When it comes to heavy-duty tools and machinery, it is crucial to have a clear understanding of how different elements are structured. Each part plays an integral role in ensuring the overall performance and longevity of the equipment. Familiarizing yourself with the overall setup can greatly aid in maintenance and troubleshooting, ensuring optimal operation.

In this section, we will explore the arrangement of various elements, focusing on their interactions and the critical role each one serves. By examining the layout, users can identify key components and better understand the importance of each connection. This knowledge can be especially valuable when addressing performance issues or planning regular upkeep.

Comprehensive knowledge of the internal structure and key elements not only makes repairs simpler but also ensures long-term reliability. Gaining insights into how these elements work together will improve overall efficiency and reduce the likelihood of unexpected problems.

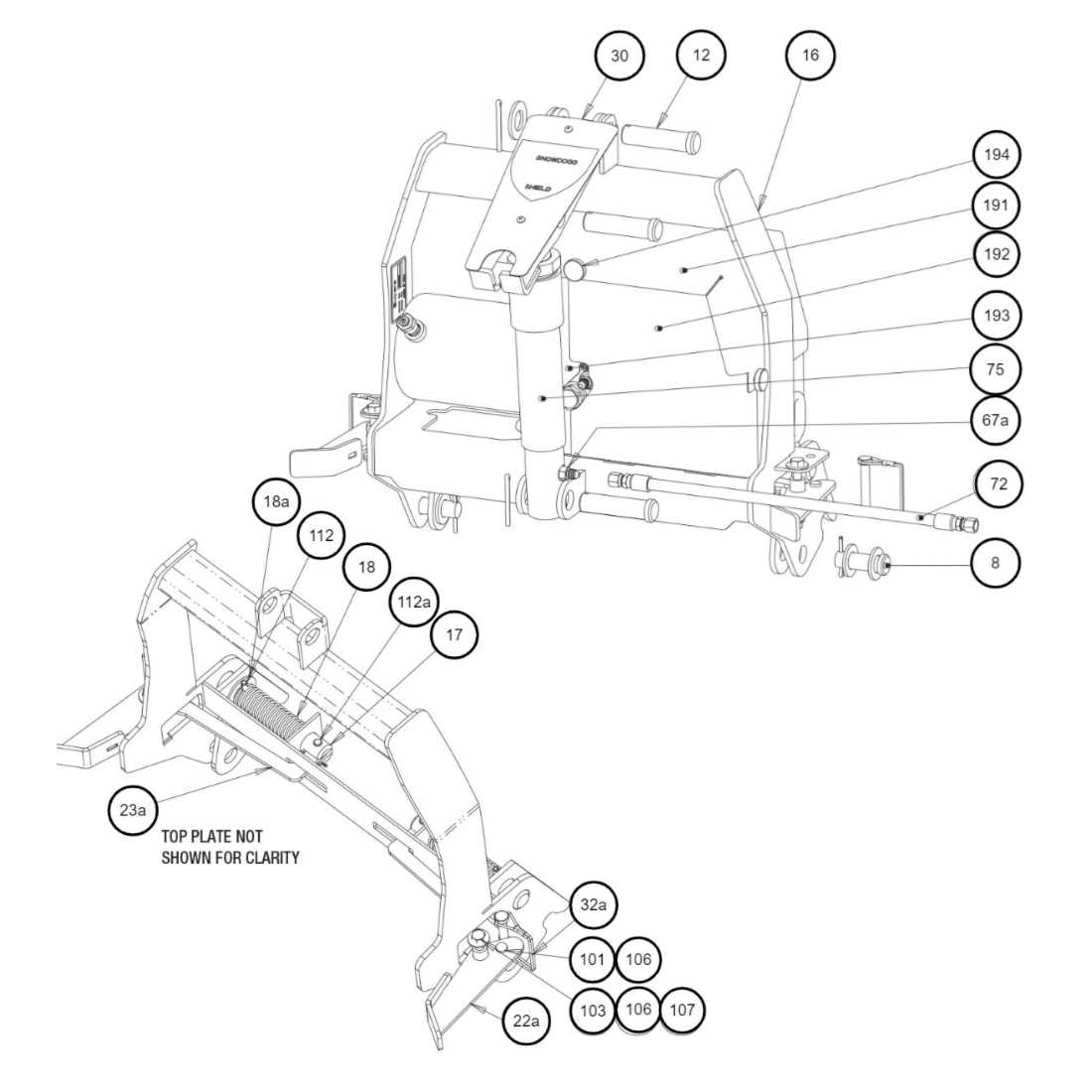

Snowdogg Parts Diagram Overview

Understanding the layout and function of individual components in equipment is essential for proper maintenance and repairs. By exploring the structure and interactions of different elements, users can easily identify issues and perform necessary fixes. This section provides a comprehensive look into how the various sections of the equipment work together seamlessly.

