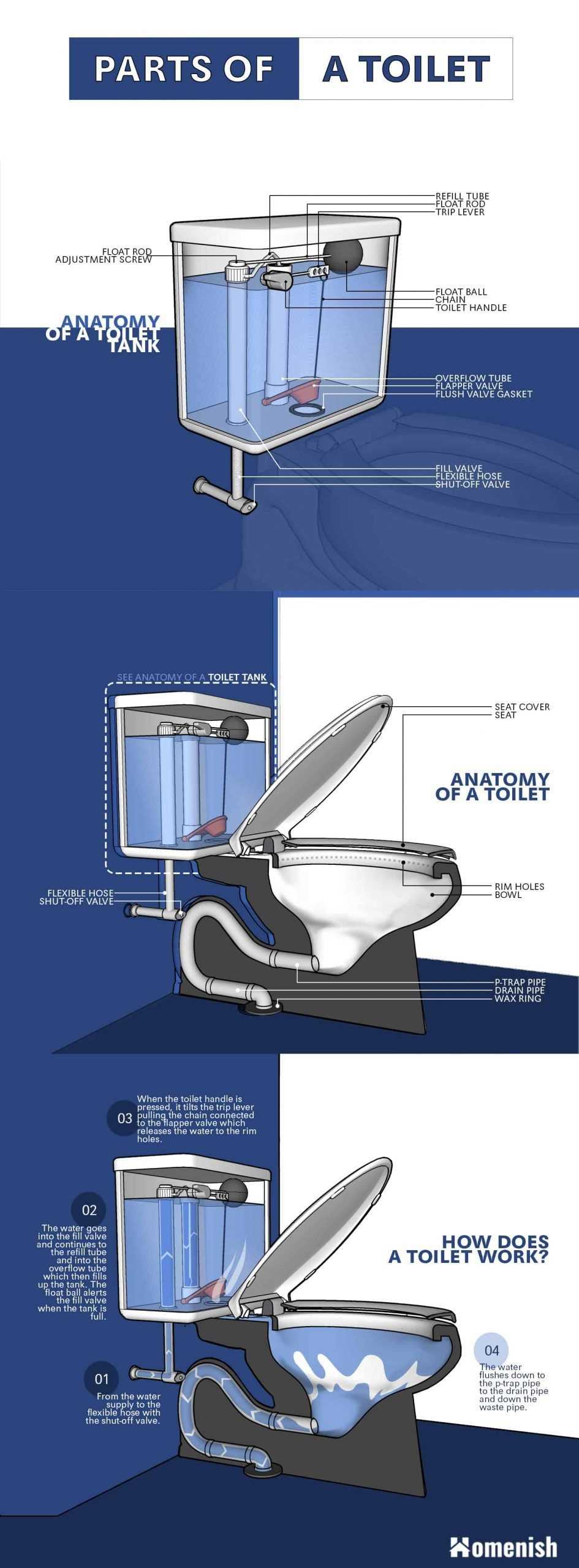

Modern water disposal systems found in household restrooms are designed to efficiently manage liquid waste while conserving resources. Their internal structure, though hidden from sight, plays a vital role in ensuring smooth operation. A closer look at the components involved reveals an intricate design, each piece performing a specific function to control the movement of water.

The inner workings of these systems rely on various mechanisms working together to regulate water flow, discharge, and refill cycles. By exploring the different elements involved, we can better understand how this process is executed seamlessly. This knowledge is useful for both identifying potential malfunctions and maintaining the overall system’s efficiency.

In the following section, we will delve into the essential elements responsible for managing water flow, providing a clearer perspective on how they interact and contribute to the functi

Toilet Flush Mechanism Overview

The mechanism responsible for activating the release of water in a modern sanitary appliance is a complex system designed for efficiency and reliability. This system involves various components that work together to ensure the proper flow of water, preventing any unnecessary waste and maintaining cleanliness. Understanding how these elements interact provides a clearer picture of the engineering behind these essential household devices.

Main Components and Their Functions

The key elements of this system include devices that regulate water flow, control the pressure, and initiate the release process. Each part plays a crucial role in ensuring smooth operation, from the initial trigger to the controlled refill of the water chamber. Proper maintenance of these elements is essential for consistent performance and to avoid potential malfunctions.

How the Release Mechanism Works

When activated, the release mechanism causes an immediate discharge of water through an outlet, effectively clearing the vessel. The water level is then restored through a refill system that controls the flow back into the storage chamber. This entire process is engineered to be both swift

