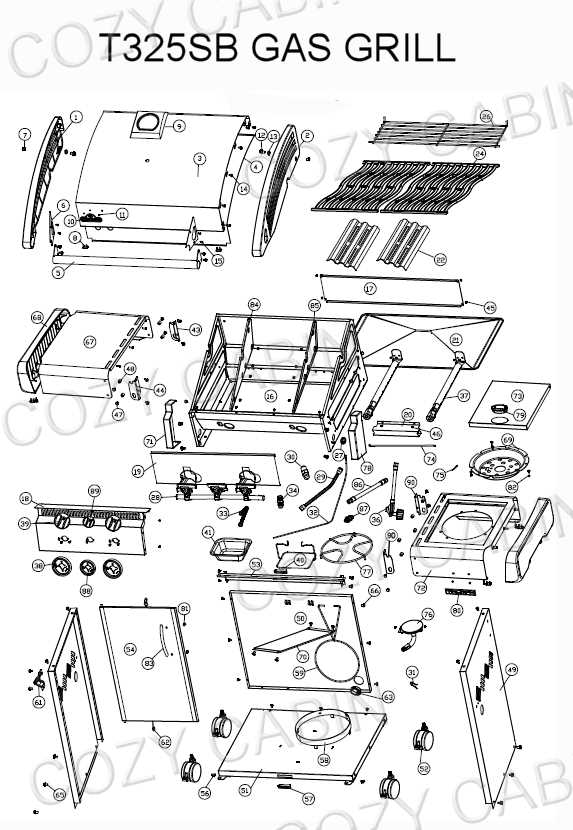

The detailed visualization of mechanical systems plays a crucial role in ensuring smooth maintenance and repairs. By organizing the various elements in a clear and structured way, it becomes easier to understand how everything functions together, making both servicing and replacements far more efficient.

A well-organized layout allows for the quick identification of each element and its location. This not only simplifies the process of finding specific components but also reduces the time needed to perform necessary repairs. It’s an essential tool for anyone looking to keep their machine in top working condition.

In addition, accurate schematics offer invaluable insights into how different mechanisms interact. Whether it’s ensuring compatibility between various pieces or planning an upgrade, having access to clear visual guides ensures precision and helps avoid costly errors.