Key Component Categories

The system can be divided into several crucial areas that ensure functionality and performance. Each category is vital for ensuring smooth operations and longevity. Below is a list of these main sections:

- Electrical units responsible for controlling the system

- Hydraulic systems ensuring movement and fluid pressure

- Mounting brackets and structural supports for stability

- Mechanical connections facilitating

Key Components of Snowdogg Plows

The efficient performance of snow removal equipment depends on several critical elements. These components work together to ensure smooth operation and longevity, contributing to effective snow clearing in various conditions. Understanding these elements is essential for maintaining and troubleshooting the system when necessary.

Blade is one of the most recognizable features, responsible for pushing heavy snow out of the way. Made from durable materials, it is built to withstand the force of repeated use in harsh environments.

The

How to Read a Snowdogg Diagram

Understanding the layout and structure of a technical illustration can help you quickly identify different components and their relationships. This type of visual representation is essential when working with mechanical systems, as it provides a clear guide to various elements and their connections.

To navigate through the illustration effectively, follow these steps:

- Identify the key sections – Diagrams are usually divided into distinct areas, each representing a different part of the system.

- Look for labeled numbers – Each component is often assigned a unique identifier, helping you match it with the corresponding part in the list.

- Pay attention to lines and arrows – These indicate connections between different pieces and how they interact with each other.

- Check the legend – The legend usually explains symbols,

Common Snowdogg Replacement Parts

When maintaining equipment, it’s essential to replace key components over time to ensure smooth operation and longevity. These essential items play a crucial role in keeping the system running efficiently, helping prevent breakdowns and ensuring optimal performance in demanding conditions.

- Blades: Regular inspection and replacement are necessary for consistent performance.

- Hydraulic hoses: Wear and tear can lead to leaks, affecting overall efficiency.

- Mounting brackets: Properly functioning attachments help keep everything securely in place.

- Electrical components: These are vital for controlling various operations and should be replaced when malfunctioning.

- Spr

Identifying Wear and Tear on Parts

Regular maintenance of machinery is crucial to ensure its longevity and efficiency. Over time, various components of the equipment can show signs of wear, which, if left unaddressed, may lead to more significant issues. Recognizing the early indicators of deterioration helps in preventing unexpected breakdowns and costly repairs.

Typical signs of aging include cracks, rust, and thinning of material, especially in areas exposed to constant movement or friction. It’s essential to visually inspect these elements frequently and look for any irregularities, such as deformities or loose connections, which may affect performance.

By staying attentive to the condition of key elements and addressing minor issues promptly, one can significantly extend the service life of the equipment and maintain its optimal operation.

Snowdogg Plow Electrical System Explained

The electrical configuration of a snow removal implement is crucial for its effective operation. Understanding the various components and their interactions can significantly enhance the efficiency and reliability of the equipment during harsh winter conditions. This section delves into the fundamental aspects of the electrical system, shedding light on its essential functions and features.

Key Components of the Electrical Configuration

At the heart of the system lies a reliable power source, typically a battery, which supplies energy to the unit’s motor and other critical elements. Switches and relays play a vital role in controlling the flow of electricity, enabling the operator to manage the blade’s movements with precision. Additionally, wiring harnesses ensure seamless communication between various components, facilitating smooth operations.

Functionality and Maintenance Tips

Regular maintenance of the electrical system is essential to prevent unexpected failures. Inspecting connections for corrosion and ensuring proper voltage levels can help maintain optimal performance. Furthermore, understanding the system’s functionality allows users to troubleshoot common issues, ensuring that the equipment remains in peak condition throughout the winter season.

Hydraulic Components in Snowdogg Systems

The hydraulic system in these snow management machines plays a crucial role in ensuring efficient operation and maneuverability. This section delves into the essential elements that contribute to the overall functionality of the hydraulic mechanisms, highlighting their importance in enhancing performance.

Hydraulic pumps are vital for generating the necessary pressure to drive various functions, such as lifting and tilting. These pumps convert mechanical energy into hydraulic energy, allowing for precise control over movements. Additionally, hydraulic cylinders are responsible for converting this hydraulic energy back into mechanical force, facilitating tasks like snow clearing and equipment adjustment.

Furthermore, the system incorporates valves that regulate the flow of hydraulic fluid, ensuring optimal performance. These components are designed to manage the distribution of fluid to various parts, allowing for simultaneous operations and improved efficiency. The careful selection and maintenance of these hydraulic elements are essential for sustaining the reliability and effectiveness of the entire system.

Upgrading Your Snowdogg Plow Parts

Improving the functionality of your snow removal equipment can greatly enhance its performance and longevity. By focusing on specific components, you can ensure that your plowing experience becomes more efficient and effective. This section explores various enhancements that can be made to your snow clearing apparatus.

