When it comes to maintaining and repairing outdoor machinery, having a clear visual reference of the various elements is essential. A comprehensive overview not only aids in identification but also enhances the efficiency of troubleshooting and servicing tasks.

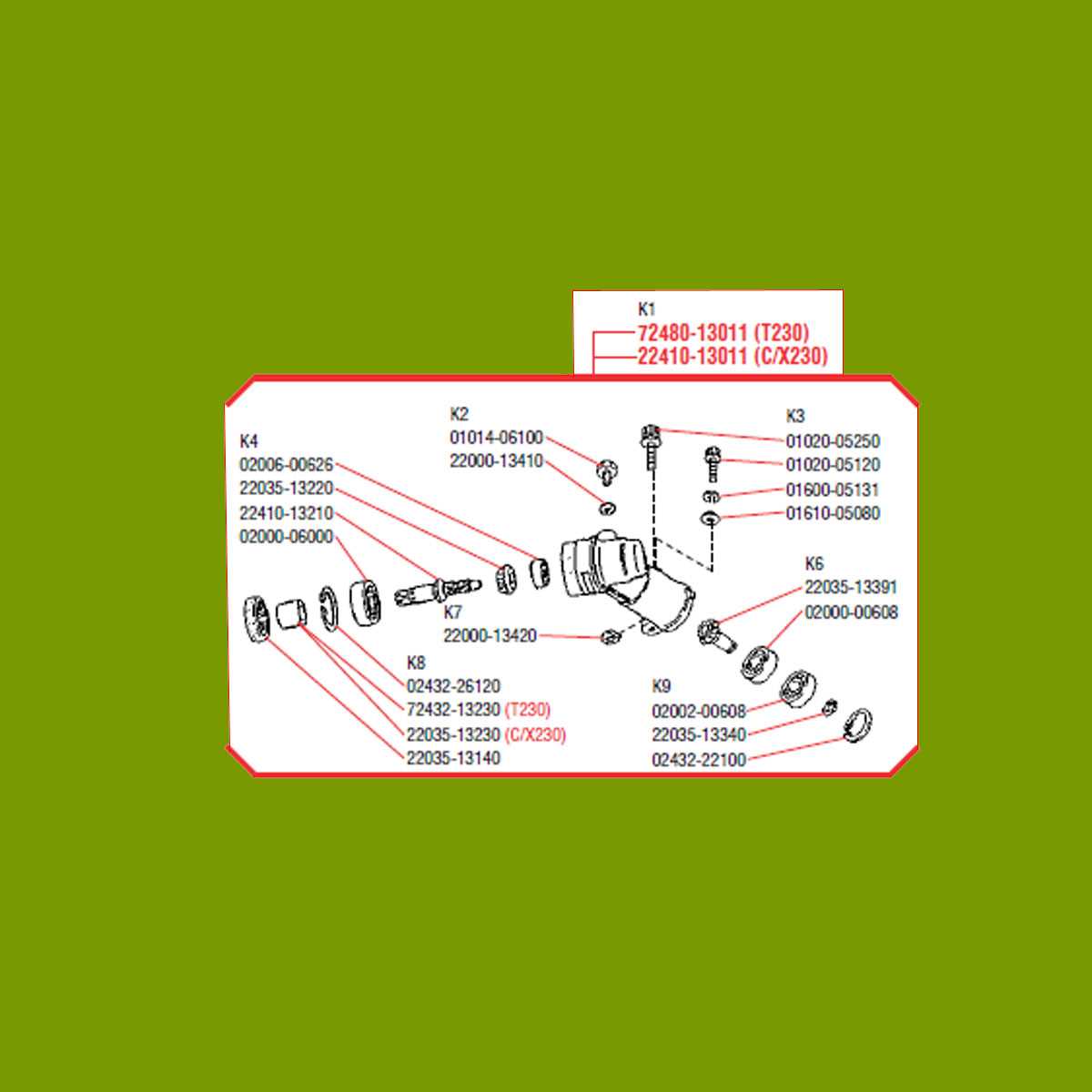

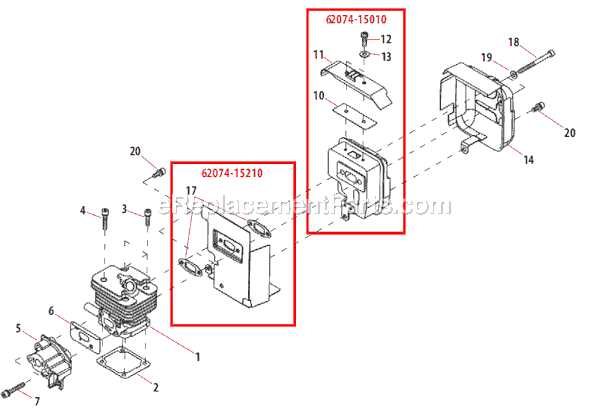