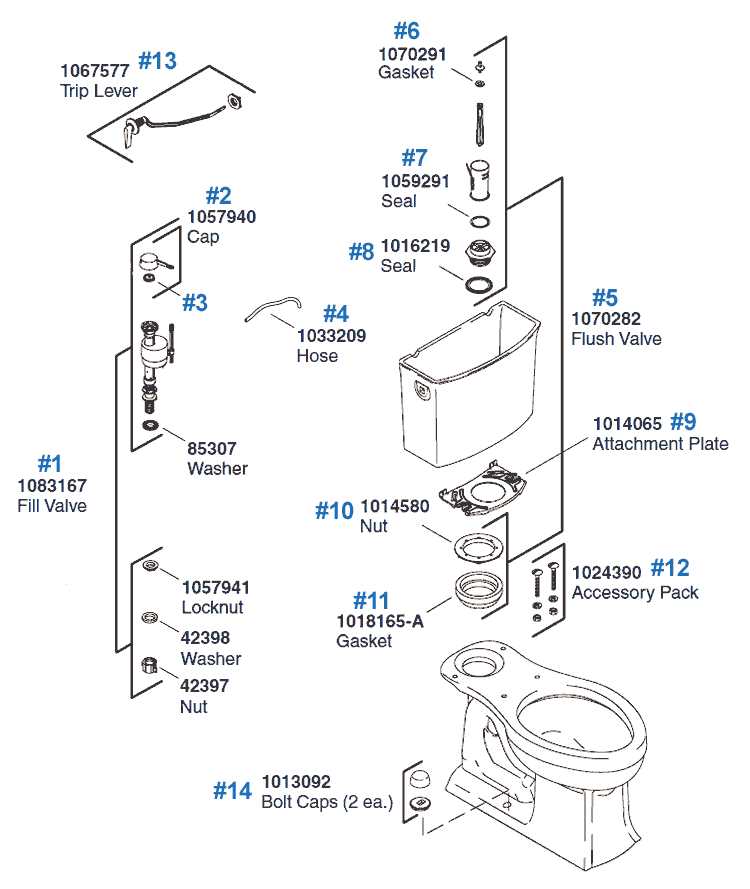

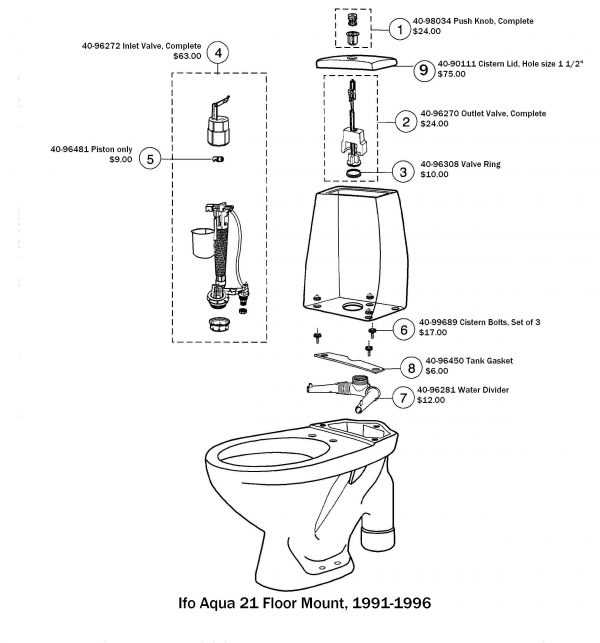

Main Components of a Toilet Flush System

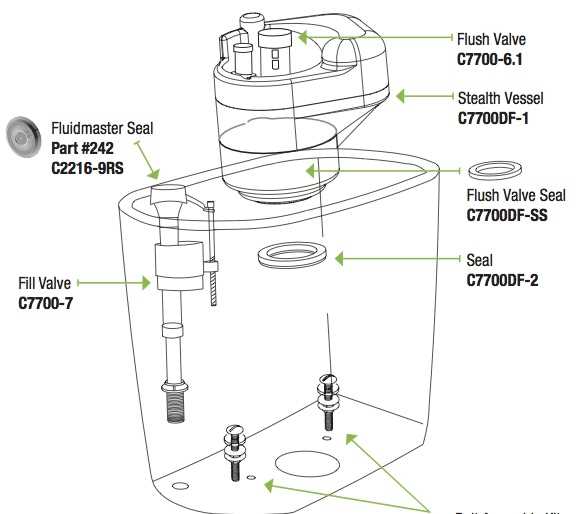

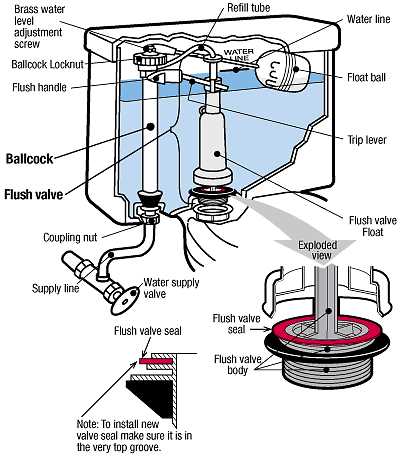

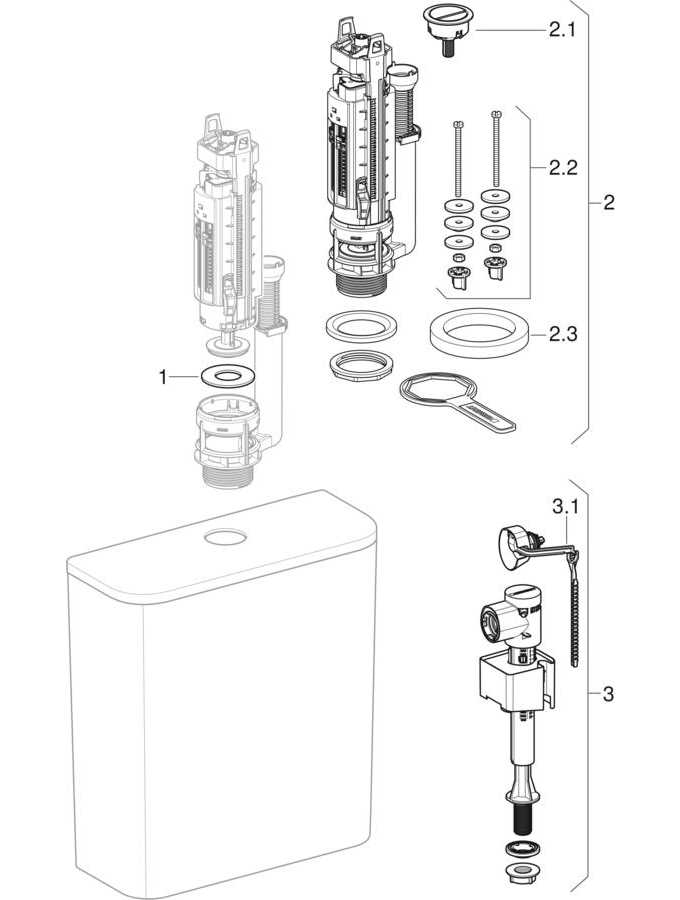

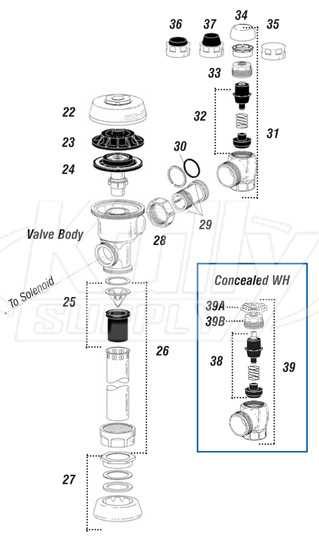

The internal structure of a water release mechanism consists of several key elements that work together to ensure efficient water flow management. These components are designed to control the movement of water, regulate pressure, and maintain the overall function of the system. Understanding the main elements and how they interact can help with both installation and maintenance.

Water Flow Control Mechanism

- Valve: This component is responsible for regulating the inflow and outflow of water. It opens and closes based on the pressure changes in the system.

- Float: A buoyant piece that monitors the water level, signaling when the flow needs to start or stop.

- Linkage: The connection between the handle and the internal controls, which triggers the entire system when activated.

Sealing and Drainage Elements

- How the Fill Valve Regulates Water Flow

- Gather Your Tools:

- New handle assembly

- Screwdriver (flathead or Phillips)

- Adjustable wrench

- Towel or rag

- Turn Off the Water Supply: Locate the shut-off valve behind the fixture and turn it clockwise to stop the water flow.

- Remove the Cover: If applicable, gently lift off the decorative cover that conceals the handle attachment.

- Unscrew the Handle: Use the screwdriver to remove the screws securing the handle to the mechanism.

- Detach the Old Handle: Carefully pull the damaged handle off the mechanism.

- Install the New Handle:

- Align the new handle with the mechanism.

- Secure it in place by tightening the screws with the screwdriver.

- Replace the Cover: If a cover was removed, snap it back into position over the handle.

- Turn On the Water Supply: Rotate the shut-off valve counterclockwise to restore water flow.

