When it comes to water-based flush mechanisms, the internal components play a crucial role in ensuring smooth operation and proper function. Inside the main structure, various mechanisms work together to control water flow, refill, and release. A well-maintained internal system contributes to efficient use, helping to avoid leaks and malfunctions.

Each element within this system has a specific function, from regulating the release of liquid to controlling the pressure. Proper knowledge of these mechanisms can assist in identifying potential issues, making adjustments, or performing basic maintenance. Understanding the purpose of each component can lead to improved performance and longevity of the entire mechanism.

In this guide, we will explore how these various elements function together and what role they play in overall performance. This information will prove invaluable when troubleshooting issues or replacing worn-out components to maintain optimal performance.

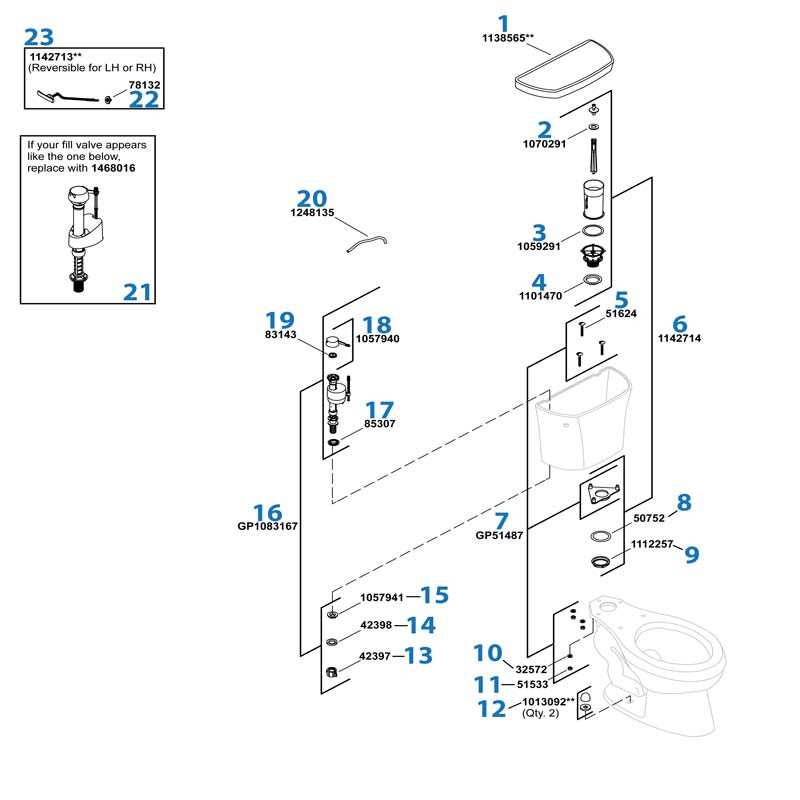

Understanding Key Components Inside a Toilet Tank

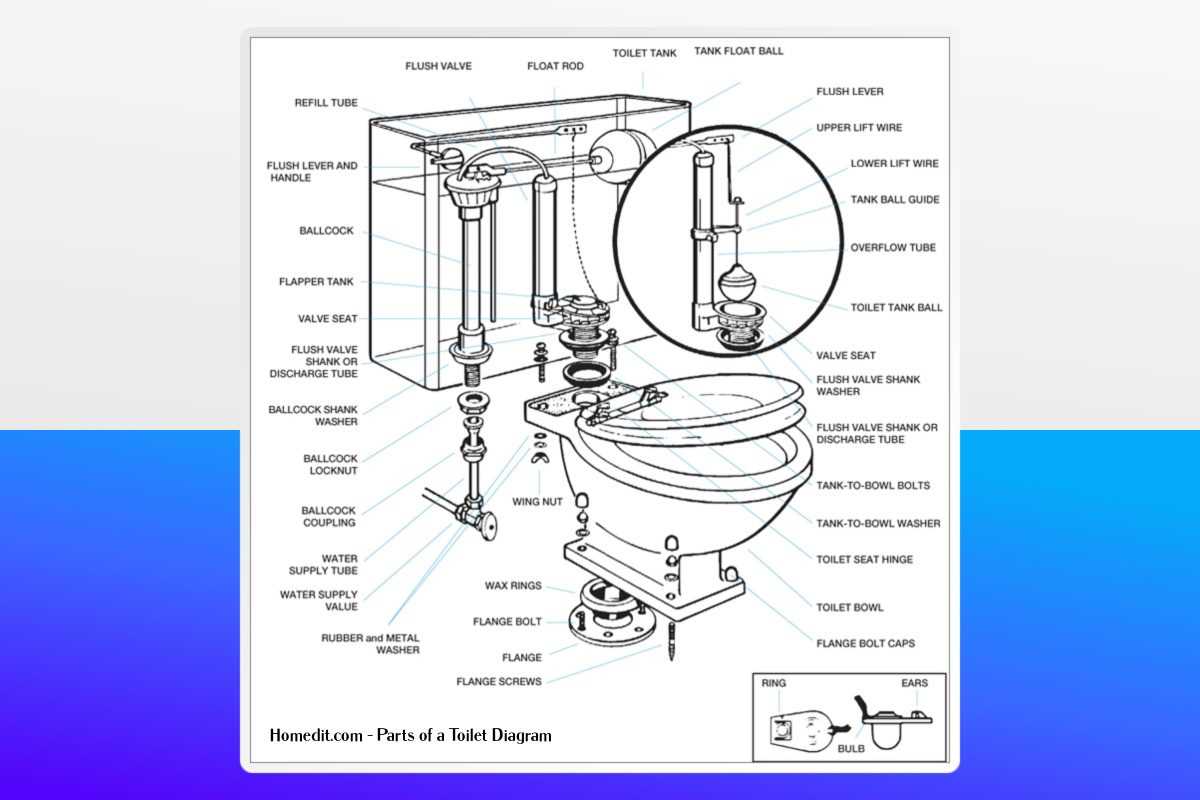

The internal structure of the flushing mechanism consists of several essential elements working in harmony to ensure proper function. Each of these elements plays a specific role in regulating water flow and controlling the flushing cycle. By exploring these components, one can better comprehend how this system operates and how to maintain it effectively.

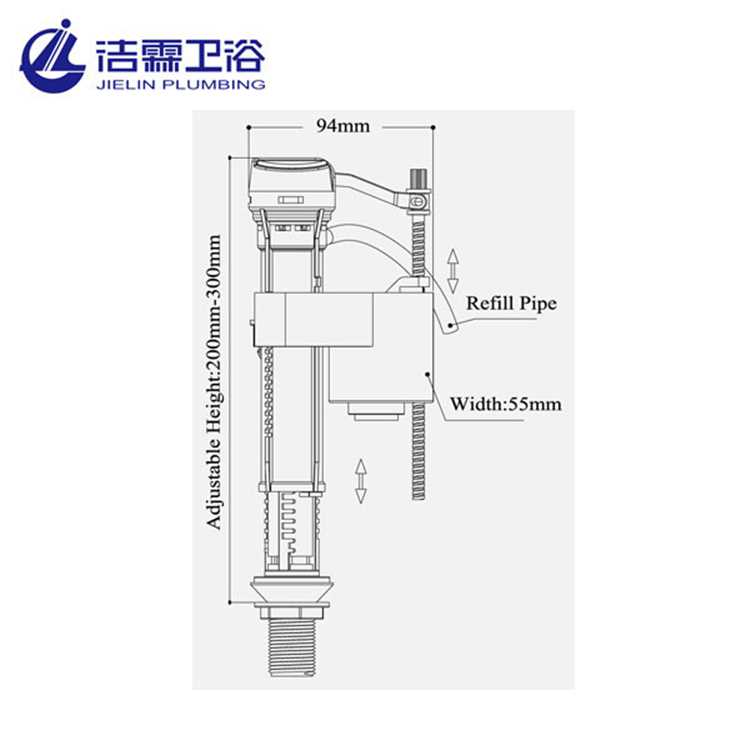

Fill Valve

The fill valve is responsible for refilling the container after each flush. It controls the flow of water, allowing it to enter the container until the water level reaches a predetermined height. A floating device attached to the valve helps to monitor the water level and shut off the flow once the container is adequately filled.

