In the realm of winter maintenance equipment, effective functionality relies heavily on the intricate interplay of various elements. Each component plays a crucial role in ensuring optimal performance, contributing to the overall efficiency of the apparatus. A thorough grasp of these individual sections can lead to enhanced understanding and better maintenance practices.

Dissecting the Mechanism of these machines reveals a complex assembly designed to withstand harsh conditions while delivering consistent results. From the drive system to the distribution mechanism, every part is engineered to fulfill specific tasks, making it essential for operators and technicians alike to familiarize themselves with these intricacies.

To achieve superior outcomes during winter operations, one must not only recognize the functionality of each component but also appreciate how they interconnect. A comprehensive exploration of these elements aids in troubleshooting, repair, and overall equipment longevity, ensuring readiness for the challenges of winter weather.

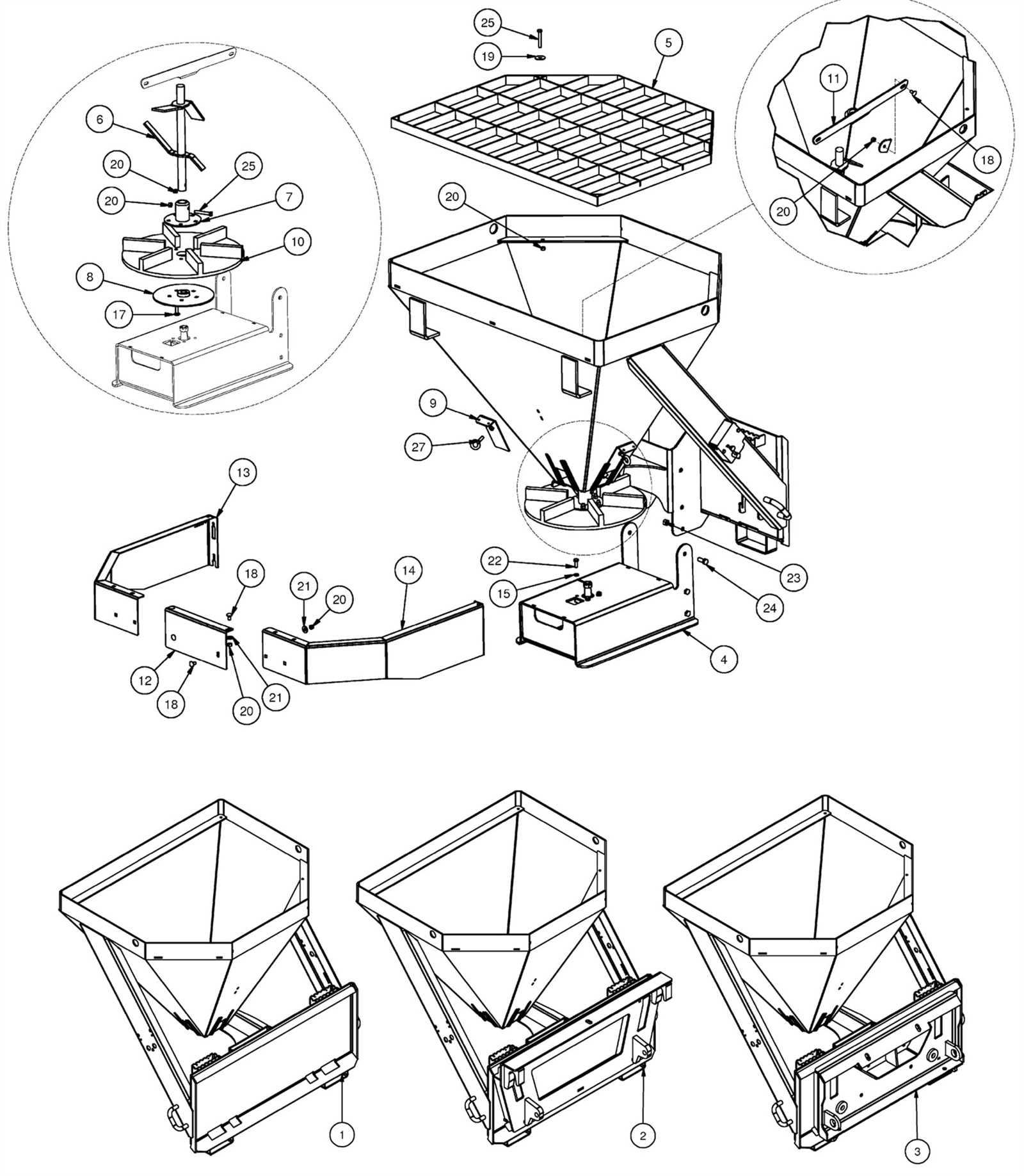

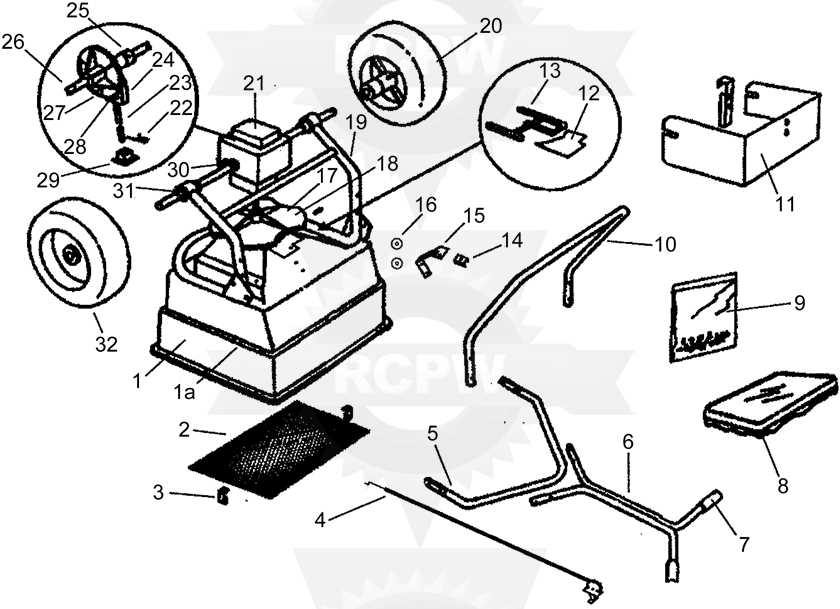

Understanding Snowex Salt Spreader Components

Grasping the various elements of a winter material distribution system is essential for efficient operation and maintenance. Each component plays a pivotal role in ensuring that the equipment functions smoothly, allowing for effective coverage during adverse weather conditions.

These systems are comprised of several key elements, each contributing to the overall performance:

- Hopper: The main container responsible for holding the material before it is dispensed.

- Auger: A spiral mechanism that helps move the material from the hopper to the spreading mechanism.

- Spinner: This element distributes the material evenly across the desired surface area.

