Temperature measurement plays a crucial role in various industries, where accuracy and reliability are paramount. To effectively capture thermal readings, these sensors consist of several integral elements that work in harmony. Grasping the function and arrangement of these components is essential for anyone involved in temperature monitoring or control systems.

Each section of the sensor is designed to fulfill a specific role, contributing to the overall efficiency of the device. By exploring the individual characteristics and interactions of these elements, one can gain insights into how temperature is converted into an electrical signal. This understanding is vital for optimizing performance and ensuring precise data collection.

In this exploration, we will delve into the key features of these thermal devices, highlighting the importance of each component in the context of their collective operation. Recognizing how these parts collaborate will enhance your comprehension of temperature measurement technologies and their practical applications.

Understanding Thermocouples Basics

This section aims to provide a foundational overview of a widely used temperature sensing device, highlighting its functionality and significance in various applications. By exploring its principles, we can better appreciate how it measures temperature through the interaction of different conductive materials.

Principles of Operation

The device operates on the principle of electromotive force generated when two dissimilar metals are joined and exposed to varying temperatures. This creates a voltage that correlates with the temperature difference, allowing for accurate measurements in a range of environments.

Applications and Uses

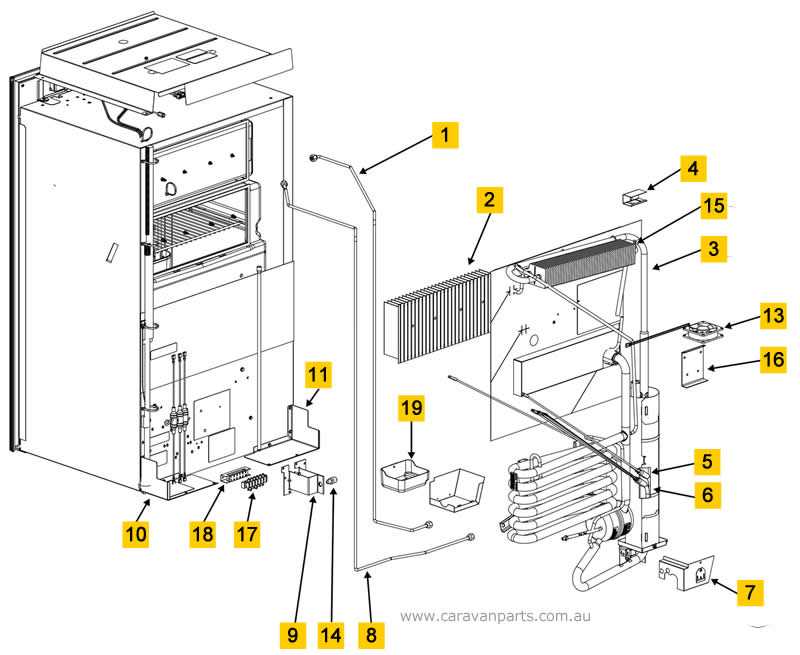

Components of a Thermocouple

The construction of a temperature-sensing device involves several essential elements that work together to measure thermal variations. Each component plays a crucial role in ensuring accurate readings and efficient operation.

The two primary wires are made from different metal alloys, which generate a voltage when exposed to temperature changes. These wires are joined at one end, forming a junction that is sensitive to heat. The other ends are connected to a measurement device, allowing for the detection of temperature differences.

Insulation materials surround the wires, protecting them from environmental factors and ensuring reliable performance. Additionally, protective sheaths may be used to enhance durability and safeguard against physical damage or corrosive elements.

Ultimately, understanding these elements provides insight into how temperature measurement devices function and their significance in various applications.

Types of Thermocouples Explained

Understanding the various categories of temperature sensors is essential for selecting the right one for specific applications. Each category possesses unique properties that make them suitable for different temperature ranges and environments.

Common Categories

There are several widely used types, such as Type K, which is known for its versatility and broad temperature range. Type J, on the other hand, excels in reducing oxidation and is often utilized in vacuum or inert gas environments.

Specialized Varieties

Some specialized options include Type T, which is ideal for low-temperature measurements, and Type R, known for its stability at high temperatures. Each of these variations offers distinct advantages based on the specific needs of an application.

