In the realm of automotive engineering, comprehending the intricate assembly of a particular transmission mechanism is essential for both enthusiasts and professionals. This intricate system plays a crucial role in the overall functionality of vehicles, impacting performance, efficiency, and reliability. A detailed exploration of its elements provides insights into how each component interacts and contributes to the seamless operation of the system.

Familiarity with the various sections and their respective roles enables technicians and mechanics to diagnose issues effectively and implement necessary repairs or upgrades. Each component serves a unique purpose, and understanding their layout can significantly enhance one’s ability to maintain and optimize vehicle performance. The visual representation of these elements aids in grasping the relationships and workflows inherent in the transmission’s design.

By delving into the specifics of these components, one can appreciate the engineering prowess involved in creating such a complex assembly. A systematic approach to learning about these sections not only fosters technical skills but also cultivates a deeper respect for the craftsmanship that goes into modern automotive technology. This knowledge becomes invaluable in troubleshooting and ensuring the longevity of the transmission system.

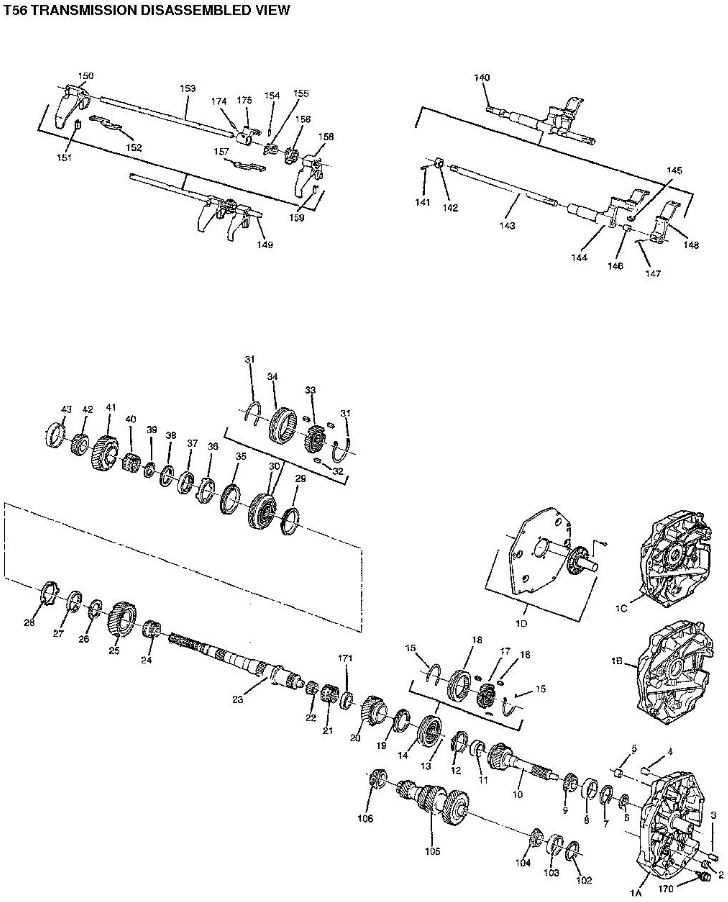

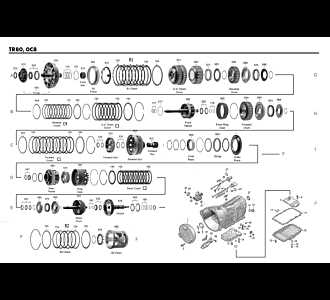

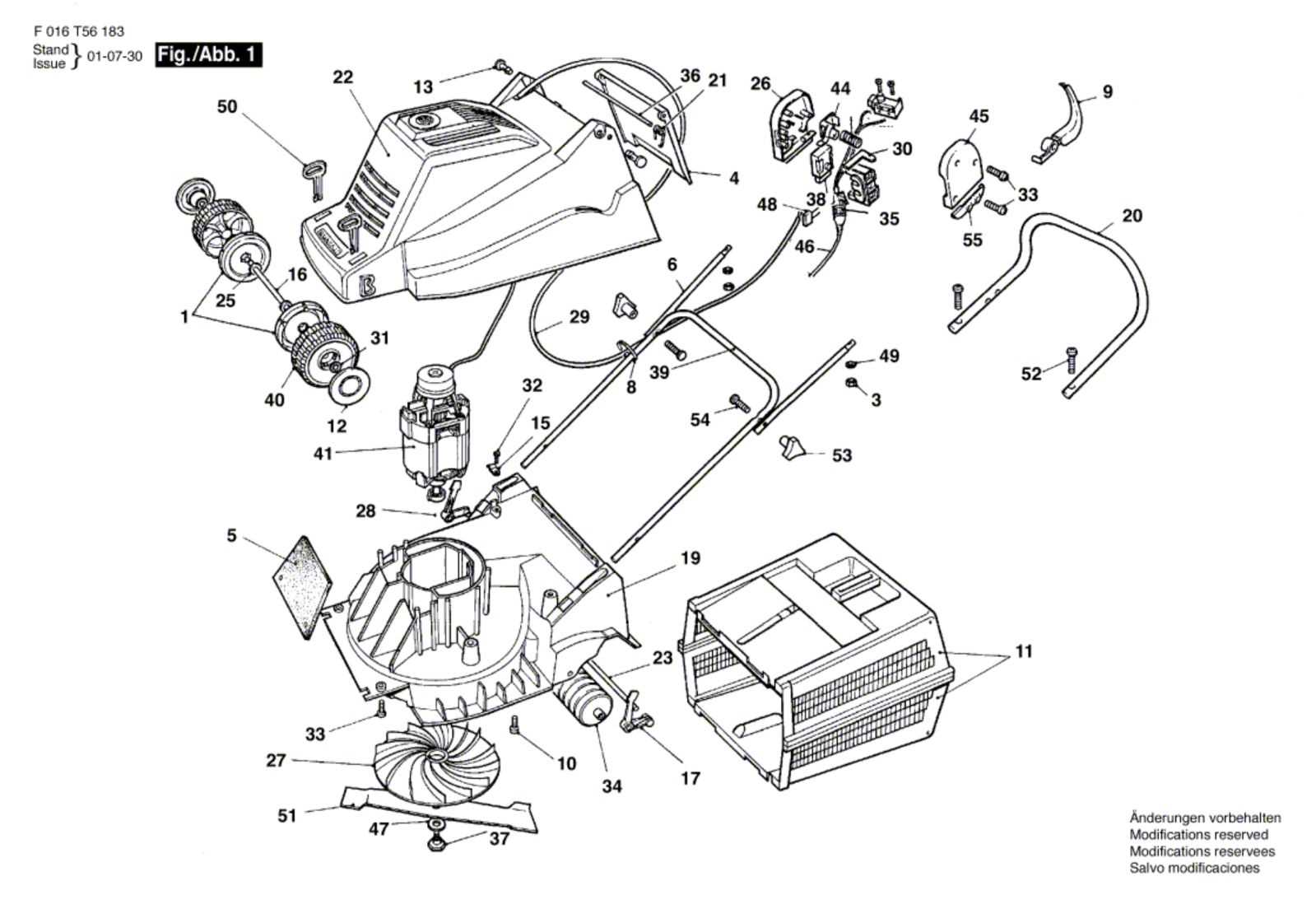

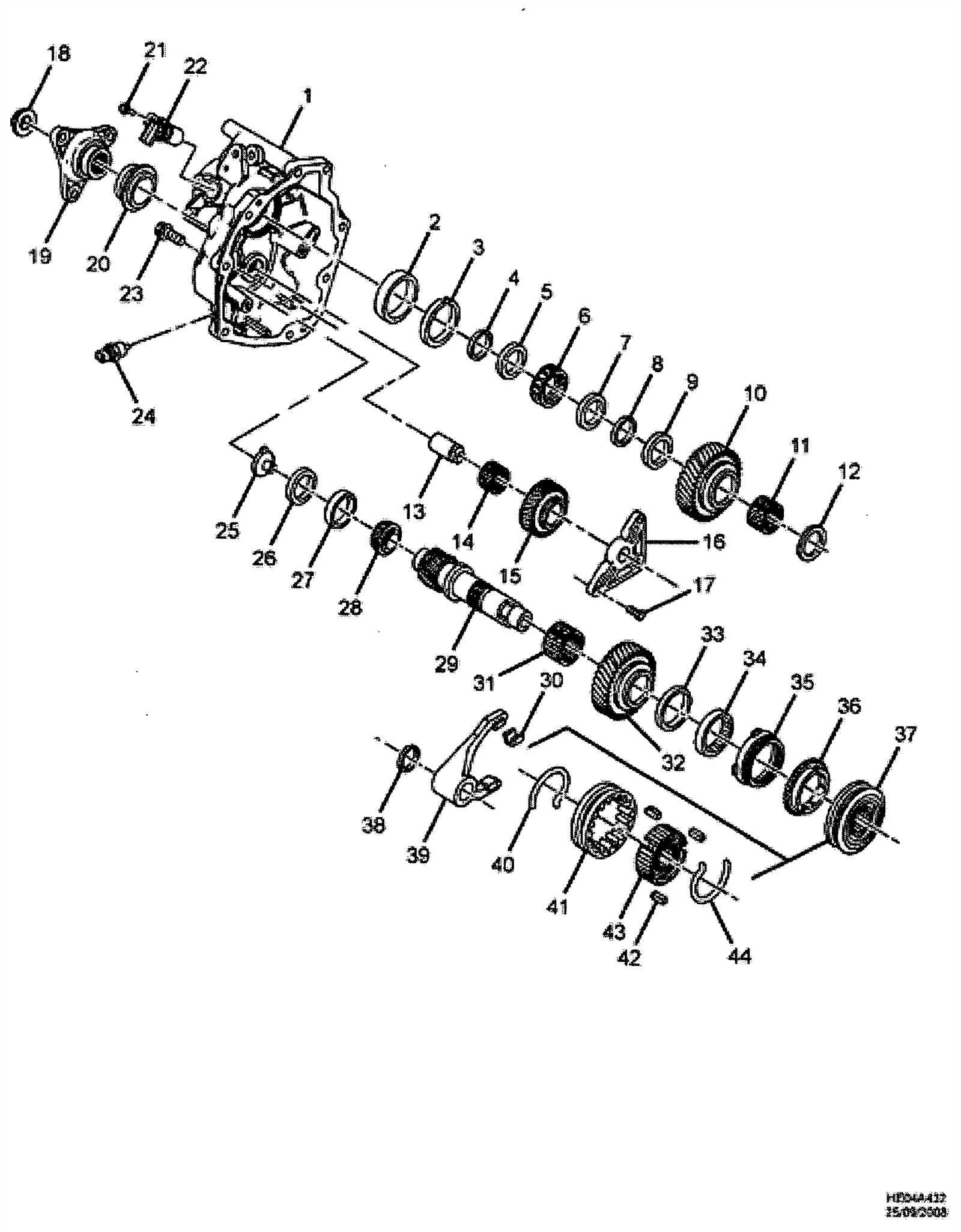

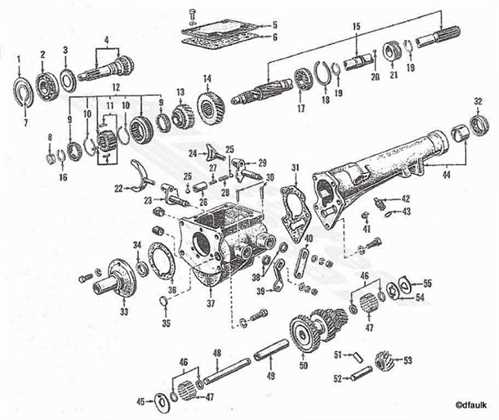

T56 Parts Diagram Overview

This section aims to provide a comprehensive look into the components and their arrangement within a specific transmission model. Understanding these elements is crucial for effective maintenance and repair, enabling enthusiasts and professionals alike to navigate the intricacies of the system.

Component Structure

The structure comprises various essential elements, each playing a vital role in the overall functionality. Identifying these pieces can greatly enhance one’s ability to troubleshoot issues and perform upgrades.

Benefits of Understanding the Layout

Grasping the configuration allows for more efficient repairs and modifications. This knowledge not only simplifies the repair process but also empowers users to delve deeper into performance enhancements, achieving the ultimate driving experience.

Key Components of T56 Engine

The inner workings of this powerplant consist of several crucial elements that contribute to its performance and efficiency. Each component plays a vital role in ensuring the engine operates smoothly, delivering the ultimate power needed for various applications.