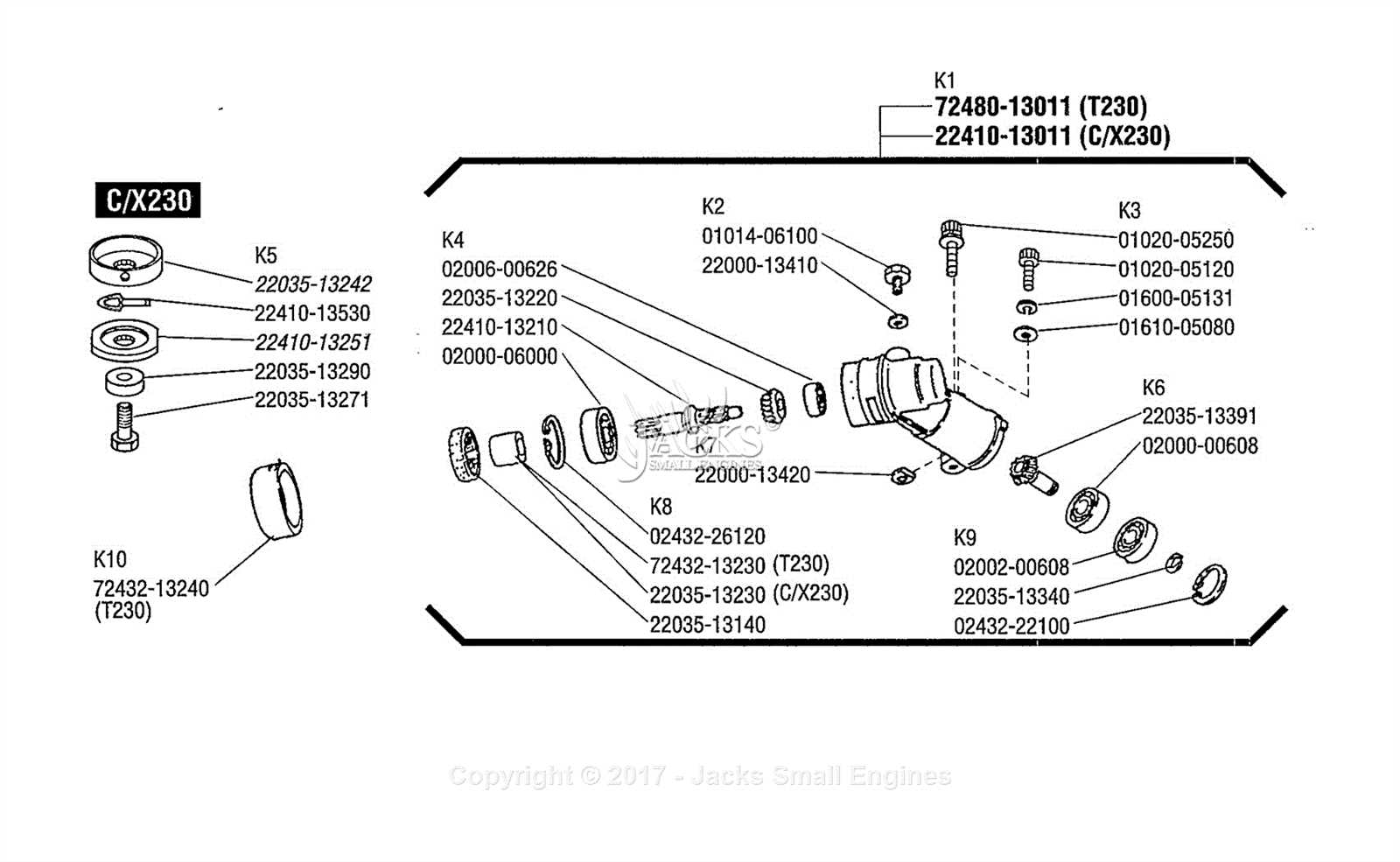

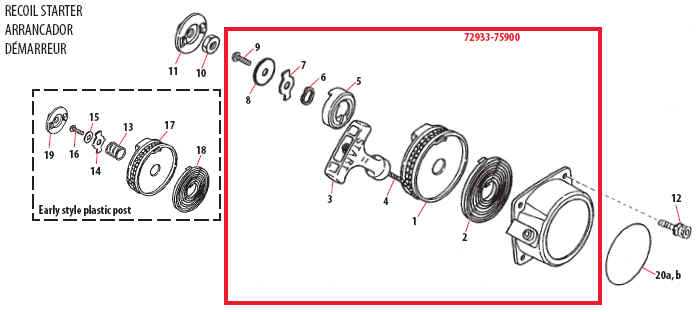

Visual representations serve as invaluable tools for both novice and experienced users, allowing them to navigate through the intricate assembly of their equipment. By breaking down the components into understandable segments, one can easily locate and replace parts as needed.

In this section, we will explore the intricate layout of components related to specific models, ensuring that users are well-equipped with the knowledge necessary for effective maintenance. The ultimate goal is to facilitate a smoother experience in both understanding and managing outdoor tools.

