Understanding the intricate arrangement of components within a scaled vehicle model is essential for both maintenance and customization. These models are built with a variety of mechanical and electronic parts that work together to deliver high performance and durability. Familiarizing yourself with the structure of each element ensures better performance and extends the life of your model.

This section provides a detailed look at the layout of key elements within the vehicle. By exploring the connections and placement of various components, users can gain insight into how different systems interact to maintain functionality. Whether you’re looking to upgrade or simply maintain the model, knowing the position and function of each element will prove invaluable.

From suspension systems to power modules, every part plays a crucial role in the overall operation

Key Components of Traxxas E-Revo 1/16

This high-performance model consists of several integral mechanisms working together to ensure its speed, stability, and agility. Understanding these elements is crucial for maintaining the vehicle and optimizing its performance on various terrains.

Chassis and Suspension System

The base frame, which provides structural support, is designed to handle intense movement and impacts. The suspension setup is adjustable and absorbs shocks effectively, ensuring smooth rides over bumps and uneven surfaces.

- Durable frame with high impact resistance

- Adjustable suspension for versatile handling

- Shock absorbers for smooth landings

Drive and Power Elements

Understanding the Chassis Structure

The chassis serves as the foundation of any model vehicle, providing support and housing for essential components. Its design directly impacts stability, durability, and overall performance, making it crucial to understand how the structure is laid out. The chassis must balance weight distribution and ensure proper protection for internal systems during high-speed runs or rough terrain handling.

Main Elements of the Chassis

- Central Frame: The core section that holds the vehicle together and connects various mechanical parts.

- Suspension Mounts: Attachments that support the suspension arms, allowing for smooth handling and shock absorption.

- Battery Compartment: A secure space designed to hold the power source, ensuring easy access and proper placement for optimal balance.

- Rotor: The rotating part of the motor responsible for transferring energy to the drivetrain.

- Stator: A stationary piece that interacts with the rotor to create the magnetic fields needed for rotation.

- Bearings: These

Battery Placement and Configuration

Proper battery positioning and setup are essential for ensuring balanced performance and extended usage of your model. The correct alignment of power cells affects not only the vehicle’s speed but also its stability and weight distribution.

Optimal Positioning: Place the battery securely within the designated compartment, ensuring it is centered for even load distribution. A balanced layout reduces unnecessary strain on components and enhances overall handling.

Configuration Tips: Connect the battery terminals following the recommended guidelines, making sure the wiring is safely routed. For certain models, parallel or series connections may be required to optimize power output based on your needs.

Finally, regularly inspect the battery connections and ensure they remain secure during operation. Proper maintenance of the battery setup is critical for both safety and performance.

