In the realm of cleaning solutions, having a thorough comprehension of the internal elements is essential for effective maintenance and repair. This knowledge not only enhances the longevity of the device but also ensures optimal performance during usage. A well-structured visual representation can greatly assist users in identifying and understanding these crucial components.

By delving into the intricate layout of the cleaning apparatus, individuals can gain insights into how each element interacts within the system. Such insights are invaluable for troubleshooting issues and executing repairs. Whether one is a seasoned technician or a novice user, familiarizing oneself with these fundamental components fosters confidence in managing any challenges that may arise.

Moreover, understanding the configuration of these elements promotes efficient usage, enabling users to harness the full potential of their equipment. This exploration serves as a guiding resource, illuminating the path toward achieving superior cleaning results. An informed approach not only saves time but also enhances the overall experience with the cleaning device.

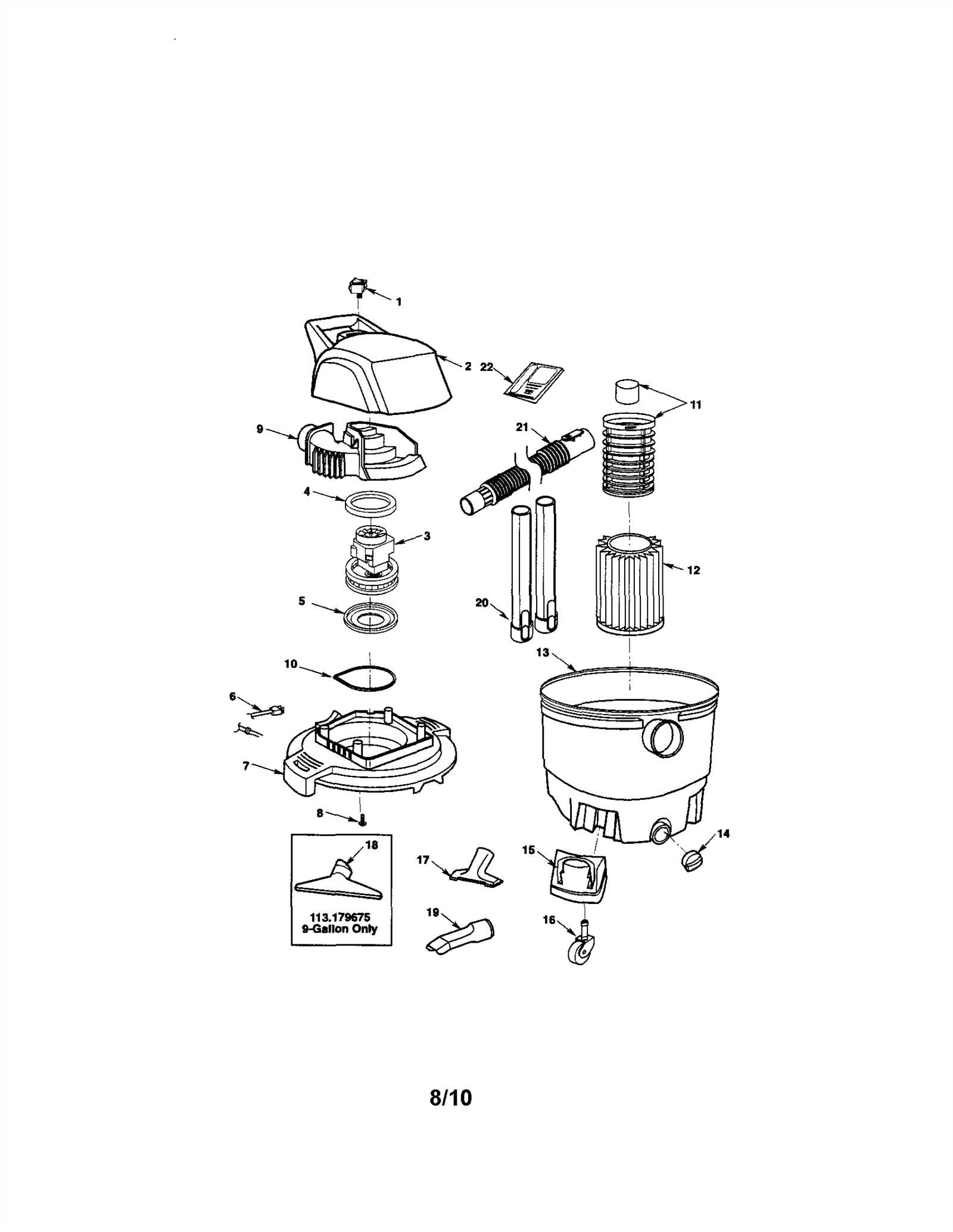

Understanding Shop-Vac Components

This section provides an overview of the essential elements found within vacuum systems designed for heavy-duty cleaning tasks. Familiarizing yourself with these components can enhance your understanding of how the equipment operates and aid in effective maintenance.

| Component | Function |

|---|---|

| Motor | Drives the suction power for efficient debris collection. |

| Filter | Traps particles to prevent them from re-entering the air. |

| Tank | Holds collected materials for easy disposal. |

| Hose | Transfers suction from the unit to the cleaning area. |

| Accessories | Enhance versatility for various cleaning applications. |

Types of Shop-Vac Models

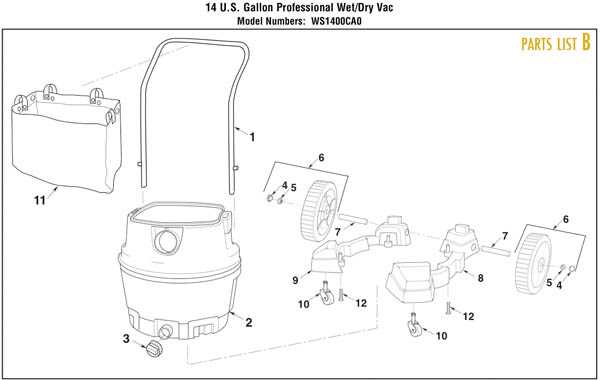

There are various cleaning equipment models designed to tackle different tasks, each offering unique features tailored to specific needs. These units come in a range of sizes and power levels, allowing users to choose the most suitable option for home, workshop, or industrial environments. Depending on the intended use, the units can vary in capacity, mobility, and additional attachments.

| Model Type | Capacity | Key Features | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compact Units | 1-5 gallons | Lightweight, portable, ideal for small cleanups | ||||||||||||||||

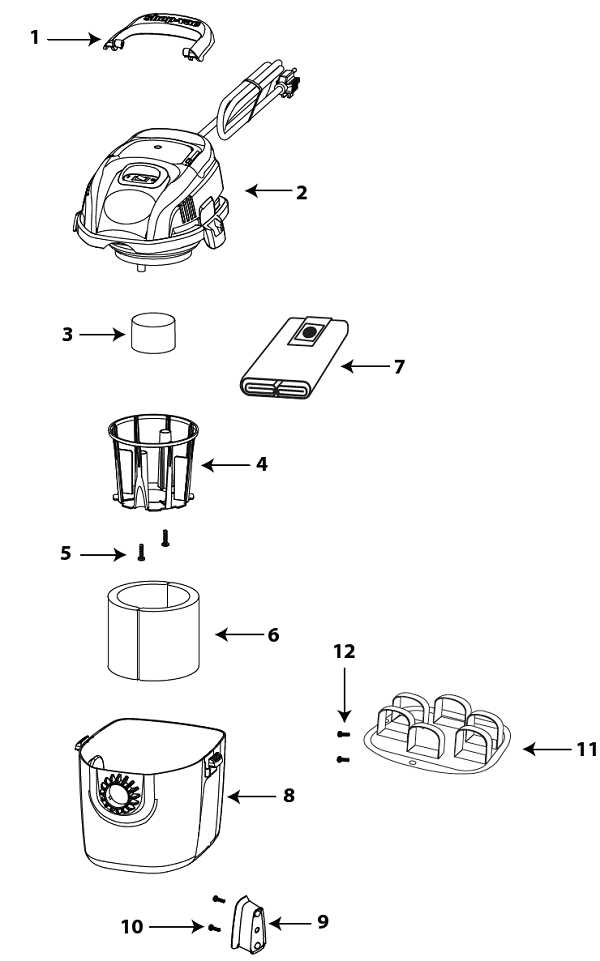

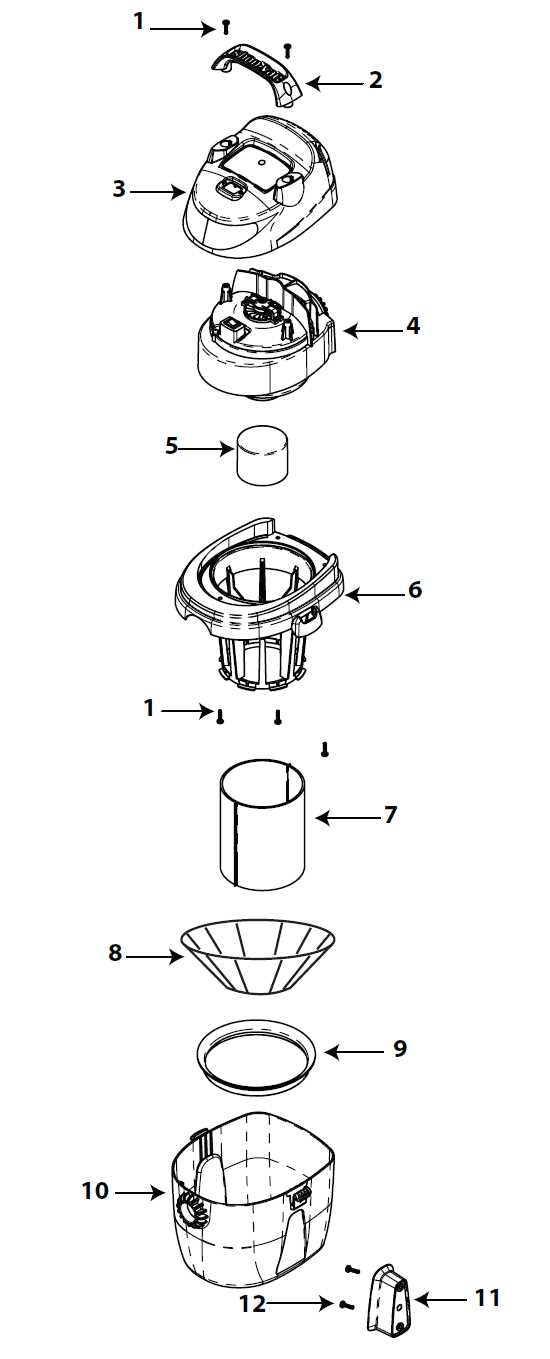

Common Issues and RepairsWhen maintaining cleaning equipment, users may encounter various operational challenges. These can range from minor inefficiencies to significant malfunctions, impacting overall performance. Understanding the frequent problems and knowing how to address them is essential for prolonging the life of the device. Reduced Suction PowerA common issue faced by users is a decrease in suction efficiency. This can be caused by blockages in the airflow system, clogged filters, or a damaged hose. Regularly cleaning or replacing filters and inspecting the hose for cracks can help restore optimal performance. OverheatingOverheating can result from prolonged use or restricted airflow. This issue may also arise due to dirty filters or obstructions in the system. To prevent overheating, ensure that all components are clean and free from debris, and allow the device to cool between extended sessions. Importance of Maintenance PracticesConsistent upkeep is vital for ensuring that equipment remains in optimal working condition. Without regular attention, even the most reliable machines can experience a decline in performance and efficiency over time. Routine care not only prolongs the lifespan of tools but also prevents unexpected malfunctions and costly repairs. Prolonging DurabilityWhen tools are maintained properly, their components stay in good shape for much longer. This means fewer breakdowns and the ability to withstand regular usage without compromising functionality. Regular cleaning, inspection, and lubrication of key elements are essential steps that significantly enhance the longevity of any device. Preventing Major IssuesBy identifying potential problems early on, preventive measures can be taken to address minor issues before they escalate. Regular maintenance routines allow for quick fixes, which can prevent the need for expensive replacements or extensive downtime. Attention to detail during these procedures ensures safety and reliable operation. How to Identify PartsUnderstanding the different components of a cleaning device is crucial for proper maintenance and repair. By familiarizing yourself with the key elements and their functions, you can easily spot what needs attention and ensure everything operates smoothly. This guide will help you recognize and differentiate the various elements, aiding in troubleshooting and part replacement. Visual CuesOne of the most effective ways to distinguish between different components is by their shape, size, and positioning. Larger elements, like the container and the cover, are often the most prominent and easy to spot. Smaller pieces, including connectors and fasteners, require closer attention but often play critical roles in the device’s functionality. Noticing specific textures and finishes can also help identify parts meant for different purposes, such as filtration versus power distribution. Functional GroupingAnother approach to identifying components is by considering their role within the overall system. Elements responsible for suction and airflow are typically located near the motor Where to Find Replacement Parts

When seeking components for your vacuum unit, there are various avenues to explore. Understanding where to locate these essential items can save time and ensure your equipment operates efficiently. Below are some recommended resources to assist you in your search.

Tools for DIY RepairsEmbarking on do-it-yourself projects can be both rewarding and economical. To ensure success in various repair tasks, having the right tools on hand is essential. This section highlights the must-have instruments that can aid in troubleshooting and restoring equipment to optimal working conditions. Hand Tools: A reliable set of hand tools is fundamental for any repair task. Wrenches, screwdrivers, and pliers are indispensable for loosening or tightening components. A quality toolkit that includes various sizes and types will facilitate most jobs efficiently. Power Tools: For larger or more complex tasks, power tools can significantly expedite the process. Drills, saws, and sanders can make short work of tough materials. Investing in durable and versatile power tools will enhance your capability for both repairs and projects. Measuring Instruments: Precision is key in any repair endeavor. Measuring tapes, levels, and calipers help ensure accurate adjustments and alignments. These tools not only enhance the quality of work but also prevent errors that could lead to further complications. Safety Gear: Never underestimate the importance of safety while undertaking repairs. Protective eyewear, gloves, and masks should be standard components of your toolkit. Ensuring personal safety will allow you to focus on the task at hand without unnecessary distractions. Organizational Aids: Keeping your workspace organized can significantly impact efficiency. Toolboxes, storage bins, and labels help maintain order and ensure that essential instruments are readily accessible. An organized space promotes a smoother workflow and can enhance overall productivity. Using the Parts Diagram EffectivelyUnderstanding the layout and components of your cleaning equipment is crucial for efficient maintenance and repair. A visual reference can significantly aid in identifying individual elements and their functions, ensuring that users can navigate their tasks with confidence. Steps to Maximize Utility

Additional Tips

Assembly Instructions for Shop-VacsPutting together a vacuuming device can seem daunting, but with clear guidance, the process becomes straightforward. Proper assembly ensures optimal performance and longevity, allowing users to efficiently manage cleanup tasks. Follow these essential steps for a successful assembly:

Following these steps will help ensure a seamless setup, allowing for effective cleaning operations. Safety Precautions During RepairsWhen undertaking maintenance on equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a secure working environment and facilitate effective repair processes. Adhering to safety guidelines not only protects the technician but also extends the lifespan of the machinery. Use of Personal Protective EquipmentWearing appropriate personal protective equipment (PPE) is essential during maintenance tasks. This includes items such as gloves, safety goggles, and masks, which shield against potential hazards like sharp objects, dust, and harmful substances. Always ensure that the PPE fits correctly and is in good condition before commencing any repair work. Disconnecting Power SourcesBefore starting any service activities, it is vital to disconnect all power sources. This simple step minimizes the risk of electrical shocks or accidental machine operation. Ensure that the equipment is completely powered down and that any residual energy is discharged. Double-checking this aspect can significantly enhance safety during repair operations. Upgrading Your Shop-Vac System

Enhancing your cleaning apparatus can significantly improve its efficiency and effectiveness. Whether you’re a DIY enthusiast or a professional, investing in better components can transform your tool into a powerhouse, ready to tackle even the toughest tasks. From improved filtration systems to more powerful motors, each upgrade can contribute to a more robust and versatile cleaning solution. First and foremost, consider upgrading the filtration mechanism. A high-efficiency filter can trap smaller particles, ensuring cleaner air is expelled back into your workspace. This is particularly important for those who may have allergies or sensitivities to dust and debris. Additionally, a more advanced filter can prolong the lifespan of your equipment by preventing dust buildup in the motor. Next, evaluate the capacity of your collection container. Opting for a larger receptacle allows for extended cleaning sessions without the need to stop frequently for emptying. This is especially useful in large areas or when tackling extensive projects, as it minimizes downtime and enhances productivity. Moreover, think about attachments and accessories. Specialized nozzles and hoses can make a significant difference in how effectively your device operates in various environments. Whether it’s a crevice tool for tight spaces or a wide nozzle for large surfaces, having the right accessories at hand can streamline your cleaning process. Finally, consider the power source and performance features. Upgrading to a motor with higher wattage can provide increased suction strength, allowing you to handle more challenging messes with ease. Additionally, features such as variable speed settings can offer greater control over the cleaning process, making it adaptable to different tasks and surfaces. Customer Support and ResourcesThis section is dedicated to providing valuable information and assistance for users seeking help with their cleaning equipment. Access to effective support and relevant resources is essential for ensuring optimal functionality and longevity of your device. Here, you will find various avenues for assistance, including contact information, troubleshooting guides, and community forums. For immediate inquiries, customers can reach out to the service team through the official contact channels. Quick responses and expert advice are available to resolve any issues that may arise during usage. Additionally, online manuals and instructional videos offer step-by-step guidance for maintenance and operation, making it easier for users to navigate their devices. Engaging with fellow users in community forums can also be beneficial. Sharing experiences, tips, and solutions can lead to better understanding and innovative ways to utilize your equipment. Together, these resources ensure that users have the support needed to maximize their experience and address any challenges that may occur. |