Core Elements

Among the fundamental constituents, the compressor stands out, responsible for increasing the air pressure entering the combustion chamber. This process enhances the overall efficiency of fuel combustion, resulting in improved thrust. Additionally, the turbine converts the energy from exhaust gases back into mechanical energy, facilitating continued operation.

Supporting Systems

Lubrication is another essential system, ensuring that all moving parts function seamlessly. Without proper lubrication, wear and tear could compromise engine integrity. Fuel delivery mechanisms also play a critical role, providing the necessary mixture for combustion, ensuring optimal performance under various conditions.

Importance of Accurate Diagrams

Detailed representations play a crucial role in understanding complex mechanical systems. Their precision ensures that users can effectively navigate the intricacies of assembly and maintenance. Without such clarity, the risk of errors and inefficiencies increases significantly.

Key reasons for the significance of precise illustrations include:

- Enhanced Understanding: Clear visuals facilitate a better grasp of component relationships and functions.

- Streamlined Processes: Accurate representations lead to quicker and more efficient assembly and disassembly.

- Reduction of Errors: Well-crafted visuals minimize the chances of mistakes during installation or repairs.

- Improved Communication: They provide a common language for technicians and engineers, reducing misinterpretations.

- Increased Safety: Precise depictions help identify potential hazards, ensuring safer working conditions.

In summary, the importance of accurate visual aids cannot be overstated. They are essential tools that contribute to the efficiency, safety, and reliability of mechanical operations.