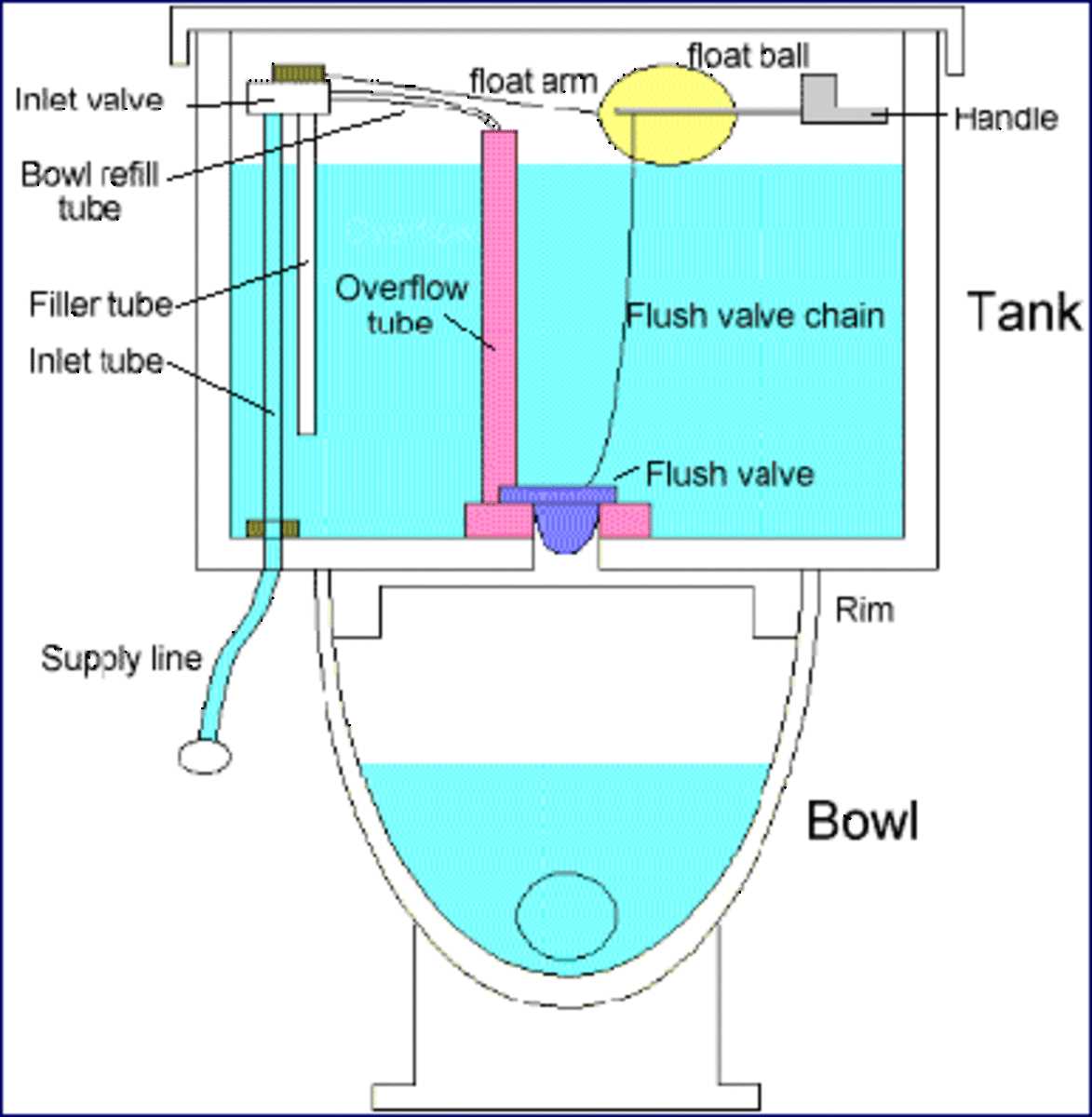

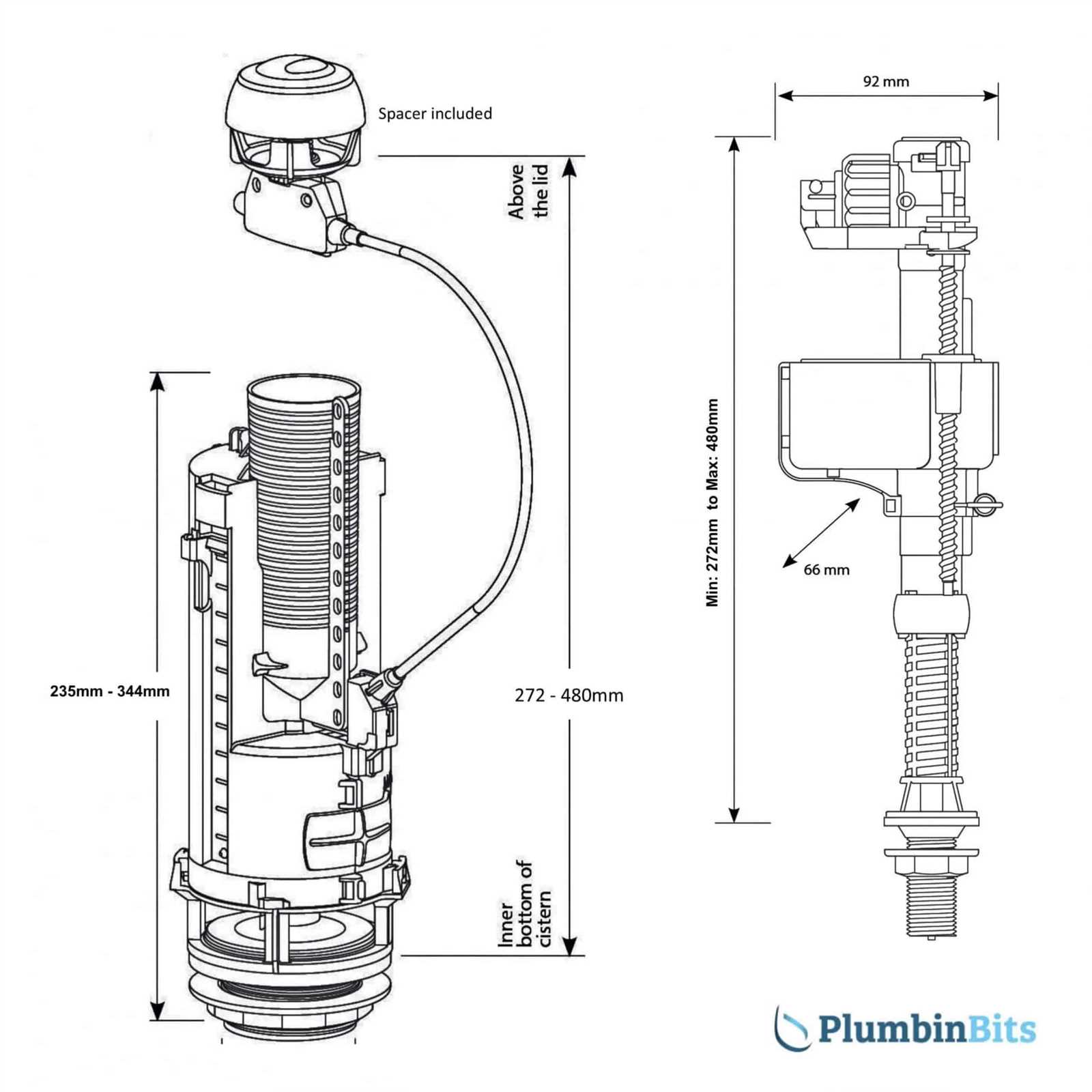

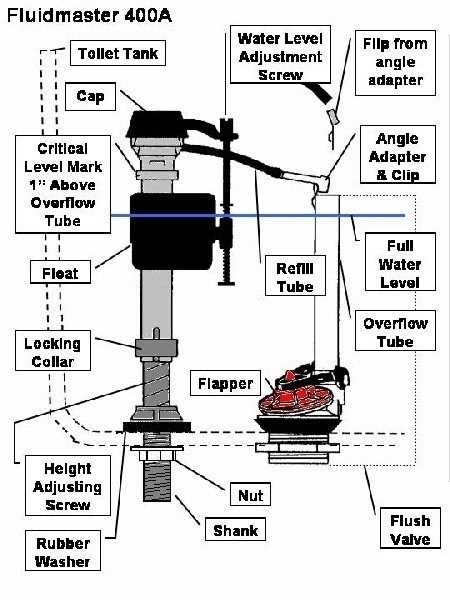

The fill valve plays a crucial role in controlling the flow of water within the system, ensuring that it operates efficiently. It is designed to manage the amount of liquid that enters and maintains the correct level, preventing both overflows and shortages. This ensures a balanced operation every time the mechanism is activated.

