When maintaining outdoor power equipment, a clear understanding of the engine’s structure is essential. Each component plays a vital role in the overall functionality, ensuring optimal performance and efficiency. This section will explore the intricate layout of a specific engine model, highlighting key elements and their respective functions.

By familiarizing yourself with the arrangement of various parts, you can effectively diagnose issues and carry out repairs. The layout provides insight into how components interact, allowing for better troubleshooting and maintenance strategies. Whether you are a professional technician or a DIY enthusiast, grasping this information will enhance your capabilities in managing engine-related tasks.

In the following sections, we will delve into detailed explanations of the essential components, their connections, and how they contribute to the engine’s operation. This knowledge will empower you to handle repairs and replacements with confidence, ensuring your equipment runs smoothly for years to come.

Gaining insight into the various elements of an engine is crucial for anyone interested in its functionality and maintenance. Each part plays a significant role in the overall performance and efficiency of the machinery, contributing to its ability to operate smoothly.

Engines are composed of numerous components, each designed to perform specific tasks. Here are some of the key elements:

- Fuel System: Responsible for storing and delivering fuel to the combustion chamber.

- Air Intake: Allows fresh air to enter the engine for combustion.

- Ignition System: Generates a spark to ignite the fuel-air mixture.

- Cooling System: Maintains optimal operating temperatures by dissipating heat.

- Lubrication System: Reduces friction between moving parts to enhance longevity.

Understanding these components helps in troubleshooting and maintaining engine performance. Regular inspection and knowledge of each element’s function can lead to improved reliability and efficiency.

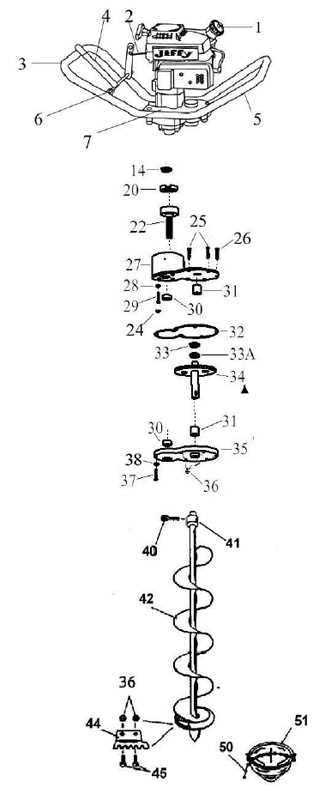

Importance of Parts Diagrams

Understanding the intricate layout of mechanical systems is essential for effective maintenance and repair. Visual representations that outline the components of machinery provide valuable insights into how each element interacts with others. These illustrations serve as a critical resource for technicians and hobbyists alike, facilitating a smoother workflow during service tasks.

Enhanced Clarity and Understanding

Visual aids significantly improve the ability to comprehend complex assemblies. By offering a clear overview of the various elements involved, these resources allow users to identify specific pieces quickly. This clarity helps in diagnosing issues and planning repairs more effectively.

Streamlined Maintenance Processes

Having access to detailed schematics simplifies the maintenance process. It enables users to pinpoint parts that require attention and ensures that replacements are correctly installed. Moreover, this efficiency reduces the likelihood of errors, ultimately saving time and resources.

Locating the Parts Diagram

Finding the schematic for specific components can greatly enhance the understanding and maintenance of machinery. This visual representation provides essential information about the various elements, their arrangement, and how they interact with each other. Locating such a reference can help ensure proper servicing and repair processes.

Where to Search for the Schematic

There are several reliable sources to explore when seeking a visual reference for your equipment:

- Manufacturer’s Official Website: Most manufacturers offer downloadable resources on their websites, including schematics and manuals.

- Repair Manuals: Look for manuals dedicated to your equipment type, which often contain detailed illustrations and breakdowns.

- Online Forums: Communities dedicated to machinery repair often share helpful resources and links to diagrams.

- Retail Parts Suppliers: Many online suppliers provide detailed images and schematics for the components they sell.

Using the Schematic Effectively

Once you locate the visual representation, here are some tips to utilize it effectively:

- Cross-reference with your equipment: Ensure you are looking at the correct schematic for your model.

- Highlight key components: Mark the parts you intend to check or replace to streamline your process.

- Keep it accessible: Print a copy or save a digital version for easy access during maintenance or repair tasks.

Key Features of TC300 Engine

This section explores the notable characteristics of a well-regarded small engine, emphasizing its performance and efficiency. The engine has been designed to cater to various applications, providing users with reliable power and durability.