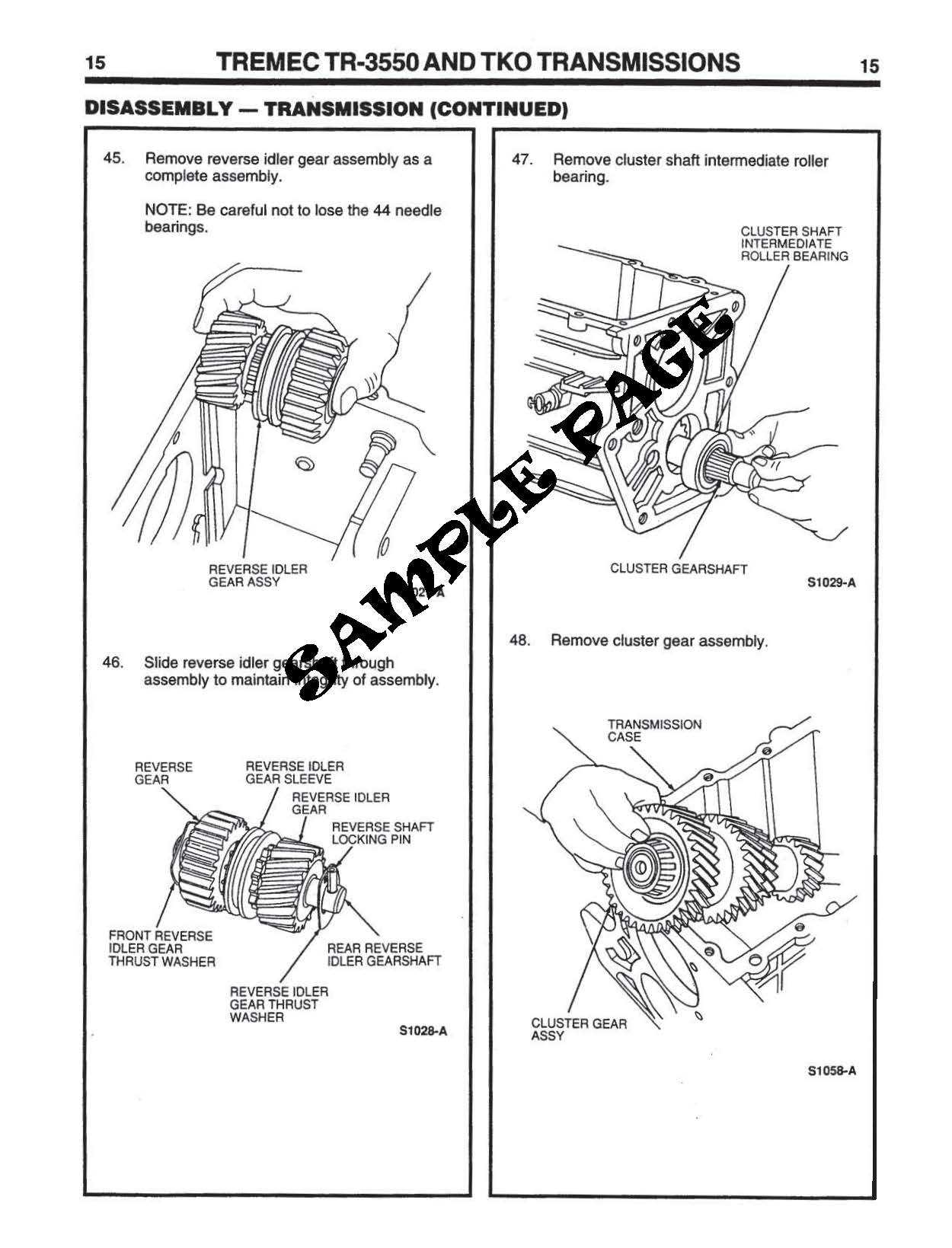

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective assembly and maintenance. These illustrations serve as a guide, showcasing the relationship between various elements, their functions, and how they fit together within a system. Grasping the key features of these images can streamline both troubleshooting and reassembly processes.

Start by identifying the labels and annotations that accompany the visuals. These notations provide essential information regarding part numbers, specifications, and installation instructions. Pay attention to any accompanying legends or keys, as they often explain symbols or color codes used in the illustration.

Next, focus on the layout. Components are usually organized in a logical sequence, reflecting their placement in the overall structure. Recognizing this arrangement will aid in comprehending how each piece interacts with others, facilitating easier identification during reassembly or replacement tasks.

Lastly, familiarize yourself with the common conventions used in these representations. Understanding standard symbols and lines will enhance your ability to interpret the visuals effectively. With practice, you will develop a quicker intuition for navigating these guides, ultimately making your repair or assembly projects more efficient.

Common Issues in T56 Engines

Engines of this specific type often encounter a range of challenges that can affect performance and reliability. Understanding these common problems is essential for effective maintenance and timely repairs.

Overheating is a frequent concern, typically caused by coolant leaks, clogged radiators, or malfunctioning thermostats. When temperatures rise, it can lead to serious damage if not addressed promptly.

Transmission issues may arise, including difficulty in shifting gears or unusual noises during operation. These symptoms can indicate worn synchronizers or low fluid levels, necessitating a thorough inspection.

Oil leaks are another prevalent issue, often stemming from aging seals or gaskets. Regular checks can help identify these leaks early, preventing potential engine damage.

Lastly, fuel delivery problems can affect engine performance, leading to misfires or reduced power. Keeping fuel filters clean and ensuring proper injector function can mitigate these risks.

Maintenance Tips for T56 Parts

Proper upkeep is essential for ensuring the longevity and optimal performance of your vehicle’s components. Regular inspections and preventive measures can significantly reduce wear and tear, enhancing efficiency and reliability. Understanding the specific requirements for maintenance will help you avoid costly repairs and downtime.

Routine Inspections

Conducting frequent examinations of critical components is vital. Look for signs of wear, leaks, or any irregularities. Regularly check fluid levels and quality, as well as any connections that may have loosened over time. Addressing minor issues promptly can prevent major failures down the line.

Lubrication and Cleaning

Keeping components clean and well-lubricated is crucial. Use the recommended lubricants for your specific system to minimize friction and heat buildup. Regular cleaning can prevent dirt and debris from causing damage. Establish a maintenance schedule to ensure these tasks are performed consistently.

Identifying Components in Diagrams

Understanding the various elements represented in schematics is crucial for effective interpretation and application. These illustrations serve as a visual guide, offering clarity and insight into the function and arrangement of each component within a system.

Key Elements to Recognize

- Symbols: Each symbol represents a specific item or function, aiding in quick identification.

- Connections: Lines and arrows indicate how components interact, revealing the flow of processes.

- Labels: Annotations provide additional information about each part, enhancing comprehension.

Tips for Effective Identification

- Familiarize yourself with common symbols used in technical illustrations.

- Pay attention to the context of connections to understand relationships between parts.

- Refer to accompanying legends or keys for clarification on complex symbols.

