Understanding how different elements of marine propulsion systems are arranged is essential for ensuring smooth operation and timely maintenance. These systems consist of various critical elements, each designed to work in harmony to deliver reliable performance. A clear layout is invaluable when it comes to identifying and managing specific elements for repair or replacement, especially for ensuring longevity and optimal function of the engine.

Each component has its role, from those responsible for fuel management to elements that regulate cooling and exhaust. Learning how these elements interact allows for more efficient troubleshooting and maintenance. With the right blueprint, even complex systems can become

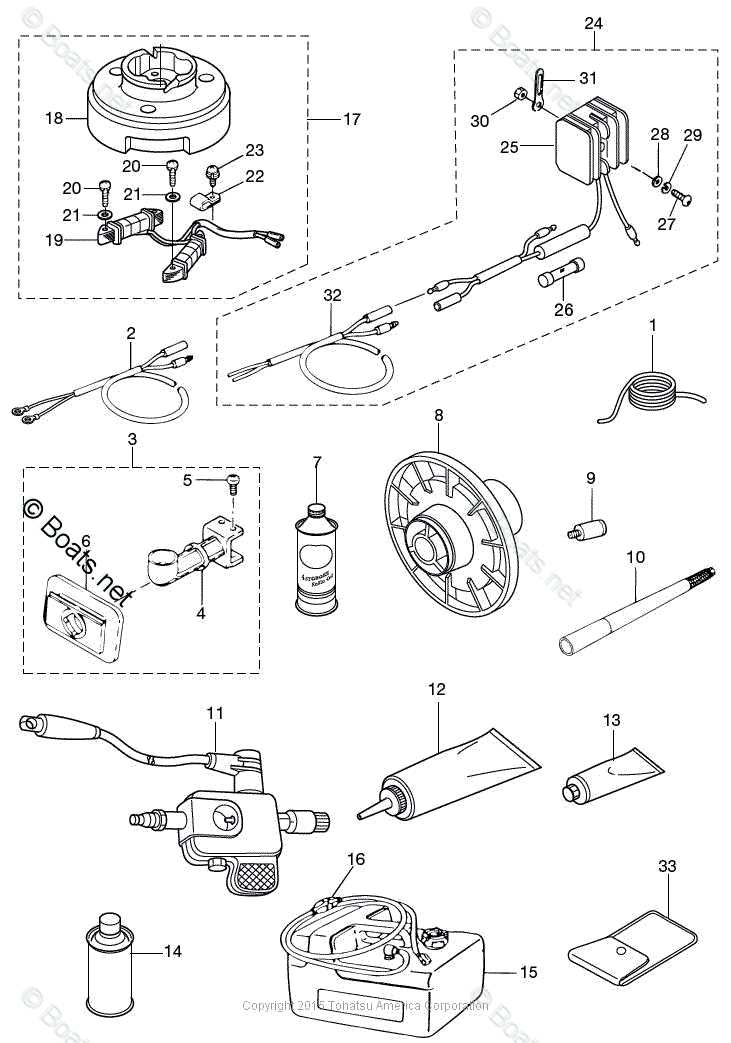

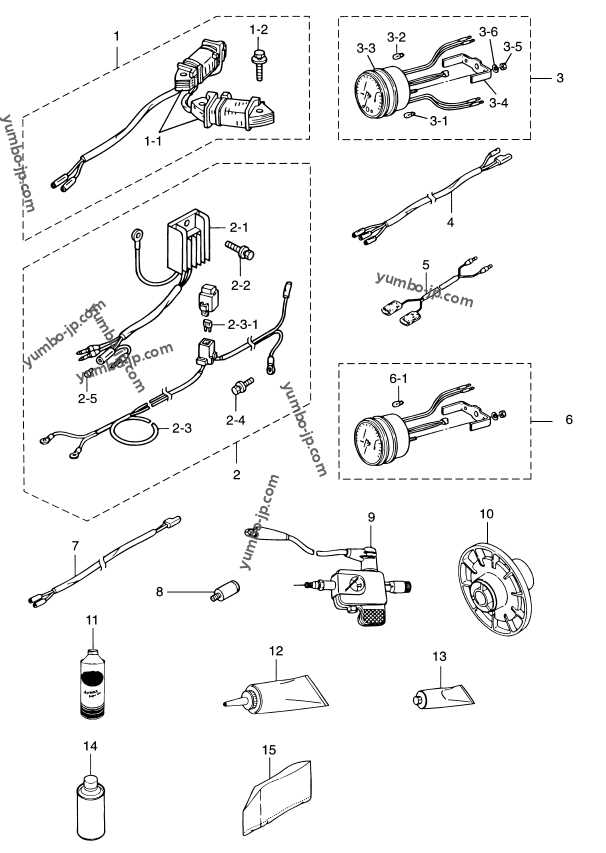

Tohatsu Components Overview

The internal structure of various marine equipment systems is made up of a wide range of essential elements, each designed to fulfill a specific function. These elements work in harmony to ensure smooth operation and long-term reliability. Understanding how the individual units interact within the larger assembly provides valuable insights into the overall mechanics and performance of the system.