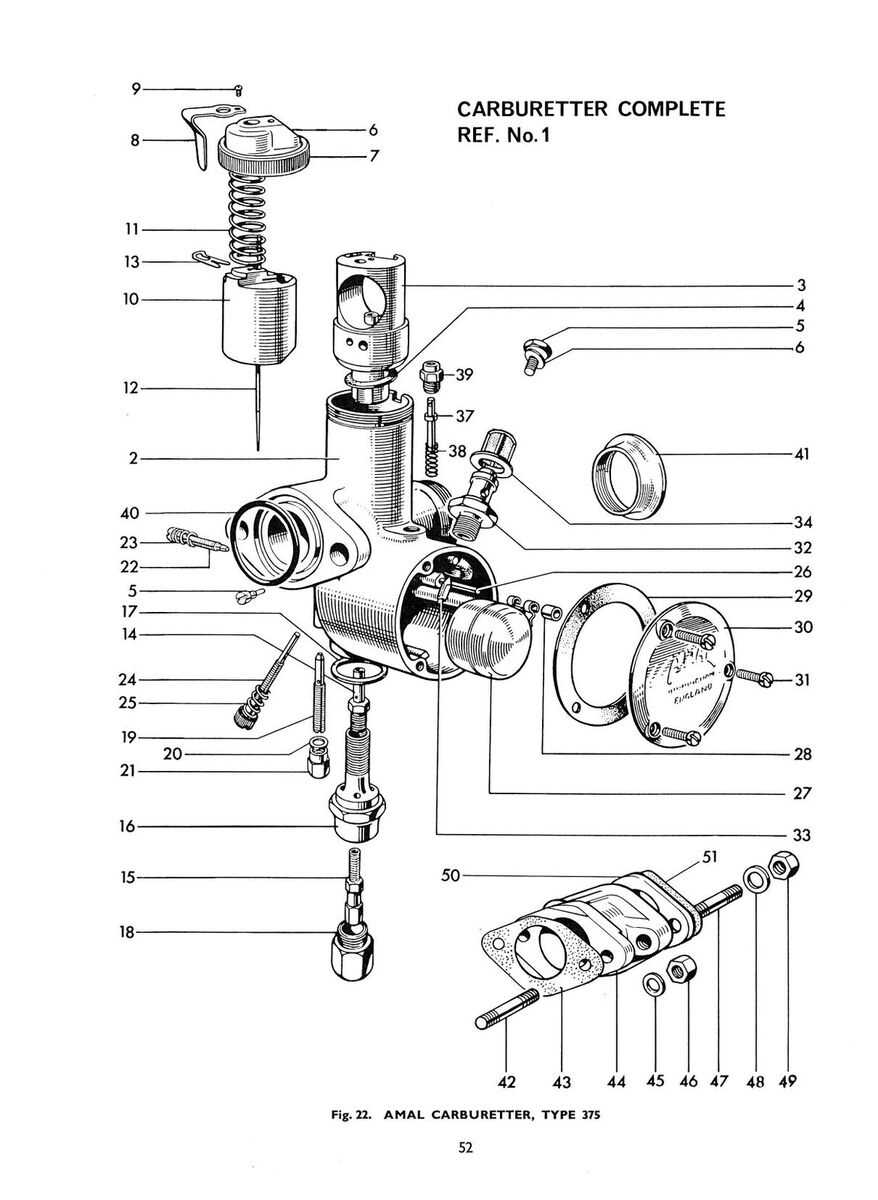

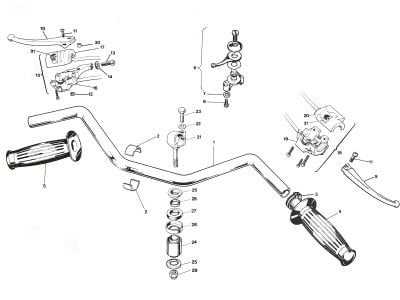

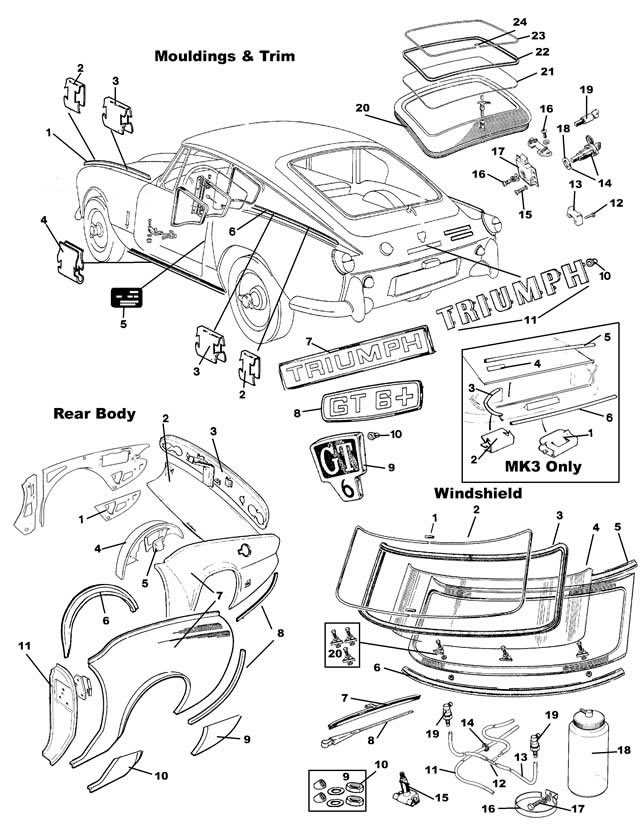

Component Layout Overview

Understanding the structure of mechanical assemblies can greatly simplify the process of maintenance and repairs. A clear visual reference helps identify the positioning and relationship between various elements, making it easier to diagnose issues and perform replacements when necessary. Each section is strategically designed to ensure compatibility and optimal functionality within the larger system.

Mechanical Element Grouping: The organization of different segments follows a logical sequence, ensuring that all components are easy to access and service. Whether you’re working with intricate details or larger structural parts, the layout ensures clarity and precision.

Optimized Functionality: Each element is carefully positioned to maximize performance and longevity, making the entire system run smoothly. By following this organized scheme, users can efficiently locate and address any issues that arise over time.

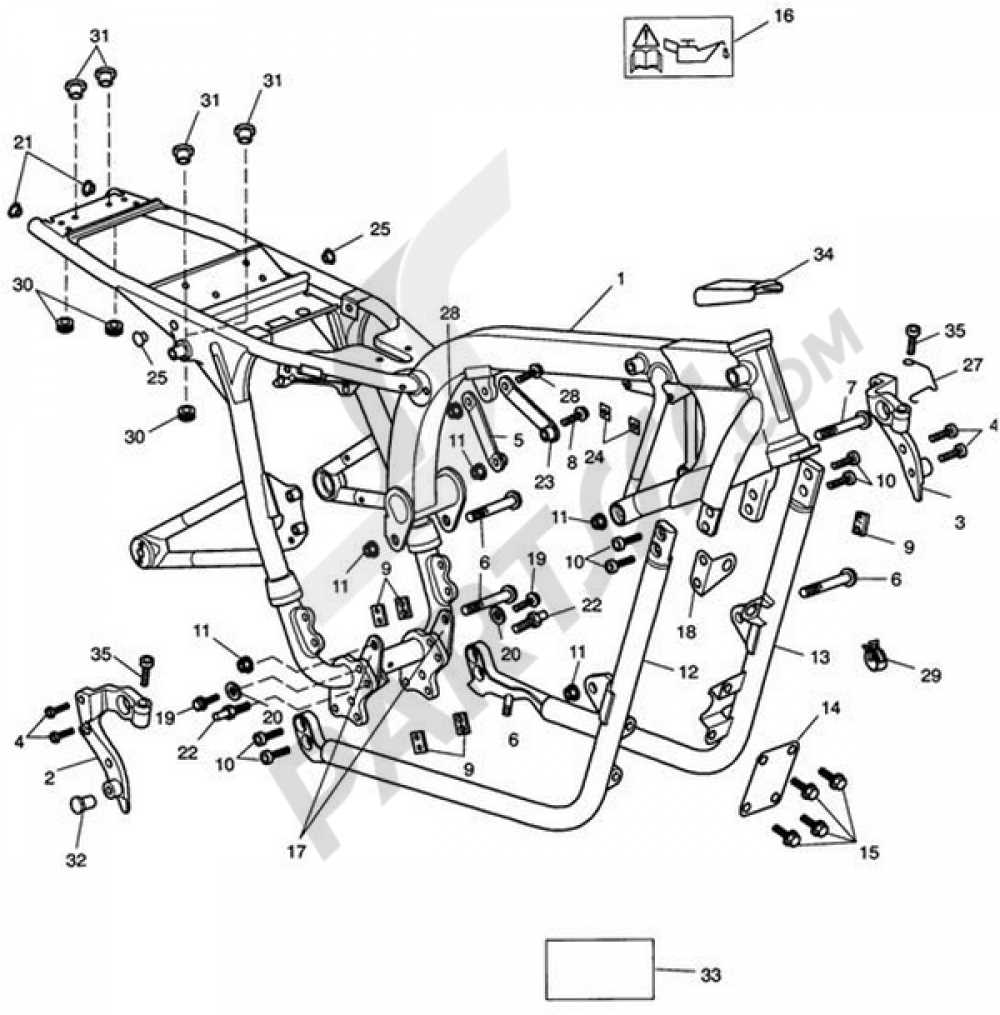

Understanding Motorcycle Components

Exploring the essential elements of any two-wheeled vehicle requires a comprehensive look at the various mechanical and electrical systems. These systems work together to ensure functionality, performance, and safety on the road.

Below is a breakdown of key sections and their roles in the operation of these machines:

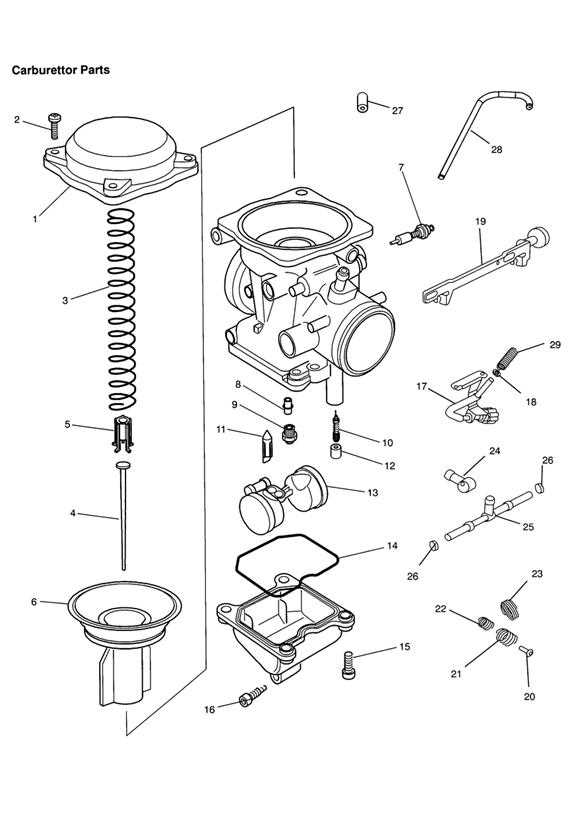

- Engine: The heart of the machine, responsible for converting fuel into motion. It consists of several interconnected parts that generate the power required to move the vehicle.