Evaluate Existing Components

Before making upgrades, it is essential to assess the current condition of your equipment. Look for signs of wear and tear, and consider how each element contributes to overall efficiency. This evaluation will help you identify which areas need attention and improvement.

Invest in Quality Accessories

Choosing high-quality accessories can significantly impact performance. Upgrading to more durable materials can prevent frequent replacements and reduce maintenance costs in the long run. Consider options such as enhanced blades or more robust mounting systems that provide better support during operation.

Regular Maintenance

Incorporating a regular maintenance schedule can prolong the life of your snow clearing apparatus. Routine checks and adjustments ensure that all components function smoothly. Staying proactive with maintenance will minimize the risk of breakdowns and keep your equipment ready for the demands of winter.

Seek Expert Advice

Consulting with professionals can provide valuable insights into the best upgrades for your specific needs. Experts can recommend improvements based on current trends and technologies in the snow removal industry, helping you make informed decisions about your equipment.

By focusing on these key areas, you can enhance the performance of your snow clearing apparatus and tackle winter challenges more effectively.

Troubleshooting Diagram for Snowdogg Parts

This section aims to provide insights into resolving issues related to various components of a specific winter maintenance machine. Understanding how to identify and rectify common problems can significantly enhance the efficiency and longevity of the equipment. By following a systematic approach, users can effectively diagnose malfunctions and implement appropriate solutions.

Common Issues and Solutions

Identifying frequent challenges faced during operation is essential for maintaining optimal performance. Below are some typical problems and their corresponding remedies.

Issue Possible Cause Recommended Action Insufficient Performance Clogged components Clear any debris and ensure all parts are clean No Power Electrical connection failure Check wiring and replace any damaged connections Uneven Distribution Worn-out parts Inspect and replace worn components Excessive Vibration Loose fittings Tighten all bolts and ensure secure attachments Preventive Maintenance Tips

Implementing regular maintenance routines can prevent many issues from arising. Below are some tips for keeping the machinery in top condition:

- Conduct routine inspections of all components

- Keep the equipm

Maintenance Tips Using Snowdogg Diagrams

Regular upkeep of equipment is essential for optimal performance and longevity. Utilizing visual representations can significantly enhance the maintenance process by providing clear guidance on components and their functions. Understanding how to effectively interpret these illustrations allows users to address potential issues proactively.

Identifying Key Components

Familiarizing yourself with crucial elements of your machinery is a vital step in maintenance. By examining visual aids, you can pinpoint where specific parts are located and how they interact with one another. This knowledge enables efficient troubleshooting and repair, ultimately minimizing downtime.

Scheduling Routine Inspections

Implementing a regular inspection schedule is crucial for preventing wear and tear. Refer to visual resources to create checklists for routine maintenance tasks. This approach ensures that all necessary components are evaluated consistently, helping to extend the lifespan of your equipment. By staying proactive, you can avoid more significant issues down the line, saving both time and resources.

How to Order Snowdogg Replacement Parts

When seeking to acquire components for your snow removal equipment, understanding the process can greatly enhance your efficiency. This section outlines essential steps to facilitate the ordering of necessary replacements, ensuring your machinery remains in optimal condition.

Firstly, it is crucial to identify the specific items you need. This can typically be accomplished by consulting the user manual or reference guides that provide detailed information about the required components. Once you have determined the necessary replacements, you can proceed with the ordering process.

Next, it is advisable to choose a reliable supplier. Many vendors offer a variety of options, so take the time to compare prices and reviews to ensure you are selecting a trustworthy source. Additionally, make sure to verify that the supplier provides genuine components to maintain the integrity of your equipment.

After selecting a vendor, you can place your order online or by contacting them directly. Be prepared to provide the exact details of the components you wish to purchase, including any part numbers if available. This will help the supplier fulfill your order accurately.

Step Action 1 Identify needed items through manuals or guides. 2 Select a reliable supplier based on reviews. 3 Place your order online or via direct contact. 4 Provide specific details and part numbers as needed. Finally, after completing your order, keep track of shipping details and expected delivery times. This ensures you are prepared to receive and install the components promptly, allowing your equipment to function effectively once again.

Compatible Parts for Different Snowdogg Models

Understanding the interchangeability of components among various models is essential for efficient maintenance and operation. This section provides insights into how different models can utilize similar elements, enhancing versatility and ease of repairs.

Many of these units share specific features that allow for compatibility across a range of systems. For instance, certain components may be used interchangeably, reducing the need for a wide array of replacements. This not only simplifies the process but also minimizes costs for users.

It is advisable to consult the manufacturer’s guidelines to ensure proper fitting and functionality. By identifying the common characteristics of these models, operators can optimize their equipment’s performance while ensuring reliability and longevity.

In addition, having a selection of interchangeable components on hand can significantly decrease downtime. Users can benefit from a streamlined inventory approach, making it easier to manage and maintain their machinery effectively.