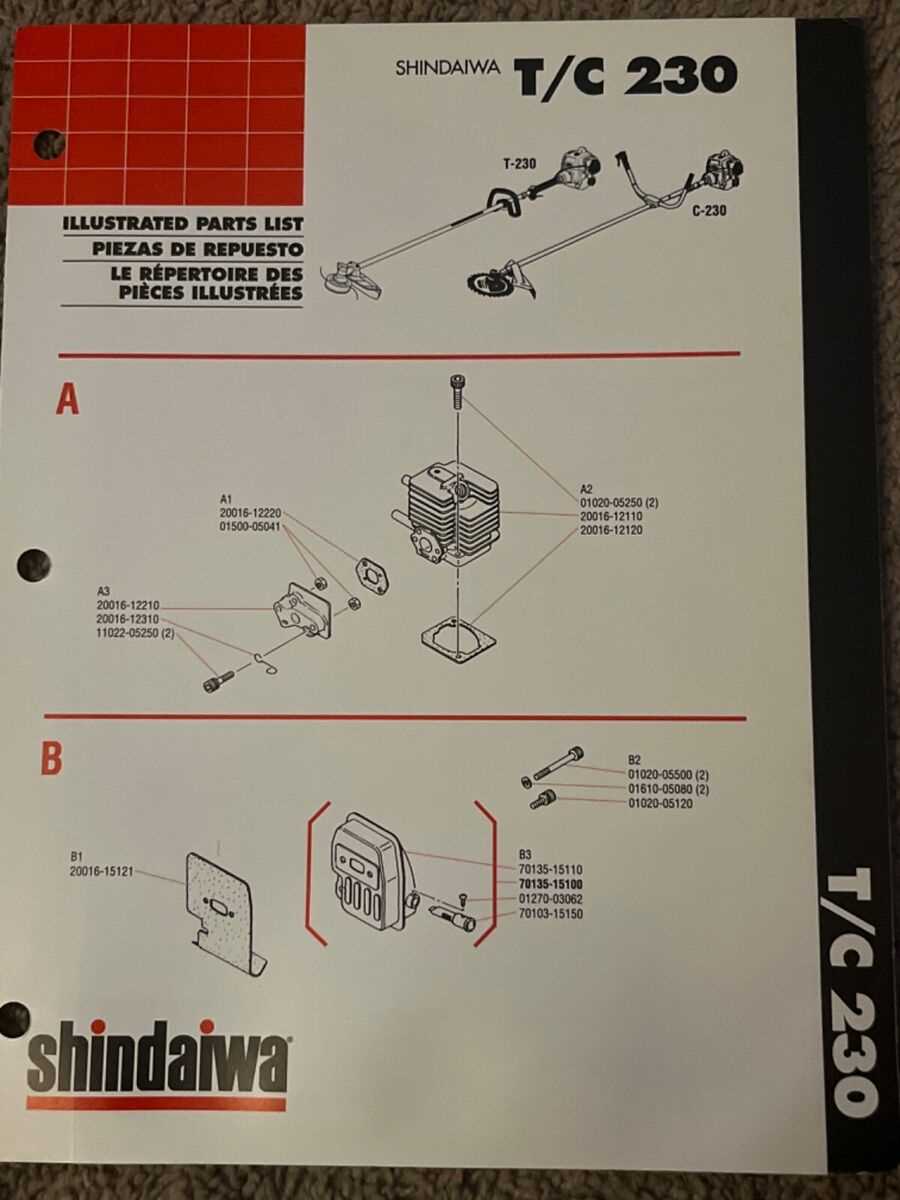

Understanding Shindaiwa T230X Components

Grasping the various elements of a gardening tool is essential for efficient maintenance and operation. Each component plays a significant role in the overall functionality and performance, contributing to the machine’s reliability and effectiveness in outdoor tasks.

When examining these essential elements, it is helpful to categorize them into several groups:

- Engine Components:

- Piston

- Cylinder

- Carburetor

- Cutting Mechanisms:

- Blades

- Trimmer Line

- Head Assembly

- Fuel System:

- Fuel Tank

- Filter

- Fuel Lines

- Starting Mechanism:

- Starter Rope

- Recoil Starter

- Ignition Coil

Understanding these classifications can aid in troubleshooting and repairs, ensuring that each component functions harmoniously within the system. Regular maintenance of these individual parts is crucial for extending the life of the tool and enhancing its performance.

Key Features of T230X Model

The model in question stands out due to its exceptional design and performance characteristics. Engineered for versatility, it caters to a range of outdoor tasks, making it an ideal choice for both professional landscapers and home enthusiasts.

One of its defining attributes is the lightweight construction, which enhances maneuverability while reducing operator fatigue. Coupled with an ergonomic handle, it ensures a comfortable grip during extended use, promoting efficiency and ease of handling.

Another significant feature is the powerful engine, which delivers impressive performance without compromising fuel efficiency. This balance enables users to tackle demanding jobs while minimizing downtime for refueling.

The user-friendly starting mechanism simplifies operation, allowing for quick ignition even in challenging conditions. Additionally, the durable materials used in its construction contribute to longevity and reliability, ensuring that it can withstand rigorous outdoor use.

Finally, compatibility with a variety of attachments expands its functionality, making it a versatile tool for a wide range of applications, from trimming to edging, thereby enhancing its value for any user.

Importance of Parts Diagrams

Understanding the intricate details of any mechanical system is crucial for effective maintenance and repair. Visual representations play a vital role in comprehending how various components interact and fit together. These illustrations serve not only as guides but also as essential tools for troubleshooting and ensuring optimal performance.

