In this section, we delve into the intricate components that form the essential framework of crucial equipment. Understanding these fundamental elements is key to comprehending their role in operational functionality.

Key Components: Each component plays a pivotal role in ensuring optimal performance. By examining these integral parts, we gain insight into their intricate designs and functional synergy.

Functionality Insights: Detailed analysis of these elements provides invaluable insights into their operational dynamics, illustrating their criticality in real-world applications.

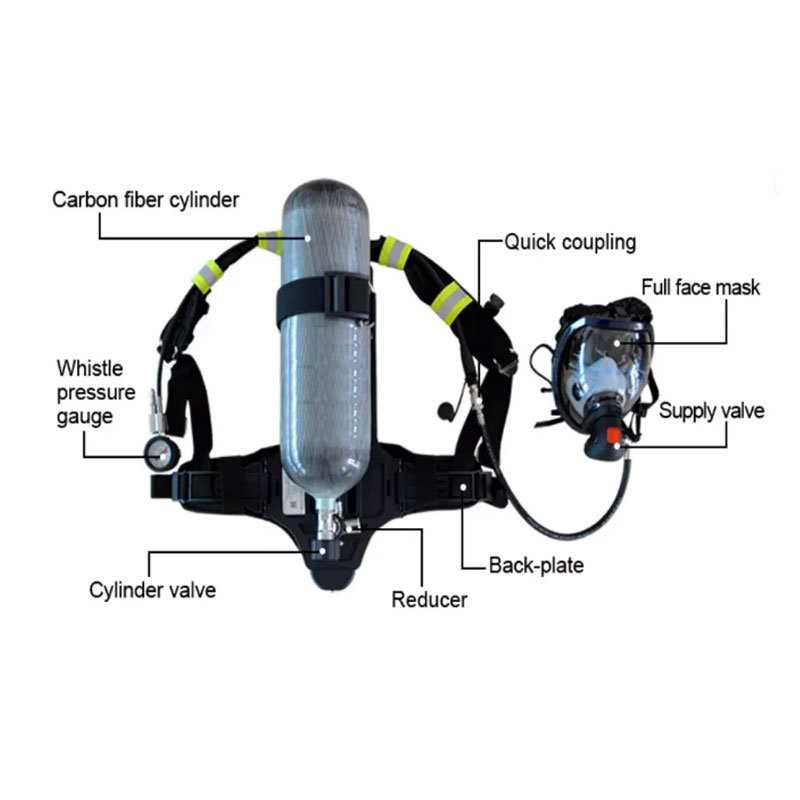

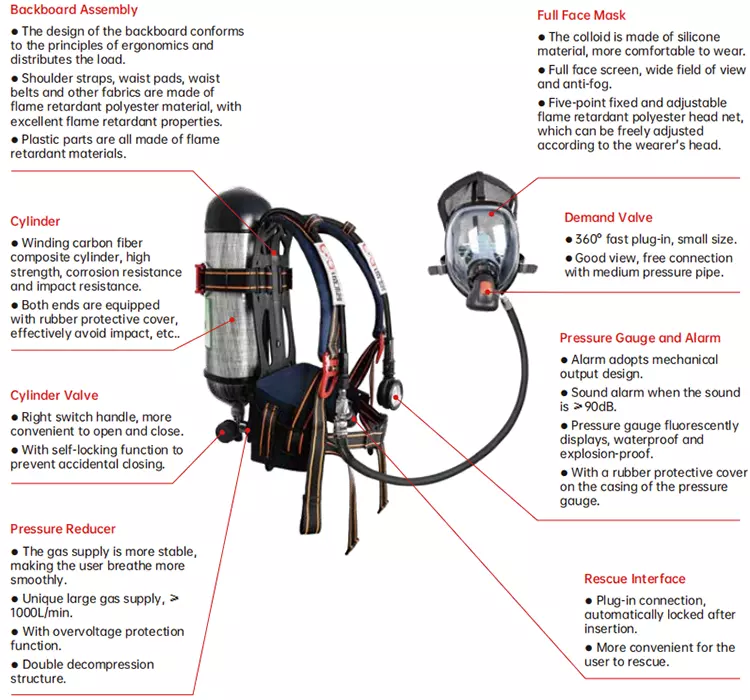

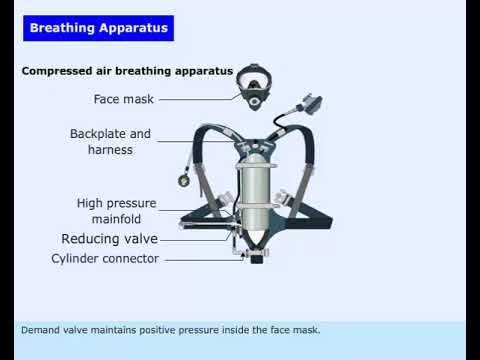

Overview of Breathing Apparatus Components

The effectiveness of a breathing apparatus relies on the careful integration of its various components. Each element serves a specific function, contributing to the overall safety and efficiency of the equipment. Understanding these components is essential for users to operate the apparatus effectively and to ensure their protection in hazardous environments.

Key Elements of the Device

At the core of the device is the air supply mechanism, which stores breathable air under pressure. This component is typically constructed from durable materials to withstand extreme conditions. Connected to this is a pressure regulator, which ensures that air is delivered at a safe and manageable rate. The mask, another critical component, provides a secure fit over the face, allowing for optimal airflow while protecting the user from contaminants.

Safety Features

Additionally, advanced breathing apparatuses may include features such as pressure gauges and alarms. The pressure gauge allows users to monitor the air supply, while alarms provide warnings when air levels are low, enhancing user safety. Each of these components works in unison, forming a reliable system designed to safeguard individuals operating in dangerous situations.

Main Features of Self-Contained Breathing Apparatus Systems

In exploring the functionality and components of modern respiratory protection systems, it is crucial to delve into their core attributes and operational capabilities. These devices are designed to ensure the safety and survival of individuals in hazardous environments, offering essential respiratory support through a combination of advanced technologies and robust construction.

Advanced Respiratory Support

One of the primary functionalities of these systems revolves around providing advanced respiratory support in environments where breathable air is compromised. This capability is achieved through a sophisticated network of components that work together seamlessly to filter and deliver clean air to the user.

