Exploring the intricate design of a modern handgun reveals a world of precision engineering and thoughtful construction. Each element plays a vital role in ensuring functionality, safety, and performance, creating a seamless interaction between user and weapon.

The arrangement of these components can be quite complex, yet understanding them is crucial for both maintenance and effective use. Familiarity with the various sections enhances not only operational efficiency but also the overall shooting experience.

In this section, we will delve into the detailed layout of each segment, providing insights into their ultimate purposes and interrelationships. By comprehending how everything fits together, enthusiasts can better appreciate the craftsmanship behind their chosen sidearm.

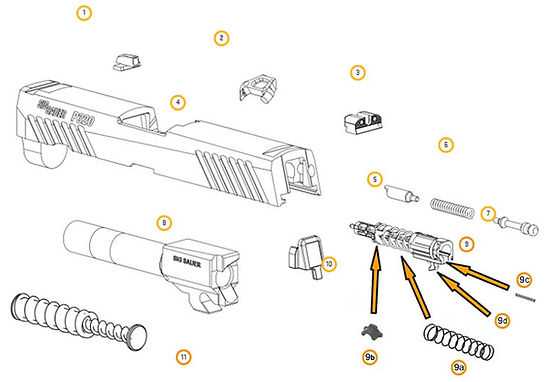

Understanding the Sig P320 Structure

To fully appreciate the design and functionality of this modern firearm, it is essential to explore its various components and how they interact. Each element plays a crucial role in ensuring reliability and performance, contributing to the overall efficiency of the weapon.

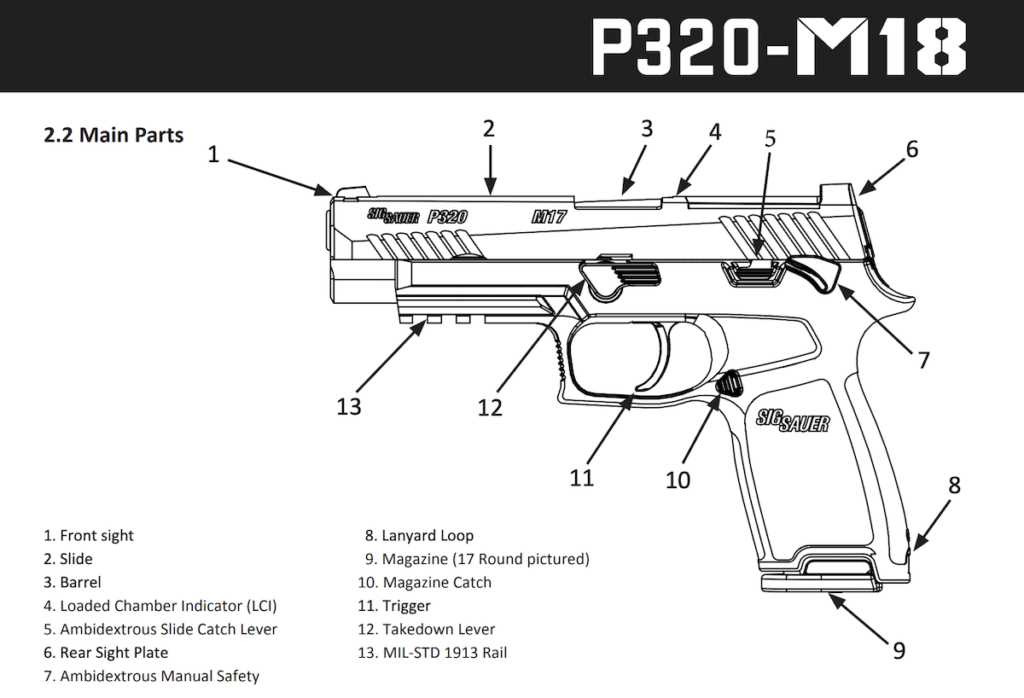

Core Components: The foundation of this firearm includes several key sections that work together harmoniously. The frame provides stability and houses the internal mechanisms, while the slide facilitates the loading and firing process.

