When it comes to efficient wood processing, having a clear understanding of the machinery involved is essential. Each element plays a vital role in ensuring smooth operation and optimal performance. Familiarizing oneself with the individual components can significantly enhance both maintenance practices and troubleshooting efforts.

The intricacies of these machines often lie in their design and assembly. Recognizing how each piece interacts with others can provide valuable insights into their functionality. This knowledge is particularly useful for operators who aim to maximize productivity while minimizing downtime.

In this exploration, we will delve into the various segments that make up these devices, emphasizing their specific functions and relationships. By doing so, users can better appreciate the engineering behind their equipment, leading to more informed decisions in both usage and care.

Understanding Swisher Log Splitter Basics

When it comes to efficiently processing timber, having a solid grasp of the essential components and their functions is crucial. This understanding not only enhances operational efficiency but also ensures safety during usage. Familiarity with the main elements involved in the machinery allows users to troubleshoot issues, perform maintenance, and optimize performance effectively.

The core functionality of this equipment revolves around the mechanics of splitting and shaping wood for various applications. Each element, from the power source to the blade, plays a vital role in the overall process. Recognizing how these components interact can significantly impact the user experience and productivity.

Moreover, regular upkeep and understanding of potential wear and tear can extend the lifespan of the machine. By identifying the key sections that require attention, operators can prevent breakdowns and ensure a smooth operation. Overall, a foundational knowledge of how these systems work together empowers users to tackle their tasks with confidence and efficiency.