Once the mechanism is triggered, the fill valve opens, allowing water to move into the tank. As the water rises, the valve gradually adjusts the flow, slowing it down as the tank reaches its optimal capacity. When the appropriate level is achieved, the valve shuts off completely, ensuring no more liquid is added. This process not only conserves water but also prevents malfunction due to overfilling.

Additionally, the fill valve is designed to react quickly to

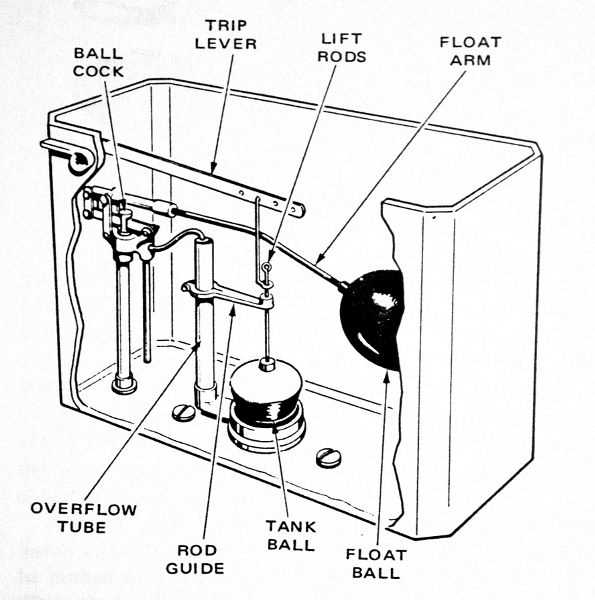

Understanding the Role of the Flush Lever

The mechanism that activates the flow of water plays a vital role in the operation of many household systems. Its design is simple yet effective, acting as the key component in releasing water when prompted by the user. Without it, the process of initiating water movement would require more effort and be far less efficient.

When engaged, this handle lifts an internal element that allows water to flow freely. This triggers a sequence of events leading to the release of water from the main reservoir. The ease of use and mechanical reliability of this lever make it an essential element in managing water distribution in everyday appliances.

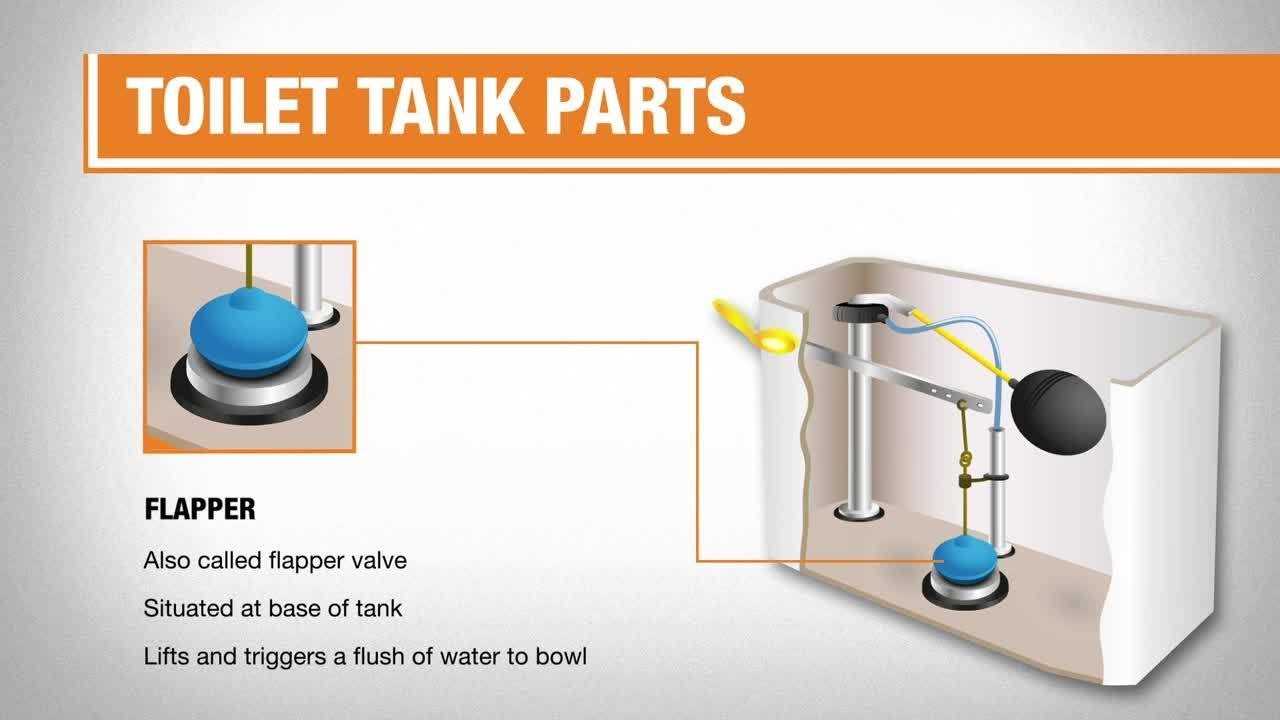

Functions of the Flapper Valve

The flapper valve is a crucial component responsible for regulating the release of water from the tank into the bowl. Its primary role is to ensure proper flow control, preventing unnecessary water waste while maintaining efficient operation of the system.

| Function | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Water Release | The valve opens to allow water to flow through, ensuring that the proper amount is delivered for each cycle. | ||||||||

| Seal Maintenance | When closed, it forms a tight seal that stops any leakage, preserving water and keeping the system efficient