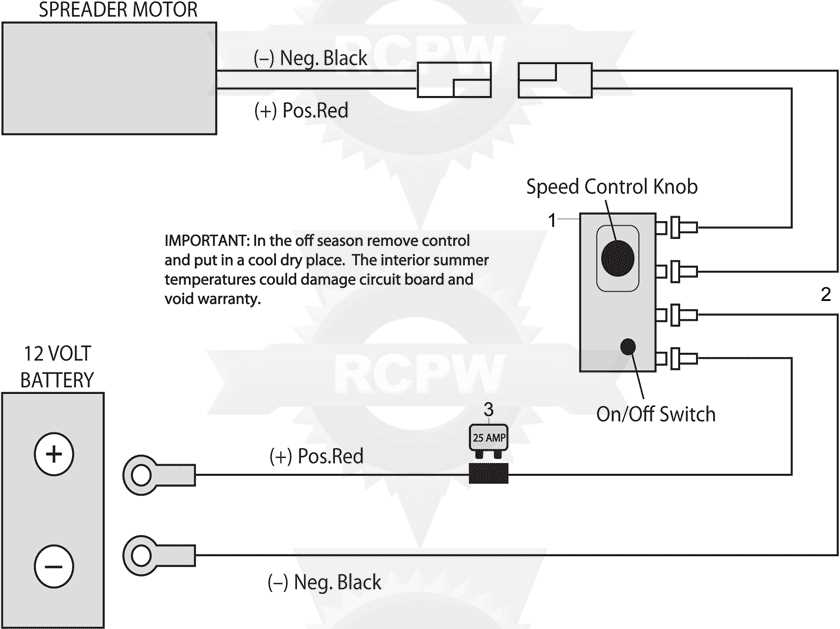

- Control System: The interface that allows the operator to adjust settings such as speed and volume of material dispensed.

- Mounting Frame: The structure that secures the unit to the vehicle, ensuring stability during operation.

Understanding how these components interact is vital for troubleshooting and enhancing the overall efficiency of the equipment. Regular maintenance and familiarity with each part can lead to improved performance and longevity of the system.

- Conduct routine checks on each component.

- Ensure that all connections are secure.

- Replace worn or damaged parts promptly.

By being informed about the intricacies of these systems, operators can ensure reliable performance when it matters most.

Overview of Spreader Functionality

This section provides a comprehensive look at the operation and effectiveness of material distribution systems designed for winter maintenance. Understanding these mechanisms is crucial for optimizing performance during adverse weather conditions.

Key aspects of these devices include:

- Material Distribution: The systems are engineered to deliver substances uniformly across surfaces, ensuring enhanced safety and mobility.

- Adjustment Features: Many units come equipped with customizable settings, allowing users to control the flow rate based on environmental conditions.

- Durability: Constructed from robust materials, these devices are built to withstand harsh weather and heavy usage.

- Compatibility: Designed to integrate seamlessly with various types of vehicles, enhancing versatility and usability.

In summary, these distribution systems play a vital role in maintaining safe travel conditions during winter storms by effectively applying necessary materials to roads and pathways.

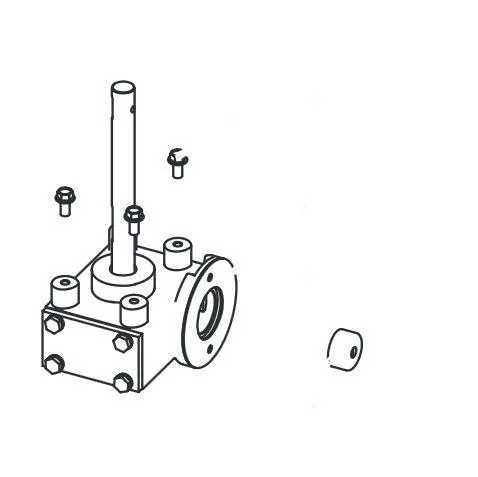

Key Parts of the Spreader

Understanding the essential components of a distribution unit is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring the effective dispersion of materials, enhancing efficiency in operation.

Hopper: This is the main container that holds the material before it is released. A well-designed hopper ensures a steady flow and prevents clogs.

Auger: The auger is responsible for moving the contents from the hopper to the spreading mechanism. Its design is crucial for consistent delivery.

Spinner: The spinner disperses the material across the desired area. Its rotation speed and angle greatly affect the coverage and effectiveness.

Control System: This allows the operator to manage the flow rate and spreading width. An intuitive interface can enhance operational efficiency.

Frame: The structural component that supports all other elements. A robust frame is essential for durability and stability during use.

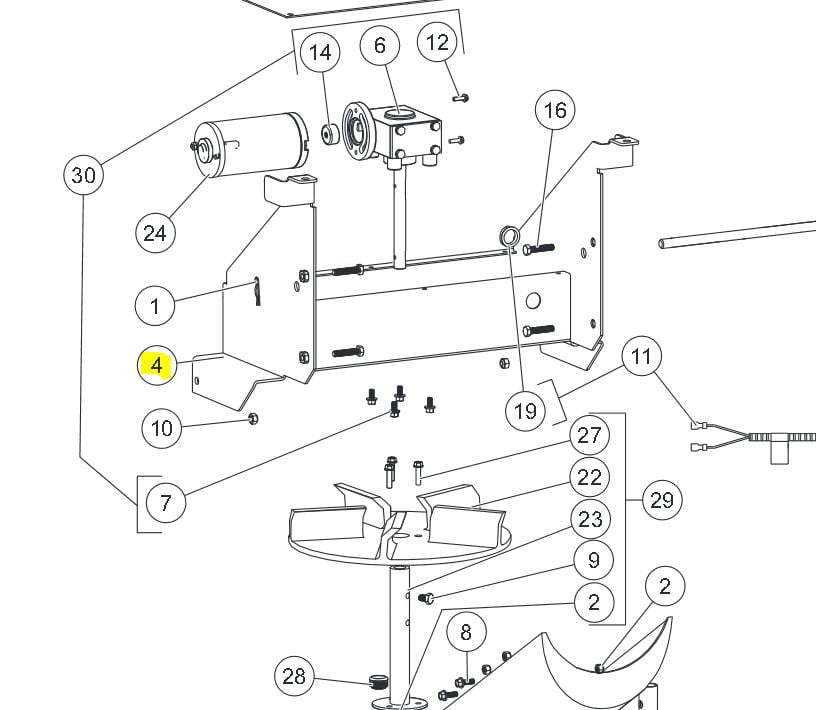

How to Read the Diagram

Understanding a technical illustration can significantly enhance your ability to maintain and troubleshoot equipment effectively. These visuals are designed to provide a clear representation of various components and their interconnections, making it easier to identify specific elements and their functions.

Familiarizing with Symbols

The first step in decoding any technical illustration is to become familiar with the symbols used. Each icon represents a different component, and recognizing these can streamline your efforts in locating parts. Take note of any legends or keys provided, as they often explain the meaning behind each symbol.

Interpreting Connections

Next, focus on the connections depicted in the illustration. Arrows and lines typically indicate how components interact with one another. Understanding these relationships is crucial for grasping the overall functionality of the system. Pay attention to any annotations that highlight specific interactions or operational guidelines.

By following these steps, you can navigate through technical illustrations with confidence, enabling you to address maintenance tasks more efficiently.

Importance of Regular Maintenance

- Enhances reliability

- Increases lifespan

- Improves safety

- Ensures consistent performance

By investing time in regular maintenance, users can significantly reduce the risk of unexpected failures and ensure that their machinery operates at its ultimate capacity. This proactive approach ultimately saves money and enhances productivity.

Common Issues and Solutions

This section addresses frequent problems encountered with equipment used for distributing materials, along with practical remedies. Understanding these issues can help users maintain optimal performance and extend the lifespan of their machinery.

Frequent Problems

Operators may notice a range of complications, such as uneven distribution, mechanical failures, or blockages. Identifying these issues promptly is crucial for effective resolution.

Solutions Overview

| Issue | Solution |

|---|---|

| Uneven distribution | Check calibration and ensure proper settings are applied. |

| Mechanical failure | Inspect components for wear and replace as needed. |

| Blockages | Clear any debris and ensure proper flow paths are maintained. |

Replacement Parts Availability

When maintaining and repairing essential equipment, ensuring access to suitable components is critical for optimal performance. Users often seek reliable sources for high-quality replacements that can extend the lifespan of their machinery. Understanding the availability of these elements can streamline repairs and enhance overall functionality.

Where to Find Quality Components

- Authorized Dealers: Official distributors often carry a comprehensive inventory of certified items.

- Online Retailers: E-commerce platforms provide a wide selection, often with user reviews and competitive pricing.

- Local Supply Stores: Many brick-and-mortar establishments offer essential items and may provide personalized assistance.

- Manufacturer’s Website: Visiting the producer’s online portal can reveal specialized options and updated catalogs.

Considerations for Selection

- Compatibility: Ensure that the chosen elements are suitable for your specific model.

- Quality: Opt for durable materials that meet industry standards to prevent premature wear.

- Warranty: Look for components that come with guarantees for added peace of mind.

- Customer Support: Reliable sellers often provide assistance and troubleshooting to enhance the purchasing experience.

Installation Tips for New Components

Ensuring the proper setup of new elements is crucial for optimal performance and longevity. Following best practices during installation can significantly enhance efficiency and prevent future issues.

- Read the Manual: Always start by thoroughly reviewing the installation guide provided.

- Gather Tools: Make sure you have all necessary tools at hand before beginning the process.

- Check Compatibility: Verify that the new components are compatible with your existing setup to avoid any conflicts.

- Follow Step-by-Step: Adhere to the recommended sequence in the manual to ensure proper installation.

- Secure Connections: Double-check that all connections are tight and secure to prevent leaks or disconnections.

- Test Functionality: After installation, perform a thorough test to confirm everything is functioning correctly.

Taking the time to implement these strategies will lead to a smoother installation process and enhance overall performance.

Safety Precautions During Operation

Ensuring a safe working environment is crucial when handling equipment designed for the distribution of materials. Adhering to specific guidelines not only protects the operator but also enhances overall efficiency.

General Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Inspect the machinery before use to identify any potential hazards.

- Ensure the area is clear of obstructions and bystanders.

Operational Best Practices

- Read the manufacturer’s instructions thoroughly before beginning operation.

- Maintain a safe distance from others while operating the machinery.

- Be aware of weather conditions that may affect visibility and control.

Comparing Different Snowex Models

This section explores various models designed for winter maintenance, highlighting their unique features and functionalities. Understanding these differences can aid in making an informed decision tailored to specific needs.

| Model | Capacity | Weight | Application Type |

|---|---|---|---|

| Model A | 500 lbs | 150 lbs | Residential |

| Model B | 800 lbs | 200 lbs | Commercial |

| Model C | 1000 lbs | 250 lbs | Industrial |

Each variant offers distinct advantages depending on the scale of operation, making it essential to delve into specifications before selecting the ultimate option for your requirements.

Upgrading Your Salt Spreader

Enhancing your distribution equipment can significantly improve performance and efficiency during winter maintenance tasks. By investing in quality upgrades, you can ensure even application, reduce waste, and save time. This section outlines key considerations and potential enhancements for your system.

Key Considerations for Enhancements

Before proceeding with upgrades, assess the current state of your equipment. Consider factors such as capacity, ease of use, and compatibility with existing components. Prioritizing features that align with your specific needs will yield the best results.

Potential Upgrades

| Upgrade Type | Benefits |

|---|---|

| Precision Control System | Enhances accuracy in material distribution and minimizes over-application. |

| Heavy-Duty Components | Increases durability and extends the lifespan of the equipment. |

| Smart Technology Integration | Allows for remote operation and monitoring, optimizing efficiency. |

| Improved Agitation Mechanisms | Ensures consistent flow and reduces clumping of materials. |

Implementing these enhancements can lead to a more reliable and effective tool for winter weather management. Prioritize upgrades that align with your operational goals to maximize the benefits of your equipment.

FAQs About Salt Spreader Parts

This section addresses common inquiries regarding components used in material distribution equipment, focusing on their functions, maintenance, and compatibility. Understanding these elements can enhance operational efficiency and prolong equipment lifespan.

Common Questions

| Question | Answer |

|---|---|

| What are the essential components of this equipment? | The key elements typically include a hopper, auger, and distribution system, each playing a vital role in effective operation. |

| How often should components be inspected? | Regular inspections should be conducted before and after each use to ensure optimal performance and prevent breakdowns. |

Maintenance Tips

| Tip | Description |

|---|---|

| Clean after use | Remove any residual material to prevent corrosion and clogs. |

| Check for wear | Examine moving parts for signs of wear and replace as necessary to maintain functionality. |