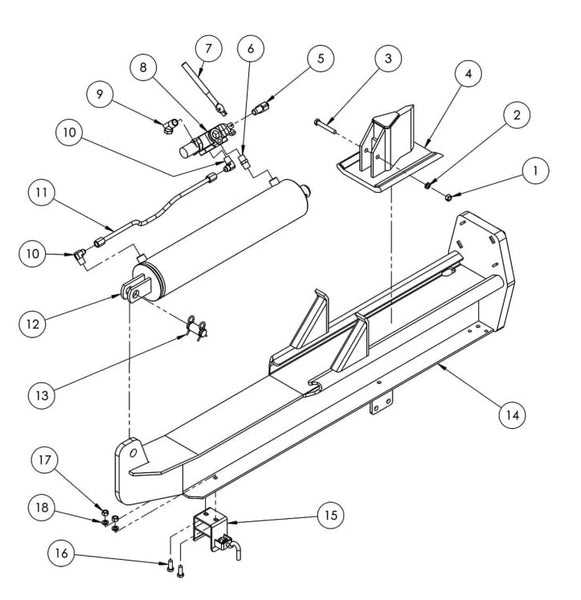

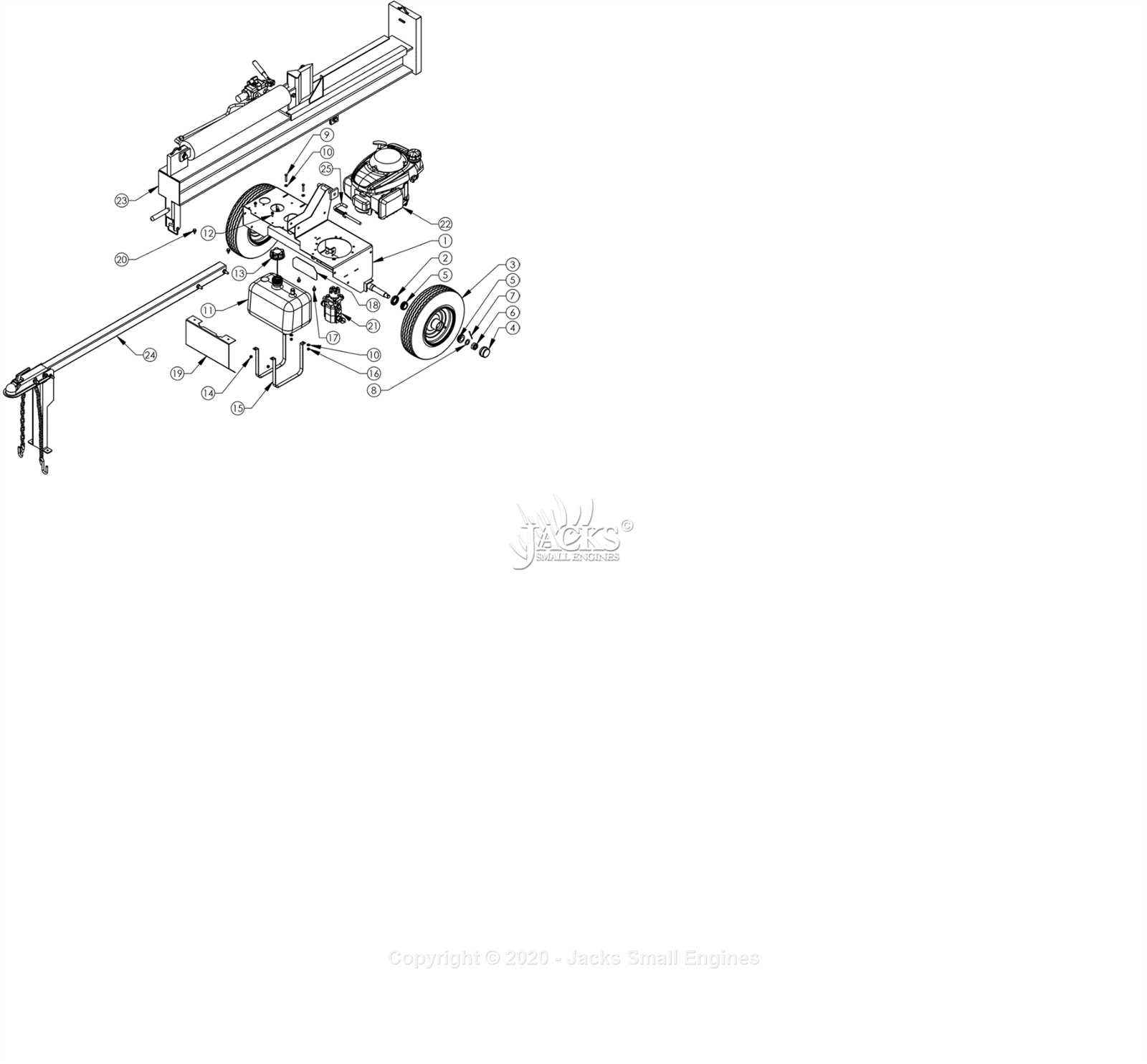

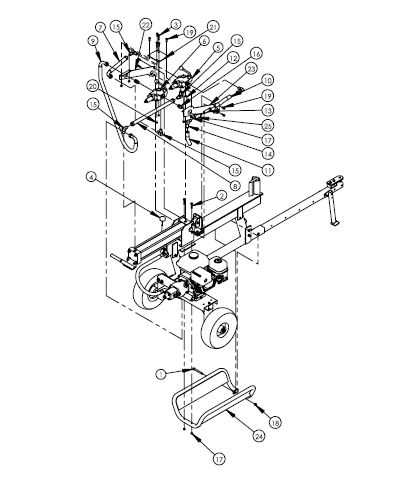

Importance of Parts Diagrams

Understanding the assembly and function of machinery components is crucial for effective maintenance and repair. Visual representations of these elements facilitate quick identification and enhance troubleshooting efficiency.

Benefits of Visual Representations

- Improved clarity in identifying individual components.

- Streamlined repair processes through clear instructions.

- Enhanced communication between technicians and users.

Efficiency in Maintenance

- Facilitates quick assessments of required repairs.

- Reduces downtime by guiding users through procedures.

- Promotes better inventory management of replacement components.