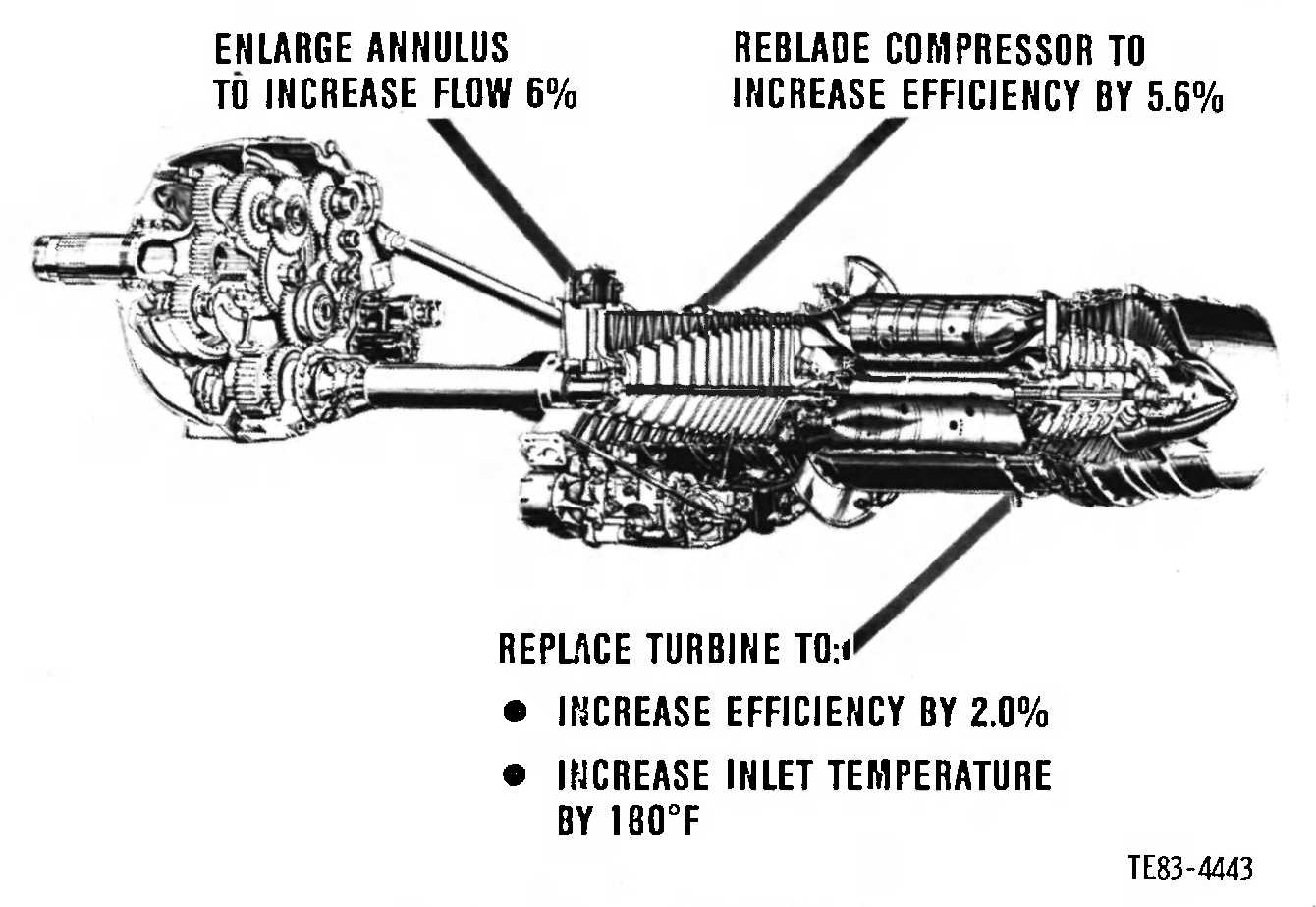

Latest Innovations in T56 Design

Recent advancements in engineering have significantly enhanced the efficiency and performance of key components in aircraft propulsion systems. These innovations focus on improving durability, reducing weight, and optimizing fuel consumption, thereby providing operators with superior operational capabilities.

One notable development is the introduction of advanced materials that withstand higher temperatures and stresses, allowing for longer service intervals and lower maintenance costs. Furthermore, aerodynamic refinements contribute to improved thrust and efficiency, making these systems more competitive in today’s market.

Additionally, the integration of smart technologies facilitates real-time monitoring and diagnostics, enabling proactive maintenance and enhancing overall reliability. As a result, these cutting-edge enhancements ensure that modern propulsion systems meet the ultimate demands of performance and sustainability.