Common Issues with the Overflow Tube

The overflow tube plays a crucial role in regulating water levels and preventing overflow in various water management systems. However, several problems can arise that may compromise its functionality. Understanding these common issues can help in maintaining optimal performance and avoiding costly repairs. Leakage ProblemsOne of the most frequent issues associated with the overflow tube is leakage. This can occur due to wear and tear, improper installation, or corrosion. When water leaks from the tube, it not only leads to a waste of water but can also cause damage to surrounding structures. Regular inspections can help identify any signs of leakage early on, allowing for timely repairs. Clogging Issues

Another significant concern is clogging. Debris, sediment, or mineral buildup can obstruct the flow of water through the overflow tube. This can lead to inadequate drainage and increased pressure within the system, potentially causing further complications. Routine cleaning and maintenance are essential to ensure that the overflow tube remains clear and functional. Exploring the Float Ball and Its Purpose

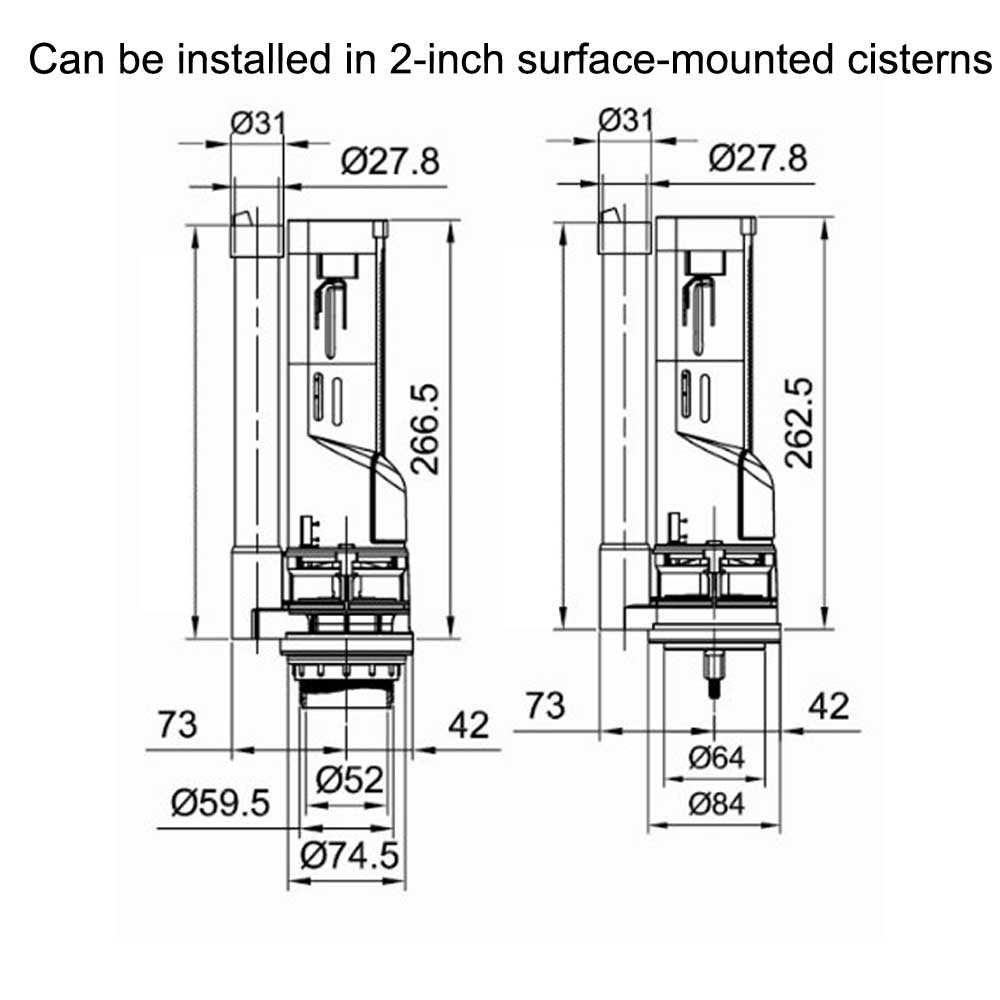

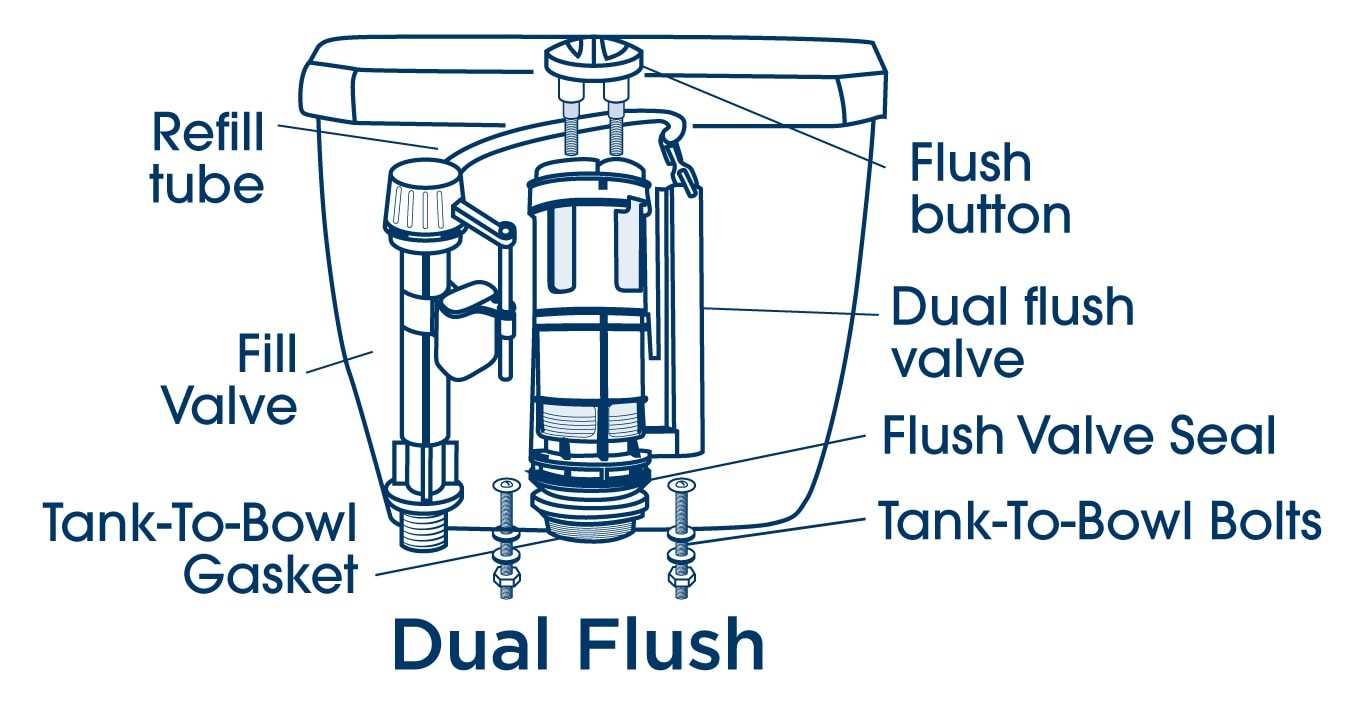

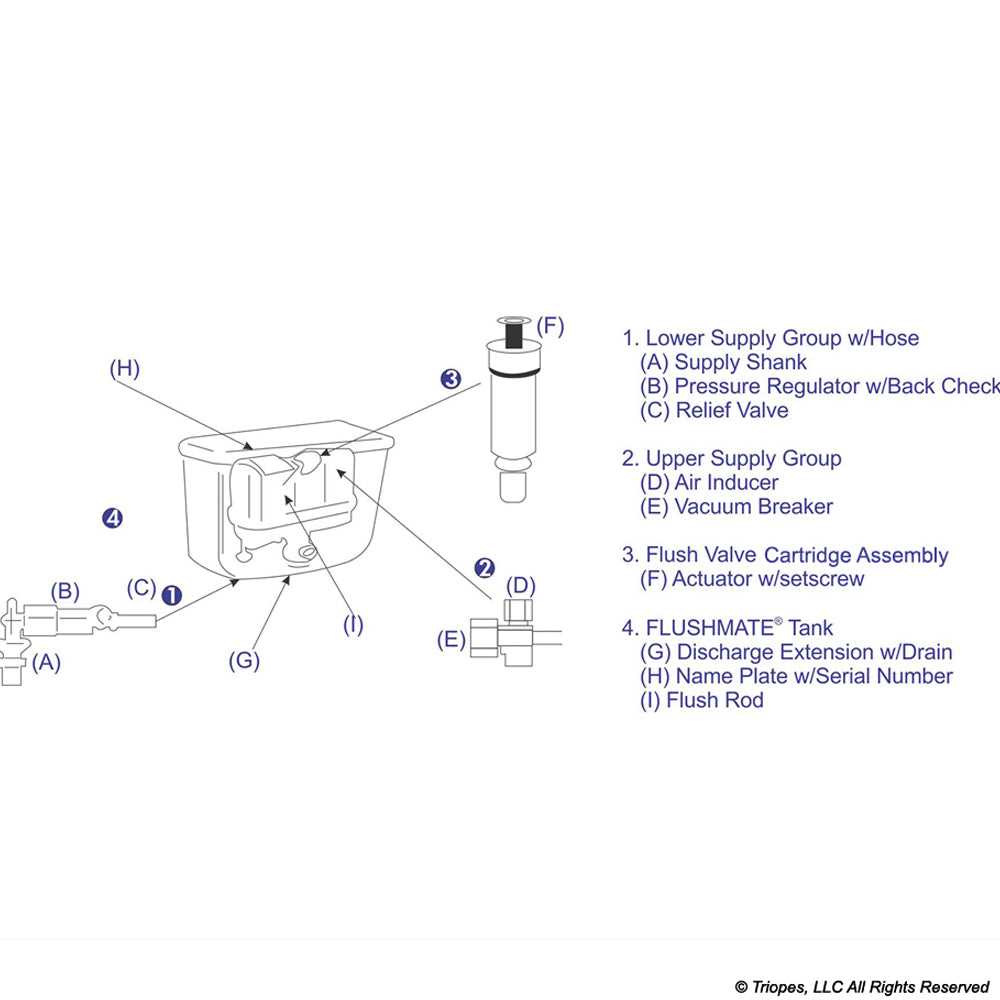

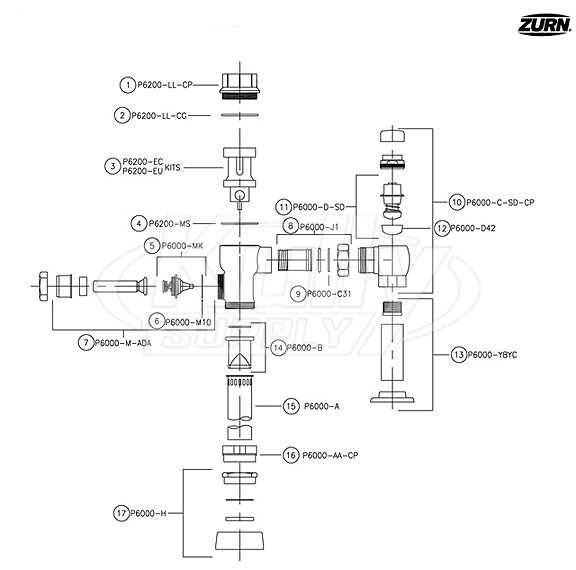

The float ball is a crucial element in the mechanism that controls water levels within a tank. Its primary role is to maintain the balance of fluid inside, ensuring proper functionality when required. This component operates by responding to changes in water levels, allowing for efficient management of the system’s operations Differences Between Flush Valve TypesThe various mechanisms used in water release systems serve distinct purposes and function in unique ways. Understanding these variations is essential for making informed decisions about installation and maintenance. Each type has its characteristics, advantages, and limitations, which can significantly influence performance and user experience. Gravity-Operated Valves are commonly found in traditional installations. They rely on the weight of water to initiate the release process. When the handle is activated, water from the tank flows down, effectively clearing the bowl. This type is generally simpler and requires less maintenance due to fewer moving parts. Pressure-Assisted Valves, on the other hand, utilize air pressure to enhance the flushing action. This technology allows for a more powerful release, effectively using less water to achieve better results. Although they may be noisier during operation, they offer superior performance in terms of efficiency and effectiveness. Dual-Flush Mechanisms present a more environmentally friendly option by allowing users to choose between a full or partial discharge. This flexibility reduces water