Key mechanical units, electrical connections, and support structures form the backbone of the system. Each of these components plays a crucial role in maintaining optimal performance under varying conditions. When examining the arrangement, it becomes clear how each part supports the entire operation, offering both durability and efficiency.

Attention to detail in the design and integration of individual elements is what guarantees both reliability and ease of maintenance. By

Key Features of Tohatsu Engine Parts

Understanding the unique elements of this brand’s marine propulsion components reveals a blend of innovation and efficiency. These elements are designed to ensure optimal performance in various watercraft, offering a reliable solution for both recreational and commercial use.

Durability and Longevity

One of the standout characteristics of these components is their exceptional resilience. Built to withstand harsh marine environments, they are crafted from high-quality materials, ensuring long-lasting operation even under demanding conditions. This feature reduces the need for frequent replacements, saving time and maintenance costs.

Performance Optimization

Another important attribute is the focus on enhancing operational efficiency.

How to Identify Genuine Tohatsu Components

Ensuring the authenticity of essential elements for your machinery is crucial for maintaining optimal performance and safety. Recognizing legitimate products requires attention to specific indicators, as imitation items can sometimes appear almost identical to the originals. Understanding how to distinguish these features will help avoid potential issues caused by counterfeit alternatives.

Check Manufacturer Labels and Serial Numbers

One of the most reliable ways to confirm the authenticity of a component is by examining its manufacturer label and associated serial number. These identifiers should match official documentation and be clearly printed or etched on the item.

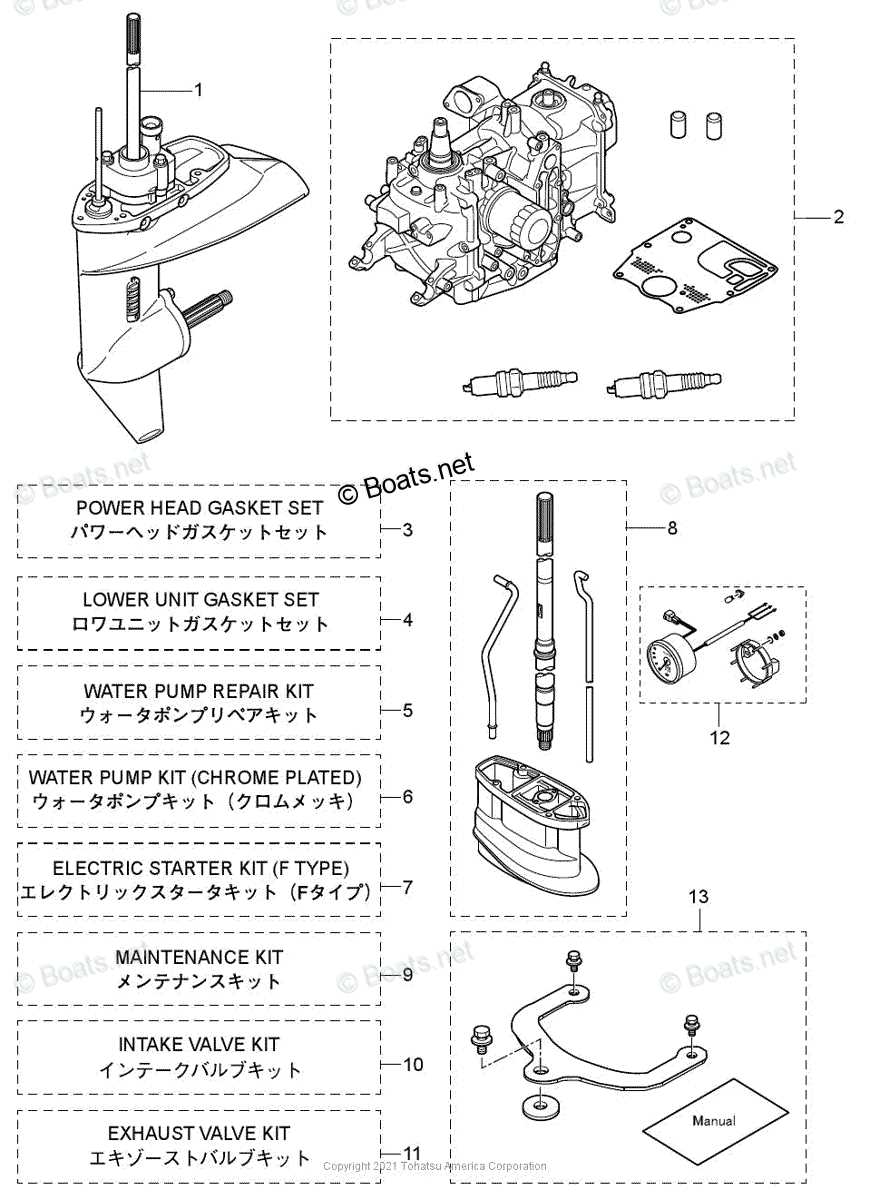

Commonly Replaced Parts in Tohatsu Outboards

Regular maintenance and repair of marine engines involve replacing several key elements to ensure smooth and reliable operation. These components are prone to wear and tear due to constant exposure to challenging conditions like saltwater, temperature fluctuations, and high operating pressure. Timely replacement of these essential elements can significantly extend the lifespan of the engine and improve performance on the water.

