The inner structure of a well-known automatic transmission has fascinated automotive enthusiasts and mechanics for decades. This robust design, used in a wide range of vehicles, has a reputation for its durability and smooth performance. Learning how the components are laid out and how they interact can give a deeper appreciation of its engineering.

Each element in this iconic transmission serves a critical role, from providing smooth shifts to ensuring long-term reliability. Exploring the various mechanical sections allows us to see how they contribute to the overall efficiency of the unit. Proper knowledge of these elements is essential for repairs, maintenance, or performance upgrades.

This breakdown will guide

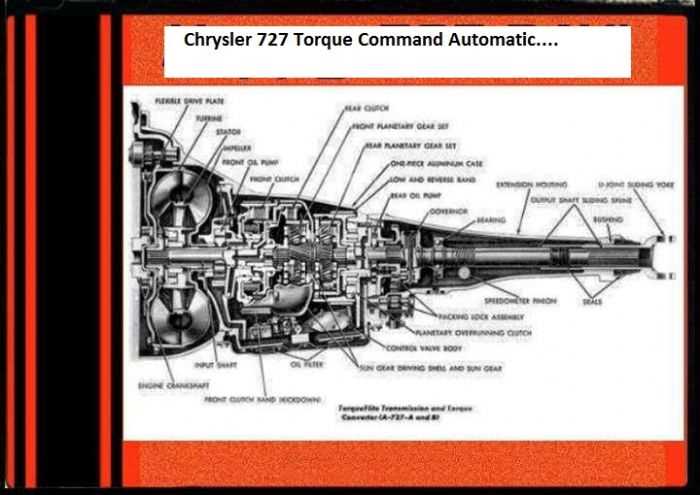

Understanding the Torqueflite 727 Transmission

The automatic transmission system in question is widely known for its durability and reliable performance across various vehicle models. Designed to efficiently handle high torque outputs, this transmission was a popular choice in many vehicles from its era. Its internal mechanisms work together to deliver smooth gear shifts and enhanced driving experience, making it a cornerstone in automotive engineering.

Key components of this transmission include a hydraulic control system, gear sets, and clutches. These elements ensure precise engagement of different gears, optimizing the vehicle’s power distribution. By utilizing a planetary gearset, the system maintains a balance between speed and torque, allowing for responsive acceleration and controlled deceleration.

The design also incorporates a fluid coupling, which plays a critical role in minimizing power loss during gear shifts. This fluid-driven mechanism transfers energy efficiently, contributing to the smoothness