Performance and Efficiency

- Optimized fuel consumption for extended operational time.

- High torque output for enhanced performance in demanding tasks.

- Robust construction ensures long-lasting reliability.

User-Friendly Design

- Lightweight design for easy handling and transportation.

- Accessible maintenance points simplify upkeep and servicing.

- Versatile compatibility with numerous attachments and accessories.

Common Parts and Their Functions

This section highlights various components commonly found in small engines and their essential roles. Understanding these elements is crucial for maintenance and repairs, ensuring optimal performance and longevity of the equipment.

One of the primary components is the cylinder, where fuel and air mix for combustion, generating power. The piston moves within this cylinder, transforming the energy produced into mechanical motion. Another vital piece is the crankshaft, which converts the linear motion of the piston into rotational energy, allowing the engine to drive connected systems.

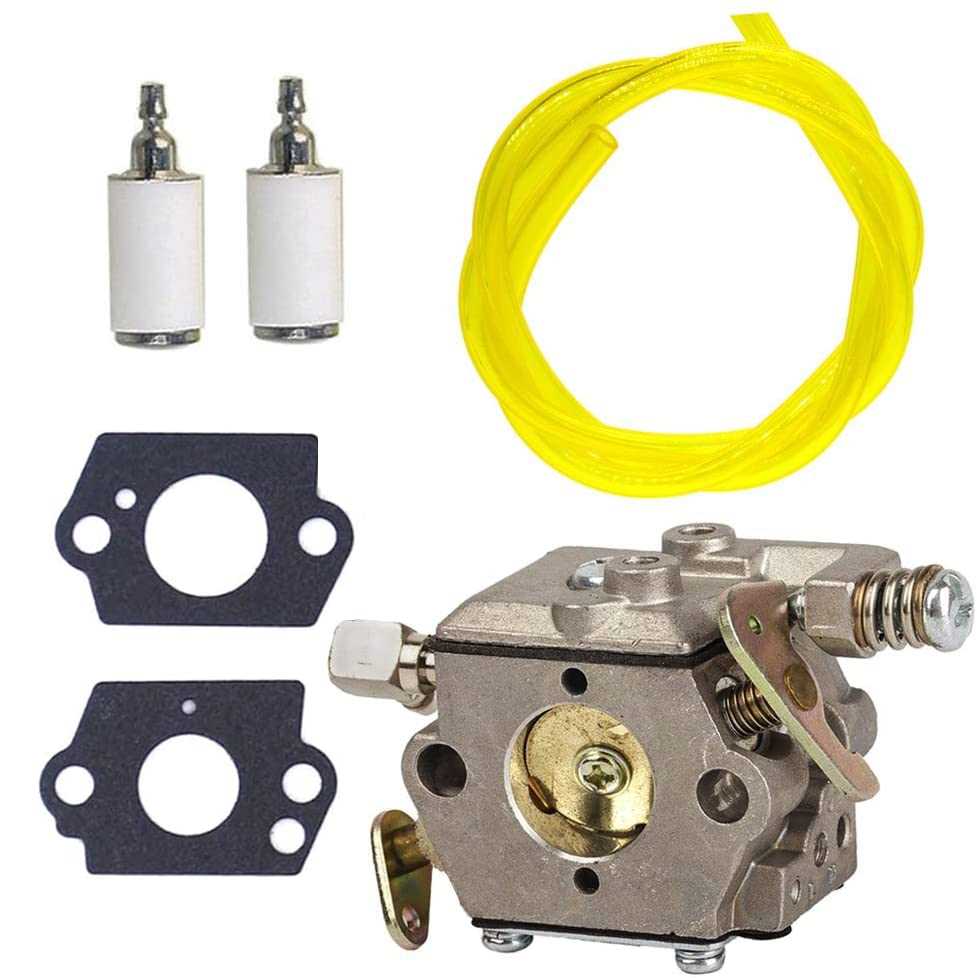

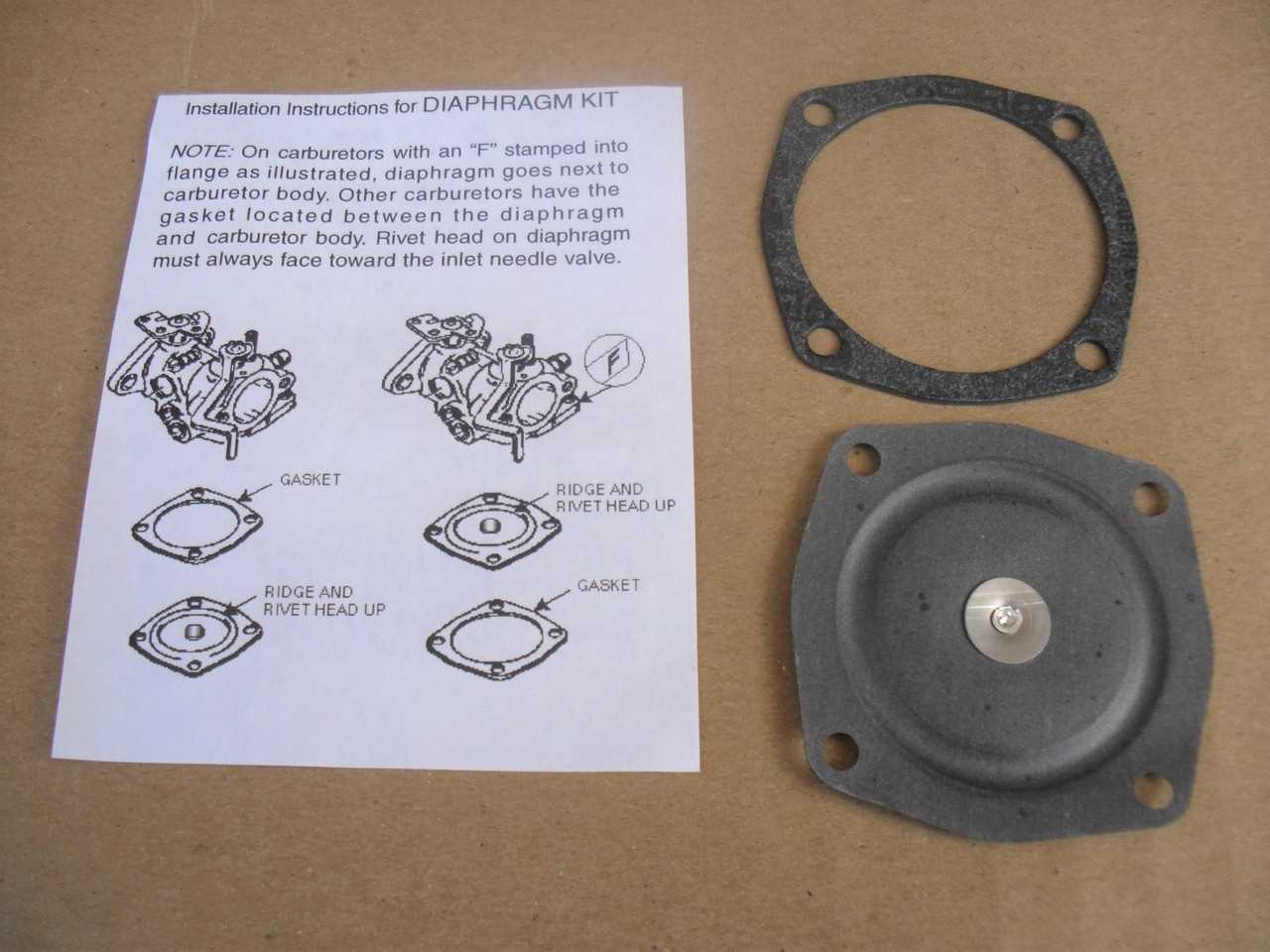

The carburetor plays a significant role in mixing air with fuel, ensuring the correct proportions for efficient combustion. Additionally, the ignition system is responsible for creating the spark that ignites the fuel-air mixture, initiating the combustion process.

Fuel lines transport the necessary fluid from the tank to the engine, while filters help maintain cleanliness by removing impurities. Lastly, cooling components, such as fans or radiators, prevent overheating, promoting smooth and efficient operation during use.

Maintenance Tips for TC300

Proper upkeep of your machinery is essential to ensure optimal performance and longevity. Regular maintenance helps prevent breakdowns and enhances efficiency. By following a few simple guidelines, you can keep your equipment running smoothly and minimize the risk of costly repairs.

Routine Checks

Performing routine inspections can help identify potential issues before they escalate. Focus on the following components during your assessments:

| Component | Inspection Frequency | Action |

|---|---|---|

| Air Filter | Every 25 hours | Clean or replace as necessary |

| Oil Level | Every 10 hours | Check and top off if needed |

| Spark Plug | Every 50 hours | Inspect and replace if worn |

| Fuel Lines | Every season | Inspect for leaks and replace if damaged |

Seasonal Maintenance

In addition to routine checks, seasonal maintenance is crucial for preparing your machinery for changing conditions. Ensure the following tasks are completed:

- Drain and replace old fuel to prevent system clogging.