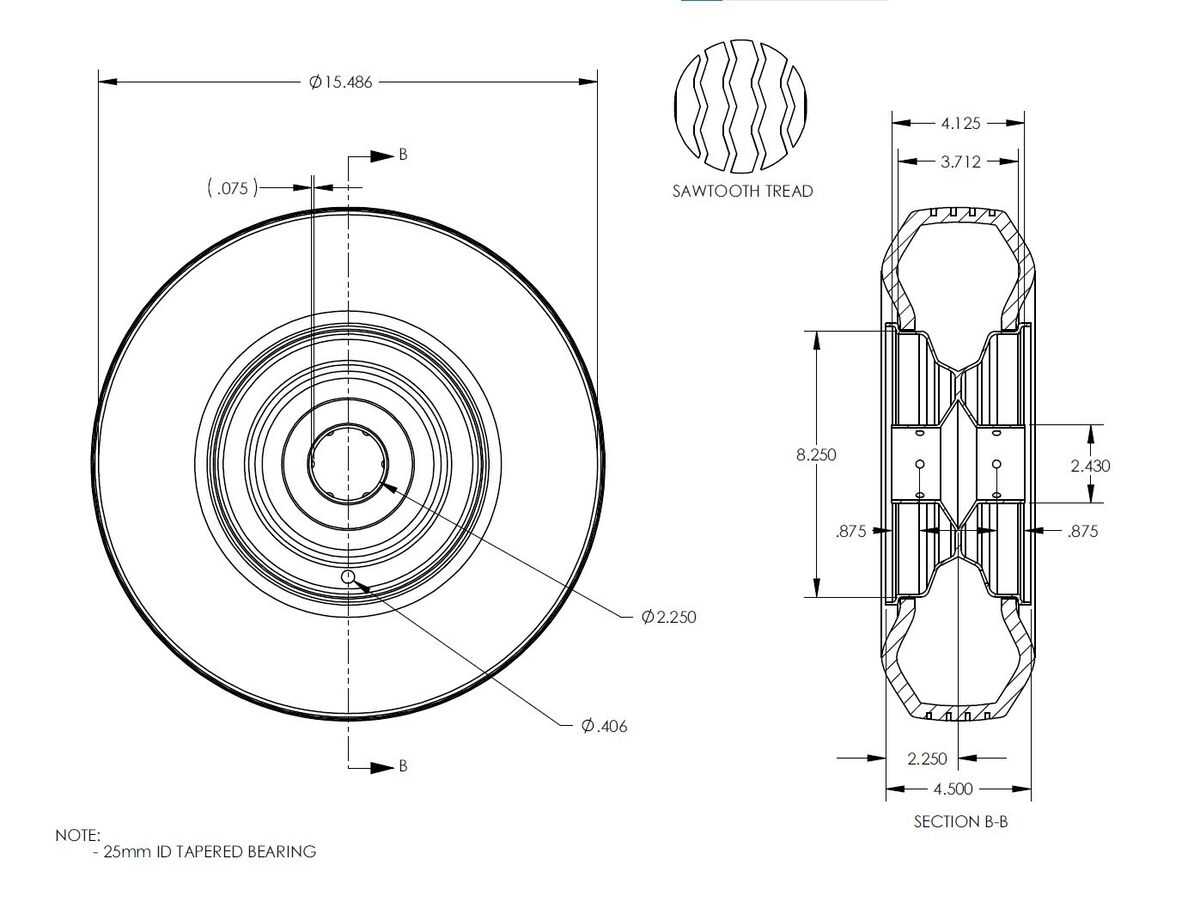

Common Components of Log Splitters

Understanding the essential elements of wood processing machinery is crucial for effective operation and maintenance. These devices typically consist of several key components that work together to facilitate the efficient splitting of timber. Familiarity with these parts helps users optimize performance and troubleshoot issues.

Main Elements

- Power Source: Provides the necessary energy, whether it’s electric, gas, or hydraulic.

- Frame: The structure that supports and houses all other components.

- Wedge: The sharp piece that penetrates and splits the wood.

- Cylinder: The part that generates pressure to move the wedge.

- Hydraulic Pump: Transforms mechanical energy into hydraulic pressure for operation.

Supporting Parts

- Control Valve: Regulates the flow of hydraulic fluid to control the movement of the wedge.

- Safety Features: Includes guards and switches that protect users during operation.

- Wheels: Facilitate mobility, allowing for easy transportation across various terrains.

- Hoses and Fittings: Connect hydraulic components and ensure fluid transfer.

By comprehending these fundamental components, users can enhance their experience and ensure the longevity of their equipment.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly simplify the process of maintenance and repairs. By familiarizing yourself with the layout and symbols used, you can efficiently identify and locate each element.

Here are some key steps to effectively interpret such illustrations:

- Familiarize Yourself with Symbols: Each representation may use unique symbols. Check the legend or key for clarification.

- Identify Major Sections: Look for grouped components that serve similar functions, making it easier to pinpoint issues.

- Follow the Flow: Trace the connections between components to understand how they interact.

- Use Reference Numbers: Many diagrams include numbers that correspond to parts lists, aiding in ordering replacements.

With practice, reading these visual guides will become intuitive, enhancing your ability to tackle any repair challenge efficiently.

Identifying Wear and Tear Signs

Recognizing signs of deterioration is crucial for maintaining the efficiency and safety of your equipment. Regular inspections can help you spot potential issues before they escalate, ensuring optimal performance and longevity. By understanding common indicators, you can take timely action to address wear and prevent further damage.

Common Indicators

Look for cracks, rust, or unusual noises during operation. Additionally, check for any abnormal vibrations or decreased performance, as these may signal underlying problems. A thorough visual inspection can reveal areas that need attention.

Preventive Measures

Implementing routine maintenance schedules can significantly reduce wear. Regular cleaning, lubrication, and timely replacement of worn components are essential practices. By being proactive, you can enhance the overall durability and functionality of your equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your machine, reducing the risk of breakdowns and costly repairs.

Regular Inspections

Conduct periodic assessments of the machinery to identify any signs of wear or damage. Check for loose bolts, frayed wires, or any components that may require lubrication. Addressing these issues early can prevent more significant problems down the line.

Proper Cleaning

Maintaining cleanliness is crucial for optimal performance. After each use, remove debris and dirt that may accumulate on the surface and in hard-to-reach areas. Using a soft brush or compressed air can help keep the machinery in top condition, ensuring that all mechanisms function smoothly.

Emphasizing the importance of maintenance not only enhances performance but also provides peace of mind knowing that your equipment is in good working order. Consistent care leads to greater efficiency and longevity.