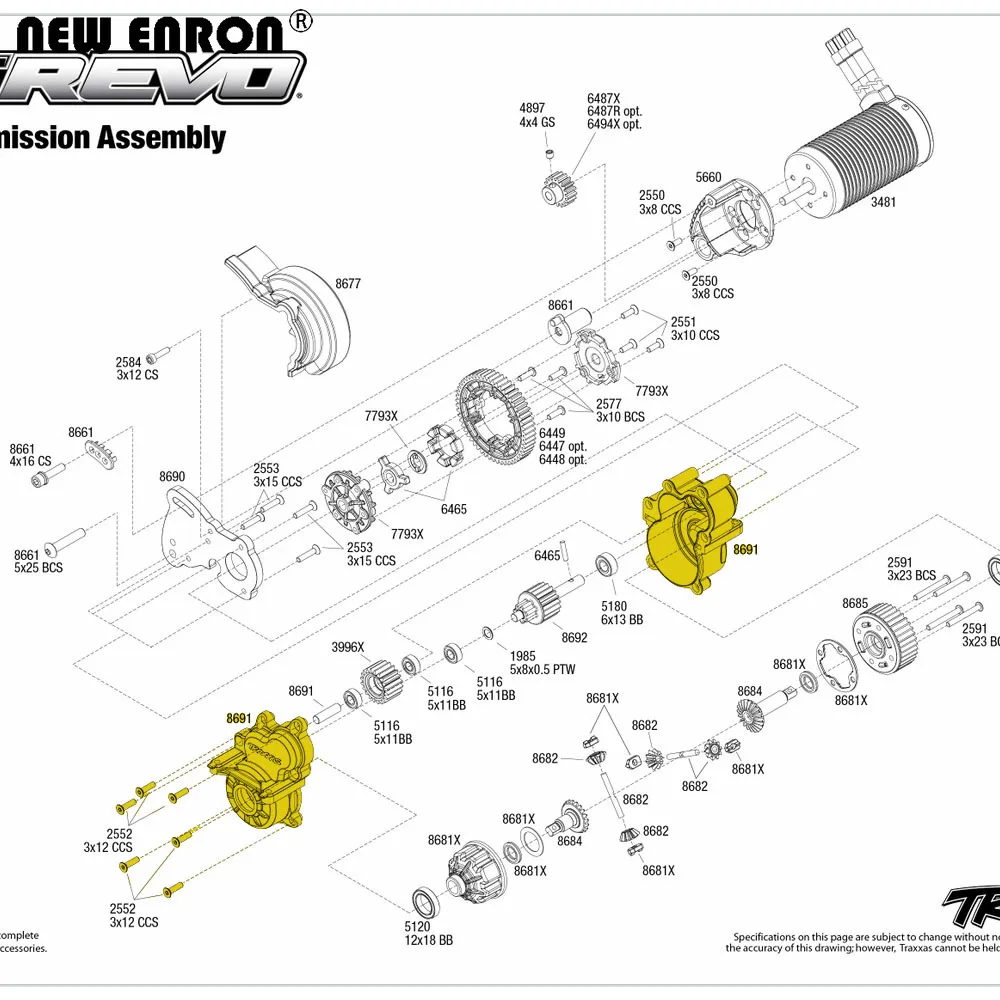

Transmission System Overview

The transmission system is a crucial component that facilitates the transfer of power from the motor to the wheels, ensuring efficient movement and control. This mechanism plays a vital role in optimizing performance and handling, allowing for a smooth driving experience across various terrains.

Key elements of the transmission system include gears, differentials, and various linkages that work together to manage torque and speed. Each component contributes to the overall functionality, providing necessary adjustments based on driving conditions.

Component Function Gears Adjust torque and speed ratios for optimal performance Differential Allows wheels to rotate at different speeds, enhancing stability during turns Linkages Connect various components, facilitating smooth transitions and control Understanding the intricacies of this system is essential for maintenance and upgrades, ensuring longevity and reliability in operation. Regular checks and adjustments can significantly enhance the overall driving experience.

Steering Mechanism Breakdown

The steering system is a crucial component that facilitates maneuverability and control of the vehicle. Understanding its intricate design and functionality can significantly enhance performance and responsiveness during operation. This section delves into the essential elements of the steering mechanism, examining its structure and role in ensuring optimal handling.

Key Components

- Steering Servo: Responsible for translating control signals into physical movement.

- Linkage System: Connects the steering servo to the wheels, allowing for precise directional changes.

- Steering Wheel: The interface used by the operator to direct the vehicle.

- Kingpins: Serve as pivot points for the wheels, enabling smooth rotation.

Functionality Overview

The steering mechanism operates through a combination of mechanical and electronic processes:

- The operator rotates the steering wheel, initiating a signal to the servo.

- The servo adjusts the linkage system, altering the position of the wheels.

- This adjustment enables the vehicle to navigate turns and changes in direction effectively.

Maintaining the steering system is vital for ensuring reliable operation. Regular checks on the components can prevent malfunctions and enhance the overall driving experience.

Wheels and Tires: Size and Function

The components responsible for mobility and traction play a crucial role in the performance of any remote-controlled vehicle. The dimensions and design of these elements significantly impact handling, stability, and overall driving experience. Understanding the characteristics of wheels and tires can enhance the functionality of the model and optimize its performance on various terrains.

When selecting wheels and tires, size is a primary consideration. Larger wheels often provide better ground clearance and enable the vehicle to navigate over obstacles more effectively. Conversely, smaller wheels can offer improved maneuverability and agility, making them suitable for tighter spaces. The choice of tire tread pattern also affects traction and grip, influencing how the vehicle performs on different surfaces.