- Sharpen blades and inspect cutting surfaces for damage.

- Lubricate moving parts to reduce friction and wear.

How to Interpret Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visual representations provide essential information on the components and their interconnections within a system. By familiarizing yourself with the symbols and notations used, you can enhance your troubleshooting and assembly skills.

Here are some key steps to effectively decode these visual guides:

- Familiarize with Symbols: Each illustration uses specific symbols to represent various elements. Learn what each symbol stands for to avoid confusion.

- Identify the Components: Look for labels or legends that clarify the parts. Understanding the function of each component is vital for proper interpretation.

- Trace Connections: Follow the lines or arrows that indicate how components are connected. This helps in grasping the flow of operation within the system.

- Refer to the Key: Most visuals include a key or reference guide. Use this as a resource to cross-check and confirm your understanding.

By applying these strategies, you can efficiently interpret complex illustrations, leading to better diagnostics and repair outcomes.

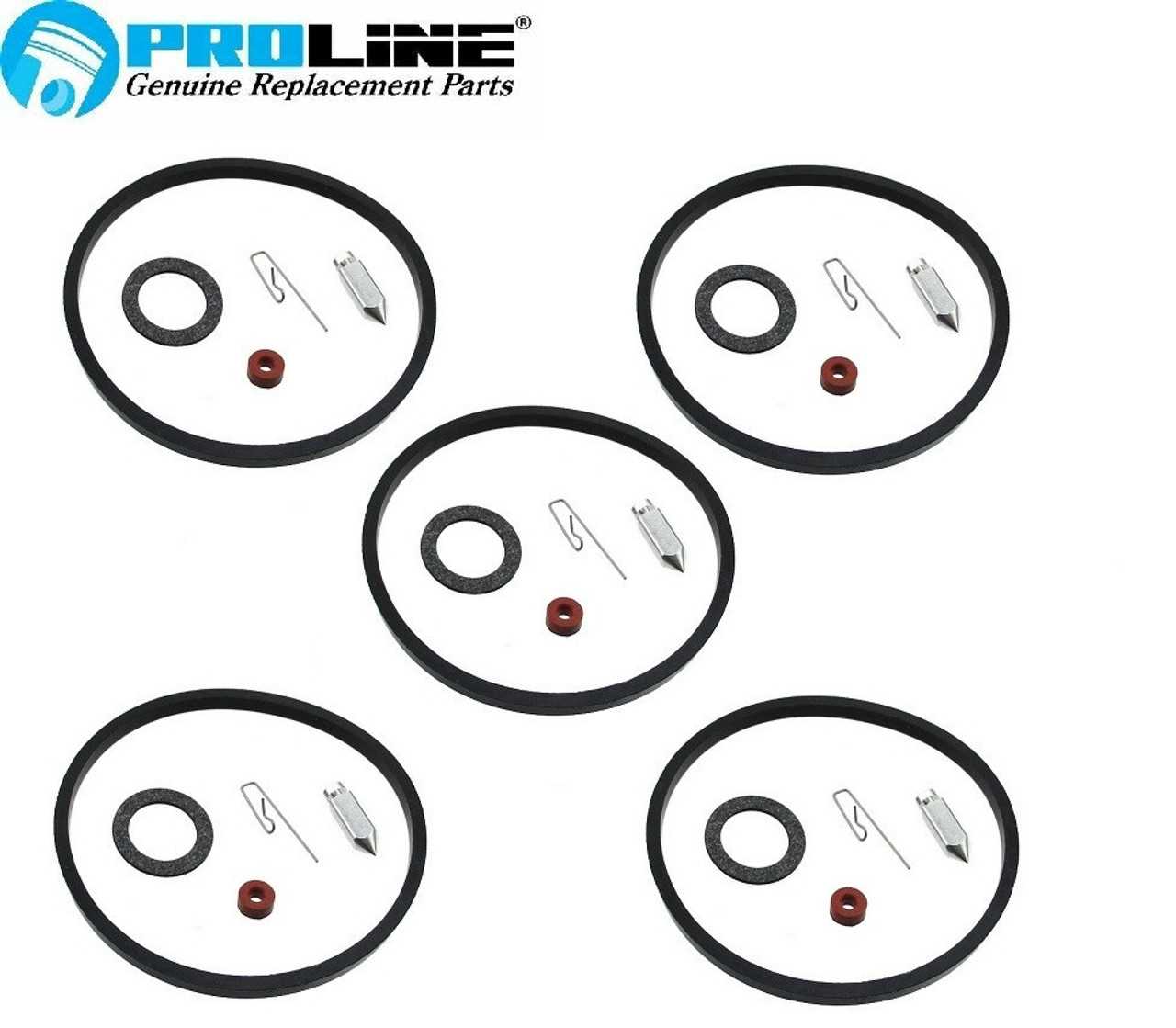

Identifying Replacement Parts

When it comes to maintaining machinery, recognizing the components that may require substitution is essential for ensuring optimal performance. Understanding the function and location of each element can significantly streamline the repair process. Familiarity with the various components can help users identify which ones need to be replaced to keep the equipment running smoothly.

Common Elements to Consider: Several key elements should be inspected regularly. Look for signs of wear and tear on items such as the ignition system, fuel components, and seals. These components are often the first to degrade and can lead to inefficiencies if not addressed promptly.

Using Reference Materials: Utilizing reference guides or manuals can greatly aid in identifying specific components that may need to be replaced. These resources typically provide valuable insights into the configuration and function of each element, making it easier to pinpoint issues.

Consulting with Professionals: If uncertainty arises regarding which components to replace, consulting with experts in the field can provide clarity. Professionals can offer guidance and recommendations based on experience, ensuring that the correct elements are addressed.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving optimal results. The following tools will assist in effectively diagnosing issues and performing necessary fixes.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help in loosening or tightening screws on various components.

- Wrenches: Adjustable wrenches or a complete set of metric and standard wrenches are crucial for handling nuts and bolts of different sizes.

- Socket Set: A socket set allows for easier access to hard-to-reach fasteners, making tasks more efficient.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or other materials.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specified torque, preventing damage from over-tightening.