Interchangeability: One of the ultimate features of this model is its modularity. Users can customize their experience by easily swapping out specific sections, enhancing versatility and adaptability for different shooting needs.

Functionality: Understanding how each part operates in conjunction allows users to maintain and troubleshoot effectively. Regular familiarity with the structure not only aids in proper handling but also elevates overall shooting proficiency.

Key Components of the P320

Understanding the fundamental elements of this versatile firearm is essential for enthusiasts and users alike. Each component plays a crucial role in functionality, safety, and performance, contributing to the overall effectiveness of the weapon.

Frame and Grip Module

The frame serves as the backbone, providing structural integrity and housing essential mechanisms. The grip module is designed for comfort and control, allowing users to maintain a secure hold during operation.

Fire Control Unit

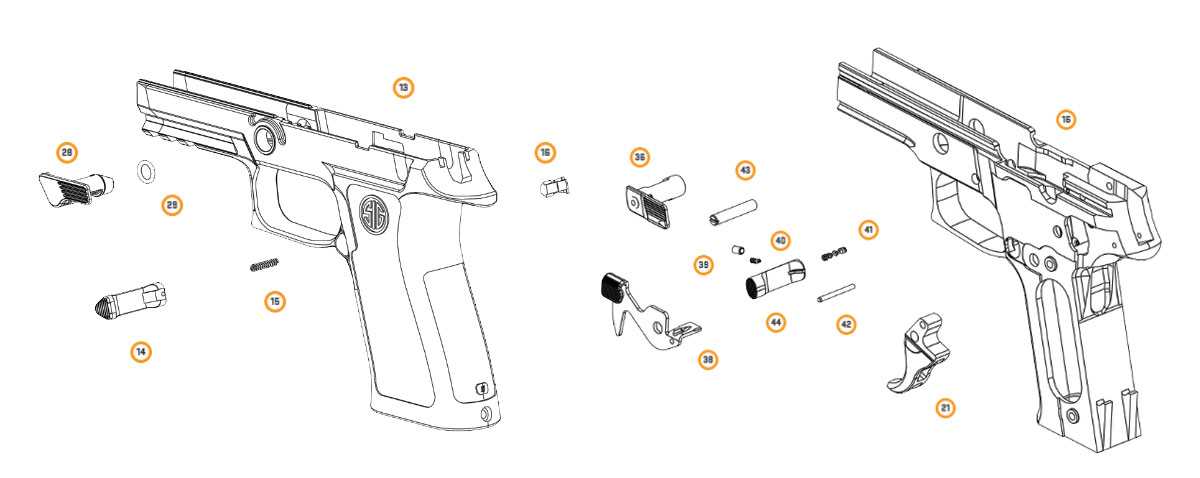

This pivotal element encompasses the trigger system and sear, ensuring reliable firing action. It is engineered for both safety and responsiveness, making it a critical aspect of the firearm’s operation.

Exploring the Fire Control Unit

The fire control unit plays a pivotal role in the operation and functionality of modern handguns. This essential component not only houses key mechanisms but also influences overall performance, reliability, and user experience. Understanding its design and features is crucial for enthusiasts and professionals alike who wish to enhance their knowledge of firearm engineering.

Key Components and Functions

| Component | Function |

|---|---|

| Trigger Assembly | Controls the firing mechanism and ensures proper engagement. |

| Hammer | Strikes the firing pin to initiate the ignition of the cartridge. |

| Disconnector | Prevents automatic firing by ensuring the hammer can only fall once per trigger pull. |

| Sear | Holds the hammer in a cocked position until the trigger is pulled. |

Importance of Maintenance

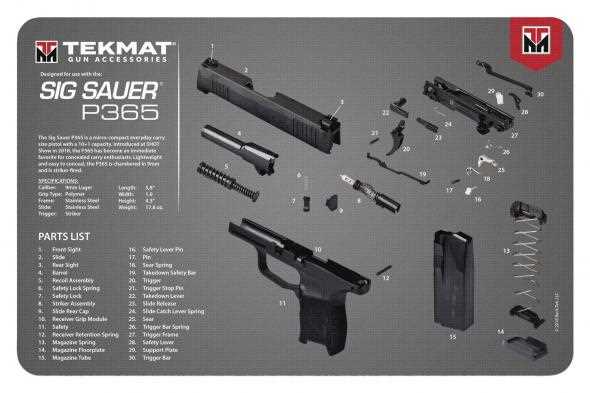

Replacement Parts for Sig P320

When it comes to maintaining a high-performance firearm, understanding the components that may require substitution is crucial. Ensuring each element functions optimally enhances reliability and safety during use. This section explores essential replacements that can elevate the firearm’s overall performance.

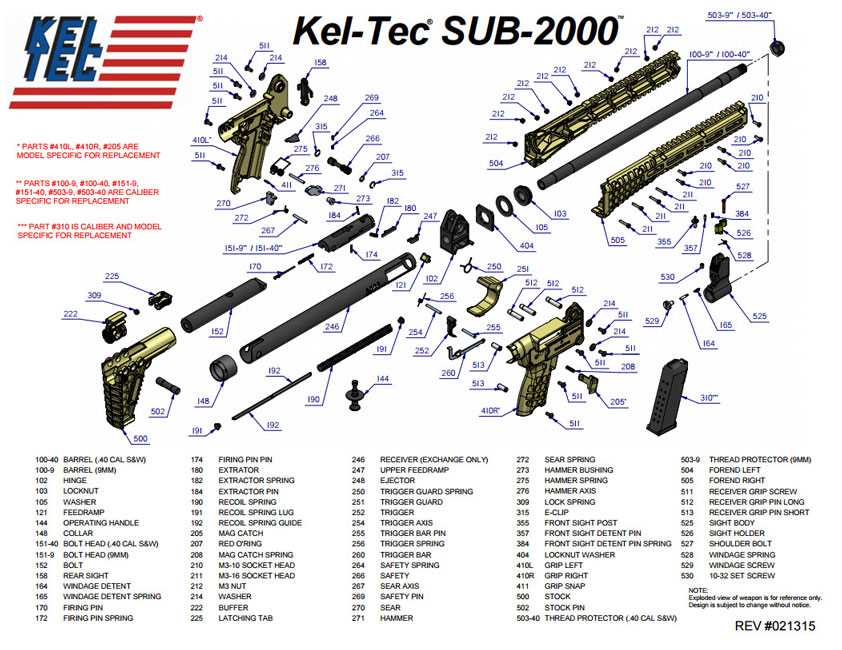

Common Components for Replacement

Key items often needing replacement include the firing mechanism, recoil springs, and trigger assemblies. Regular inspection of these components can prevent malfunctions and ensure peak functionality. Upgrading to enhanced versions can provide additional benefits, improving both feel and responsiveness.

Choosing Quality Alternatives

When selecting replacements, it’s vital to consider the quality and compatibility of the components. Opting for reputable manufacturers guarantees longevity and performance. Always consult with experts or reliable sources to make informed decisions for optimal upgrades.

Assembly Process of the P320

The assembly of this modular firearm involves a series of precise steps to ensure functionality and reliability. Each component plays a crucial role in the overall performance, and understanding this process is essential for both enthusiasts and professionals.

- Preparation:

- Gather all necessary components.

- Ensure a clean workspace.

- Frame Assembly:

- Insert the fire control unit into the frame.

- Secure it with pins as needed.

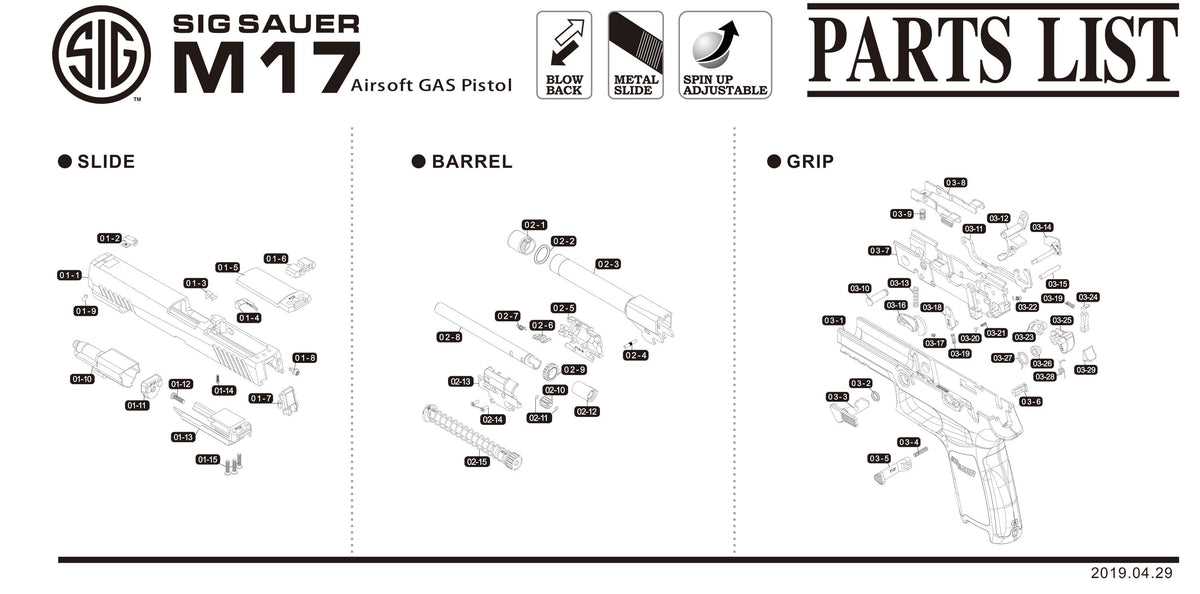

- Slide Assembly:

- Attach the barrel to the slide.

- Install the recoil spring and guide.

- Final Assembly:

- Combine the frame and slide.

- Ensure all components fit securely.

- Function Check:

- Test all mechanisms for proper operation.

- Perform safety checks before use.

This structured approach guarantees that each firearm operates at its ultimate efficiency, making it suitable for various applications.

Common Issues and Solutions

In the realm of firearm maintenance, users often encounter various challenges that can affect performance and reliability. Understanding these common obstacles and their respective remedies is essential for ensuring optimal operation. Here, we explore frequent problems and effective solutions.

1. Malfunctioning Trigger Mechanism: A common issue is a trigger that feels gritty or fails to reset properly. This can often be resolved by cleaning the trigger assembly and ensuring all components are properly lubricated. If problems persist, consider replacing worn parts.

2. Failure to Eject: Users may experience rounds failing to eject after firing. This can typically be attributed to dirt buildup or a weak extractor. Regular cleaning and inspection of the extractor can help, and replacing it if necessary will ensure reliable function.

3. Slide Sticking: When the slide does not operate smoothly, it can lead to feeding issues. Ensuring the slide and rails are clean and lubricated is crucial. Additionally, checking for debris or damage can prevent future complications.

4. Magazine Problems: Feeding issues can arise from faulty magazines. Inspecting magazines for wear and ensuring they are properly seated can often solve these issues. Replacing damaged magazines is also advisable for consistent performance.

By addressing these common concerns proactively, users can maintain the functionality and safety of their firearms, enhancing the overall experience.

Differences in P320 Variants

Understanding the various iterations of this firearm reveals significant distinctions in design and functionality, appealing to different preferences and uses. Each variant caters to specific needs, making it essential for enthusiasts to grasp these nuances.

Key Variants Overview

Each model offers unique features, influencing handling and performance. Below is a comparison of some notable versions.

| Variant | Caliber | Capacity | Weight |

|---|---|---|---|

| Compact | 9mm | 15 rounds | 25.1 oz |

| Full-Size | 9mm | 17 rounds | 29.5 oz |

| Subcompact | 9mm | 10 rounds | 23 oz |

Conclusion

Ultimately, the choice among these versions hinges on intended use and personal preference, ensuring that each user finds a suitable option for their needs.

Importance of Regular Maintenance

Key benefits of regular maintenance include:

- Improved accuracy and functionality

- Increased lifespan of components

- Enhanced safety for the user

- Prevention of costly repairs

To maintain peak performance, consider implementing the following practices:

- Conduct regular inspections for wear and tear.

- Clean all moving parts to prevent buildup.

- Lubricate as needed to reduce friction.

- Replace worn components promptly.

Ultimately, a commitment to routine maintenance fosters trust and confidence in the equipment, allowing users to focus on their tasks without concern.

Aftermarket Parts and Upgrades

Enhancing the performance and aesthetics of a firearm often involves the incorporation of various aftermarket components. These enhancements can significantly improve functionality, reliability, and user experience. Whether for competitive shooting, personal defense, or simply for the joy of customization, the right upgrades can make a remarkable difference.

Types of Upgrades

Common enhancements include trigger assemblies, sights, and grip modules. Upgraded triggers can provide a smoother pull, while improved sights can enhance target acquisition. Additionally, custom grip modules can offer better ergonomics, ensuring a more comfortable hold during use.

Considerations for Selection

When choosing components, it’s essential to consider compatibility, material quality, and manufacturer reputation. Quality parts can enhance performance, while inferior options may lead to malfunctions or compromise safety. Researching user reviews and expert recommendations can help in making informed decisions.

Safety Features of the P320

The design of this firearm emphasizes user safety through various innovative mechanisms. These features work together to minimize the risk of accidental discharges while ensuring reliable performance during use.

Integrated Safety Mechanisms

One of the key attributes includes a striker safety, which prevents the firing pin from moving forward unless the trigger is fully pulled. This ensures that the weapon will not discharge unless intentionally activated by the user.

Drop Safety Design

Additionally, the model incorporates a drop safety feature that secures the firing mechanism in the event of an unintended impact. This provides peace of mind, particularly when handling or transporting the firearm.