Flush Valve and Flapper

At the heart of the system is the flush valve, which works in conjunction with the flapper. When activated, the flapper lifts, releasing water from the container into the bowl. Once the water drains, the flapper closes, and the fill valve reactivates to begin the refilling process. This sequence ensures that each cycle operates smoothly and efficiently.

The Role of the Flush Valve Assembly

The flush valve assembly plays a crucial function in managing water flow and ensuring efficient drainage. It is responsible for the release and control of water, which is essential for the overall system to work properly. A well-functioning valve assembly can help maintain smooth operation and avoid common issues related to water efficiency and performance.

Here are key components that make up this assembly:

- Valve Seal: Prevents water leakage by tightly closing after every use, allowing the system to refill without wasting water.

- Overflow Tube: Protects the system from overfilling by redirecting excess water, maintaining the right balance of water levels.

- Flush Handle Linkage: Connects the handle to the valve mechanism, initiating the release of water with a simple motion.

Regular inspection and maintenance of these elements ensure longevity and proper functionality, preventing malfunctions that can disrupt the system’s efficiency.

How the Fill Valve Controls Water Flow

The fill valve plays a crucial role in maintaining the balance of water levels. It regulates the flow of liquid into the system, ensuring efficient refilling after each use. By responding to changing water levels, it automatically opens and closes, preventing overflow and ensuring consistent operation.

Mechanism of the Fill Valve

At its core, the fill valve is designed to manage the influx of water based on pressure and level changes. When the water level decreases, a float mechanism lowers, signaling the valve to open and allow water to enter. As the level rises, the float lifts, eventually closing the valve once the desired volume is reached.

Importance of Proper Adjustment

Proper calibration of the fill valve is essential for smooth operation. If the valve is set too high or too low, it can lead to either insufficient filling or excessive water usage. Regular maintenance ensures optimal water control and prevents issues such as leakage or incomplete filling.

Flapper Function and Its Importance

The flapper plays a pivotal role in regulating the release of water. Its function is essential to ensure proper control of the flow, creating a balance between efficiency and performance. Without this mechanism, maintaining consistent operation becomes challenging.

Importance of the flapper lies in its ability to provide a seal that prevents unwanted leaks. When activated, it opens, allowing water to move efficiently. Once the task is complete, it closes, creating a secure seal. This action helps to conserve resources and maintain optimal functioning.

Ensuring the flapper operates smoothly is crucial for overall system performance. Any wear or misalignment can lead to significant inefficiencies, impacting the entire mechanism’s effectiveness. Regular inspections and timely replacements help maintain long-term reliability.

Identifying the Purpose of the Overflow Tube

The overflow tube plays a critical role in managing water levels and preventing potential overflow situations. It ensures that excess liquid is redirected safely, avoiding spills and maintaining proper functionality. Understanding how this component operates helps in maintaining the overall system and detecting issues that could arise from incorrect water levels.

How the Overflow Tube Prevents Overflow

The main task of this tube is to act as a safety mechanism that diverts surplus liquid when it reaches a certain point. By providing an escape route for excess water, it prevents flooding and maintains consistent levels within the system. This safeguard ensures that the internal mechanisms remain undamaged by avoiding pressure buildup.

Maintenance of the Overflow Tube

Routine inspection of this component is important for ensuring continuous function. Any blockages or damage can compromise its ability to manage liquid levels. Keeping the tube clean and clear allows it to function efficiently, contributing to the long-term stability of the system.