consumption, catering to both high and low volume needs. While installation may be slightly more complex, the benefits of water conservation can be substantial. In summary, the choice among these valve types can affect not only functionality but also water efficiency and user satisfaction. Recognizing the distinctions among these systems enables better decision-making for optimal performance. How a Refill Tube Maintains Water Level

A refill tube plays a crucial role in regulating the water level within a cistern. Its primary function is to channel water from the supply line back into the tank, ensuring that it reaches the appropriate level after each discharge. This mechanism not only maintains functionality but also contributes to the overall efficiency of the system. Functionality of the Refill TubeThe refill tube operates by directing a controlled stream of water into the tank. When the water level drops below a certain threshold, the tube activates, allowing water to flow back in. This process is essential for preparing the system for the next cycle of operation. Benefits of Effective Water Level ManagementProper management of the water level has several advantages. It helps prevent overflow, minimizes water waste, and ensures that the tank is ready for immediate use. A well-functioning refill tube enhances the overall performance and reliability of the system.

Signs of a Malfunctioning Flush Valve Seal

A properly functioning sealing mechanism is crucial for maintaining efficiency and preventing leaks in the water delivery system. When this component begins to fail, it can lead to various issues that affect performance and water usage. 1. Constant Water Running: If you notice water continuously flowing into the reservoir, this may indicate that the seal is not closing correctly. This inefficiency can lead to increased water bills and wastage. 2. Water Leaks: Puddles forming around the base of the reservoir or within the tank area can suggest a compromised seal. Regular inspection can help identify leaks before they escalate. 3. Inconsistent Water Levels: Fluctuations in the water level within the tank can signify that the seal is not effectively regulating water flow. This can impact the overall operation and effectiveness of the system. 4. Noisy Operation: Unusual sounds, such as hissing or gurgling, may indicate that water is escaping due to a failing seal. Addressing this promptly can prevent further damage. 5. Inefficient Performance: If the mechanism fails to operate as intended, requiring multiple attempts to achieve the desired result, this could be a sign of a deteriorating seal that needs attention. Replacing a Damaged Toilet HandleWhen a handle becomes worn or broken, it can lead to difficulties in operating the mechanism effectively. Replacing it is a straightforward task that can restore functionality and improve the overall experience. This section outlines the necessary steps to complete the replacement process with ease. After completing these steps, test the handle to ensure it operates smoothly. A new handle will not only enhance functionality but also contribute to the overall aesthetic of the fixture. Upgrading to a Dual-Flush Mechanism

