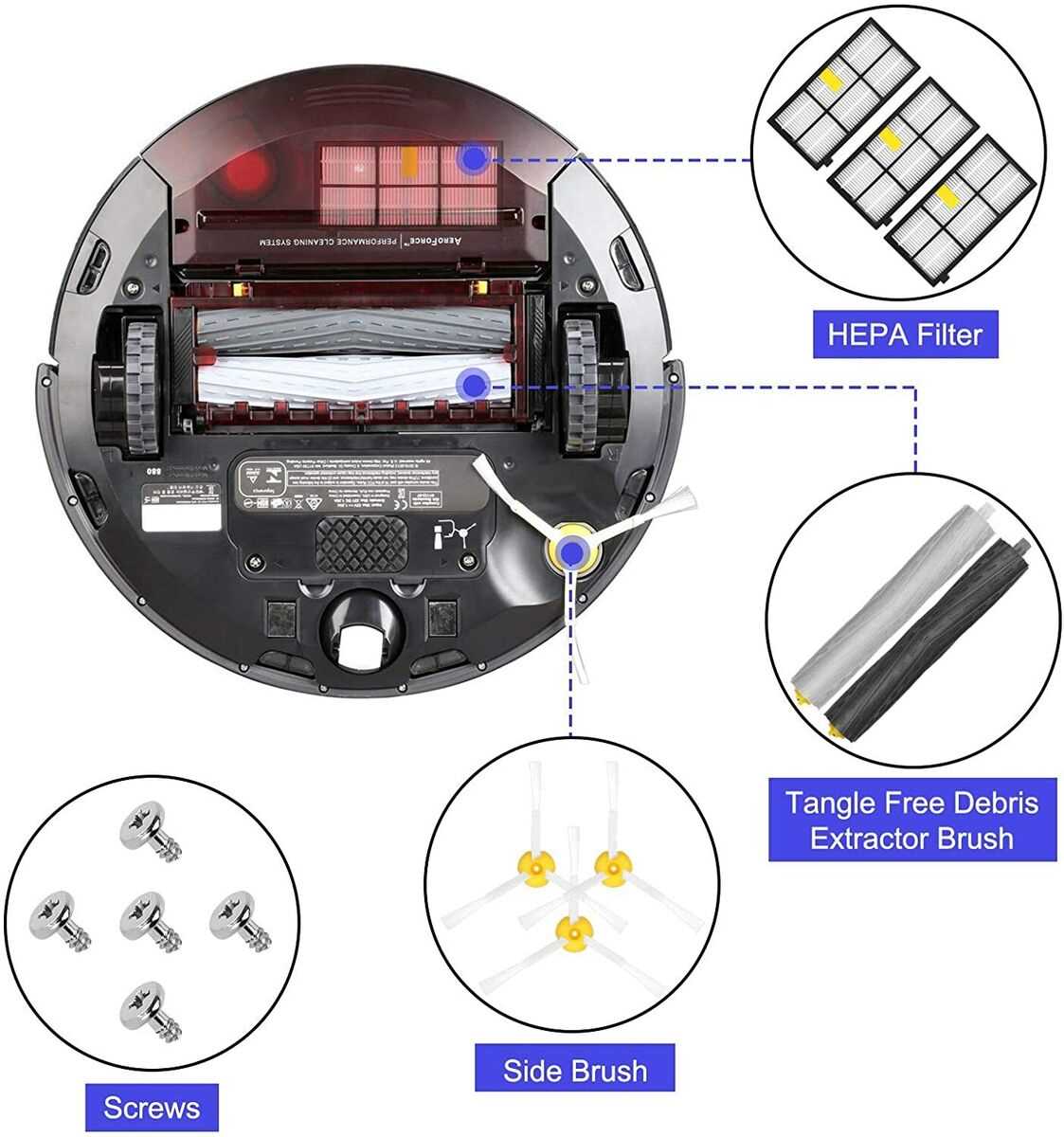

Diagram Analysis and Features

This section delves into the visual representation and structural components of a robotic cleaner. Understanding the arrangement and function of various elements can significantly enhance maintenance and troubleshooting processes. By analyzing the layout, users can identify critical parts, their interactions, and the overall design strategy.

Understanding Component Layout

Each segment plays a vital role in the machine’s performance. For instance, the mobility system, which includes wheels and brushes, is essential for navigation and cleaning efficiency. Identifying these components can aid in optimizing the unit’s effectiveness and addressing any operational issues that may arise.