Size (Diameter) Function Best For 50mm Enhanced agility and quick turns Tight spaces and indoor environments 60mm Balanced performance and stability General use on various terrains 70mm Improved clearance and obstacle navigation Off-road and rugged conditions In conclusion, selecting the appropriate wheels and tires involves considering size, function, and intended use. By making informed choices, users can enhance their model’s capabilities and ensure a more enjoyable driving experience.

Electronic Speed Control (ESC) Layout

The electronic speed control unit is a vital component in any remote-controlled vehicle, responsible for managing the power supplied to the motor. This intricate device plays a crucial role in determining the performance and responsiveness of the model, ensuring smooth acceleration and braking.

The layout of the speed control system encompasses several key elements that work together harmoniously. The main unit typically features a microprocessor, which interprets signals from the transmitter and adjusts the power output accordingly. Additionally, it includes various connectors for the battery and motor, facilitating easy installation and maintenance.

Integrated within the layout are safety features designed to protect the system from overheating and other potential issues. This includes a thermal shutdown mechanism that disengages the motor when temperatures exceed safe levels, thereby prolonging the lifespan of the components. Furthermore, the system often incorporates programmable settings that allow enthusiasts to customize performance characteristics to suit their driving style.

In summary, understanding the configuration of the electronic speed control unit is essential for optimizing the performance of a remote-controlled vehicle. A well-designed ESC layout not only enhances functionality but also contributes to the overall enjoyment of the hobby.

Body Shell and Aerodynamics

The outer casing of an electric vehicle plays a crucial role in its overall performance and aesthetic appeal. This component not only protects internal elements but also significantly impacts airflow and stability during operation. A well-designed shell can enhance speed and maneuverability, allowing for a more enjoyable driving experience.

When considering the aerodynamic properties, the shape and contour of the shell are vital. Streamlined designs minimize air resistance, enabling smoother navigation through various terrains. Additionally, incorporating features such as vents and spoilers can improve downforce, which enhances grip and control, especially at higher speeds.

Material selection is equally important, as lightweight substances can reduce overall mass while maintaining durability. This balance between weight and strength contributes to better handling and responsiveness, essential for both competitive racing and casual enjoyment. Therefore, focusing on both aesthetics and functionality in the shell design is fundamental for optimizing performance.

Maintaining and Replacing Parts Efficiently

Effective upkeep and timely substitution of components are essential for ensuring optimal performance and longevity of your remote-controlled vehicle. By adhering to a systematic approach, enthusiasts can enhance reliability and reduce the likelihood of unexpected failures during operation.

Regular Inspection: Conduct frequent evaluations of the vehicle to identify any wear or damage. Look for signs of stress on the chassis, wheels, and electrical systems. Early detection can save time and resources by addressing minor issues before they escalate.

Utilizing Quality Components: When it comes to replacement, always opt for high-quality alternatives that meet or exceed the original specifications. This choice guarantees compatibility and enhances performance, ultimately extending the life of the vehicle.

Documenting Changes: Keep a detailed log of any maintenance performed and parts exchanged. This record serves as a valuable reference for future upkeep and assists in recognizing patterns that may indicate recurring problems.

Following Manufacturer Guidelines: Adhering to the recommended procedures provided by the manufacturer ensures that maintenance is conducted correctly. These guidelines typically outline the necessary steps for replacing specific components, contributing to smoother operations.

Community Engagement: Engaging with fellow enthusiasts and accessing online forums can provide additional insights and tips for effective maintenance. Sharing experiences fosters a community of knowledge that can enhance your understanding and skill set.

Suspension System and Its Role

The suspension system is a crucial component in ensuring stability and control during movement. It acts as the primary mechanism that absorbs impacts from uneven terrain, reducing the stress on the overall structure. A well-designed suspension system allows for smoother handling and better responsiveness, enhancing both performance and durability during use.

Key elements of the suspension system include springs, shocks, and linkages, each of which works together to maintain optimal balance and adaptability in various conditions. These elements are designed to manage the weight distribution and ensure that all wheels remain in contact with the ground, maximizing grip and minimizing wear.

| Component | Function |

|---|---|

| Springs | Absorb shocks and return the system to its original position after compression. |