Durable Construction and Ergonomic Design

Another key feature lies in their durable construction and ergonomic design, which enhances comfort and mobility for the wearer during prolonged use. These systems are crafted from high-strength materials and engineered with ergonomic considerations to minimize user fatigue and optimize performance in demanding conditions.

Key Functions of the Air Cylinder

The core of any breathing apparatus lies in its ability to store and deliver breathable gas under high pressure. One of the most critical elements in this system is the container that ensures a continuous flow, providing users with the necessary supply during demanding conditions.

Storage of Compressed Gas

The primary purpose of the cylinder is to securely hold a large volume of pressurized air. This allows individuals to perform tasks in hazardous environments, relying on the cylinder for extended periods without requiring frequent refills. The high-pressure design ensures maximum efficiency in gas storage.

Controlled Release Mechanism

Equally important is the mechanism that regulates the release of air. The cylinder is equipped with a valve system that ensures a steady and safe output, allowing users to breathe comfortably while maintaining control over the available supply. This ensures that the gas is delivered at a manageable rate to meet the needs of the situation.

Understanding the Role of the Face Mask

The face mask is a critical component designed to protect the individual in challenging environments. It ensures safe breathing by isolating the respiratory system from harmful substances in the surrounding air. This essential equipment provides comfort and security, allowing for extended periods of use in hazardous conditions.

There are several key features that contribute to the functionality of the mask:

- Sealing mechanism: Ensures an airtight fit to prevent contaminants from entering.

- Clear visor: Provides unobstructed visibility while maintaining durability and protection.

- Exhalation valve: Facilitates easy removal of exhaled air without compromising the internal pressure.

- Adjustable straps: Allows the user to customize the fit for comfort and safety.

By understanding these components, users can maximize the effectiveness of this equipment in various environments, ensuring both safety and functionality.

Importance of the Pressure Regulator

The pressure regulator is an essential component in systems that involve controlled air distribution. Its role is to manage the flow and maintain a steady output, ensuring that users receive the correct amount of air during critical moments. Without precise regulation, both safety and performance could be compromised.