Replacing Worn-Out Parts Efficiently

Maintaining machinery in top condition is crucial for optimal performance. Timely replacement of deteriorated components ensures longevity and reliability, reducing downtime and enhancing productivity. Understanding the process can help streamline the task, making it more manageable.

Identifying Components for Replacement

Recognizing which elements require attention is the first step. Regular inspections can reveal signs of wear such as cracks, rust, or reduced efficiency. Keeping a checklist can aid in tracking these indicators effectively.

Steps for Efficient Replacement

Once you’ve identified the necessary components, follow these steps for an efficient replacement:

| Step | Description |

|---|---|

| 1 | Gather tools and new components required for the replacement. |

| 2 | Turn off the machine and ensure safety precautions are in place. |

| 3 | Carefully remove the worn components using the appropriate tools. |

| 4 | Install the new parts, ensuring a secure fit and proper alignment. |

| 5 | Test the equipment to confirm functionality and efficiency. |

Tools Required for Repairs

When undertaking maintenance or repairs on machinery, having the right tools at hand is essential for achieving efficient and effective results. Proper equipment not only simplifies the process but also ensures safety and precision during work.

Essential Tools

| Tool | Description |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Screwdrivers | Essential for removing and securing screws of various types. |

| Hammer | Useful for driving nails or adjusting components. |

| Pliers | Handy for gripping, bending, and cutting wires or small parts. |

Safety Equipment

| Item | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and injuries. |

| Safety Goggles | Shield eyes from debris and harmful substances. |

| Ear Protection | Minimize noise exposure during operation. |

Swisher Log Splitter Models Overview

This section provides a comprehensive look at various models designed for efficient wood processing. Each variant offers unique features tailored to meet the needs of users, from residential to commercial applications. Understanding these options allows potential buyers to make informed decisions that best suit their requirements.

Key Features

Each model incorporates different specifications, enhancing performance and usability. Users can choose based on power output, operational speed, and additional functionalities. These factors significantly influence efficiency and overall satisfaction.

Comparison Table

| Model | Power (HP) | Cycle Time (Seconds) | Weight (lbs) |

|---|---|---|---|

| Model A | 5 | 10 | 150 |

| Model B | 6 | 8 | 175 |

| Model C | 7 | 7 | 200 |

Where to Find Replacement Parts

Locating components for your machinery can enhance its performance and longevity. Various resources are available to assist you in finding the necessary items to keep your equipment running smoothly. Exploring both online and local options can yield the best results.

Start by checking manufacturer websites for official offerings. These platforms often provide a comprehensive catalog of available components tailored for specific models. Additionally, authorized dealers may have inventory and can assist with finding the right fit.

Online marketplaces, such as e-commerce sites, can be invaluable. Many users share reviews and recommendations, helping you make informed choices about quality and compatibility. Community forums and social media groups dedicated to equipment maintenance can also offer insights and suggestions for sourcing parts.

Local hardware stores or specialty shops may carry some items, or they can assist in ordering specific components. Building relationships with local suppliers can facilitate quicker access to needed materials in the future.

Common Issues and Troubleshooting

In the realm of machinery designed for cutting and processing timber, various challenges can arise during operation. Identifying and resolving these issues efficiently is essential to maintain optimal performance and extend the lifespan of the equipment. Below are some frequent problems encountered, along with their possible solutions.

Frequent Problems

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Inadequate Cutting | Worn blades or dull edges | Sharpen or replace the blades |

| Overheating | Lack of lubrication or blocked airflow | Check oil levels and clean air filters |

| Unresponsive Controls | Faulty wiring or blown fuses | Inspect electrical connections and replace fuses |

| Vibration and Noise | Loose components or imbalanced assembly | Tighten bolts and ensure proper alignment |

Maintenance Tips

Regular upkeep can prevent many of these issues from occurring. Ensure that all components are regularly inspected, lubricated, and replaced as necessary. Keeping the machinery clean and free of debris will also contribute to smoother operations and better efficiency.

Upgrading Your Log Splitter Components

Enhancing the efficiency and performance of your outdoor equipment can significantly impact your productivity. By focusing on key elements that may require improvement, you can ensure a smoother operation and increased durability. Whether you’re looking to boost power, reduce wear and tear, or improve safety features, there are several components to consider upgrading.

Key Components to Consider

Start by evaluating the hydraulic system, which is crucial for achieving optimal force. Upgrading to a high-performance pump can lead to faster cycle times and greater efficiency. Additionally, consider enhancing the blade quality; a sharper, more durable cutting edge will reduce strain on the machine and improve cutting effectiveness.

Maintenance and Accessories

Regular maintenance is essential for longevity, but adding accessories can also make a significant difference. Investing in quality protective gear and efficient loading ramps can improve safety and usability. Furthermore, consider integrating a more advanced control system to enhance ease of use and precision during operation.