Transitioning to a more efficient mechanism can significantly enhance water conservation while maintaining optimal functionality. This upgrade not only reduces water consumption but also promotes sustainable practices in everyday life. By implementing a system that offers different options for varying needs, users can contribute to environmental preservation without sacrificing performance. Benefits of a Dual-Flush System

Adopting a dual-action system provides several advantages. It allows for a low-volume option for liquid waste and a higher-volume choice for solid waste, thereby minimizing unnecessary water use. This feature leads to lower utility bills and a reduced environmental footprint. Moreover, many modern mechanisms are designed for easy installation, making them accessible for DIY enthusiasts. Installation Process

The installation process for a dual-action mechanism is straightforward and can typically be completed within a short time frame. Begin by removing the existing mechanism, ensuring that the water supply is turned off. Follow the manufacturer’s instructions to fit the new system properly, connecting it to the water supply and testing for leaks. Once installed, enjoy the benefits of improved efficiency and savings. Tips for Adjusting Water Pressure in a Toilet

Ensuring optimal water flow within your restroom system is essential for efficiency and functionality. Adjusting the pressure can lead to improved performance, preventing issues such as slow refills or weak flow. Here are some effective strategies to help you regulate the pressure effectively. First, check the water supply valve. This valve controls the flow from the main line, and turning it clockwise can increase the pressure, while turning it counterclockwise will decrease it. Make small adjustments and observe the changes. Next, inspect the fill valve assembly. If it’s too low, it may restrict the flow; consider raising the float height to allow for a higher water level during the refill process. Adjusting the float arm can significantly impact performance. Also, consider cleaning or replacing any clogged components. Mineral buildup can impede the flow, so regular maintenance is key. A thorough cleaning of the inlet screens and valves can restore functionality. Finally, if issues persist, evaluate the overall plumbing system. A professional inspection can determine if there are underlying problems affecting the water supply, ensuring a smooth operation for your restroom fixture. |