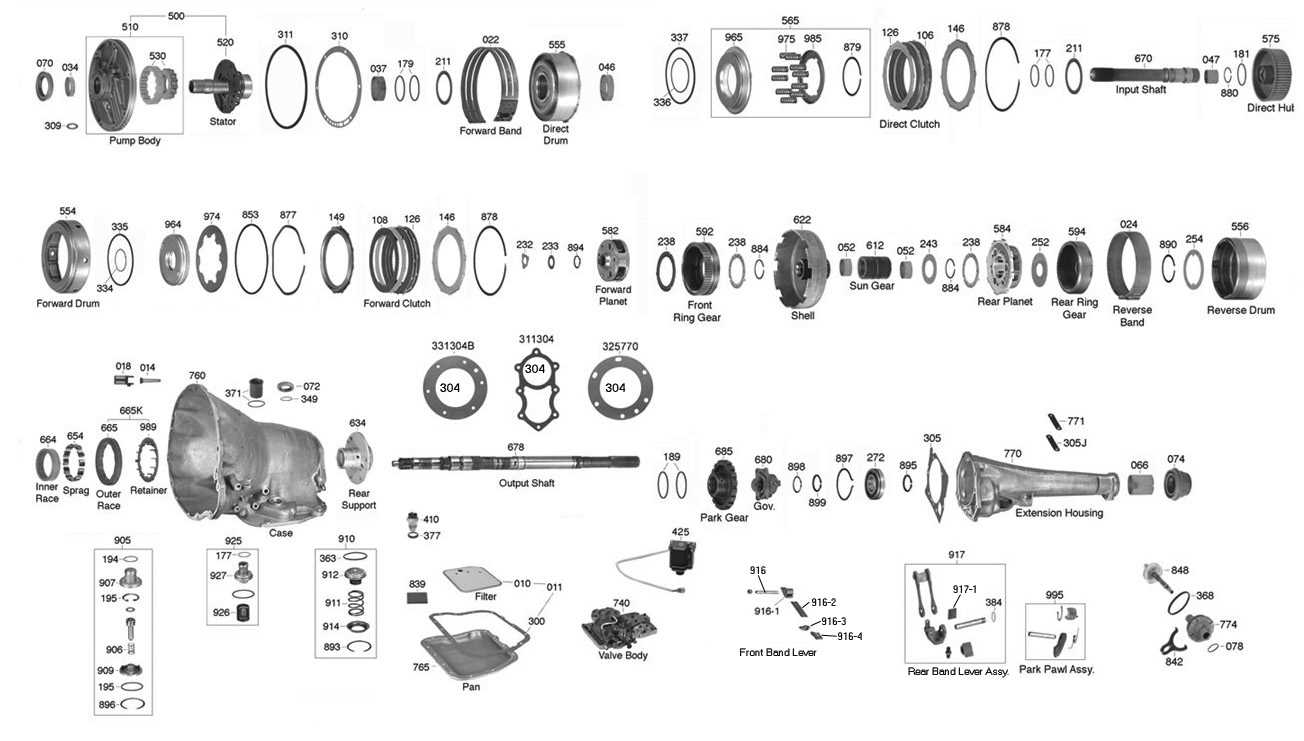

Essential Components of the 727 Gearbox

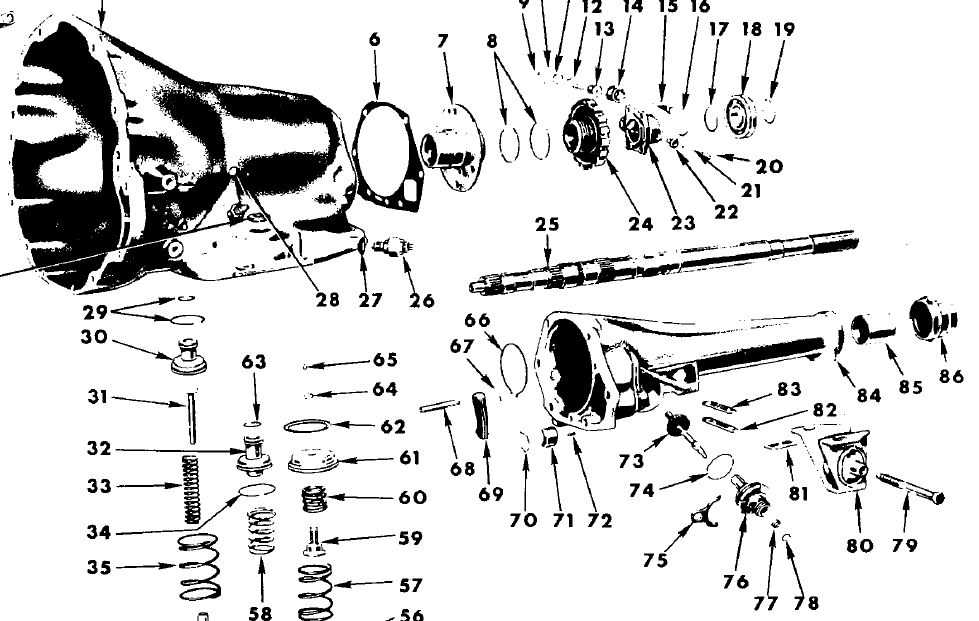

The gearbox in question is a complex assembly of interconnected mechanical elements designed to ensure smooth power transmission from the engine to the wheels. Each piece within the system works in harmony, contributing to the efficient operation of the entire transmission unit. Understanding the key elements of this mechanism can help in maintenance and troubleshooting.

