When it comes to mechanical systems, having a clear overview of the various elements and their configurations is essential for effective maintenance and repair. A comprehensive guide that illustrates the interrelation between different components allows users to grasp how each part contributes to the overall functionality of the equipment.

Recognizing the importance of such illustrations can greatly enhance one’s ability to troubleshoot and perform necessary adjustments. This knowledge not only aids in identifying specific elements but also in understanding the dynamics of the entire mechanism.

Moreover, being familiar with the arrangement of various components empowers individuals to make informed decisions regarding repairs or upgrades. This section aims to provide valuable insights into the structure and organization of these elements, ensuring a more proficient approach to handling the system in question.

Key Features and Specifications

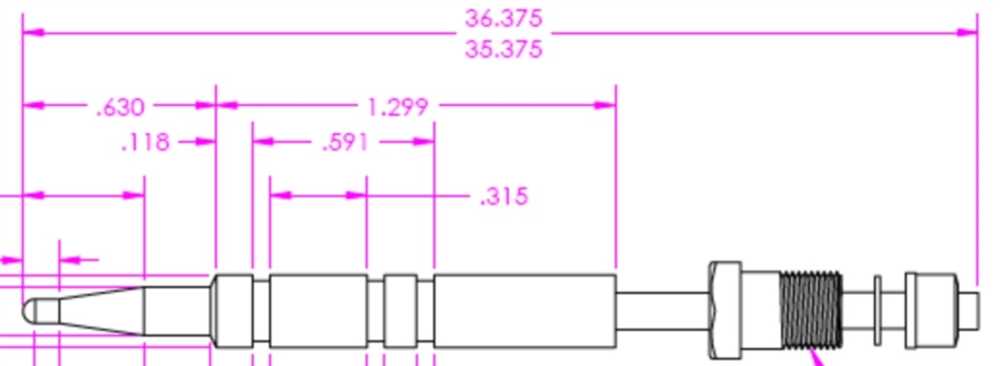

This section outlines the essential characteristics and technical details that define the equipment’s performance and usability. Understanding these elements is crucial for users to maximize functionality and ensure compatibility with their specific needs.

- Engine Type: Reliable and efficient engine designed for optimal performance.

- Capacity: Adequate size to handle a variety of tasks effectively.

- Durability: Constructed with high-quality materials for longevity and resistance to wear.

- Fuel Efficiency: Engineered to minimize fuel consumption while maintaining power output.

- Weight: Lightweight design for easy maneuverability without sacrificing strength.

These specifications ensure that the equipment meets the diverse demands of various applications, making it a versatile choice for users seeking reliability and efficiency.

- Safety Features: Integrated systems to enhance user protection during operation.

- Maintenance: Designed for straightforward upkeep and serviceability.

- Compatibility: Ability to work seamlessly with various accessories and attachments.

- Noise Level: Engineered to operate quietly, minimizing disturbance in residential areas.