Wear-and-Tear Components

Frequent replacements often include items that are crucial for engine performance and safety. These include elements responsible for controlling fuel flow, managing cooling systems, and protecting the engine from overheating. Additionally, certain moving parts that endure constant friction and load are often the first to show signs of degradation and need regular monitoring.

Understanding Tohatsu Fuel System Components

When examining the fuel delivery setup in marine engines, it’s crucial to understand how the various elements work together to ensure efficient operation. The components involved are designed to manage the flow and quality of the fuel, ensuring optimal combustion and performance. Each element plays a role in maintaining the reliability of the system.

Key Elements of the Fuel Delivery System

The fuel delivery setup consists of several key components that interact to ensure proper operation. These include mechanisms for filtering, pumping, and regulating fuel, each contributing to the overall efficiency.

- Fuel Pump: Responsible for drawing fuel from the tank and delivering it under pressure to the engine.

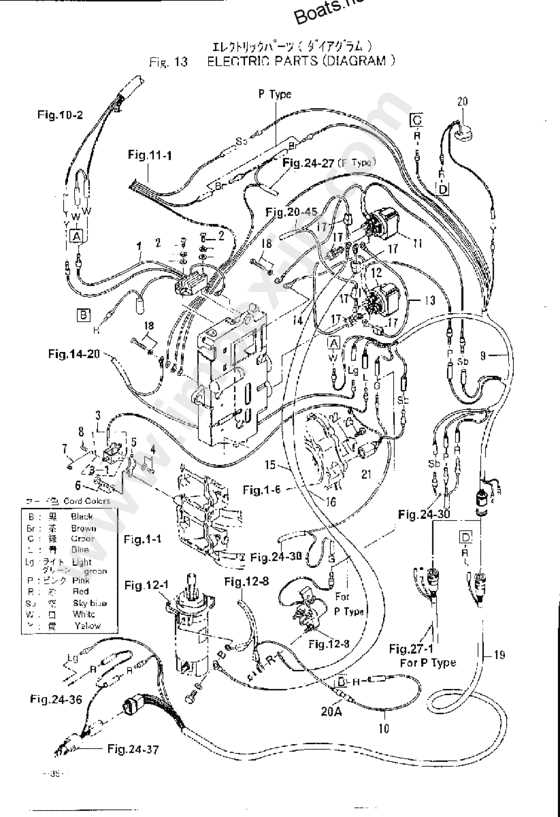

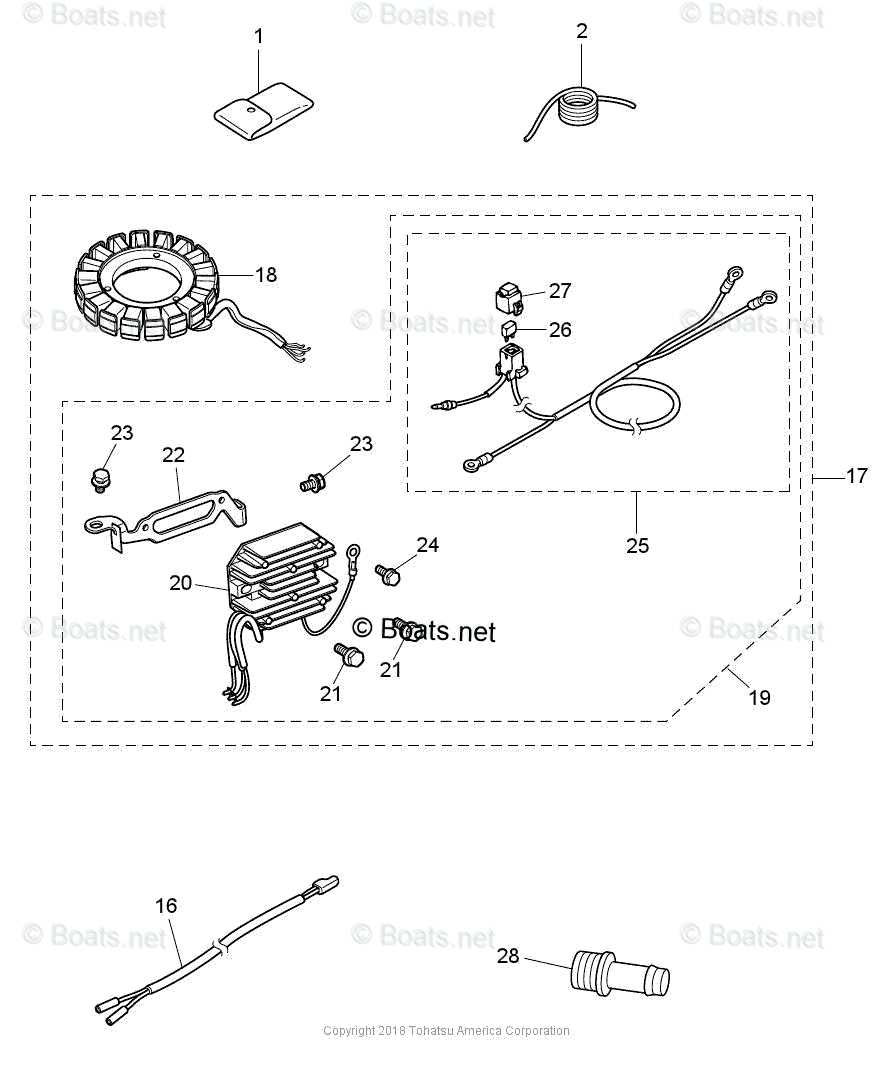

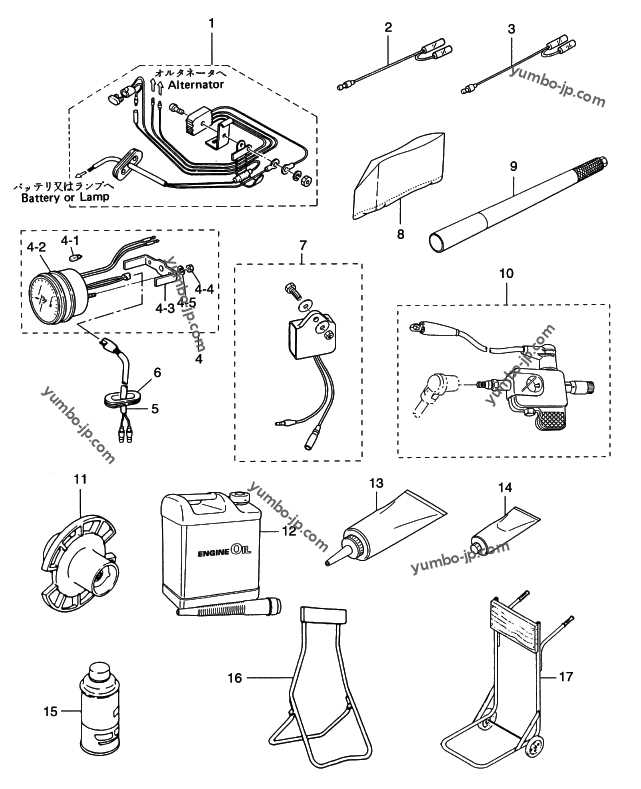

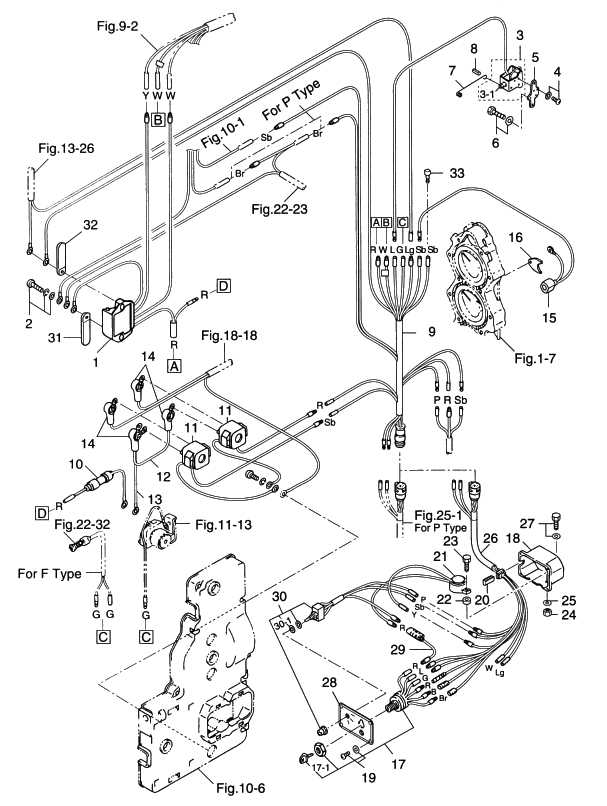

- Maintenance Tips for Tohatsu Electrical Systems

Ensuring the longevity and optimal performance of electrical components in marine engines requires regular attention and care. Proper upkeep not only enhances functionality but also prevents potential failures that could lead to costly repairs. Following a few key practices can significantly contribute to the reliability of these systems.

Regular Inspection: Schedule routine checks of all electrical connections and wiring to identify signs of wear or corrosion. Inspecting these elements can help detect issues before they escalate, ensuring uninterrupted operation.

Cleaning Components: Keep connectors and terminals clean to promote efficient electrical flow. Use a suitable cleaning solution to remove any dirt, salt, or oxidation that may accumulate over time.

Check Battery Health: Monitor the condition of the battery regularly. Ensure that terminals are secure and free from corrosion, and test the battery voltage to confirm it is functioning correctly. Replacing an aging battery can prevent unexpected failures.

Protect Against Moisture: Moisture can be detrimental to electrical systems. Use waterproof covers and sealants on exposed connections to safeguard against water intrusion. This step can significantly reduce the risk of short circuits and component damage.

Consult the Manual: Refer to the manufacturer’s manual for specific maintenance schedules and guidelines. Following these recommendations will ensure that all electrical systems are serviced appropriately, maintaining peak performance.