What a Toilet Float Does

The float mechanism plays a crucial role in regulating water levels within a cistern. Its primary function is to ensure that the reservoir fills and stops at the appropriate height, preventing overflow and maintaining the efficiency of the flushing system.

How It Operates

This device operates on a simple principle of buoyancy. As the water level rises, the float ascends, triggering a valve that halts the water supply once the desired height is reached. Conversely, when the water level drops, the float descends, allowing the valve to open and refill the reservoir.

Common Float Types

Various designs of this mechanism are utilized in modern systems, each with its own advantages. Below is a comparison of the most commonly used types:

| Float Type | Description | Advantages |

|---|---|---|

| Bouyant Ball | A spherical device that floats on water. | Simple installation and reliable operation. |

| Vertical Float | A rod connected to a float that moves vertically. | Compact design suitable for smaller spaces. |

| Diaphragm Float | Uses a flexible diaphragm to regulate flow. | Offers precise control over water levels. |

Common Issues with the Lift Chain

The lift chain plays a crucial role in the operation of the flushing mechanism, and various complications can arise that hinder its effectiveness. Understanding these common issues can help identify and resolve problems swiftly, ensuring optimal performance.

Frequent Problems

- Tangling: Over time, the chain may become tangled or knotted, preventing smooth movement and proper flushing.

- Wear and Tear: Continuous use can lead to wear, causing the chain to stretch or break, which can disrupt the entire flushing system.

- Improper Length: A chain that is too long or too short may not provide the necessary lift, leading to ineffective flushing.

- Corrosion: Exposure to moisture can result in rust or corrosion, compromising the integrity and functionality of the chain.

Troubleshooting Tips

- Inspect the chain regularly for tangles or knots.

- Replace any worn or broken links promptly.

- Ensure the chain is the correct length for optimal operation.

- Consider using a rust-resistant material if corrosion is a recurring issue.

Handle Lever Mechanism Explained

The handle lever mechanism plays a crucial role in the operation of flushing systems, providing a simple yet effective way to initiate the flushing action. This component transforms a user’s manual input into a functional movement that activates the flow of water. Understanding how this mechanism works can enhance maintenance practices and improve overall functionality.

Key elements of the handle lever mechanism include:

- Lever Arm: A long arm that pivots around a fixed point, allowing for effective transfer of force.

- Connecting Rod: Links the lever to the flush valve, translating the lever’s movement into a vertical action.

- Flush Valve: The device that controls the release of water from the reservoir, activated by the movement of the connecting rod.

Operation of the handle lever mechanism involves the following steps:

- The user pulls or pushes the handle, which moves the lever arm.

- This movement shifts the connecting rod, initiating the motion of the flush valve.

- The flush valve opens, allowing water to flow through and perform the desired function.

- Upon release of the handle, the system resets, preparing for the next use.

Regular inspection of the handle lever mechanism is essential to ensure proper functioning and to prevent issues such as jamming or leaks. Maintenance can include lubrication of pivot points and checking for any wear or damage in the connecting components.

Seals and Gaskets: Preventing Leaks

In any plumbing system, the integrity of seals and gaskets plays a crucial role in maintaining functionality and preventing unwanted water loss. These components are designed to create a watertight barrier, ensuring that liquid remains contained within designated areas. Over time, wear and tear can compromise their effectiveness, leading to potential leaks and inefficiencies.

Importance of Quality Materials

Using high-quality materials for seals and gaskets is essential for optimal performance. Durable materials can withstand temperature fluctuations and pressure changes, significantly reducing the risk of deterioration. Investing in reliable components can lead to long-term savings by minimizing the need for repairs and replacements.

Regular Maintenance and Inspection

Routine checks of these vital components are necessary to identify any signs of damage or wear. Monitoring for small leaks or moisture buildup can help address issues before they escalate. Replacing worn seals and gaskets promptly ensures the efficiency of the entire plumbing system, ultimately promoting a dry and safe environment.