Comparative Analysis with Other Engines

This section explores the distinctions and similarities among various powertrains, focusing on performance, design, and reliability. By examining these elements, we can understand the unique attributes and benefits of each engine type, ultimately aiding in informed decision-making for enthusiasts and professionals alike.

Performance Metrics

When assessing output capabilities, several engines display varied levels of horsepower and torque. The comparison highlights how some units excel in acceleration, while others prioritize efficiency. Understanding these differences enables users to select an engine that aligns with their specific driving needs and preferences.

Design and Reliability

Engine architecture significantly influences durability and maintenance requirements. Some models feature advanced materials and innovative designs, enhancing longevity. By delving into the construction of each engine, we can identify which options offer the ultimate balance between performance and upkeep, guiding users toward the most suitable choice for their applications.

Supplier Sources for T56 Parts

When seeking components for high-performance machinery, identifying reliable sources is crucial. Various suppliers cater to specific needs, offering a range of options for both new and refurbished elements. This section outlines some notable avenues to consider when sourcing these essential items.

Types of Suppliers

- OEM Providers: Original Equipment Manufacturers guarantee authenticity and quality, making them a top choice for those prioritizing reliability.

- Aftermarket Vendors: These suppliers offer a wide selection of alternatives that may provide cost savings without compromising functionality.

- Specialty Distributors: Focusing on niche markets, these distributors often carry unique items that may not be readily available elsewhere.

Where to Find Suppliers

- Online Marketplaces: Platforms such as eBay and Amazon can provide a vast array of options from various sellers.

- Industry Trade Shows: Attending expos can connect you with multiple suppliers and offer opportunities to view products firsthand.

- Manufacturer Websites: Many companies maintain an updated list of authorized distributors and provide direct purchasing options.

- Local Retailers: Checking with local auto parts stores or specialized shops can yield quick access to essential components.

Tools for T56 Assembly and Repair

When working on the assembly and maintenance of high-performance transmission systems, having the right tools is crucial for achieving optimal results. The selection of specialized instruments not only enhances efficiency but also ensures precision in every aspect of the process. This section outlines essential equipment that facilitates the rebuilding and servicing of these complex mechanisms.

Wrenches and Sockets: A comprehensive set of wrenches and sockets is indispensable. These tools allow for secure fastening and loosening of various components. Ratchet sets with multiple sizes help access tight spaces, ensuring that all connections are tight and secure.

Torque Wrench: Precision is key in maintaining the integrity of a transmission. A torque wrench ensures that all bolts are tightened to the manufacturer’s specifications, preventing potential failures caused by over- or under-tightening.

Gear Puller: This tool is vital for removing gears and other press-fitted components without causing damage. A gear puller allows for safe disassembly, which is essential when inspecting or replacing worn parts.

Seal Installer: Proper installation of seals is critical to prevent fluid leaks. A dedicated seal installer helps achieve even and accurate placement, prolonging the lifespan of the assembly.

Measuring Tools: Calipers and micrometers are necessary for checking tolerances and ensuring components fit correctly. Accurate measurements can prevent operational issues and enhance overall performance.

In summary, utilizing the right assortment of tools not only streamlines the assembly and repair process but also guarantees that the transmission operates smoothly and reliably. Investing in quality equipment is essential for any technician aiming to achieve the best outcomes in their work.

Future of T56 Technology

The advancements in transmission systems are poised to revolutionize various industries, promising enhanced performance and efficiency. With ongoing research and development, the future looks bright for these intricate mechanisms.

Emerging trends suggest a shift towards more sustainable and efficient designs. Key areas of focus include:

- Integration of smart technologies for improved diagnostics and monitoring.

- Development of lightweight materials to enhance fuel efficiency.

- Utilization of advanced manufacturing techniques for better precision.

Moreover, the increasing demand for electrification in vehicles will drive innovation in hybrid and electric transmission solutions. This transformation will likely include:

- Enhanced energy recovery systems.

- Improved power delivery mechanisms.

- Seamless integration with electric drivetrains.

As the industry evolves, collaboration among manufacturers, engineers, and researchers will be essential to push the boundaries of what these systems can achieve. The future promises a harmonious blend of performance, sustainability, and cutting-edge technology.