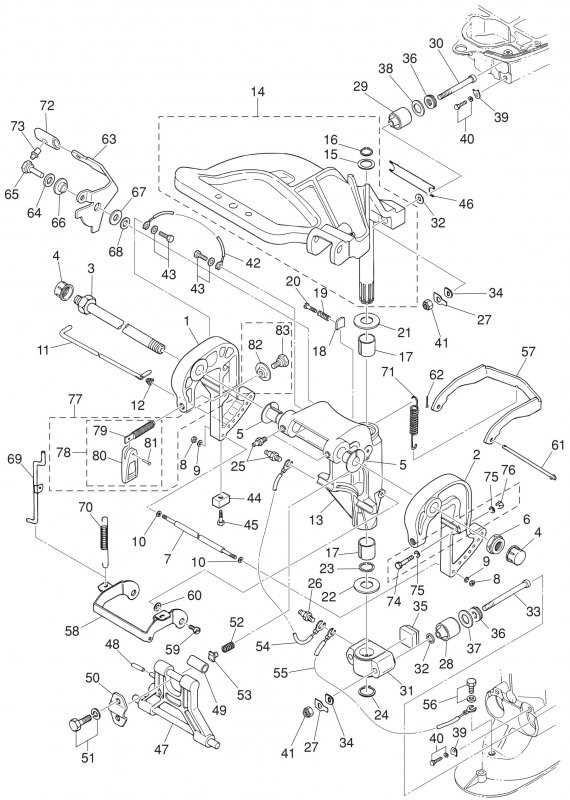

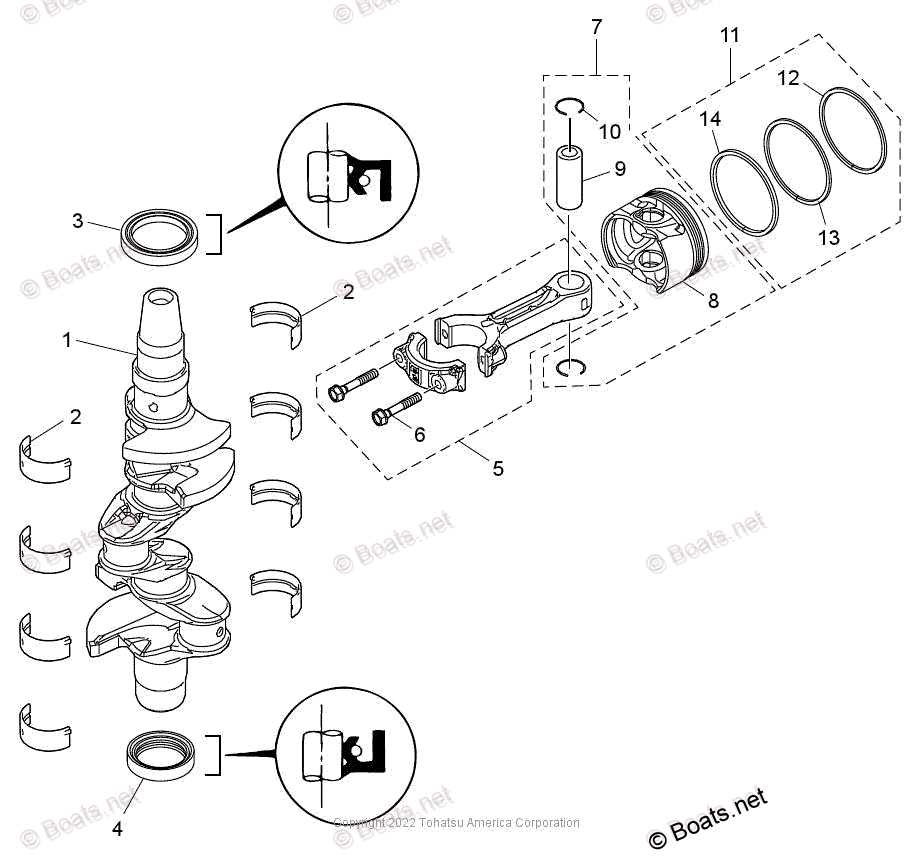

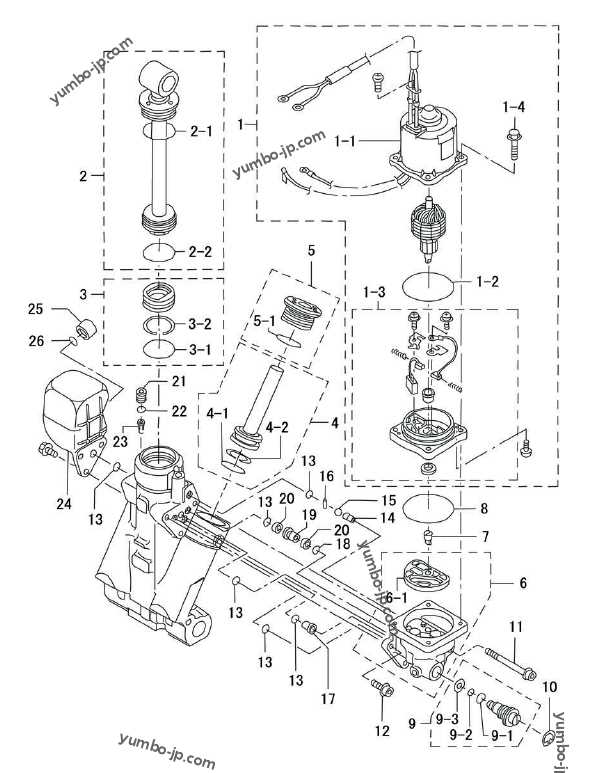

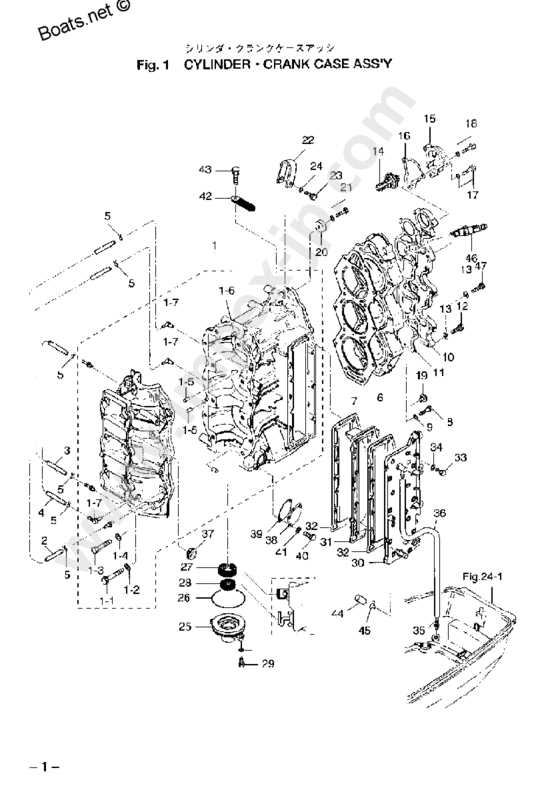

Visual Breakdown of Tohatsu Gear Mechanisms

This section offers an in-depth exploration of the gear systems utilized in various marine engines. Understanding these intricate assemblies is essential for maintaining optimal performance and reliability. Each component plays a crucial role in the overall functionality, ensuring smooth operation and longevity of the machinery.

Key Components of the Gear Systems

The gear systems consist of various essential elements that work together harmoniously. Here is a concise overview of these critical components:

Component Description Drive Gear This element transmits rotational motion from the engine to other components. Idle Gear Facilitates smooth engagement and disengagement of the drive