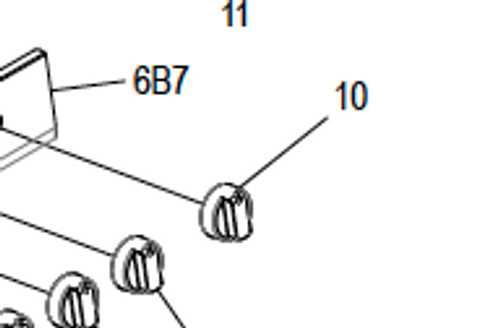

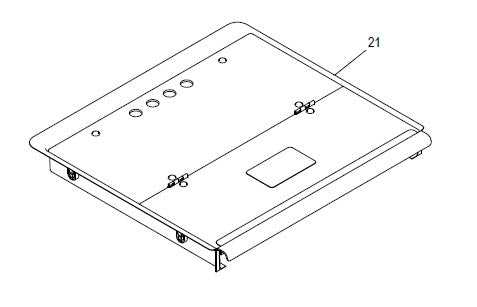

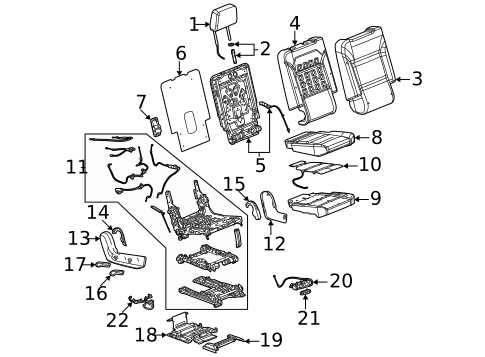

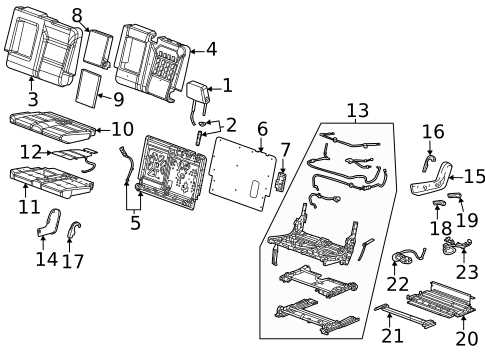

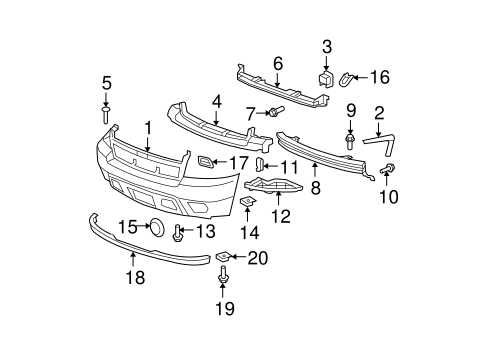

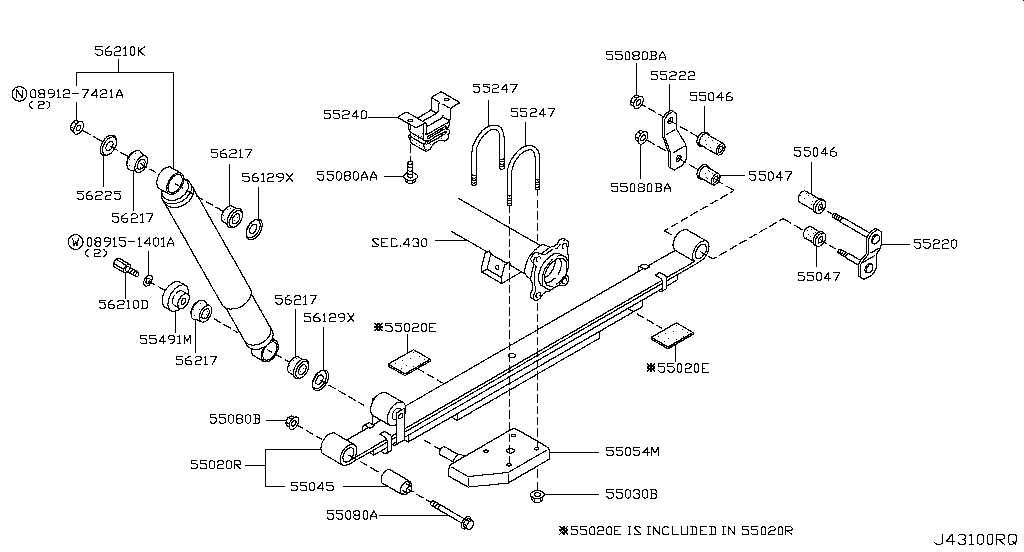

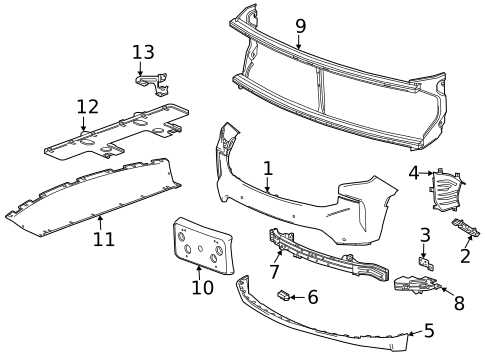

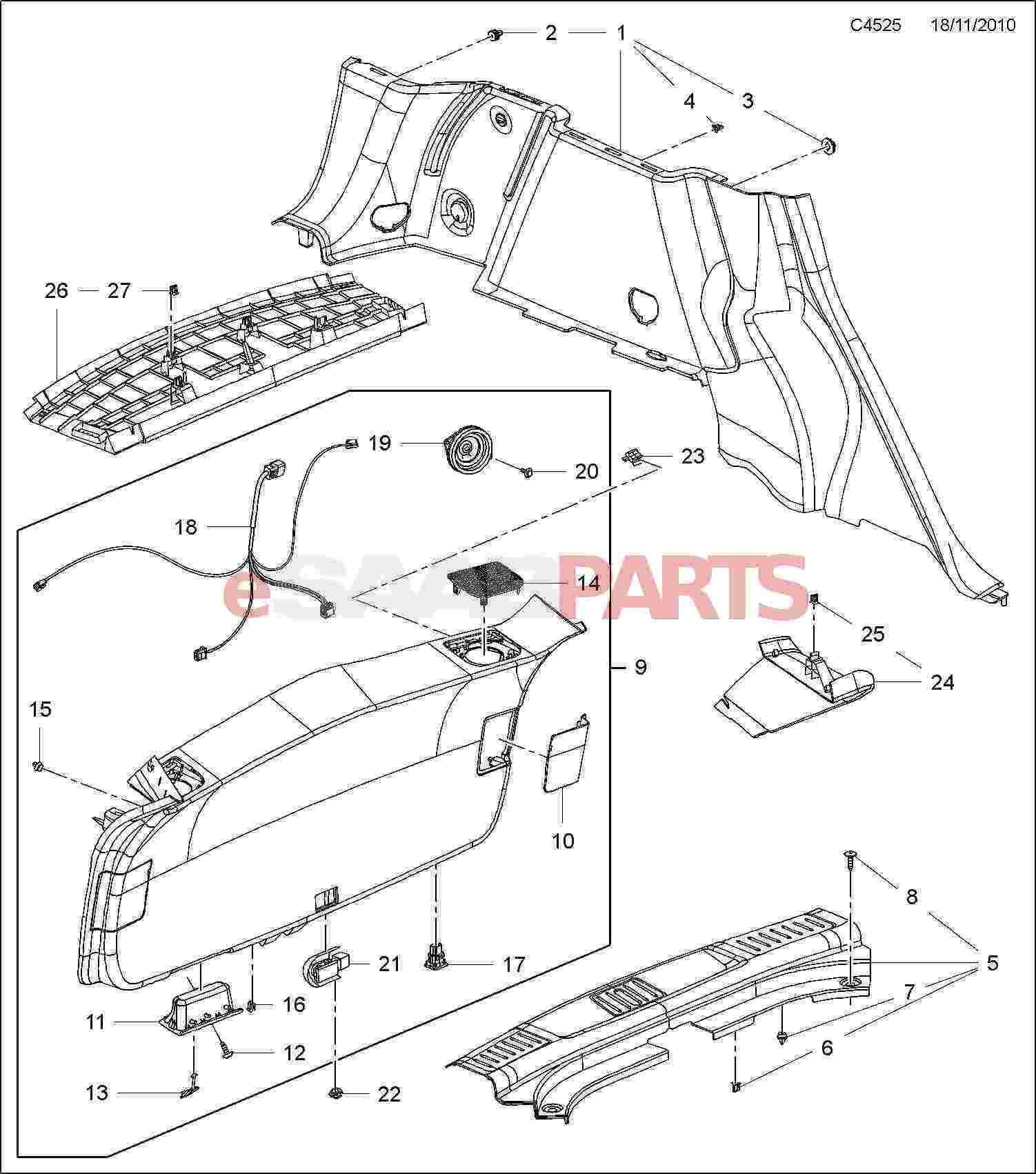

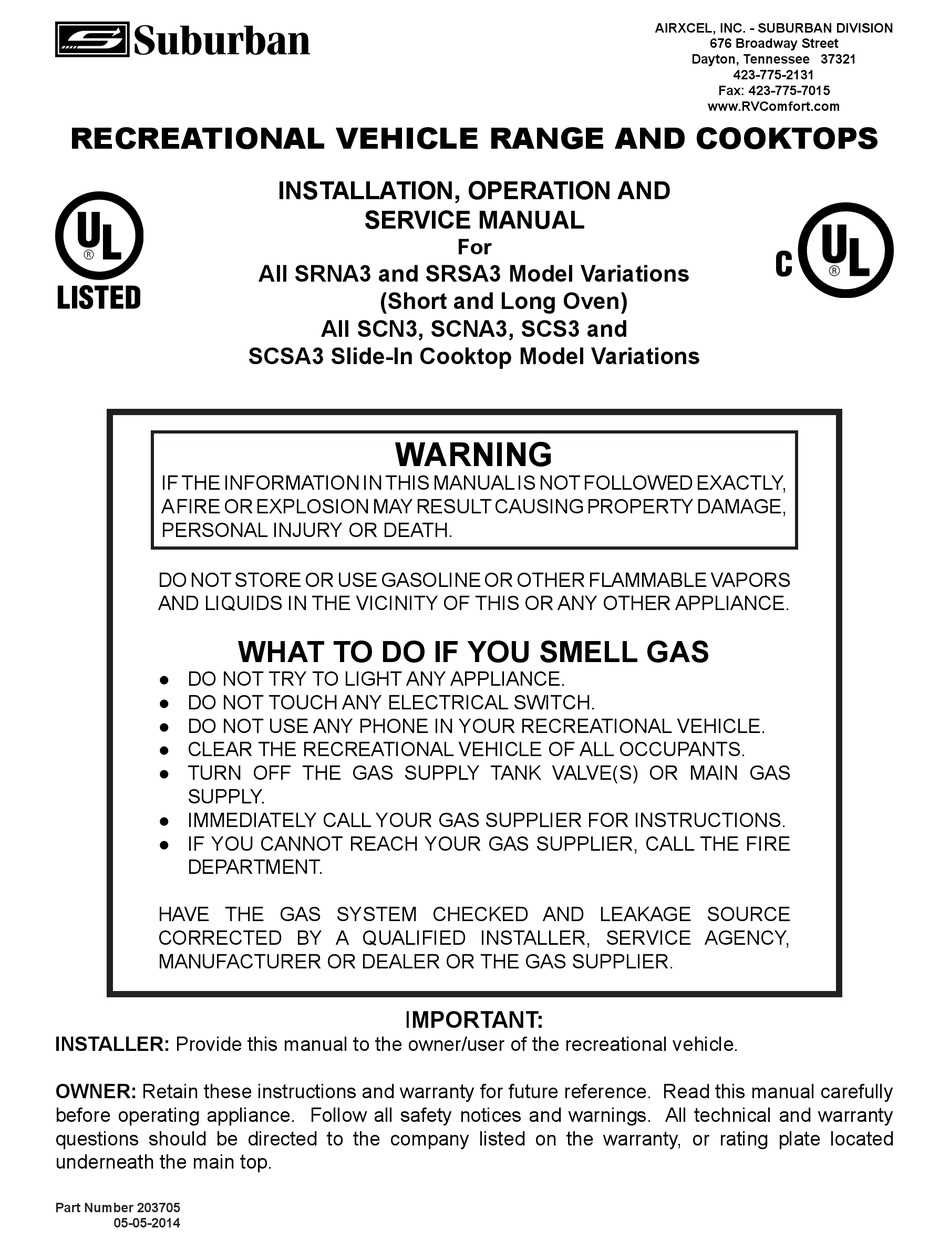

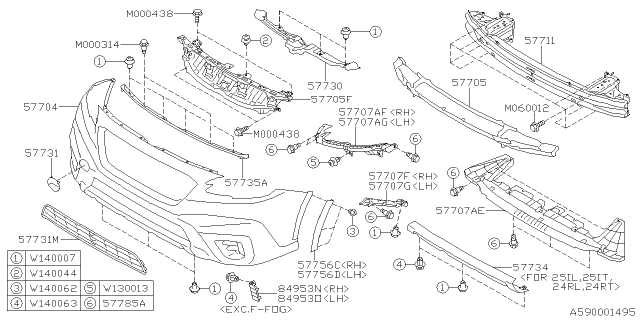

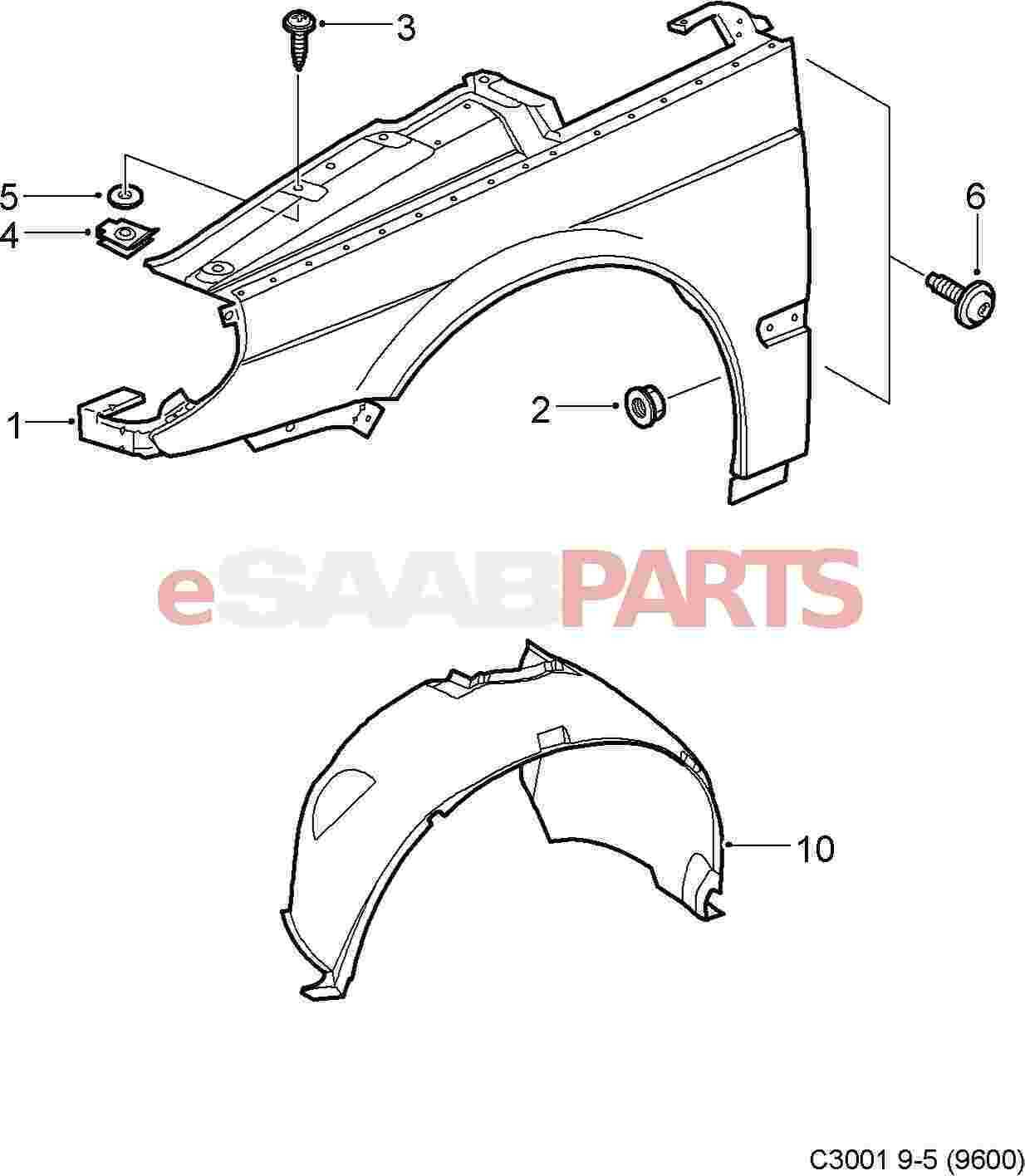

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for anyone engaged in maintenance or assembly tasks. This graphical guide serves as a roadmap, illustrating the intricate relationships and functions of various elements within a system. By mastering this representation, one can enhance their ability to identify specific elements and understand their roles effectively.

The Importance of Clarity

Clear visuals are crucial in conveying the structure and interconnectivity of different pieces. A well-designed graphical representation allows users to quickly locate components and understand their placement within the overall setup. This clarity not only facilitates smoother repairs and replacements but also aids in the troubleshooting process, making it easier to pinpoint issues.

Decoding Symbols and Labels

Every visual representation contains unique symbols and labels that denote specific components. Familiarizing oneself with these notations is vital for accurate interpretation. Pay attention to the various icons and annotations, as they provide essential information about the function and compatibility of each element. This knowledge empowers users to make informed decisions during maintenance tasks.

Essential Components and Their Functions

Understanding the fundamental elements and their roles is crucial for ensuring optimal performance and longevity. Each component contributes significantly to the overall operation, working harmoniously to achieve desired results. Grasping how these elements interact can enhance maintenance and troubleshooting efforts.

Engine: The heart of the system, the engine converts fuel into mechanical energy. Its efficiency directly impacts performance, making it essential to monitor its condition and functionality.

Transmission: This component transfers power from the engine to the wheels, enabling movement. A smooth and responsive transmission is vital for an enjoyable driving experience.

Braking System: Responsible for slowing down or stopping, this system includes various elements such as discs, pads, and hydraulic mechanisms. Regular checks ensure safety and responsiveness.

Suspension: This system supports the vehicle’s weight and absorbs shocks from the road. A well-maintained suspension improves comfort and handling, ensuring stability during operation.

Electrical System: Comprising the battery, alternator, and wiring, this system powers all electronic components. Maintaining the electrical system is crucial for reliability and efficiency.

Fuel System: Responsible for storing and delivering fuel to the engine, this system includes the tank, pump, and injectors. Proper functioning ensures optimal fuel efficiency and performance.

Common Issues and Troubleshooting

When working with specific heating systems, various challenges may arise, often causing inconvenience and frustration. Identifying and resolving these problems is crucial for maintaining optimal functionality and performance. Understanding common complications can help users diagnose issues efficiently and implement effective solutions.

Below is a table summarizing frequent problems along with their potential causes and recommended fixes:

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Insufficient heating | Clogged burner or insufficient fuel supply | Clean the burner and ensure a proper fuel level |

| Unexpected shutdowns | Overheating or faulty thermostat | Inspect the thermostat and check for obstructions |

| Unusual noises | Loose components or debris in the system | Tighten loose parts and clear any debris |

| Flame issues | Improper air-to-fuel mixture | Adjust the air shutter or inspect fuel lines for leaks |

By following these guidelines, users can troubleshoot common issues effectively, ensuring their heating system operates smoothly and efficiently.

Maintenance Tips for Longevity

To ensure the durability and efficient operation of your equipment, regular upkeep is essential. Following a structured maintenance routine not only prolongs the lifespan of your machinery but also enhances its overall performance. Here are some key practices to consider for optimal functionality.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect and Clean | Monthly | Regularly check and clean components to prevent buildup and ensure smooth operation. |

| Lubrication | Every 3 Months | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Check Electrical Connections | Every 6 Months | Inspect all electrical connections for signs of corrosion or damage to ensure safety and reliability. |

| Replace Filters | Annually | Change filters regularly to maintain optimal airflow and prevent contaminants from affecting performance. |

| Review User Manual | As Needed | Refer to the manufacturer’s guidelines for specific maintenance recommendations and troubleshooting tips. |

By adhering to these maintenance tips, you can significantly enhance the reliability and efficiency of your machinery, ultimately leading to reduced operational costs and increased satisfaction.

Comparison with Similar Models

This section provides a comparative analysis of models within the same category, focusing on key features, performance metrics, and design elements. By evaluating these similar offerings, users can gain insights into the unique aspects that distinguish each model, helping them make informed decisions based on their specific needs.

| Model | Engine Power | Fuel Efficiency | Features | Price |

|---|---|---|---|---|

| Model A | 200 HP | 25 MPG | Navigation, Leather Seats | $30,000 |

| Model B | 220 HP | 22 MPG | Sunroof, Bluetooth | $32,500 |

| Model C | 190 HP | 28 MPG | Heated Seats, Rear Camera | $28,000 |

Through this comparison, it becomes evident that while certain models excel in power, others provide enhanced fuel efficiency or additional features. Understanding these differences is essential for potential buyers to align their preferences with the right model.

Replacement Parts Availability

Ensuring the seamless operation of equipment often hinges on the accessibility of components necessary for maintenance and repair. This section delves into the sources and options for acquiring these essential items, highlighting the importance of timely access to ensure optimal performance.

Where to Find Components

Numerous retailers, both online and brick-and-mortar, specialize in providing necessary items for various appliances. Websites dedicated to home improvement, automotive needs, and specialty equipment often stock a comprehensive selection, catering to diverse consumer requirements. Local distributors may also carry specific items, offering convenience for those who prefer immediate procurement.