Clarity and Precision: Having a clear visual reference allows technicians and enthusiasts to identify specific elements quickly, reducing the chances of errors during repairs.

Enhanced Efficiency: With a detailed visual aid, individuals can streamline their processes, saving time and effort when disassembling or reassembling machinery.

Furthermore, such resources can aid in the identification of wear and tear, prompting timely replacements and preventing larger issues down the line. Ultimately, these visual tools contribute to the longevity and reliability of equipment.

Common Issues with T230X Parts

When working with outdoor power equipment, various complications can arise that affect performance and longevity. Understanding these challenges can aid in effective troubleshooting and maintenance.

- Fuel-related Problems

- Clogs in the fuel lines

- Improper fuel mixture

- Starting Difficulties

- Worn-out ignition components

- Weak spark plug connections

- Mechanical Wear and Tear

- Damaged bearings

- Worn blades or cutting attachments

- Vibration Issues

- Loose screws and fasteners

- Unbalanced components

Addressing these common issues promptly can significantly enhance the efficiency and lifespan of the equipment.

How to Read Parts Diagrams

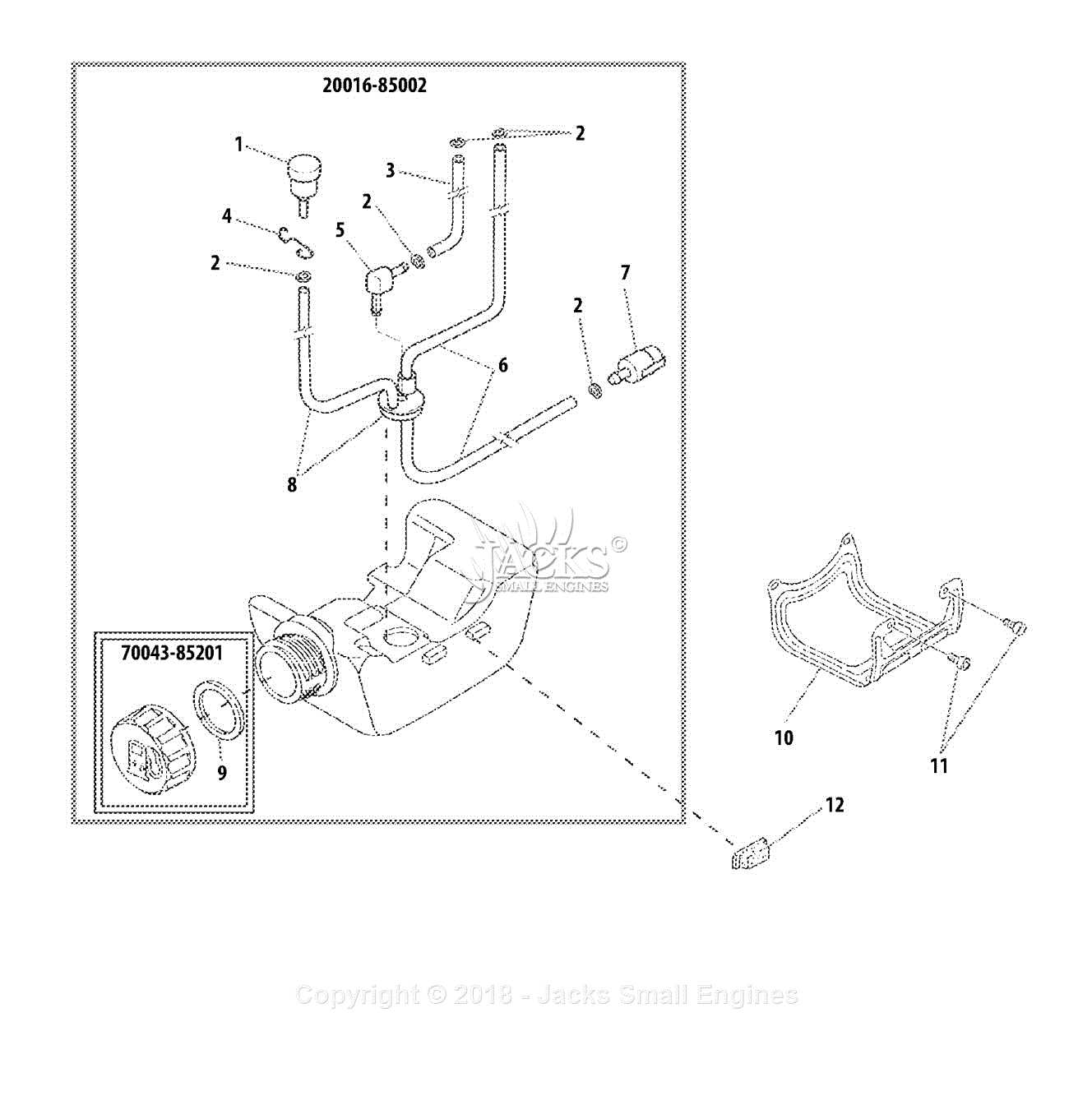

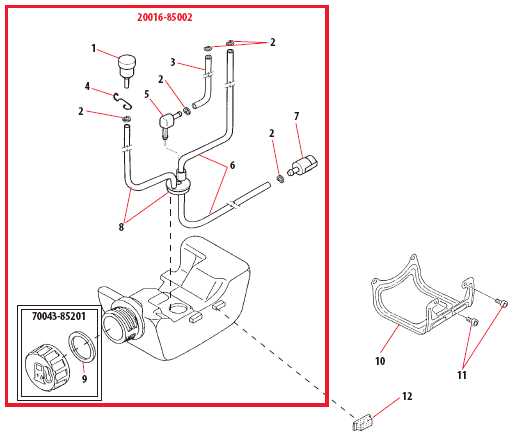

Understanding visual schematics is essential for effective maintenance and repair of equipment. These illustrations provide a clear representation of components and their relationships, aiding users in identifying necessary elements for replacement or servicing. Familiarity with the layout and symbols used can significantly streamline the troubleshooting process.

To effectively interpret these visuals, follow these key guidelines:

| Step | Description |

|---|---|

| 1 | Identify the Main Sections: Begin by recognizing the primary divisions in the illustration, which typically categorize parts based on their function or location. |

| 2 | Locate Individual Components: Zoom in on specific elements, noting their labeling and how they connect with others. This helps in understanding the assembly and disassembly process. |

| 3 | Refer to the Legend: If available, consult the accompanying legend or key that explains any symbols, numbers, or color codes used in the schematic. |

| 4 | Understand Relationships: Pay attention to how components interact. Arrows or lines often indicate connections or flows, which are crucial for proper installation. |

| 5 | Cross-Check with Manuals: Use the manufacturer’s manuals alongside the visuals for detailed information on specifications, installation tips, and maintenance procedures. |

Mastering these steps will enhance your ability to navigate these essential tools, making repairs more efficient and informed.

Ordering Replacement Parts Effectively

When it comes to acquiring necessary components for your equipment, a systematic approach can save both time and resources. Understanding the specific requirements and having a clear plan can streamline the procurement process.

Research is crucial. Begin by gathering information about the model and specifications of the item you need to repair. This ensures compatibility and prevents errors in your order.

Utilize reputable sources. Choose suppliers known for their reliability and quality. Reading reviews and comparing prices can help you find the best options available.

Keep track of your orders. Maintain a record of what you’ve ordered, along with any tracking information. This helps manage expectations regarding delivery times and ensures you receive what you need.

By following these guidelines, you can effectively navigate the process of obtaining the right components, ensuring your equipment remains in optimal condition.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention not only enhances performance but also minimizes the risk of unexpected failures. By following a consistent maintenance routine, you can enjoy reliable operation and reduce the need for costly repairs.

- Regular Cleaning: Keep the exterior and accessible internal components free from dirt and debris. This prevents overheating and maintains optimal performance.

- Routine Inspections: Periodically check for wear and tear. Look for signs of damage or excessive wear on critical components.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear.

- Fuel Quality: Use high-quality fuel and ensure it is fresh. Contaminated or stale fuel can lead to engine issues.

- Air Filter Maintenance: Regularly inspect and clean or replace the air filter to ensure efficient airflow and prevent dirt from entering the engine.

Following these guidelines will not only enhance performance but also prolong the useful life of your machinery, allowing you to maximize your investment.

Tools Required for Repairs

When it comes to performing maintenance or repairs on equipment, having the right tools at your disposal is crucial for a successful outcome. The appropriate instruments not only facilitate the process but also ensure that the job is done efficiently and safely. Understanding the necessary gear can help streamline your work and enhance your overall experience.

Essential Hand Tools

Basic hand tools are fundamental for any repair task. A set of screwdrivers, both flathead and Phillips, is vital for accessing various components. Wrenches in different sizes will aid in loosening or tightening bolts and nuts. Pliers, particularly needle-nose and slip-joint types, can help grip and manipulate small parts effectively. Additionally, having a sturdy utility knife and a set of hex keys will be beneficial for more intricate tasks.

Power Tools and Equipment

In some cases, power tools can significantly speed up the repair process. A cordless drill can be invaluable for driving screws and drilling holes. A reciprocating saw or a circular saw may be required for cutting through tougher materials. Furthermore, a torque wrench is essential for ensuring that fasteners are tightened to the correct specifications. Always prioritize safety by using protective gear, such as gloves and goggles, when working with power tools.

Comparing T230X with Other Models

When evaluating various tools in the same category, it’s essential to identify key differences and similarities that may impact performance and usability. This comparison allows users to make informed decisions based on specific features and capabilities, ultimately guiding them toward the most suitable option for their needs.

The examined model offers a balance of power and efficiency, making it ideal for light to medium tasks. In contrast, other models might emphasize heavier-duty applications, providing increased horsepower but often at the cost of maneuverability. Users seeking a lightweight solution will appreciate the design of this particular model, which prioritizes ease of use without sacrificing essential functionality.

Moreover, while some alternatives may incorporate advanced technology for enhanced performance, this model remains a favorite due to its reliability and straightforward maintenance requirements. Users often find that simplicity in design can lead to greater longevity and less downtime, making it a practical choice for various applications.

Ultimately, the decision will depend on individual preferences and specific job demands. A thorough comparison highlights not only the strengths of this model but also the potential advantages of others, ensuring users can select the best tool for their unique tasks.

Customer Reviews and Feedback

This section highlights the opinions and experiences of users regarding their recent purchases. Feedback is essential for understanding the quality and functionality of equipment, helping potential buyers make informed decisions.

Overall Satisfaction

Many users express a high level of satisfaction with their devices, noting reliability and performance as key factors. The combination of durability and ease of use has earned positive remarks from a diverse range of customers.

Common Concerns

While most reviews are favorable, some customers mention issues with specific components. Timely maintenance and occasional replacements have been cited, but overall, users appreciate the long-term value and effectiveness of their investments.

Where to Find Parts Diagrams Online

Locating technical illustrations for equipment can greatly aid in maintenance and repairs. Fortunately, various resources are available online to assist users in accessing these valuable visual guides.

- Manufacturer Websites: Official sites often host detailed visuals for their products, ensuring accuracy and reliability.

- Online Retailers: E-commerce platforms frequently provide manuals and illustrations alongside product listings.

- Forums and Community Groups: Engaging with user communities can lead to shared resources and helpful insights.

- Service Manuals: Many websites specialize in archiving manuals and technical documents that include detailed images.

Utilizing these resources can streamline the process of finding necessary information, ultimately enhancing the repair experience.