gear. Propeller Shaft Connects the gear assembly to the propeller, translating motion into thrust. Bearings Support the gears, reducing friction and ensuring smooth operation. Understanding Gear Interactions

The interactions between the gears significantly influence performance. Analyzing these relationships allows for better troubleshooting and optimization. Regular inspection and maintenance of these systems can prevent malfunctions and extend the lifespan of the machinery.

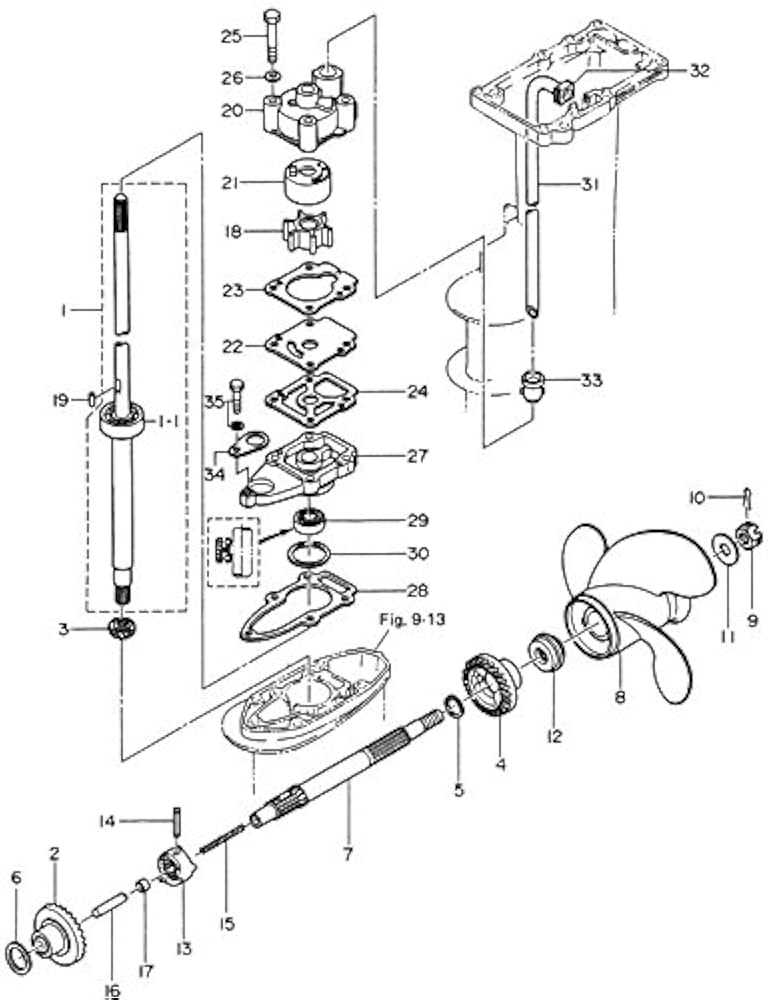

Tohatsu Cooling System Parts and Functions

The cooling mechanism in marine engines plays a crucial role in maintaining optimal operating temperatures. Understanding the various components and their respective functions is essential for efficient maintenance and troubleshooting. Each element contributes to the effective dissipation of heat, ensuring the engine operates smoothly and efficiently.