Water Level Adjustment Tips

Maintaining the correct water height within the flushing mechanism is crucial for optimal performance and efficiency. Proper calibration ensures effective waste removal while minimizing water wastage. Here are some valuable suggestions for achieving the ideal level.

1. Identify the Adjustment Mechanism: First, locate the adjusting component within the assembly. This may be a float ball or a rod, depending on the design. Understanding how this mechanism operates is essential for making precise modifications.

2. Make Gradual Adjustments: When altering the water level, proceed with small increments. Incremental changes allow for better control and help avoid overcorrection, which can lead to undesirable outcomes.

3. Test After Adjustments: After making any changes, it’s important to test the functionality. Flush the system several times to observe if the new water height achieves the desired effect. If necessary, repeat the adjustment process.

4. Check for Leaks: After adjustments, inspect for any leaks that may occur due to shifting components. Ensuring a tight seal is crucial for preventing water loss and maintaining efficiency.

5. Regular Maintenance: Periodic checks and adjustments are advisable. Regular maintenance helps to keep the flushing system operating smoothly and prevents potential issues in the future.

By following these guidelines, you can effectively manage the water level, promoting efficiency and longevity in your flushing system.

Why the Refill Tube is Essential

The refill tube plays a crucial role in maintaining the proper functionality of water flow systems. Its primary purpose is to ensure that the water level is restored efficiently after each use, preventing potential issues related to insufficient water supply.

Here are several reasons why this component is vital:

- Consistent Water Level: It helps maintain a steady level of water, which is essential for the effective operation of the flushing mechanism.

- Prevention of Overflow: The refill tube directs water back into the correct chamber, avoiding overflows that can lead to leaks and water wastage.

- Improved Hygiene: By ensuring adequate water levels, it reduces the likelihood of unpleasant odors and bacterial growth caused by stagnant water.

- Efficient Operation: A properly functioning refill tube allows for swift replenishment, ensuring that the system is ready for subsequent uses without delay.

In conclusion, the refill tube is a vital element in ensuring the seamless operation of water systems, contributing to both efficiency and hygiene in daily use.

Tank Bolts and Their Function

In any plumbing system, certain fasteners play a crucial role in ensuring stability and effective operation. These elements are essential for securely fastening different components together, allowing for proper functioning and preventing leaks.

Fastening Mechanism: These fasteners are designed to hold various components in place, ensuring that they do not shift or detach during use. Their secure fit contributes to the overall integrity of the assembly.

Material Composition: Typically made from durable materials, these elements resist corrosion and wear, ensuring longevity and reliability. The choice of material is vital to withstand the conditions they are exposed to in the environment.

Adjustment Capability: Many of these fasteners allow for adjustment, enabling users to achieve the desired tightness or alignment. This feature is important for maintaining optimal performance over time.

Maintenance Importance: Regular inspection and maintenance of these fasteners can prevent potential issues, such as leaks or structural failures. Ensuring that they are in good condition is key to the longevity of the overall system.

Replacing Worn-Out Components for Efficiency

Maintaining optimal functionality in your restroom fixture is essential for ensuring it operates smoothly and efficiently. Over time, various internal mechanisms may become worn, leading to issues such as leaks, noise, and decreased performance. Addressing these concerns promptly can enhance water conservation and improve the overall user experience.

Identifying Components That Need Replacement

Regular inspection of the internal mechanisms can help in recognizing which elements require attention. Look for signs of wear, such as cracks, discoloration, or mineral buildup. Components like seals and flappers are particularly susceptible to degradation, and replacing them can prevent leaks and ensure proper sealing.

Steps to Effectively Replace Components

Once you’ve identified the elements that need replacing, gather the necessary tools and new components. Start by turning off the water supply and draining the fixture. Carefully remove the worn items, taking note of their configuration for easier installation of the new ones. When fitting the replacements, ensure a snug and secure fit to maintain efficiency and prevent future issues.

By proactively addressing worn components, you can significantly enhance the efficiency and longevity of your restroom fixture, ensuring it remains functional and effective for years to come.