Maintaining Optimal Flow

A well-calibrated regulator ensures consistent flow, preventing any sudden spikes or drops in pressure. This is vital for users who rely on a steady and safe supply in high-risk environments. By maintaining balance, it promotes both efficiency and safety.

Protection Against Overpressure

The pressure regulator also plays a protective role by preventing dangerous overpressurization. It reduces potential damage to other connected components and protects users from receiving an overwhelming surge of air, which could result in injury or equipment failure.

Valve Mechanisms and Their Operation

In the intricate workings of respiratory equipment, valve mechanisms play a pivotal role in regulating airflow and ensuring safety during operation. These mechanical components, essential for controlling the direction and intensity of gases, operate with precision and reliability. Understanding their function is crucial for grasping the dynamics of air circulation within the system.

Valves employ various methods to manage gas flow, utilizing mechanisms that range from simple ball and check valves to more complex rotary and solenoid valves. Each type offers distinct advantages in terms of efficiency and responsiveness, tailored to specific operational needs. Their operation involves intricate movements and interactions, ensuring seamless transitions between intake, exhaust, and standby modes.

Efforts in design focus on enhancing durability and minimizing maintenance, critical factors in ensuring operational readiness and longevity. Engineers continually innovate to refine valve mechanisms, integrating advanced materials and manufacturing techniques to optimize performance under diverse environmental conditions.

Hose Connections and Airflow Control

The system of hose attachments and airflow management plays a crucial role in ensuring the proper delivery of breathable gas to the user. These components are designed to create a seamless flow, connecting the various elements that regulate the safe transmission of air through the system.

Hose connections are typically reinforced to prevent leaks or disconnections, ensuring a secure path for the gas. They are engineered to handle high pressure and are built with user safety in mind, featuring quick-release mechanisms for emergencies.

Airflow control mechanisms are integrated to adjust the rate and volume of the gas, providing flexibility to suit different operational needs. These controls often include manual or automatic regulators that maintain consistent flow, adapting to environmental conditions and user activity.

Exploring the Monitoring and Alarm Devices

In this section, we delve into the essential components designed to oversee and alert in critical scenarios. These devices play a crucial role in maintaining safety and operational integrity, providing real-time feedback and warnings.

Functionality Overview

- Monitoring units: Devices responsible for continuous observation and data collection.

- Alarm systems: Mechanisms that signal anomalies or hazardous conditions through audible, visual, or tactile alerts.

- Data interfaces: Connectors facilitating communication between monitoring devices and external systems.

These instruments serve as vigilant guardians, employing advanced sensing technologies to detect variations in environmental parameters. They are pivotal in safeguarding personnel and optimizing operational protocols in dynamic environments.

