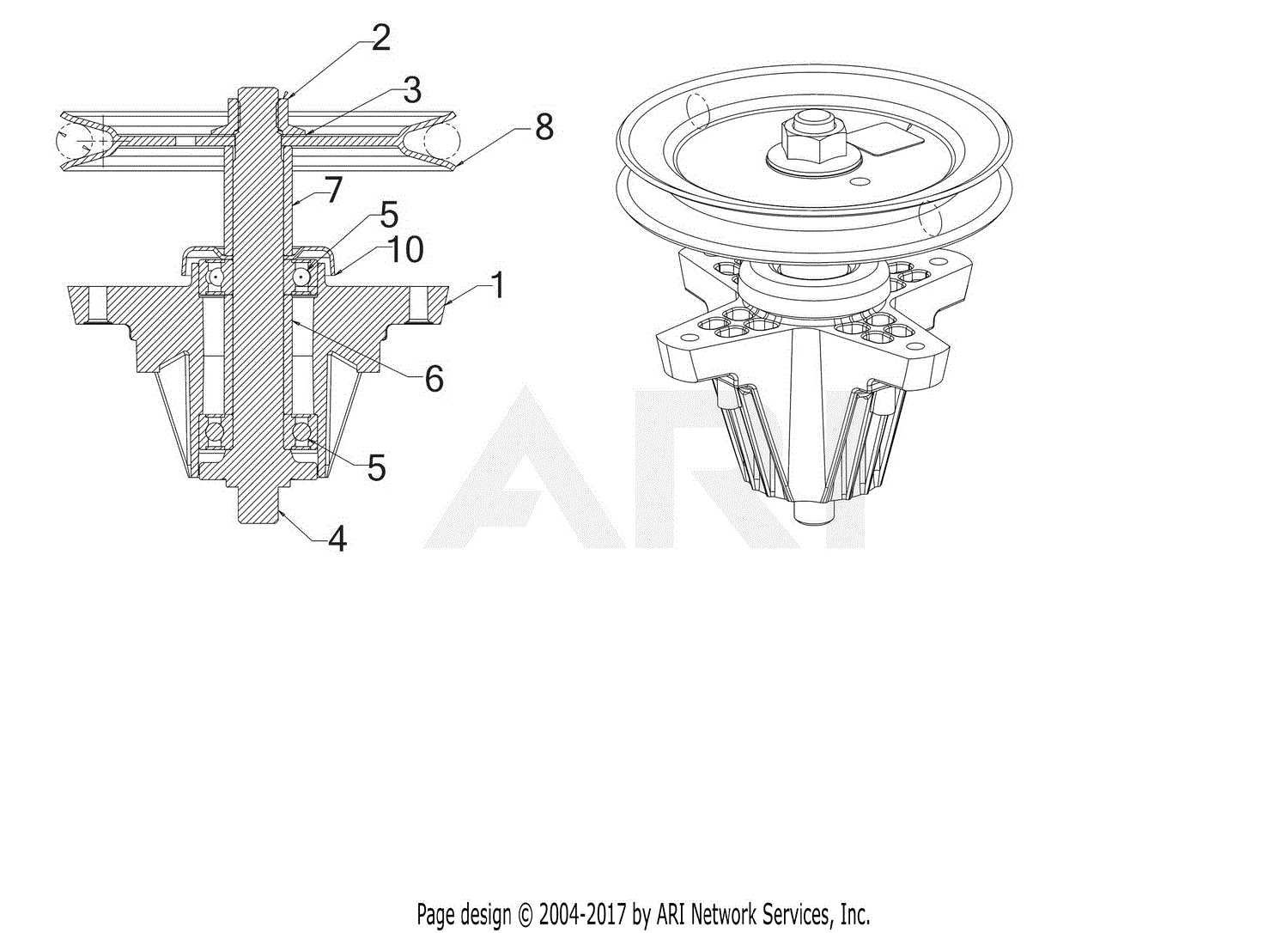

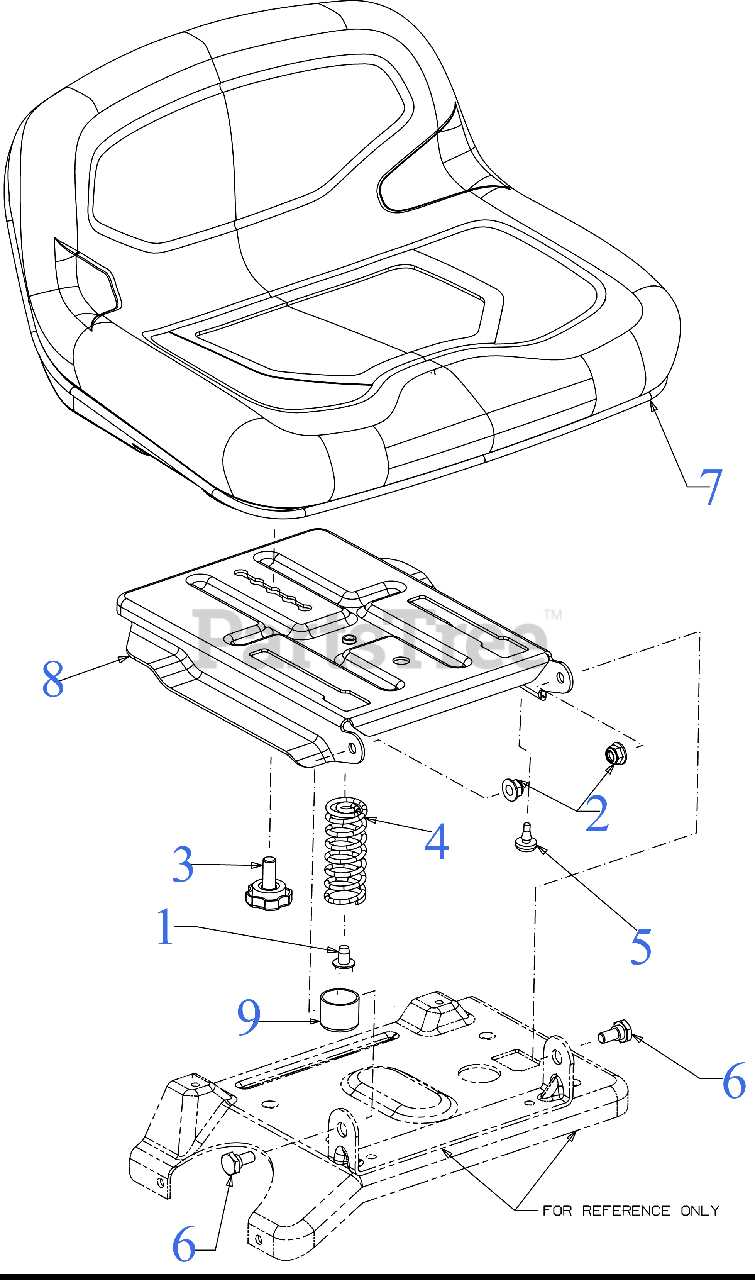

Understanding the key elements of mechanical systems and how they are interconnected is crucial for proper maintenance and repair. A detailed representation of each element’s layout can provide significant insight into the assembly and operation of the equipment.

By reviewing the structural connections between various mechanical elements, you can identify the locations of critical components and better grasp their function within the system. This knowledge is especially important when performing troubleshooting or routine maintenance tasks, ensuring that the equipment operates efficiently.

Having a clear view of the assembly helps to streamline the replacement process, making it easier to locate and exchange any worn or malfunctioning elements. This information serves as a valuable guide for anyone looking to maintain or repair their equipment effectively.

Comprehensive Guide to TB30R Components

This section provides a thorough overview of the various elements that make up the machinery. Each part plays a critical role in ensuring smooth and efficient operation. Understanding how these components interact can help maintain the equipment in optimal condition and ensure its longevity.

Key Mechanical Elements

The primary mechanical components are essential for the system’s performance. Regular maintenance of these elements is crucial to avoid breakdowns and ensure the functionality of the entire unit.

- Engine assembly and its associated mechanisms

- Transmission systems that regulate power flow

- Control mechanisms for speed and direction adjustments

Operational and Safety Features

In addition to the core mechanics, the equipment includes several features designed to enhance both performance and safety. These features contribute to the user experience and prevent potential hazards.

- Braking

Understanding the Layout of the TB30R

The structure of this model is designed to ensure efficient performance and ease of maintenance. By gaining a clear understanding of how its various elements are positioned, users can better navigate the setup, troubleshoot issues, and perform routine tasks. Recognizing the placement of key components is essential for anyone looking to work with the device effectively.

Key Sections and Their Functions

Each section plays a vital role in the overall operation. The engine, drive system, and control mechanisms are strategically arranged to provide both power and user control. The layout simplifies access to frequently maintained areas, ensuring users can easily handle servicing and adjustments.

Efficient Design for Maintenance

The thoughtful design ensures that key components are placed in a way that reduces the time needed for routine checks and repairs. This not only improves efficiency but also minimizes downtime, making the unit more user

Key Features of TB30R Machine Parts

This section provides an overview of essential components that ensure the smooth functioning of the machinery. The individual elements play a crucial role in maintaining performance and durability, ensuring reliable operation across various tasks.

Main Components and Their Functions

The machine is equipped with several key elements, each designed for a specific role in its operation. These components are engineered to provide efficiency and longevity, reducing the need for frequent maintenance.

Component Description Function Engine Assembly Central power source of the machine Generates power to operate other mec Identifying Critical Components in TB30R

Understanding the key elements of a machine is essential for proper maintenance and troubleshooting. These essential parts ensure smooth operation and longevity. By recognizing them, users can effectively address potential issues and keep the system running efficiently.

- Engine: The core of the machine, responsible for powering all functions.

- Transmission: Transmits power from the motor to the wheels, allowing for movement and control.

- Braking System: Critical for safety, this mechanism ensures the equipment stops when needed.

- Electrical Circuitry: Manages the distribution of power to various components and ensures everything operates as intended.