Considerations for Purchasing

When seeking replacements, it’s crucial to evaluate factors such as compatibility, quality, and warranty. Prioritize sourcing from reputable suppliers to guarantee that the components meet necessary standards. Additionally, checking for customer reviews can provide insights into product reliability and performance.

Installation Guidelines for New Parts

Properly fitting new components is crucial for ensuring optimal functionality and longevity of your equipment. Following established procedures will help prevent common issues and enhance the performance of your system. This section outlines essential steps and considerations to keep in mind during the installation process.

Preparation Steps

Before beginning the installation, it’s important to prepare adequately. This includes gathering all necessary tools and ensuring that you have a clean, organized workspace. Additionally, reviewing the manufacturer’s recommendations and familiarizing yourself with the specific requirements of the new components will facilitate a smoother installation.

Installation Procedure

Follow these systematic steps to ensure successful installation:

| Step | Description |

|---|---|

| 1 | Disconnect all power sources to avoid electrical hazards. |

| 2 | Remove the old component carefully, taking note of how it is connected. |

| 3 | Align the new component with the connection points and secure it properly. |

| 4 | Reconnect all necessary wiring and ensure tight connections. |

| 5 | Test the system to confirm that the new component is functioning as intended. |

By adhering to these guidelines, you can help ensure that your new components are installed correctly, thus maximizing the efficiency and reliability of your system.

Wiring and Electrical Connections

This section provides an overview of the essential components and arrangements involved in establishing effective electrical links within a vehicle. Proper connections are crucial for ensuring the reliable operation of various systems, including lighting, ignition, and sensors. A well-organized wiring setup not only enhances performance but also simplifies troubleshooting and maintenance procedures.

When addressing electrical connections, it’s important to understand the significance of using high-quality materials and components. Insulated wires, secure terminals, and reliable connectors play a vital role in minimizing resistance and preventing short circuits. Additionally, ensuring that all connections are free from corrosion and damage will help maintain optimal functionality over time.

Furthermore, following a logical layout when routing wires can significantly impact the overall efficiency of the system. Keeping wires organized and away from heat sources or moving parts can prevent wear and reduce the risk of failures. Proper labeling of connections also aids in future repairs or modifications, making it easier to identify and access specific components as needed.

Safety Precautions During Repairs

Ensuring a secure environment during maintenance tasks is crucial for both the technician and the equipment. Adhering to safety guidelines minimizes the risk of accidents and enhances the overall effectiveness of the repair process. Understanding potential hazards and taking proactive measures can significantly contribute to a safer working experience.

Preparation and Awareness

Before commencing any repair work, it is vital to prepare adequately. This includes reviewing the user manual, familiarizing oneself with the equipment, and identifying any potential risks. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and masks can prevent injuries and exposure to harmful substances. Additionally, maintaining a clutter-free workspace promotes efficiency and reduces the likelihood of accidents.

Proper Handling of Tools

Utilizing the correct tools for each task is essential for safety. Ensure that tools are in good condition and suitable for the specific job at hand. When using power tools, follow the manufacturer’s instructions closely. Always disconnect the power source before performing maintenance to prevent unintended operation. Being mindful of one’s surroundings and the equipment being serviced will further enhance safety during repairs.

Expert Resources and Support

Accessing reliable information and professional assistance is crucial for ensuring optimal performance and longevity of your equipment. Various platforms and specialists offer valuable guidance, helping users navigate potential challenges and enhance their understanding of specific components.

Technical Manuals provide detailed instructions and insights, allowing users to familiarize themselves with operational guidelines and maintenance procedures. These resources can often be obtained directly from manufacturers or through authorized dealers, ensuring accuracy and reliability.

Additionally, online forums and community groups serve as excellent venues for sharing experiences and solutions among users. Engaging with peers can foster a supportive environment where individuals can discuss common issues and effective strategies, enriching their knowledge base.

Professional Services are also available for those seeking personalized assistance. Experienced technicians can offer diagnostic evaluations and repairs, ensuring that your system operates smoothly and efficiently. Establishing a relationship with a qualified expert can significantly enhance the overall reliability of your equipment.

In conclusion, leveraging expert resources and support systems is essential for maximizing the performance and reliability of your equipment. By tapping into these valuable avenues, users can navigate complexities with confidence and maintain their systems effectively.