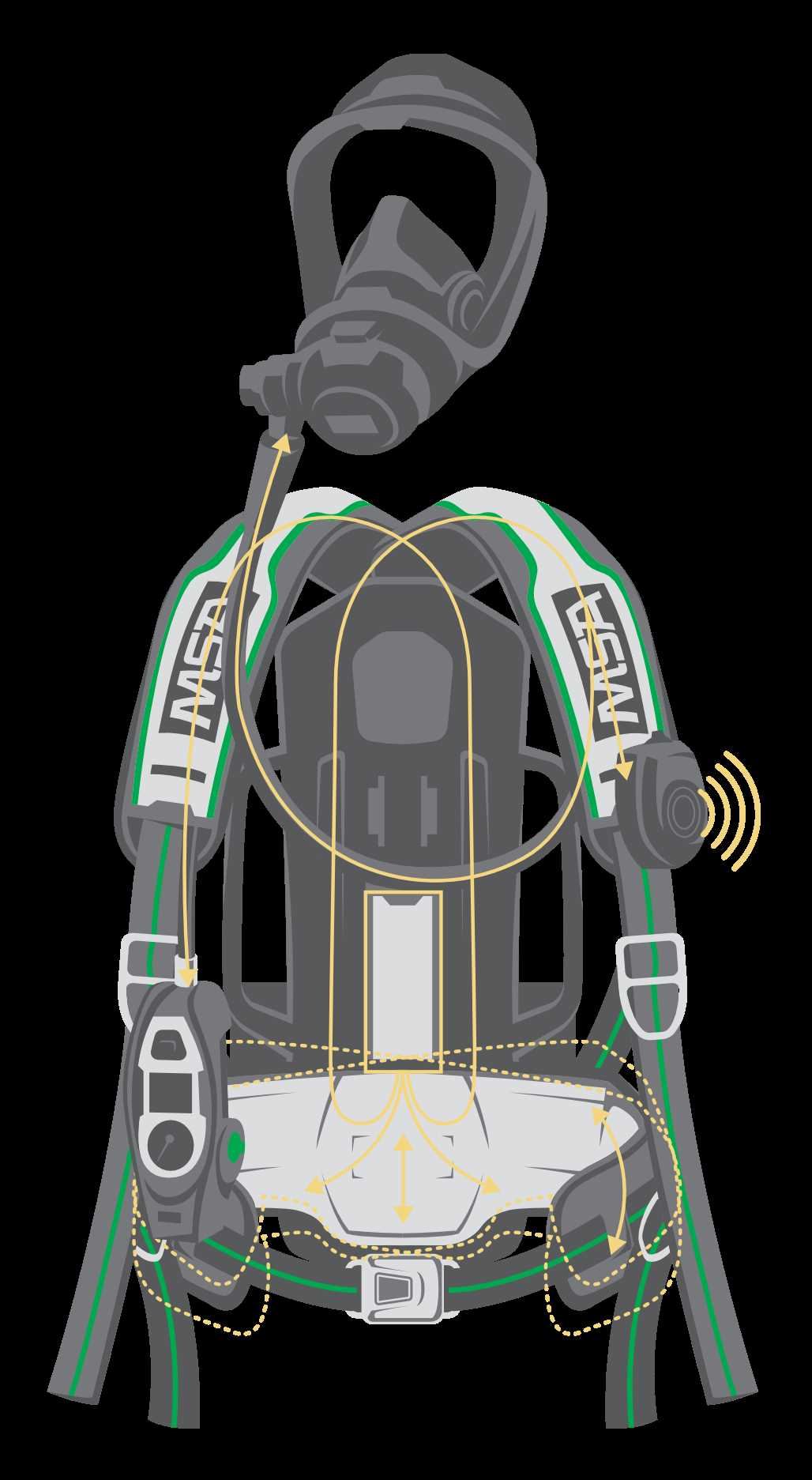

Backplate and Harness System Explained

The backplate and harness system serves as the foundation for secure and efficient equipment wear during demanding tasks. This setup provides essential support, distributing weight evenly across the user’s body, ensuring both comfort and mobility. The structure is designed to reduce strain, allowing for prolonged use without compromising safety or performance.

Durability and Comfort are key features of the system. The materials used are rugged yet ergonomic, combining resilience with ease of movement. Adjustable straps and pads enhance personalization, allowing users to fit the system according to their specific body needs and preferences.

The connection points ensure reliable attachment of other gear, creating an integrated solution that supports a wide range of activities. This combination of strength and adaptability makes the system ideal for a variety of environments.

Maintenance and Care for SCBA Parts

Proper upkeep of essential breathing equipment is crucial for ensuring reliability during operation. Regular inspections and cleaning can significantly extend the lifespan of various components, reducing the likelihood of failure when the device is most needed. Attention to detail and routine care are key in maintaining functionality.

Inspection Routine

It is important to perform frequent visual checks on critical components to identify any signs of wear, damage, or contamination. Particular attention should be paid to connections, seals, and fasteners to ensure they are secure and free from deterioration.

Cleaning and Storage

Thorough cleaning after each use helps prevent contamination and buildup that could compromise performance. Mild detergents and soft brushes are typically recommended for removing debris from exterior surfaces. Proper drying and storage in a controlled environment will further ensure the equipment remains in optimal condition for future use.

| Component | Maintenance Frequency | Recommended Care |

|---|---|---|

| Facepiece | After each use | Wash with mild soap, rinse, and air dry |

| Key Safety Aspect | Description |

|---|---|

| Pre-use Inspection | Ensure all components are intact and functioning before entering hazardous environments. |

| Maintenance Schedule | Follow a strict maintenance routine to identify wear or damage that could compromise safety. |

| User Training | Comprehensive training is mandatory to familiarize personnel with the correct handling and emergency protocols. |