These are just some of the most vital components that require regular attention to ensure optimal performance.

Exploring the Functionality of TB30R Systems

Understanding the inner workings of complex systems is crucial for optimizing their performance and ensuring longevity. Each component plays a vital role, contributing to the overall efficiency and functionality of the system. This section delves into the various elements that make up these advanced mechanisms, highlighting their significance and interconnectivity.

Key Components and Their Roles

The core elements of these systems are designed to work in harmony, facilitating smooth operations. For instance, the engine components are engineered to generate power, while the transmission system efficiently relays that energy to the necessary parts. Moreover, auxiliary units ensure that all functions are executed seamlessly, enhancing the user experience.

Maintenance for Optimal Performance

Regular upkeep is essential for maintaining the functionality of these systems. Routine inspections and timely replacements of worn-out components can prevent breakdowns and extend the lifespan of the equipment. Proactive maintenance not only safeguards against potential issues but also maximizes efficiency, ensuring that the system operates at its best.

Maintenance Tips for TB30R Parts

Proper upkeep of your machinery components is essential for ensuring optimal performance and longevity. Regular maintenance helps to identify potential issues early and prevents costly repairs down the line. Here are some effective strategies to keep your equipment in top shape.

1. Regular Inspections: Conduct frequent assessments of the various elements to catch wear and tear before it escalates. Look for signs of damage, corrosion, or loose fittings.

2. Cleanliness is Key: Keeping all components clean enhances their functionality. Use appropriate cleaning agents to remove dirt and debris, ensuring that moving parts operate smoothly.

3. Lubrication: Apply the recommended lubricants to reduce friction and prevent overheating. Regularly check the lubrication levels and top them off as needed.

4. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule provided by the manufacturer. This includes recommended service intervals and specific procedures tailored for your equipment.

5. Replace Worn Out Elements: Don’t delay in replacing components that show significant wear. Timely replacements can prevent further damage and ensure uninterrupted operation.

6. Keep Records: Maintain detailed records of all maintenance activities, including inspections, replacements, and repairs. This documentation can be invaluable for tracking the performance and identifying trends over time.

By following these maintenance tips, you can enhance the reliability and efficiency of your machinery, ultimately leading to better performance and extended lifespan.

How to Troubleshoot Common TB30R Issues

Troubleshooting mechanical equipment can often be a daunting task, but with the right approach, you can identify and resolve prevalent problems efficiently. Understanding the typical symptoms of malfunctions is essential for effective diagnosis and repair.

Step 1: Start by examining the device for any visible signs of wear or damage. Look for loose connections, frayed wires, or any components that appear out of place. Ensuring that everything is securely attached can often solve basic operational issues.

Step 2: Next, check the functionality of the system by conducting a performance test. If you notice any irregular noises or vibrations, it may indicate an internal problem. Take note of any unusual behavior as this information will be helpful during repairs.

Step 3: Consult the user manual for troubleshooting tips specific to the equipment. Often, manuals contain valuable information on common faults and their solutions, guiding you through the process step-by-step.

Step 4: If problems persist, consider reaching out to a professional technician. They have the expertise to diagnose more complex issues that may not be immediately evident. A qualified professional can provide insights into the underlying causes of persistent problems.

By following these steps, you can systematically address common challenges and restore functionality to your machinery.

Replacement Options for TB30R Components

When considering the restoration or enhancement of your equipment, exploring various alternatives for its elements is crucial. Having a solid understanding of available replacements can significantly improve performance and longevity.

Original Equipment Manufacturer (OEM) Parts: Opting for components directly from the original manufacturer ensures compatibility and quality. These parts are designed specifically for your machinery, providing reliability and performance that matches or exceeds the original specifications.

Aftermarket Components: Many third-party manufacturers produce compatible elements that can serve as effective substitutes. These alternatives often come at a lower cost and can offer similar performance. However, it is essential to research their quality and reliability before making a purchase.

Rebuilt and Refurbished Parts: For those seeking a more sustainable option, consider rebuilt or refurbished elements. These are often restored to meet original specifications and can provide significant savings while contributing to environmental sustainability.

Ultimately, the choice of replacement components depends on factors such as budget, performance needs, and the specific requirements of your equipment. Evaluating all available options ensures optimal functionality and longevity.

TB30R Upgrade

Enhancing your machinery can significantly improve performance and efficiency. This section explores various enhancements that can be made to elevate the capabilities of your equipment, ensuring it operates at its optimal level.

Benefits of Upgrading

Upgrading components not only enhances functionality but also extends the lifespan of the equipment. Here are some key advantages:

- Improved efficiency and productivity.

- Enhanced reliability and reduced maintenance costs.

- Access to advanced features and technologies.

- Better fuel economy and reduced emissions.

Key Components for Consideration

When planning an upgrade, consider the following essential components:

- Engine: Upgrading to a more powerful engine can provide better torque and acceleration.

- Transmission: Enhancing the transmission system ensures smoother operation and better gear shifts.

- Suspension: Improved suspension systems contribute to better handling and stability.

- Braking System: Upgrading brakes enhances safety and responsiveness.