Working Principle of Thermocouples

This section explores the fundamental operation of temperature sensors that rely on the interaction between two different metals. When these metals are joined at one end, they create a voltage that varies with temperature, enabling precise measurement. The relationship between voltage and temperature is defined by specific laws of physics, allowing for reliable readings across a range of conditions.

| Metal Combination | Typical Applications |

|---|---|

| Nickel-Chromium / Nickel-Alumel | Industrial processes |

| Iron / Constantan | Laboratory settings |

| Platinum / Platinum-Rhodium | High-temperature measurements |

The output voltage generated is directly related to the temperature difference between the junctions of the metals, which allows for efficient temperature monitoring and control in various applications.

Common Applications in Industry

Temperature measurement devices play a crucial role across various sectors, ensuring processes operate within optimal parameters. Their ability to deliver accurate and reliable readings makes them indispensable in numerous industrial applications.

In manufacturing, these instruments are essential for monitoring and controlling heat treatment processes, which directly influence material properties. Additionally, in food processing, they help maintain safety standards by ensuring products are cooked or stored at appropriate temperatures.

Energy production also relies heavily on these sensors for efficient operation. They are used in power plants to monitor boiler temperatures, ensuring safety and maximizing efficiency. Moreover, in HVAC systems, these devices facilitate climate control by regulating temperature levels in buildings.

Overall, their versatility and precision make them a foundational element in maintaining quality and efficiency across diverse industries.

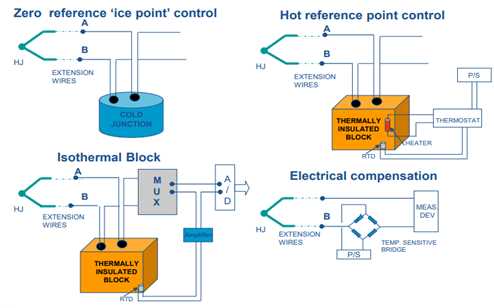

Interpreting Thermocouple Diagrams

Understanding the layout and components involved in temperature measurement systems is crucial for accurate interpretation and application. These representations provide insights into how various elements interact, ensuring effective monitoring and control in different environments.

Key Components Overview

Each symbol and line in these illustrations conveys specific functions and relationships between the elements. Familiarity with these representations helps in troubleshooting and optimizing the performance of the measurement setups.

Symbol Interpretation Table

| Symbol | Description |

|---|---|

| Circle | Represents junction points where connections are made. |

| Line | Indicates the conductive path between components. |

| Arrow | Denotes direction of heat flow or signal. |

| Square | Indicates a protective casing or insulation. |

Material Selection for Thermocouple Wires

The choice of materials for temperature sensing elements is crucial for achieving accurate measurements and reliable performance. Different alloys exhibit unique properties that can significantly influence sensitivity, range, and durability. Understanding these characteristics is essential for selecting the appropriate wire for specific applications.

Conductivity is a key factor; higher conductivity materials allow for better signal transmission, leading to improved accuracy. Common choices include various metal combinations, each offering distinct advantages in terms of thermal response and stability under varying conditions.

Temperature Range also plays a vital role in material selection. Some metals maintain their properties at extreme temperatures, while others may degrade or become unstable. Evaluating the operational environment ensures that the selected alloy can withstand the intended thermal range without compromising performance.

Corrosion Resistance is another important consideration, especially in harsh environments. Materials that resist oxidation and chemical reactions enhance longevity and reduce maintenance needs. Selecting a wire with appropriate resistance can significantly extend the lifespan of the sensing device.

Ultimately, understanding the interplay of these factors aids in making informed decisions, ensuring optimal functionality and reliability in various industrial and research applications.

Thermocouple Calibration Techniques

Accurate measurement of temperature is crucial in various industrial applications, necessitating reliable adjustment methods for sensors. Ensuring precision involves various techniques to align readings with established standards. Proper calibration not only enhances accuracy but also prolongs the lifespan of these devices.

Types of Calibration Methods

There are several approaches to achieving optimal performance, including comparison against reference standards and utilizing calibration baths. Each method provides a framework for assessing and correcting deviations in temperature readings, ensuring consistency in measurements across different environments.

Best Practices for Calibration

Regular calibration intervals and environmental control are essential for maintaining reliability. Documenting procedures and results contributes to traceability and accountability, fostering a culture of precision in measurement practices.

Temperature Range Considerations

Understanding the operational limits of temperature-sensing devices is crucial for effective applications. The selection of materials and design influences the ability to accurately measure heat across various environments, ensuring reliability and precision in data collection.

Material Selection

The choice of materials plays a pivotal role in determining the measurement range. Different substances exhibit unique thermal properties, which directly impact the performance under high or low temperatures. Selecting appropriate materials can enhance durability and responsiveness.

Calibration and Accuracy

Regular calibration is essential to maintain accuracy within specified temperature limits. As conditions change, the device’s readings may drift, making it imperative to regularly assess and adjust for optimal performance. This process helps achieve the ultimate reliability needed in critical applications.

Wiring Configurations for Thermocouples

The arrangement of connections in temperature sensing devices plays a crucial role in ensuring accurate readings and effective signal transmission. Understanding various wiring layouts is essential for achieving optimal performance in measurement applications. Each configuration has its own advantages and considerations, influencing both the functionality and reliability of the system.

Common Configurations

Two primary arrangements are frequently used: series and parallel. In a series setup, multiple sensors are connected in a sequential manner, which can enhance the overall voltage output. Conversely, the parallel configuration allows for redundancy, where multiple sensors can operate simultaneously, providing backup in case one fails.

Connection Types

The choice of connection type is equally important. Standard junctions and isolated junctions serve different purposes, affecting how temperature changes are detected. An isolated connection helps prevent interference from external electrical noise, while a standard junction is often easier to implement and can be sufficient for many applications.

Wire Material

The material used for wiring also impacts performance. Commonly utilized materials include copper and constantan, each offering distinct advantages in terms of conductivity and resistance to corrosion. Selecting the appropriate wire type is vital for ensuring longevity and precision in temperature measurements.

By carefully considering these factors, users can create effective configurations that optimize performance and reliability in various environments. Proper wiring setup is fundamental for achieving accurate temperature monitoring and enhancing the overall efficiency of the system.

Maintenance and Troubleshooting Tips

Ensuring the longevity and efficiency of temperature sensing devices requires regular care and prompt attention to issues. By following systematic maintenance practices and recognizing potential problems early, users can enhance performance and minimize downtime.

Regular Inspections: Periodically check connections for signs of wear or corrosion. Loose or damaged wiring can lead to inaccurate readings.

Calibration: It’s essential to recalibrate the device periodically to maintain accurate temperature readings. This ensures reliability in critical applications.

Temperature Consistency: Monitor for unusual fluctuations in temperature data. Sudden changes may indicate an underlying issue that needs immediate investigation.

Cleaning: Dust and debris can affect performance. Keep the sensing element clean and free from obstructions to promote optimal functionality.

Troubleshooting: If the device malfunctions, first check the power supply and connections. If problems persist, consider consulting the manufacturer’s guidelines for further diagnostics.

Future Trends in Thermocouple Technology

The advancement of temperature measurement technologies is poised to revolutionize various industries. As the demand for precision and efficiency increases, innovative solutions are emerging to enhance performance and reliability. These developments aim to push the boundaries of what is possible in thermal sensing.

Miniaturization is one of the key trends, allowing for smaller, more compact sensors that can be integrated into tight spaces without sacrificing accuracy. This shift will enable applications in advanced electronics and wearable devices, catering to a growing market for smart technology.

Additionally, the integration of smart materials is set to enhance responsiveness and durability. By incorporating advanced alloys and composites, the lifespan and stability of these sensors can be significantly improved, resulting in more reliable data collection.

Furthermore, the rise of wireless technologies is expected to simplify data transmission and enable real-time monitoring. This connectivity will facilitate better data analytics and improve overall operational efficiency in various fields, from manufacturing to healthcare.

Lastly, AI-driven analytics will play a critical role in interpreting the data gathered, providing actionable insights and predictive maintenance capabilities. As these trends evolve, the future of thermal measurement will be characterized by enhanced accuracy, integration, and intelligence.