Clutch Packs: These elements play a crucial role in the engagement and disengagement of gears. By compressing and releasing, they enable the smooth shifting between different drive modes.

Planetary Gear Set: This is the heart of the transmission system, responsible for controlling the gear ratios. It allows for a range of speeds and torque outputs

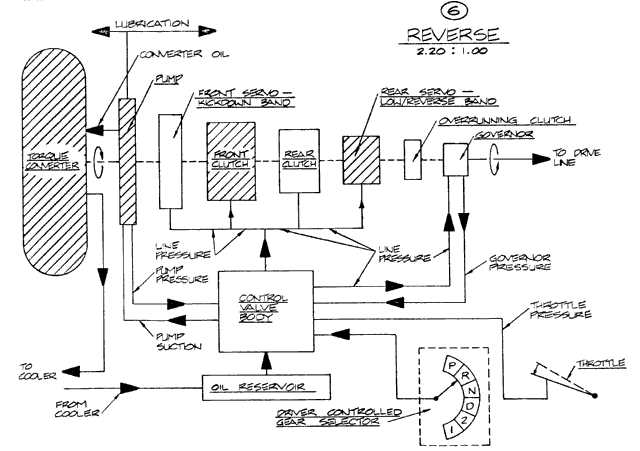

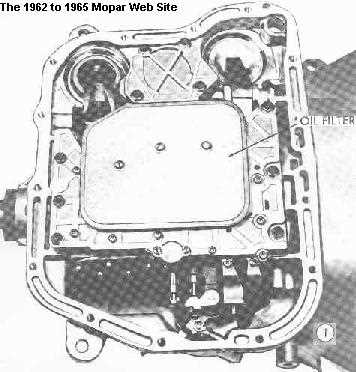

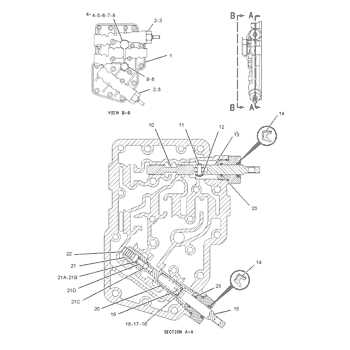

How the Valve Body Regulates Transmission

The valve body plays a crucial role in managing the flow of hydraulic fluid within an automatic gearbox. By controlling this flow, it directs key components to engage at the right moments, ensuring smooth transitions between gears. This component acts as the brain of the transmission system, coordinating the overall performance and efficiency of gear changes.

Hydraulic Fluid Control

The valve body is responsible for channeling pressurized fluid to different sections of the transmission. This hydraulic pressure determines when and how each gear is engaged or released. Different valves inside the system are activated based on the vehicle’s speed, throttle position, and other factors. The precise distribution of fluid ensures timely and responsive gear shifts.

- Fluid Coupling: The torque converter uses hydraulic fluid to transmit power from the engine to the transmission, ensuring a smooth and continuous transfer of energy.

- Torque Multiplication: During initial acceleration, the converter can increase the torque

Exploring the Planetary Gear Set Function

The planetary gear set is a core component in automatic transmissions, playing a crucial role in transferring power from the engine to the wheels. By combining several gears into a compact, versatile unit, it enables efficient control of speed and torque without manual intervention. Understanding its operation provides insight into how modern vehicles achieve smooth gear transitions and optimal performance.

