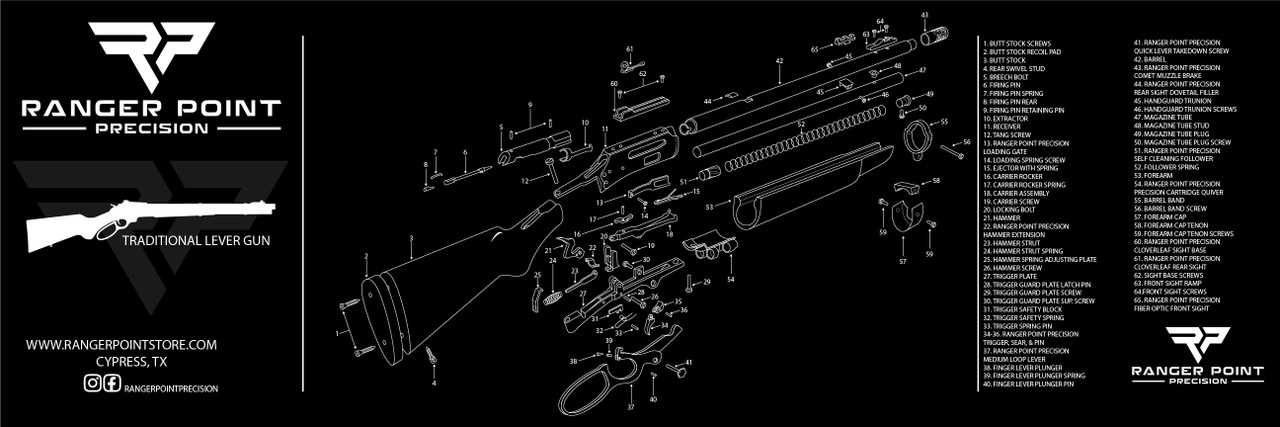

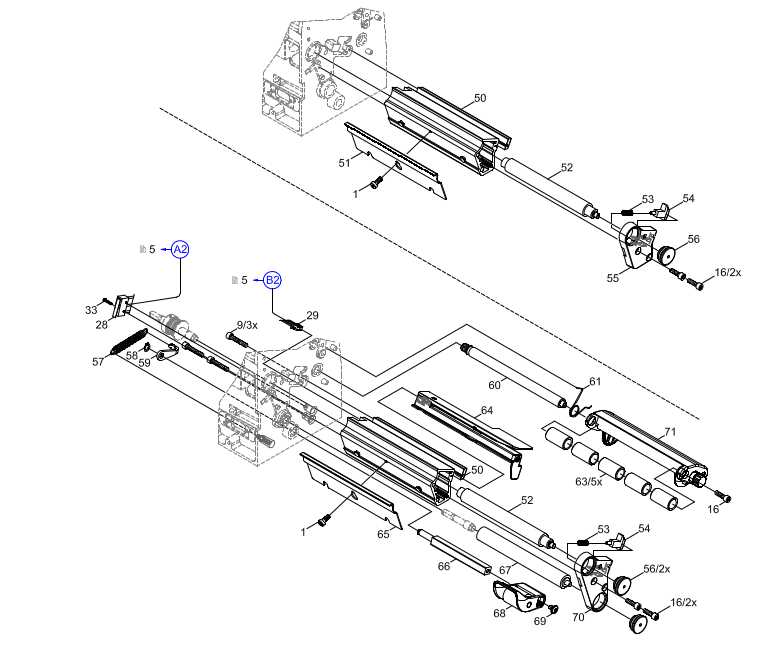

The exploration of firearm assembly is crucial for both enthusiasts and professionals. Understanding the arrangement of various elements within a specific model can greatly enhance maintenance and repair processes. This section aims to provide a clear representation of the key components involved.

In addition to facilitating effective repairs, familiarizing oneself with the configuration can lead to improved performance and longevity of the equipment. Each segment plays a vital role in the overall functionality, and recognizing these connections is essential for anyone involved in the handling or modification of such devices.

By delving into the intricate details of the arrangement, users can gain insights into potential upgrades or troubleshooting methods. Comprehensive knowledge of the various sections empowers individuals to make informed decisions regarding their equipment and enhances their overall experience.

When working with firearms, it’s crucial to be aware of potential challenges that can arise from various components. Understanding these issues can help maintain optimal performance and ensure safety during usage.

Here are some frequently encountered problems:

| Component | Common Issue | Possible Solution |

|---|---|---|

| Trigger Mechanism | Inconsistent release | Inspect for debris and lubrication |

| Loading System | Jamming during operation | Clean and check for wear |

| Firing Pin | Failure to strike | Examine for damage and replace if necessary |

| Sights | Misalignment | Adjust or recalibrate as needed |

Maintenance Tips for Rossi Firearms

Regular upkeep of your firearm is essential for optimal performance and longevity. By implementing a few simple maintenance practices, you can ensure that your weapon remains in excellent condition, ready for use whenever needed.

Cleaning Procedures

Maintaining cleanliness is critical to prevent buildup that can affect functionality. Follow these steps:

- Disassemble the firearm according to the manufacturer’s instructions.

- Use a soft brush and solvent to clean all metal surfaces.

- Ensure the bore and chamber are free from fouling.

- Wipe down exterior surfaces with a microfiber cloth.

Lubrication Guidelines

Proper lubrication helps to reduce friction and wear on moving parts. Adhere to the following tips:

- Apply lubricant sparingly to the action and moving components.

- Use high-quality gun oil suitable for your specific model.

- Remove excess oil to avoid attracting dirt and debris.

- Inspect lubrication regularly, especially before extended use.

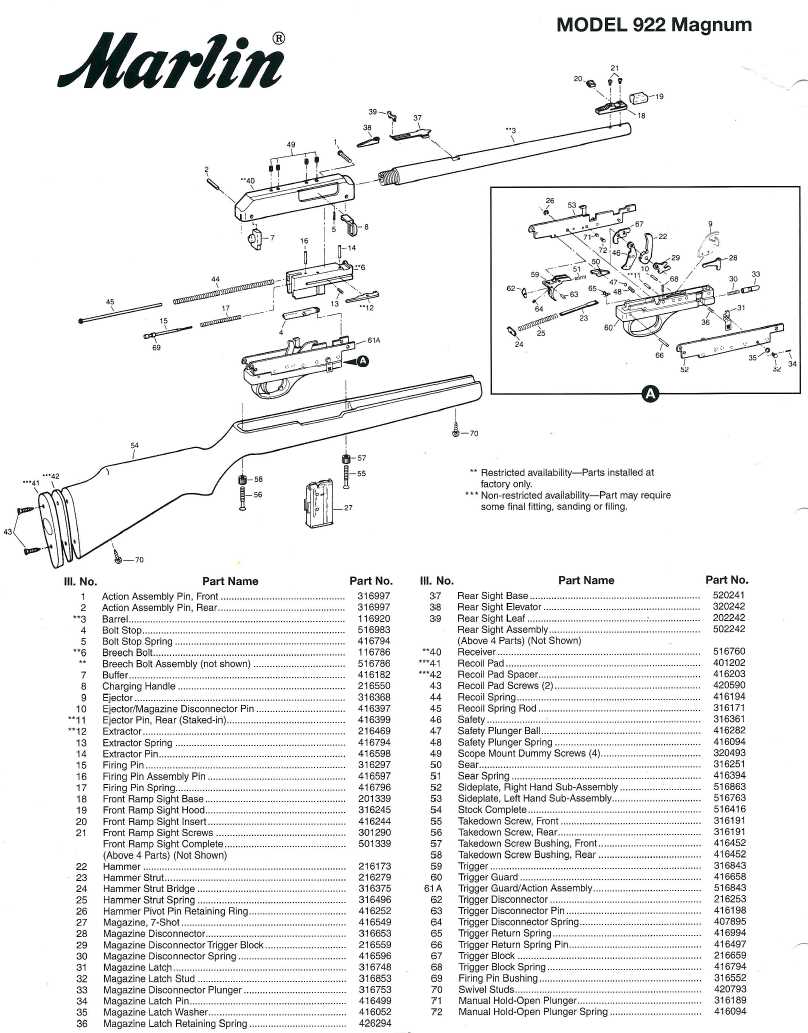

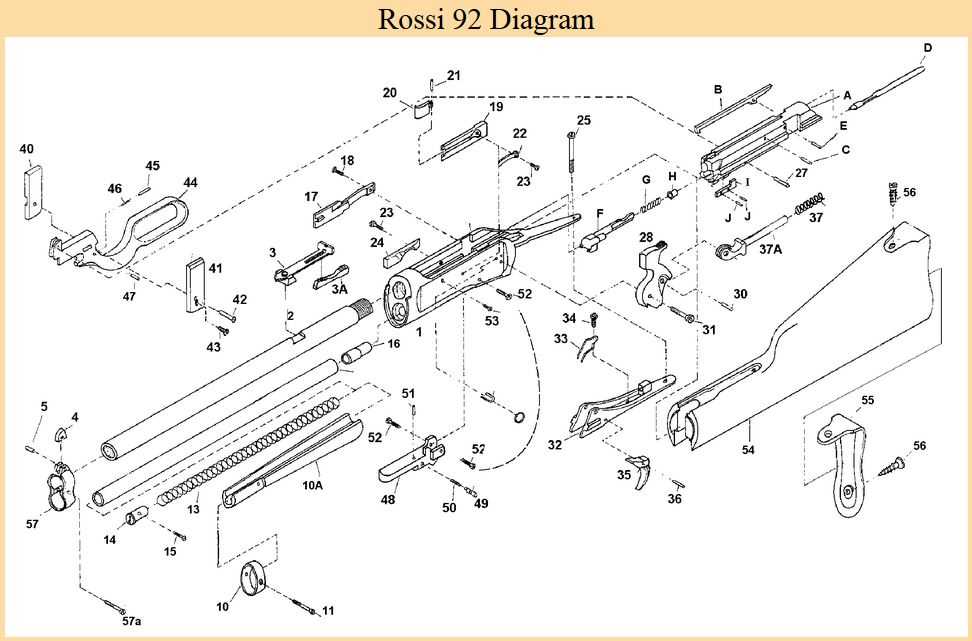

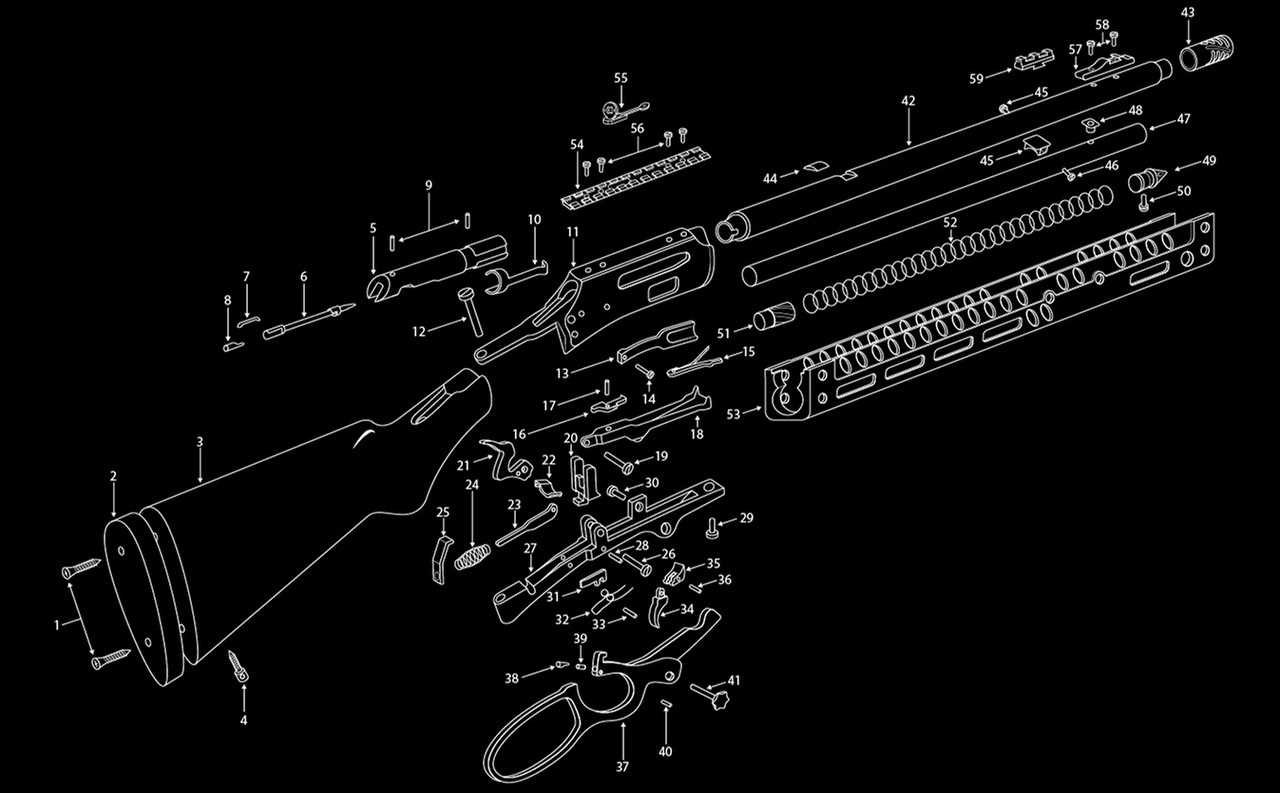

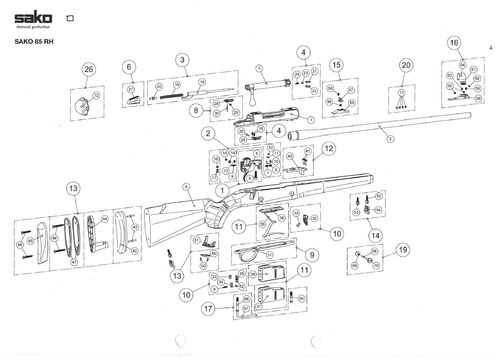

How to Identify Each Component

Understanding the various elements of a firearm is crucial for maintenance and repair. Each component plays a specific role, and recognizing them can enhance your knowledge and proficiency in handling the weapon.