Component Function Water Pump Circulates coolant throughout the system to absorb excess heat. Thermostat Regulates coolant flow based on temperature, maintaining the engine at an optimal operating temperature. Heat Exchanger Transfers heat from the engine coolant to the surrounding water, cooling the engine efficiently. Cooling Hoses Facilitate the flow of coolant between components, ensuring a continuous circulation process. Exhaust Manifold Directs exhaust gases away from the engine, preventing overheating and enabling better performance. Proper maintenance of these components is vital for the longevity of the engine. Regular checks and timely replacements can prevent overheating and potential damage, ensuring reliable performance on the water.

Choosing the Right Propeller for Tohatsu Motors

Selecting the appropriate propeller is crucial for optimizing the performance and efficiency of outboard engines. A well-matched propeller enhances speed, fuel efficiency, and overall handling, ensuring a better boating experience. Understanding the various factors that influence propeller selection can lead to significant improvements in performance and longevity of the engine.

Factors to Consider

- Diameter: The diameter of the propeller affects the thrust and speed. A larger diameter generally provides more thrust but may reduce maximum speed.

- Pitch: This measurement determines how far the boat moves forward with each rotation of the propeller. A higher pitch offers greater speed but may require more power to achieve.

- Material: Common materials include aluminum and stainless steel. Aluminum is lightweight and affordable, while stainless steel offers superior strength and performance.

- Number of Blades: Propellers typically come with two to four blades. More blades can improve acceleration and handling but may reduce top speed.

Testing and Adjustment

After selecting a propeller, it’s essential to test its performance on the water. Observing the engine’s RPM, speed, and handling will provide insights into whether adjustments are needed. If the engine operates at too low or too high RPM, consider experimenting with different pitch or diameter options. Proper tuning can maximize performance and fuel efficiency.

In summary, careful consideration of diameter, pitch, material, and blade number will help in selecting the optimal propeller, enhancing the overall performance of the outboard engine.