Key Functional Elements

The representation also highlights key operational features, such as sensors and filtration systems. Advanced sensors enhance navigation and obstacle detection, while filtration mechanisms ensure effective dirt and allergen removal. Recognizing these functionalities allows users to appreciate the technology’s sophistication and the importance of regular upkeep.

Troubleshooting with Diagrams

Visual aids can significantly enhance the process of identifying and resolving issues in robotic cleaning devices. By utilizing schematics and illustrations, users can quickly pinpoint malfunctioning components and understand their interactions within the system.

When faced with operational challenges, referring to these visual guides allows for a more structured approach to diagnostics. Detailed illustrations can clarify complex assemblies, enabling users to isolate specific areas that may require attention or repair. Furthermore, these resources often include step-by-step instructions that simplify the troubleshooting process, ensuring a more efficient resolution.

Overall, leveraging these visual references not only facilitates problem-solving but also empowers users to maintain their cleaning devices effectively, prolonging their lifespan and enhancing performance.

Where to Find Spare Parts

Finding replacement components for your robotic cleaner can enhance its performance and longevity. Whether you need a new brush, filter, or battery, various resources are available to help you locate what you need.

- Official Manufacturer Website: Start with the official site, where you’ll find a wide selection of authorized accessories.

- Authorized Retailers: Many stores specialize in home appliances and may stock compatible items.

- Online Marketplaces: Websites like Amazon, eBay, and others offer numerous options from different sellers.

- Specialty Parts Stores: Look for stores that focus on home electronics, as they often carry specific items.

- Local Repair Shops: Sometimes, local technicians can provide the components you need or recommend reliable sources.

Before purchasing, ensure that the replacement is compatible with your specific model to guarantee optimal performance.

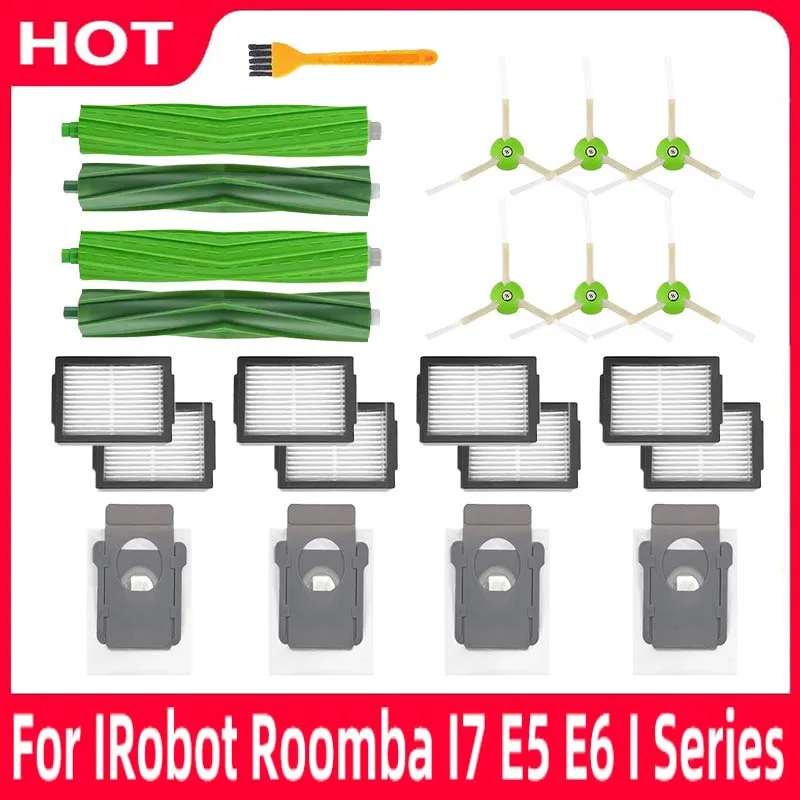

Enhancing Performance with Upgrades

Improving the efficiency of robotic cleaning devices can be achieved through various enhancements. These modifications not only extend the life of the unit but also significantly boost its overall functionality. By carefully selecting compatible components, users can experience improved suction power, better navigation capabilities, and longer operational times.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Filter Replacement | Using high-efficiency filters to trap more dirt and allergens. | Improved air quality and cleaning performance. |

| Battery Upgrade | Installing a higher-capacity battery for extended run time. | Longer cleaning sessions without recharging. |

| Brush Enhancements | Upgrading to specialized brushes designed for different surfaces. | Enhanced dirt pickup on carpets and hard floors. |

| Navigation Software | Updating or optimizing navigation algorithms for better pathfinding. | More efficient cleaning routes and less missed areas. |