Main Components to Recognize

- Barrel: The long tube through which the projectile travels.

- Trigger: The mechanism that initiates firing.

- Receiver: The central part housing the operating parts.

- Stock: The rear part that provides support and stability.

- Sights: Devices for aiming accurately at targets.

Tips for Identification

- Consult a reliable manual for detailed descriptions.

- Familiarize yourself with photographs of the firearm.

- Practice handling and disassembling the weapon safely.

- Join online forums to discuss and learn from experienced users.

Essential Tools for Disassembly

Disassembling a firearm requires a specific set of tools to ensure a smooth and safe process. Using the right equipment not only facilitates easier access to internal components but also helps prevent damage to the parts. Below are key tools that are commonly needed for disassembly.

- Screwdrivers: Various sizes and types, especially flathead and Phillips, are essential for removing screws without stripping them.

- Punches: A set of punches is useful for driving out pins and other fasteners that may be difficult to remove.

- Wrenches: An adjustable or fixed wrench can help with loosening nuts and bolts that hold various components together.

- Torque Wrench: This tool ensures that screws and bolts are tightened to the manufacturer’s specifications, preventing over-tightening.

- Bench Vise: A secure holding tool for stabilizing parts during disassembly, reducing the risk of slips and accidents.

- Cleaning Supplies: Cloths, brushes, and cleaning solvents are important for maintaining components after disassembly.

Having these tools on hand can significantly streamline the process of disassembling the firearm, allowing for efficient maintenance and repair.

Upgrading Parts for Improved Performance

Enhancing the components of your firearm can lead to significant gains in efficiency and overall functionality. By selecting high-quality replacements or upgrades, you can achieve a more reliable shooting experience, greater accuracy, and improved handling. This section will explore various upgrades that can help you maximize the performance of your weapon.

Key Areas for Upgrades

- Barrel: Consider upgrading to a precision barrel for improved accuracy.

- Trigger: A lighter and smoother trigger can enhance your shooting precision.

- Sights: Advanced optics or better iron sights can significantly aid target acquisition.

- Stock: Upgrading to a customizable stock can improve comfort and control.

Benefits of Upgrading

- Enhanced reliability during operation.

- Improved shooting comfort and ergonomics.

- Greater customization options to suit individual preferences.

- Potential for increased resale value with upgraded components.

Resources for Finding Spare Parts

Locating components for firearms can be a straightforward process if you know where to look. Various resources provide options for obtaining the necessary items, whether for maintenance or replacement purposes.

- Online Retailers: Websites specializing in firearm accessories often stock a wide range of components.

- Manufacturer Websites: Many producers offer direct sales or links to authorized dealers.

- Local Gun Shops: These establishments may carry essential items or can order them for you.

- Gun Shows: Attending events can provide opportunities to find both new and used items.

- Online Marketplaces: Platforms like eBay or GunBroker can have listings for various components from multiple sellers.

When searching, ensure to check the specifications to match the required items with your model to avoid compatibility issues.

DIY Repair Techniques for R92

Undertaking repairs on your firearm can be a rewarding endeavor, allowing you to enhance your skills while ensuring optimal performance. This section outlines various techniques that can be employed to effectively address common issues and maintain the functionality of your equipment.

Essential Tools for Repairs

Before beginning any repair work, it’s important to gather the necessary tools. Here’s a list of items that will facilitate the process:

- Screwdrivers (various sizes)

- Wrenches

- Cleaning supplies

- Lubricants

- Pliers

- Safety glasses

Common Repair Techniques

Employing the right techniques can simplify the repair process. Consider the following methods:

- Disassembly: Carefully take apart the components to access the internal mechanisms.

- Cleaning: Remove dirt and debris from the parts to prevent malfunction.

- Lubrication: Apply suitable lubricants to moving parts to ensure smooth operation.

- Replacement: Swap out any damaged components with new or refurbished ones.

- Reassembly: Reconstruct the firearm with attention to detail, ensuring all parts fit securely.

Safety Precautions During Maintenance

When performing maintenance on firearms, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions ensure that both the individual conducting the maintenance and others nearby remain unharmed throughout the process.

Always ensure that the firearm is unloaded before beginning any maintenance work. This step is crucial to avoid unintentional discharges. Double-check the chamber and magazine to confirm that no ammunition is present.

Wear appropriate protective gear, such as safety glasses and gloves, to shield yourself from potential debris or chemical exposure during cleaning or repairs. This equipment helps minimize the risk of injury and promotes a safer working environment.

It is also wise to work in a well-ventilated area, particularly when using cleaning solvents or lubricants. Inhalation of fumes can be harmful, so ensuring good airflow can mitigate health risks. Additionally, maintain a clutter-free workspace to reduce the likelihood of accidents.