Key Components of a Planetary Gear Set

At the heart of the planetary gear set are three main elements: the sun

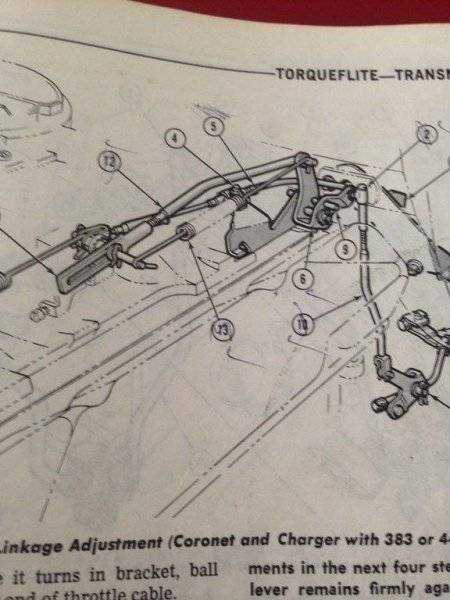

Clutches and Bands in the 727 System

The clutch and band components play a crucial role in the functionality and performance of the automatic transmission system. These elements are responsible for engaging and disengaging various gears, allowing for smooth transitions and optimal power transfer from the engine to the drivetrain. Understanding how these components interact within the system is essential for maintaining efficiency and reliability.

Clutches are mechanical devices that utilize friction to lock gears together, enabling the vehicle to shift smoothly during operation. When engaged, they ensure that power from the engine is directed to the selected gear, facilitating acceleration and deceleration. Each clutch is designed to withstand significant heat and pressure, which can occur during high-torque applications.

Bands, on the other hand, are flexible components that wrap around specific drum assemblies. They tighten to hold the drum stationary, effectively locking the associated gear in place. This action allows for precise gear selection and contributes to the overall performance of the transmission. Proper adjustment and maintenance of bands are vital to prevent slippage and ensure efficient operation.

In summary, clutches and bands are integral to the operation of an automatic transmission. Their proper functioning directly affects the vehicle’s performance, making regular inspection and maintenance critical for long-lasting reliability.

Understanding the Governor’s Impact on Shifting

The governor plays a crucial role in the operation of automatic transmission systems, particularly in regulating the shifting of gears. This component senses the vehicle’s speed and adjusts the transmission’s shift points accordingly, ensuring smooth transitions and optimal performance. By managing the pressure and timing of the shifts, the governor significantly influences the driving experience and fuel efficiency.

Function of the Governor

The governor’s primary function is to monitor the vehicle’s speed and relay this information to the transmission system. It accomplishes this through a series of mechanical and hydraulic interactions that dictate when and how the transmission shifts gears. A well-functioning governor helps maintain the engine’s power band and enhances acceleration, while a malfunctioning unit can lead to erratic shifting, poor performance, and increased wear on transmission components.

Factors Influencing Shifting Performance

Factor Impact on Shifting Governor Calibration Improper calibration can lead to premature or delayed shifts, affecting acceleration. Component Condition Worn or damaged components can cause erratic behavior and inconsistent shifting. Fluid Levels Low or dirty fluid can hinder hydraulic pressure, leading to sluggish shifting. 727 Transmission Pump Operation Overview

The pump within an automatic gearbox plays a crucial role in ensuring the proper flow and pressure of fluid throughout the system. This component is essential for the overall functionality and efficiency of the transmission, as it facilitates the movement of hydraulic fluid needed for various operations. A well-functioning pump is vital for maintaining the performance and longevity of the entire assembly.

At its core, the pump operates by drawing fluid from the sump and pressurizing it before distributing it to different parts of the transmission. This process begins with the rotation of the pump driven by the engine, which creates a vacuum that pulls fluid into the pump housing. As the fluid enters, it is subjected to centrifugal force generated by the rotating gears or vanes, leading to an increase in pressure.

Once the fluid is pressurized, it travels through various channels and passages to reach critical components such as the clutch packs and servos. These components rely on the hydraulic pressure supplied by the pump to engage and disengage gears, facilitating smooth shifting and overall operation. Furthermore, the pump also plays a vital role in cooling the transmission by circulating fluid, thus preventing overheating and potential damage.

Overall, the effective operation of the pump is integral to the seamless performance of the automatic transmission system. Regular maintenance and checks are essential to ensure that this component operates optimally, as any failure can lead to significant issues within the entire mechanism.