- Multimeter: A multimeter is essential for checking electrical connections and diagnosing any electrical issues.

- Safety Equipment: Don’t forget gloves and goggles to protect yourself during repairs.

Having these tools readily available will significantly streamline the repair process and enhance your efficiency in addressing various issues.

Frequently Asked Questions

This section addresses common inquiries regarding the components and functionality of small engine systems. Here, users can find valuable insights that may assist in troubleshooting and maintenance.

Common Inquiries

- What are the typical issues faced with engine components?

- How can I identify malfunctioning parts?

- What tools are necessary for basic repairs?

- Where can I find reliable replacement options?

Maintenance Tips

- Regularly inspect and clean all parts to ensure optimal performance.

- Consult the user manual for specific guidance on servicing your unit.

- Keep an inventory of essential components to facilitate quick repairs.

- Consider professional assistance for complex issues beyond basic troubleshooting.

Online Resources for Further Help

When seeking assistance with repair and maintenance tasks, there are numerous online platforms available to provide valuable guidance and support. These resources can help you troubleshoot issues, find replacement components, or understand complex systems more thoroughly.

Here are some helpful types of online resources you can explore:

- Manufacturer Websites: Official sites often provide manuals, FAQs, and contact information for customer service.

- Forums and Community Groups: Online communities allow users to share experiences, ask questions, and find solutions to common problems.

- Video Tutorials: Platforms like YouTube host countless instructional videos that demonstrate repair techniques and assembly processes.

- Online Retailers: Websites specializing in tools and supplies often feature guides and resources to assist with various repairs.

- Social Media Groups: Platforms like Facebook have groups dedicated to specific topics where users can exchange tips and advice.

Utilizing these resources can enhance your understanding and improve your ability to tackle maintenance projects effectively.

Customer Reviews and Experiences

This section highlights the insights and feedback from users who have interacted with specific components and systems. Their evaluations provide valuable perspectives on performance, durability, and overall satisfaction.

Many customers appreciate the ease of installation and the clarity of instructions that accompany the components. Several users have noted how straightforward the assembly process is, making it accessible even for those with limited mechanical experience. One reviewer mentioned that the components fit perfectly and worked seamlessly, leading to a quick resolution of their issues.

On the other hand, some customers expressed concerns regarding availability and sourcing. A few individuals reported challenges in finding specific items, indicating that while many components are readily available, some may require extra effort to procure. Overall feedback suggests a blend of satisfaction with the product quality and a desire for improved accessibility.