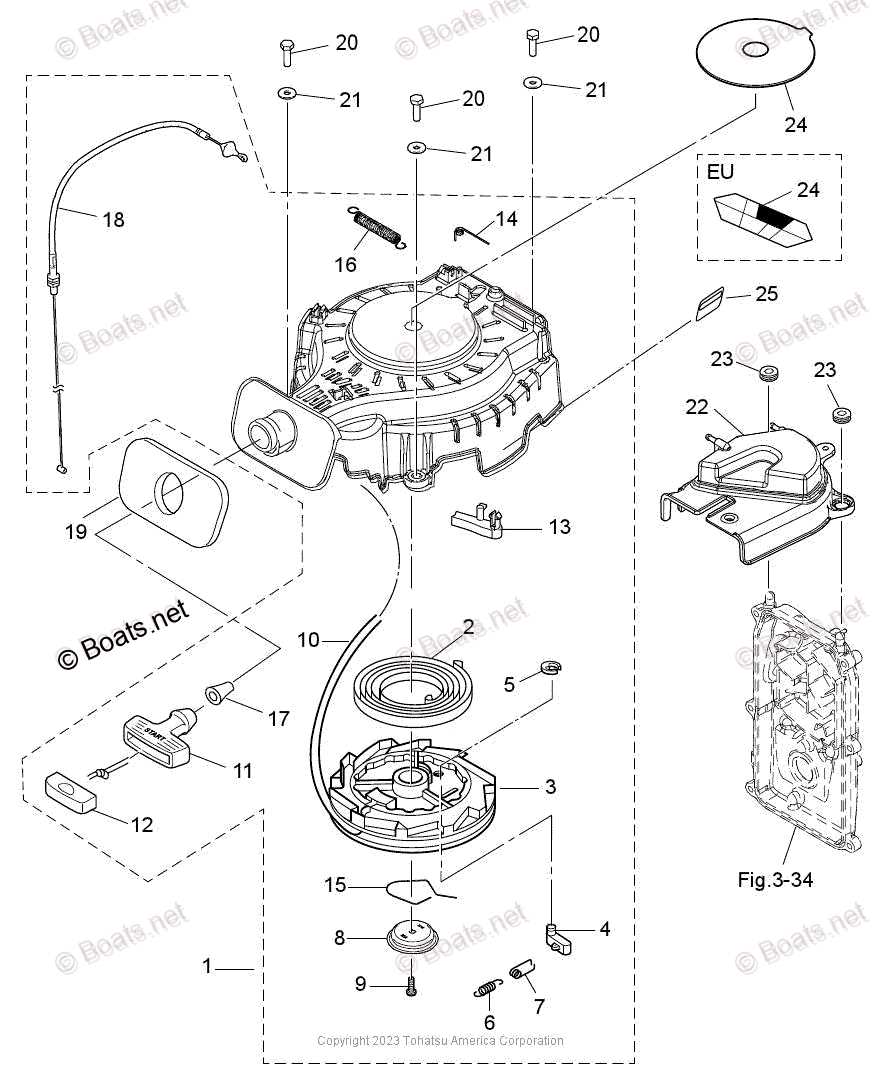

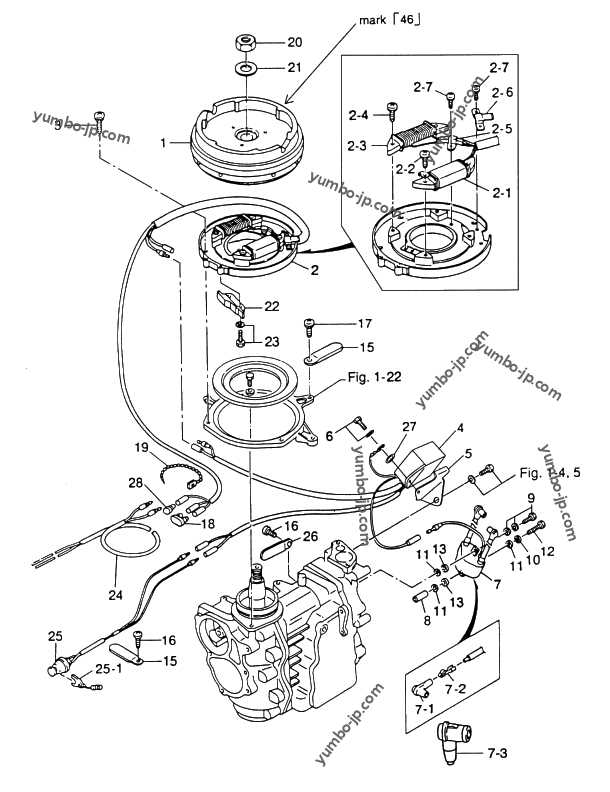

Inspecting Tohatsu Ignition System Components

Ensuring the optimal performance of an engine relies heavily on the functionality of its ignition system. This critical assembly consists of several key elements that work in harmony to generate the necessary spark for combustion. A thorough examination of these components can help identify potential issues, ensuring smooth operation and longevity of the equipment.

Key Components to Inspect

- Spark Plug: Check for wear, deposits, or damage. A faulty spark plug can lead to misfiring or difficulty starting the engine.

- Ignition Coil: Examine for signs of corrosion or burning. This component is essential for transferring voltage to the spark plug.

- Wiring Harness: Look for frayed or damaged wires that may disrupt electrical flow. Secure connections are vital for reliability.

- Control Module: Test functionality to ensure the ignition timing is correctly adjusted for optimal performance.

Inspection Process

- Begin by disconnecting the battery to prevent accidental sparks.

- Remove the spark plug and inspect its condition; replace if necessary.

- Carefully examine the ignition coil and wiring for any physical damage or wear.

- Use a multimeter to test the resistance of the coil and other electrical components.

- Reassemble and reconnect the battery, then test the ignition system for proper operation.

Regular inspections can significantly enhance the reliability and efficiency of the ignition system. Addressing issues promptly can prevent costly repairs and ensure peak performance.

Essential Tohatsu Spare Parts for Long Trips

When preparing for an extended voyage on the water, ensuring your vessel is equipped with the necessary components can make a significant difference in your experience. Carrying essential replacements not only enhances safety but also minimizes the risk of unexpected breakdowns during your journey.

Key Components to Carry

- Fuel Filter: Regularly replacing this item ensures optimal fuel flow and prevents contaminants from affecting engine performance.

- Spark Plugs: Keeping spare spark plugs on hand can facilitate quick fixes if ignition issues arise.

- Water Pump Kit: A functioning water pump is critical for cooling the engine; having a kit allows for immediate replacement if needed.

- Propeller: An extra propeller can be invaluable in case of damage, allowing you to continue your trip without significant delays.

- Hoses and Clamps: Carrying additional hoses and clamps can help address any leaks or breaks in the cooling or fuel systems.

Maintenance Tools

- Wrench Set: A comprehensive set will help you handle various repairs and adjustments on the go.

- Screwdriver Set: Essential for tightening or replacing any loose components.

- Multimeter: Useful for diagnosing electrical issues that may arise during your trip.

- Lubricants and Sealants: Having these materials can prevent corrosion and ensure watertight seals where necessary.

By packing these crucial items, you can enhance your readiness for the unexpected and enjoy a more carefree adventure on the water.

Guide

This section provides essential insights into understanding the various components and their arrangement within a specific engine system. Familiarity with these elements is crucial for efficient maintenance and repair. By examining the layout and function of each element, users can enhance their troubleshooting skills and ensure optimal performance.

Understanding Components

Recognizing the significance of each component is vital for anyone involved in maintenance. The following table outlines some common elements, their functions, and their importance within the overall system.

Component Name Function Importance Cylinder Houses the piston and facilitates combustion. Crucial for power generation. Piston Moves up and down to create pressure. Essential for converting fuel energy into mechanical work. Carburetor Mixes air with fuel for combustion. Key for efficient engine operation. Ignition System Ignites the fuel-air mixture. Vital for engine starting and operation. Maintenance Tips

Regular inspection of each element is recommended to ensure reliability. Cleaning and timely replacement of worn components can prevent potential failures. Moreover, understanding the interrelationship of these elements enhances overall efficiency and longevity.