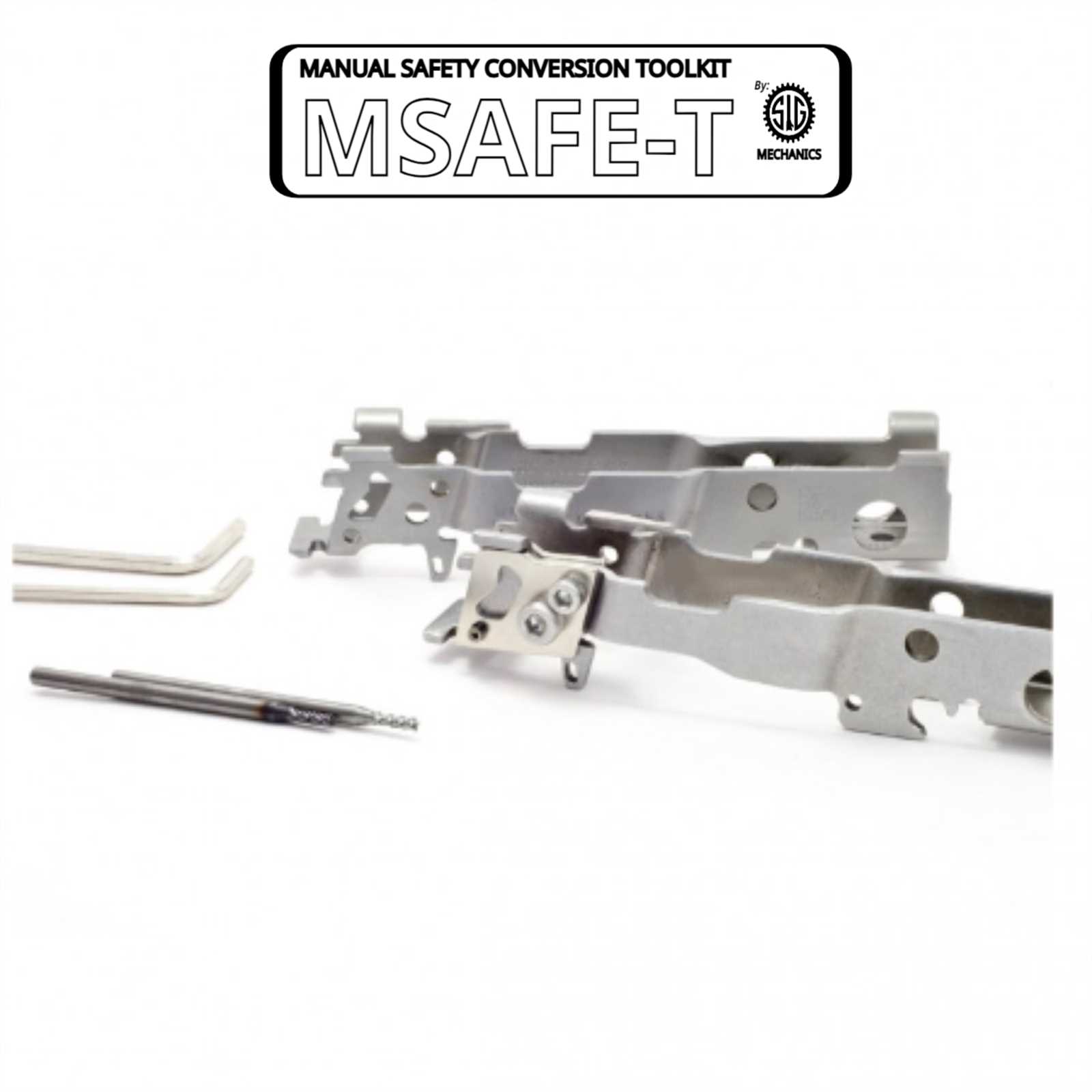

Tools Required for Disassembly

Disassembling a firearm requires specific instruments to ensure the process is safe and efficient. Proper tools not only facilitate the breakdown of components but also help maintain the integrity of the device during reassembly. Understanding which instruments are necessary can make the task easier and more effective.

Essential Instruments

First and foremost, a punch tool is crucial for removing pins without damaging surrounding parts. Additionally, a screwdriver set is important, with both flat and Phillips heads to accommodate various fasteners. A wrench might also be needed for any hex screws, while a cleaning brush ensures that debris does not interfere with the operation.

Safety Gear

Before beginning disassembly, wearing safety glasses is advisable to protect your eyes from any potential debris. Using gloves can also provide a better grip and prevent oils from your hands from contaminating parts. Proper preparation with the right tools and safety equipment ensures a smooth disassembly experience.

Understanding the Trigger Mechanism

The trigger mechanism is a crucial component of any firearm, playing a vital role in its overall functionality and user experience. This system is responsible for initiating the firing sequence, and its design influences both the accuracy and reliability of the weapon. A comprehensive understanding of this mechanism can enhance the user’s proficiency and safety.

| Component | Description |

|---|---|

| Trigger | The part that the shooter pulls to engage the firing process. |

| Connector | Links the trigger to the sear, allowing for smooth operation. |

| Sear | Holds the hammer or striker in place until the trigger is pulled. |

| Hammer/Striker | The mechanism that strikes the firing pin to ignite the cartridge. |

Best Practices for Care and Handling

Maintaining the longevity and functionality of your firearm requires a commitment to proper care and handling techniques. Implementing best practices not only enhances performance but also ensures safety during use. Understanding the essential components and their roles can significantly improve your experience with your weapon.

Regular Cleaning: Frequent cleaning is vital to prevent the buildup of debris and residue. Utilize appropriate cleaning agents and tools designed specifically for your model to ensure thorough maintenance.

Proper Lubrication: Applying the right lubricant helps reduce friction and wear. Focus on key areas as indicated in the manufacturer’s guidelines, ensuring smooth operation during use.

Safe Storage: Store your equipment in a secure, dry place to protect it from moisture and temperature extremes. Consider using a dedicated safe or storage case that provides both security and organization.

Routine Inspections: Regularly inspect your device for any signs of wear or damage. Addressing minor issues before they escalate can prevent potential malfunctions and enhance reliability.

Education and Training: Stay informed about the latest practices and techniques related to your firearm. Participate in training sessions or workshops to improve your skills and knowledge, fostering a deeper understanding of safety protocols.