Seals and Gaskets: Preventing Leaks

Effective sealing solutions are crucial for maintaining the integrity of any mechanical assembly. These components are designed to create a tight barrier that prevents fluid or gas from escaping, which is essential for the proper functioning of various systems. Understanding the importance of seals and gaskets can help in preventing leaks and ensuring longevity in performance.

Seals are typically used to close spaces between two or more parts, while gaskets serve a similar purpose but are usually installed between flat surfaces. Both play a vital role in enhancing the reliability of machinery.

Common Types of Seals and Gaskets

- O-Rings: Circular seals that fit into grooves to create a seal between two parts.

- Flat Gaskets: Typically made from various materials, these are placed between two flat surfaces to prevent leakage.

- Sealant Gaskets: These are formed on-site using liquid materials that cure to form a solid seal.

- Backup Rings: Used in conjunction with O-rings to prevent extrusion and improve sealing efficiency.

Benefits of Quality Seals and Gaskets

- Enhances system reliability by preventing leaks.

- Reduces maintenance costs associated with fluid loss and damage.

- Increases the lifespan of components by preventing contamination.

- Improves safety by minimizing the risk of fluid spills and hazards.

Regular inspection and timely replacement of these components are essential for optimal performance. By choosing high-quality seals and gaskets and ensuring proper installation, leaks can be effectively managed, resulting in better overall system functionality.

Inspecting the Output Shaft and Housing

When evaluating the integrity of a transmission system, a close examination of the output shaft and its housing is essential. These components play a critical role in transferring power from the transmission to the drive shaft, and any issues can lead to significant performance problems. This section outlines key inspection techniques and considerations to ensure these parts remain in optimal condition.

To effectively assess the output shaft and housing, follow these guidelines:

- Visual Inspection: Begin by checking for any signs of wear, cracks, or deformation on the output shaft and housing. Look for surface rust or corrosion, which can compromise structural integrity.

- Check for Play: Gently wiggle the output shaft to identify any excessive play. Movement should be minimal; significant play may indicate worn bearings or other internal issues.

- Measure Shaft Diameter: Utilize a caliper to measure the diameter of the output shaft. Compare your measurements to specifications to identify any deviations that may impact functionality.

- Inspect Seals: Examine the output shaft seals for leaks or damage. Worn seals can lead to fluid loss and should be replaced if found faulty.

- Check Alignment: Ensure that the output shaft is properly aligned with the drive shaft. Misalignment can cause premature wear and may lead to failure.

Regular inspections of these components will help maintain the efficiency and reliability of the transmission system. Address any identified issues promptly to avoid more significant problems in the future.

Common Wear Areas in the 727 Assembly

In automatic transmission systems, certain components are more prone to wear over time due to constant movement and friction. Identifying these areas is crucial for maintaining optimal performance and extending the lifespan of the assembly. Regular inspections can help detect signs of degradation, allowing for timely replacements and repairs.

Below are some of the most common areas where wear typically occurs:

- Clutch Packs: These components experience significant stress during operation, leading to wear on the friction material. Signs of wear may include slipping or harsh engagement.

- Planetary Gear Set: The gears can develop pitting or scoring, which may affect gear engagement and result in noise or rough shifting.

- Valve Body: Wear on the valve body can lead to fluid leaks and inconsistent shifting. Checking for scoring or damage is essential during maintenance.

- Servos and Accumulators: These parts can wear out due to hydraulic pressure fluctuations, causing delayed or erratic shifts.

- Seals and Gaskets: Over time, these components can become brittle and fail, leading to fluid leaks and pressure loss within the system.

Maintaining a close watch on these areas can help in preserving the functionality and reliability of the entire assembly, ensuring smoother operation and better overall performance.

Torque Converter Role in Power Transfer

The torque converter plays a crucial role in transmitting engine power to the vehicle’s transmission system. It allows the engine to run independently of the transmission while smoothly transferring power during acceleration. This seamless operation is key to the vehicle’s performance and efficiency, especially in varying driving conditions.

The operation of a torque converter can be broken down into several key functions: