In the realm of small engines, the functionality of ignition components is crucial for optimal performance. These systems ensure that the engine starts reliably and operates smoothly. Each component within the assembly plays a distinct role, contributing to the overall efficiency and longevity of the machinery.

Exploring the intricate layout of ignition assemblies can provide valuable insights into their operation. Familiarity with these elements not only aids in troubleshooting but also enhances maintenance practices. A comprehensive examination of these systems reveals how various pieces interact, ensuring a seamless ignition process.

As enthusiasts and professionals delve into the specifics of engine ignition, understanding the various components and their configurations becomes essential. This knowledge empowers users to make informed decisions regarding repairs and replacements, ultimately leading to improved engine reliability.

Tecumseh Starter Overview

This section provides a comprehensive look at a vital component commonly utilized in various small engine applications. Understanding the function and structure of this essential device is crucial for effective maintenance and troubleshooting.

The mechanism operates by converting electrical energy into mechanical energy, enabling the engine to initiate its operational cycle. This device is designed to deliver a high torque output, facilitating the rapid rotation of the engine’s flywheel. Its reliability and efficiency are paramount for seamless performance, particularly in outdoor power equipment.

| Component | Description |

|---|---|

| Drive Gear | Engages with the engine flywheel to initiate rotation. |

| Solenoid | Acts as a switch to control electrical current flow. |

| Motor Housing | Encloses the electrical components and provides protection. |

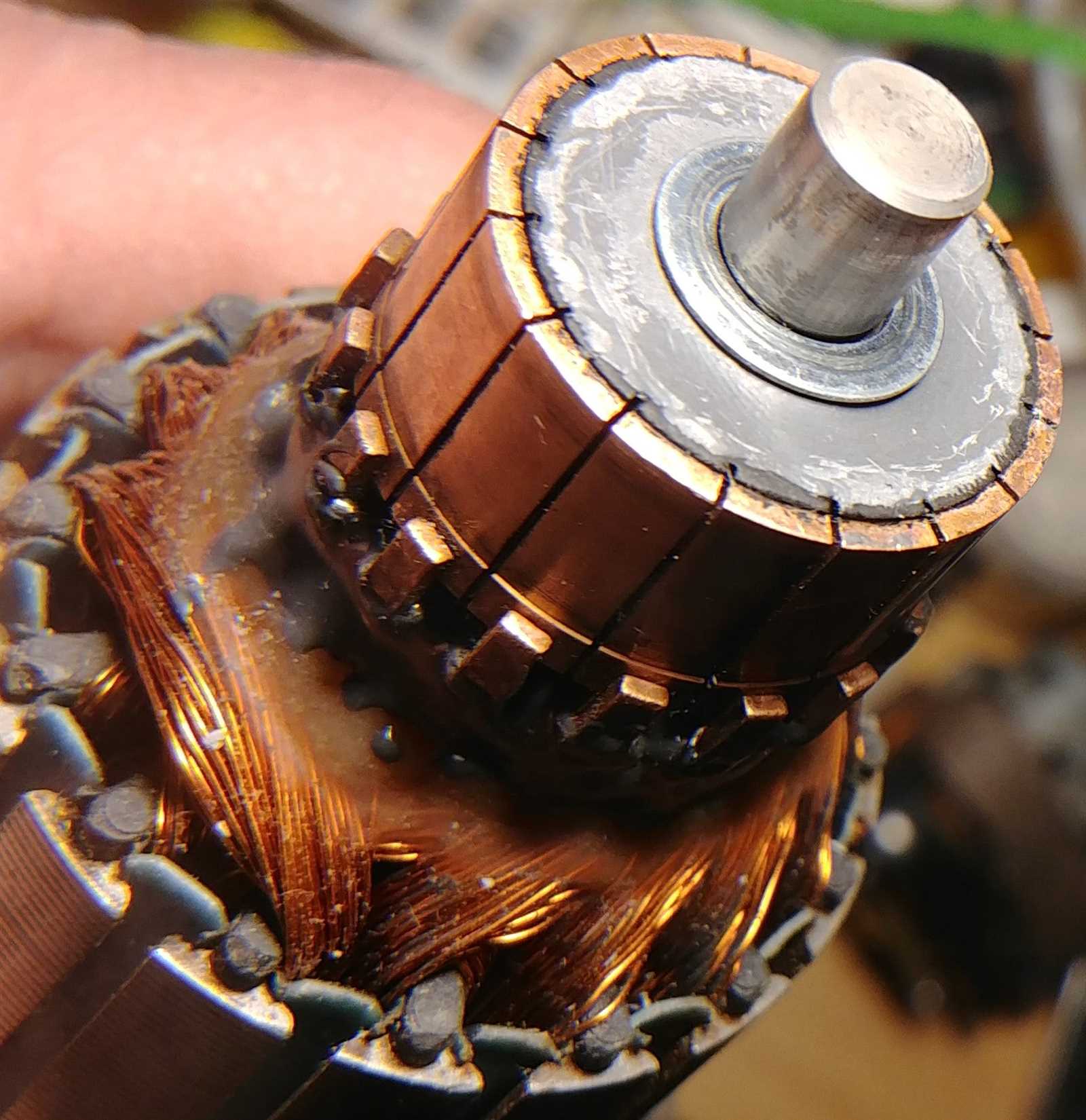

| Armature | Converts electrical energy into rotational motion. |

| Commutator | Reverses the direction of current to maintain rotation. |

Key Components of Tecumseh Starter

Understanding the essential elements of a motor initiation system is crucial for effective maintenance and performance. Each part plays a significant role in ensuring the smooth operation of the engine, enabling quick and reliable ignition. This section explores the primary components that contribute to the functionality of these systems, highlighting their importance in the overall mechanism.

Motor Assembly

The motor assembly serves as the heart of the initiation system. It converts electrical energy into mechanical energy, driving the gear mechanism that engages with the engine flywheel. A well-functioning motor is vital for achieving the necessary torque to start the engine reliably.

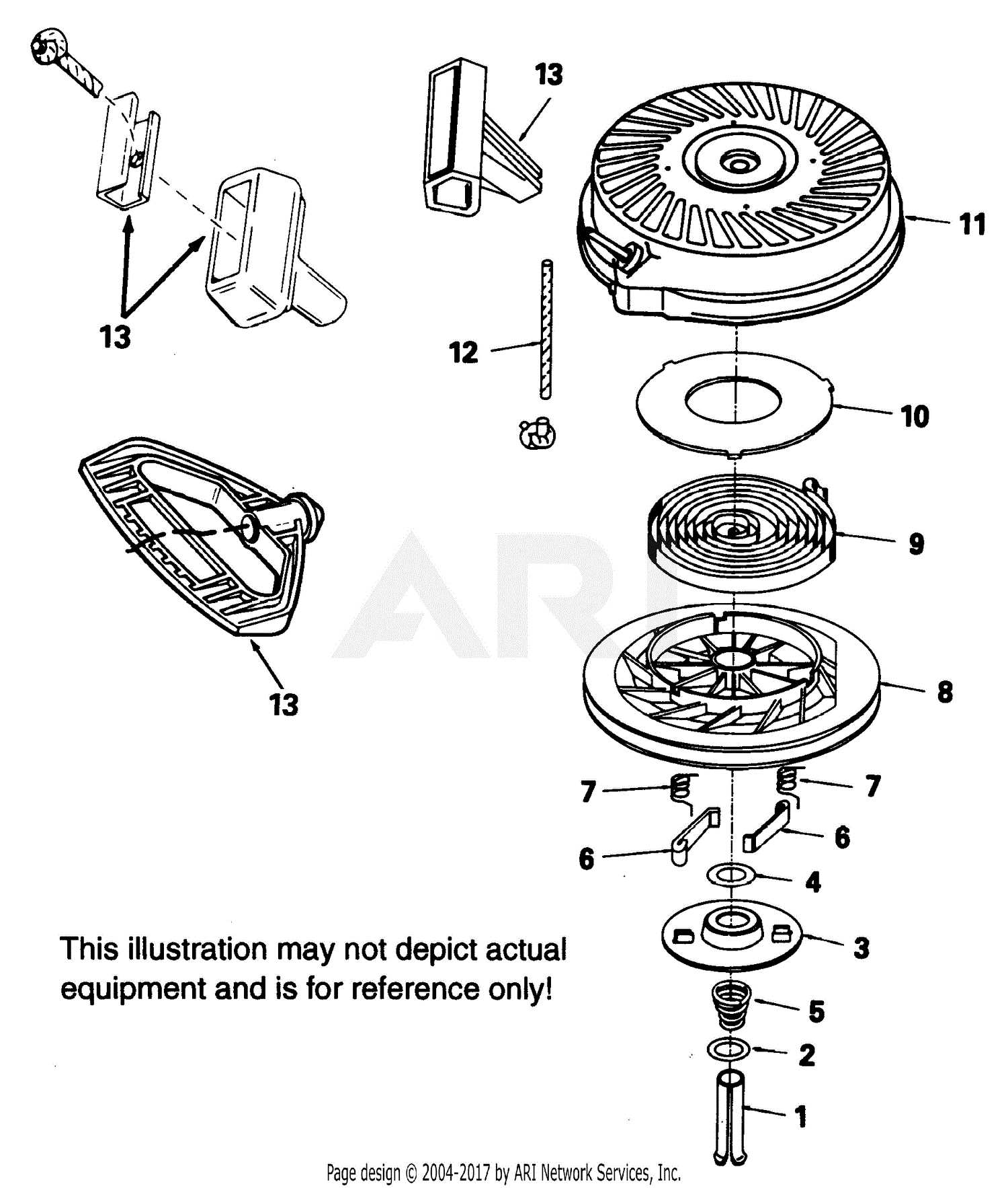

Engagement Mechanism

This mechanism is responsible for connecting the motor assembly to the engine’s flywheel. It typically consists of a gear and a spring system that allows for smooth engagement and disengagement. When the motor is activated, this component ensures that the connection is made securely, allowing the engine to turn over and start effectively.

Regular inspection and maintenance of these crucial components can prevent unexpected failures and prolong the life of the motor initiation system, ensuring optimal performance in various operational conditions.

Understanding the 37000 Model

The 37000 model is a notable component in the realm of small engine machinery, designed for reliability and performance. This specific version showcases a well-engineered approach to powering various outdoor equipment, ensuring efficient operation for users. Understanding its structure and functionality can aid in better maintenance and troubleshooting, contributing to a longer lifespan and enhanced efficiency.

Key Features

One of the standout characteristics of this model is its robust construction, which allows it to endure demanding conditions. With precision-engineered components, it provides dependable performance across a range of applications. Additionally, the user-friendly design facilitates easy installation and maintenance, making it accessible even for those with limited mechanical experience.

Functionality Insights

This unit operates by converting mechanical energy into rotational force, which is essential for starting engines. Its design incorporates various elements that work in harmony, contributing to a seamless performance. Regular inspection and understanding of the inner workings can significantly improve operational efficiency and prevent common issues.

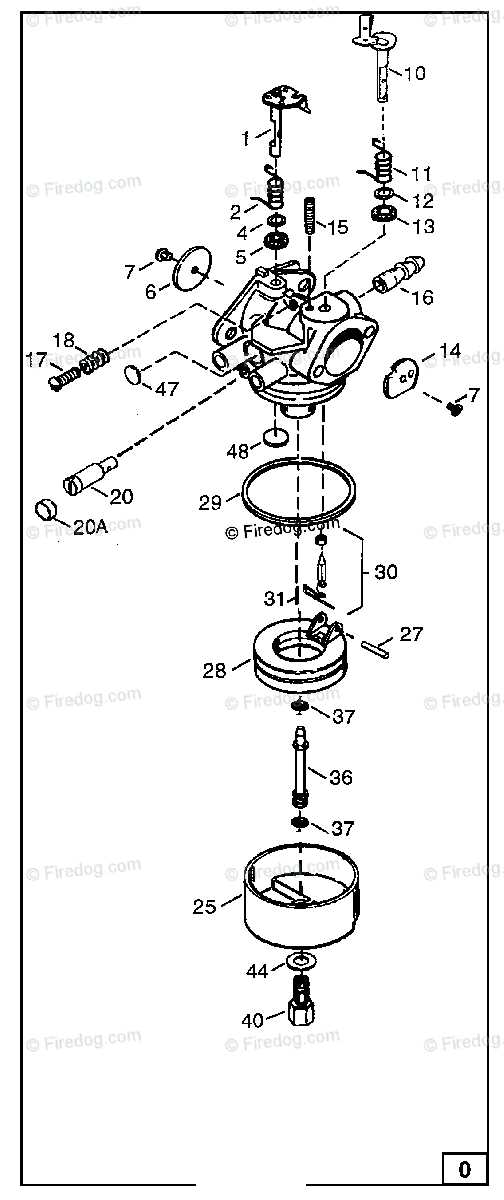

Parts Identification and Functions

Understanding the various components and their roles within an ignition system is crucial for efficient maintenance and repair. Each element plays a specific part in ensuring the smooth operation of the engine, contributing to overall performance and reliability. This section will delve into the identification of these components and their respective functions, providing insight into how they work together harmoniously.

Key Components

The assembly includes several essential elements, such as the housing, which encases the internal mechanisms, and the drive gear, responsible for engaging with the engine to initiate the starting process. Additionally, the electrical connections are vital for transmitting power from the battery to the ignition system. Understanding each component’s placement and purpose can facilitate easier troubleshooting and enhance the maintenance process.

Functionality Overview

Each component serves a unique role. For example, the coil generates the necessary voltage to ignite the fuel mixture, while the solenoid acts as a switch to engage the mechanism when required. Regular inspection of these elements can prevent malfunctions, ensuring the system operates efficiently. Proper identification and understanding of their functions not only aid in effective repairs but also promote longevity and optimal performance.

Common Issues with Tecumseh Starters

Many users encounter a range of problems with their ignition systems, often leading to frustration and delays. Understanding these challenges can help in troubleshooting and ensuring a smoother experience. Common complications may arise from electrical failures, mechanical malfunctions, or improper maintenance practices.

Electrical Issues: One of the most frequent problems involves electrical connections. Corroded terminals or loose wiring can prevent sufficient power from reaching the engine, resulting in failure to engage. Regular inspection and cleaning of these connections can mitigate this risk.

Mechanical Failures: Mechanical components, such as the drive mechanism, can wear over time. If the gearing is damaged or the unit is misaligned, it may struggle to function correctly. Regular maintenance checks can help identify these issues before they lead to complete breakdowns.

Battery Problems: A weak or dead battery is another common culprit. Ensuring that the battery is fully charged and in good condition is essential for reliable operation. Users should also be aware of how temperature fluctuations can affect battery performance.

Improper Maintenance: Neglecting routine maintenance can exacerbate existing issues. Regularly changing fluids, inspecting filters, and performing overall system checks can prolong the lifespan of the ignition assembly and reduce the likelihood

How to Replace Starter Parts

Replacing components in a motorized system can enhance performance and prolong its lifespan. This section provides a step-by-step approach to assist users in executing the replacement process efficiently. With the right tools and a clear understanding of the procedure, anyone can successfully manage this task.

Required Tools and Materials

Before beginning the replacement, ensure you have the necessary tools and materials at hand. Below is a table listing the essential items for the job:

| Tool/Material | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts |

| Screwdriver Set | For removing screws and securing components |

| Replacement Components | New parts to ensure optimal function |

| Safety Goggles | To protect eyes during the process |

| Gloves | For hand protection |

Step-by-Step Replacement Process

Follow these steps to replace the necessary components effectively:

- Begin by disconnecting the power source to avoid any accidents.

- Remove any covers or housing that obstruct access to the components.

- Identify the worn-out components that require replacement.

- Carefully detach the old components, noting their positions for reassembly.

- Install the new components in the same configuration as the old ones.

- Reassemble any covers or housing that were removed earlier.

- Reconnect the power source and test the system to ensure proper functionality.

Benefits of Genuine Tecumseh Parts

Using authentic components ensures the longevity and optimal performance of your machinery. These original elements are designed to meet strict quality standards, providing reliability and efficiency in operation. By choosing genuine replacements, you not only preserve the integrity of your equipment but also enhance its overall functionality.

Quality Assurance

One of the primary advantages of selecting authentic components is the guarantee of superior quality. Genuine items are manufactured with precise specifications, which leads to:

- Improved durability and resilience under heavy use.

- Consistent performance across various operating conditions.

- Reduced risk of malfunctions or breakdowns.

Cost-Effectiveness

Although authentic components may have a higher upfront cost, they prove to be more economical in the long run. Investing in genuine parts can result in:

- Lower maintenance expenses due to decreased wear and tear.

- Fewer repairs needed over time, saving money and effort.

- Extended lifespan of your machinery, enhancing overall value.

Tools Needed for Repairs

When embarking on maintenance tasks, having the right equipment is essential to ensure efficiency and precision. Proper tools not only simplify the process but also enhance safety, allowing for a smoother workflow. Here, we will outline the necessary instruments to facilitate repairs effectively.

Essential Hand Tools

Basic hand tools are vital for any repair project. A good set typically includes screwdrivers in various sizes, wrenches for tightening and loosening bolts, and pliers for gripping and manipulating components. Additionally, a mechanic’s toolset can provide a comprehensive range of sockets and extensions to accommodate various fasteners.

Specialized Equipment

In some cases, more specialized tools may be required. Torque wrenches are crucial for applying precise force, ensuring that components are secured without damage. A multimeter is indispensable for diagnosing electrical issues, allowing for the accurate measurement of voltage and current. Furthermore, having access to a workbench with a vice can significantly improve stability during repairs.

Step-by-Step Assembly Guide

This section provides a comprehensive guide to assembling a mechanical ignition device effectively. By following these steps, you can ensure a smooth assembly process while understanding the key components involved.

-

Gather Necessary Tools and Components:

Before starting, ensure you have the following items at hand:

- Screwdriver set

- Wrench set

- Lubricant

- Safety goggles

- Assembly manual

-

Prepare the Work Area:

Choose a clean, well-lit workspace with enough room to maneuver the components. Make sure all tools are organized and easily accessible.

-

Identify Components:

Familiarize yourself with the individual pieces that make up the device. Knowing each part’s function will aid in proper assembly.

-

Assemble the Base:

Start by securing the base plate. Use screws and the appropriate wrench to ensure it is stable.

-

Attach the Rotor:

Carefully place the rotor onto the base, ensuring that it aligns with the mounting holes. Tighten the screws securely.

-

Connect Electrical Components:

Link the necessary wiring according to the provided schematic. Ensure that all connections are tight to prevent any electrical faults.

-

Final Assembly:

After ensuring all components are in place, double-check each connection and secure any loose parts. Apply lubricant to moving parts to ensure smooth operation.

-

Test the Assembly:

Once assembled, conduct a test to ensure everything is functioning correctly. Listen for any unusual sounds and check for stability.

By following these detailed instructions, you can successfully assemble the ignition device with confidence.

Maintenance Tips for Longevity

To ensure the enduring performance of your equipment, regular upkeep is essential. By following a few straightforward strategies, you can enhance its lifespan and reliability, minimizing the need for repairs and replacements. The following tips will help you maintain optimal functioning and prevent common issues.

- Regular Cleaning: Keep the exterior and accessible components free from dirt and debris. Use a soft brush or cloth to remove any buildup that could affect performance.

- Routine Inspections: Frequently check for any signs of wear, damage, or loose connections. Early detection can prevent more significant problems down the line.

- Proper Lubrication: Apply appropriate lubricants to moving parts as specified in the user manual. This helps reduce friction and wear, ensuring smooth operation.

- Check Fluid Levels: Regularly monitor oil and fuel levels, topping them off as needed. Low levels can lead to inefficient performance and potential damage.

- Storage Practices: When not in use, store the equipment in a dry, sheltered area to protect it from the elements. Use covers or cases when possible to prevent dust accumulation.

Implementing these maintenance practices can significantly extend the life of your machinery, ensuring it remains a reliable tool for your needs. Regular attention will help maintain peak performance and reduce the likelihood of unexpected failures.

Where to Buy Replacement Parts

Finding suitable components for your equipment can significantly extend its lifespan and enhance performance. Whether you are conducting routine maintenance or need to replace a broken element, knowing where to source these items is crucial. Various options are available, including online retailers, local stores, and specialized suppliers that cater to specific machinery needs.

Online Retailers

Numerous online platforms offer a wide selection of components, often at competitive prices. These websites typically provide detailed descriptions and customer reviews to assist in making informed choices. Some popular online sources include:

| Website | Description |

|---|---|

| Amazon | A vast marketplace with a diverse range of items, including a variety of components. |

| eBay | An auction and shopping site where users can find both new and used items. |

| RepairClinic | Specializes in parts for various appliances and equipment with a user-friendly interface. |

Local Suppliers

Visiting local suppliers can also be beneficial. Not only can you see the items in person, but you can also get expert advice from staff who are knowledgeable about the products. Here are some types of local businesses to consider:

| Type of Store | Description |

|---|---|

| Hardware Stores | Often stock a range of components suitable for various machinery. |

| Specialized Equipment Dealers | Focus on specific brands or types of machinery, offering expert guidance and hard-to-find items. |

Troubleshooting Starter Problems

Addressing issues with the ignition mechanism is crucial for ensuring proper functionality of the equipment. Various symptoms can indicate malfunction, ranging from inability to engage to unusual sounds during operation. Understanding these signs can help in identifying the root causes and applying effective solutions.

1. No Response When Engaging: If there is no action when the ignition is triggered, first check the battery condition. A weak or dead battery can prevent the mechanism from functioning. Additionally, examine the connections for corrosion or loose wiring, which can disrupt the electrical flow.

2. Grinding Noise: A grinding sound when attempting to start may indicate misalignment or wear in the components. Inspect the gear assembly for damage and ensure that all parts are properly seated. Lubrication may also be necessary to reduce friction and wear.

3. Slow Cranking: If the mechanism turns slowly, it might suggest insufficient power supply or internal resistance. Testing the battery voltage and connections can reveal underlying issues. Cleaning terminals and ensuring a solid connection can enhance performance.

4. Excessive Heat: Overheating during operation can signal an overload or malfunctioning internal components. Allow the unit to cool down and check for any blockages that may hinder movement. Ensure that all components are functioning within their operational limits.

5. Frequent Failures: Recurrent issues may point to underlying design flaws or compatibility problems with other components. Reviewing the user manual for specifications and recommended parts can assist in identifying the correct replacements and upgrades.

By systematically addressing these common issues, users can restore functionality and enhance the longevity of their ignition systems.