- Transmission: This system transfers the engine’s output to the wheels, enabling smooth shifting between gears for optimum speed and control.

- Suspension: Designed to absorb shocks and maintain ride comfort, this component ensures stability and handling, especially on uneven terrain.

- Braking System: Critical for safety, the brakes allow

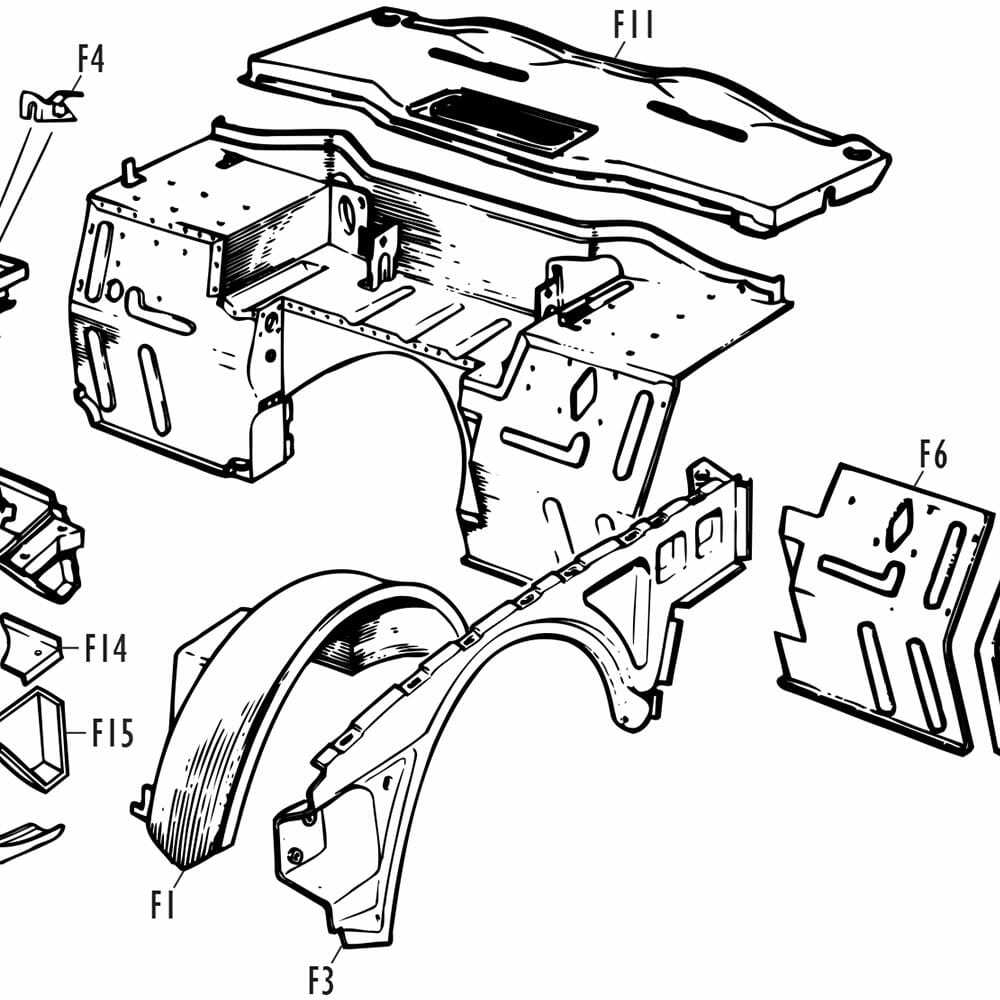

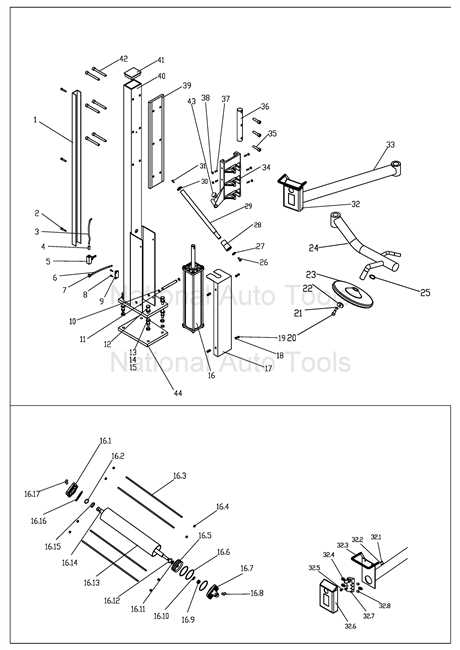

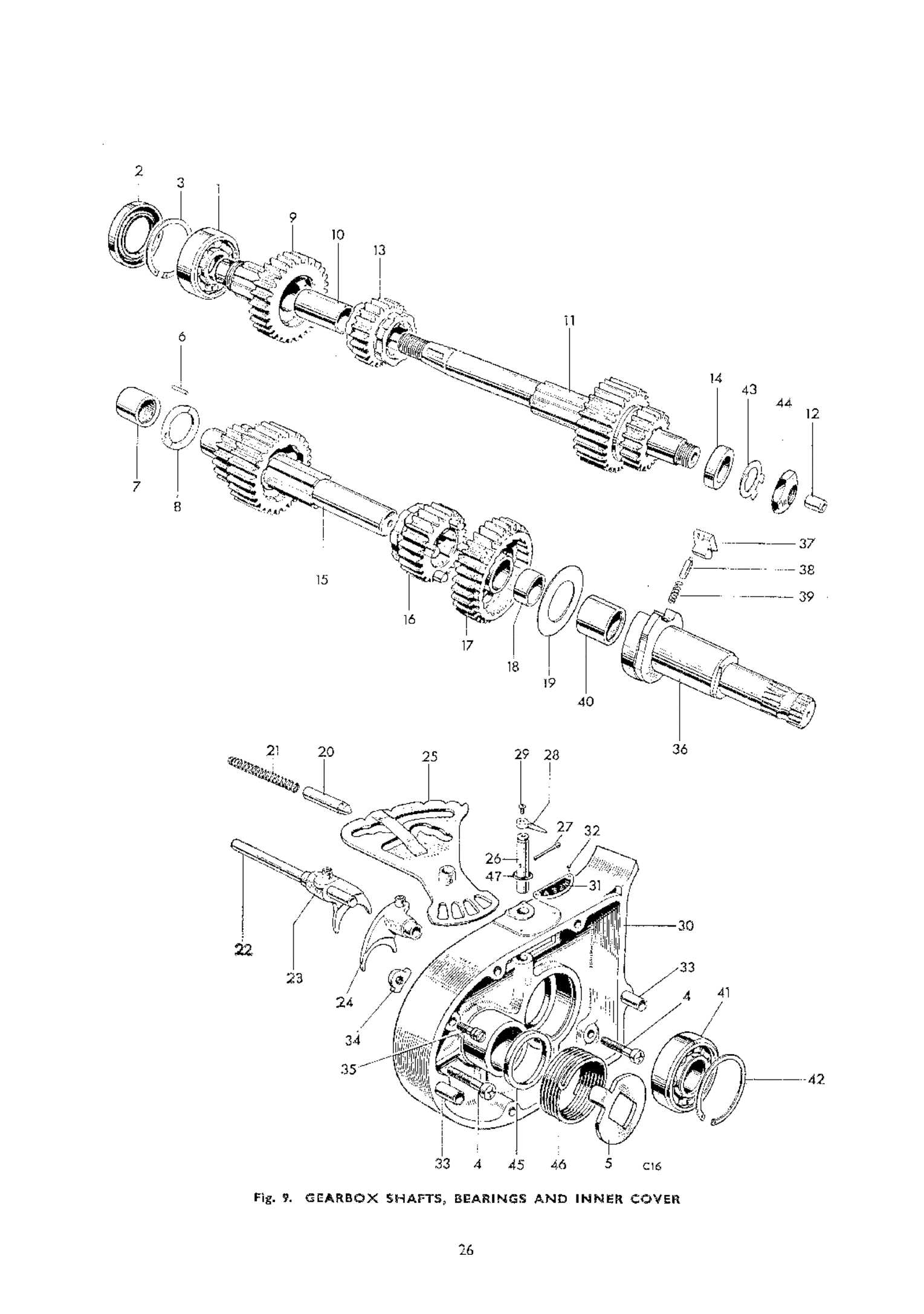

How to Read a Parts Diagram

Understanding the layout of a technical illustration is crucial when it comes to identifying components and how they relate to one another. These visual guides offer an organized way to view individual elements within a system, helping users locate and assess each part efficiently. By interpreting these drawings correctly, you can streamline both maintenance and repairs.

Recognizing Key Symbols and Labels

Each drawing is filled with symbols and labels that indicate specific components. These labels are usually accompanied by numbers or letters, which correspond to descriptions in a reference list. Knowing how to match these symbols with the correct reference is the first step to navigating the layout effectively.

Understanding Assembly Structure

The illustration typically follows a logical sequence, showing how various components are assembled. Larger elements are often positioned centrally, while smaller, supporting items branch off around them. Pay attention to the order in which elements are presented, as this can provide valuable insight

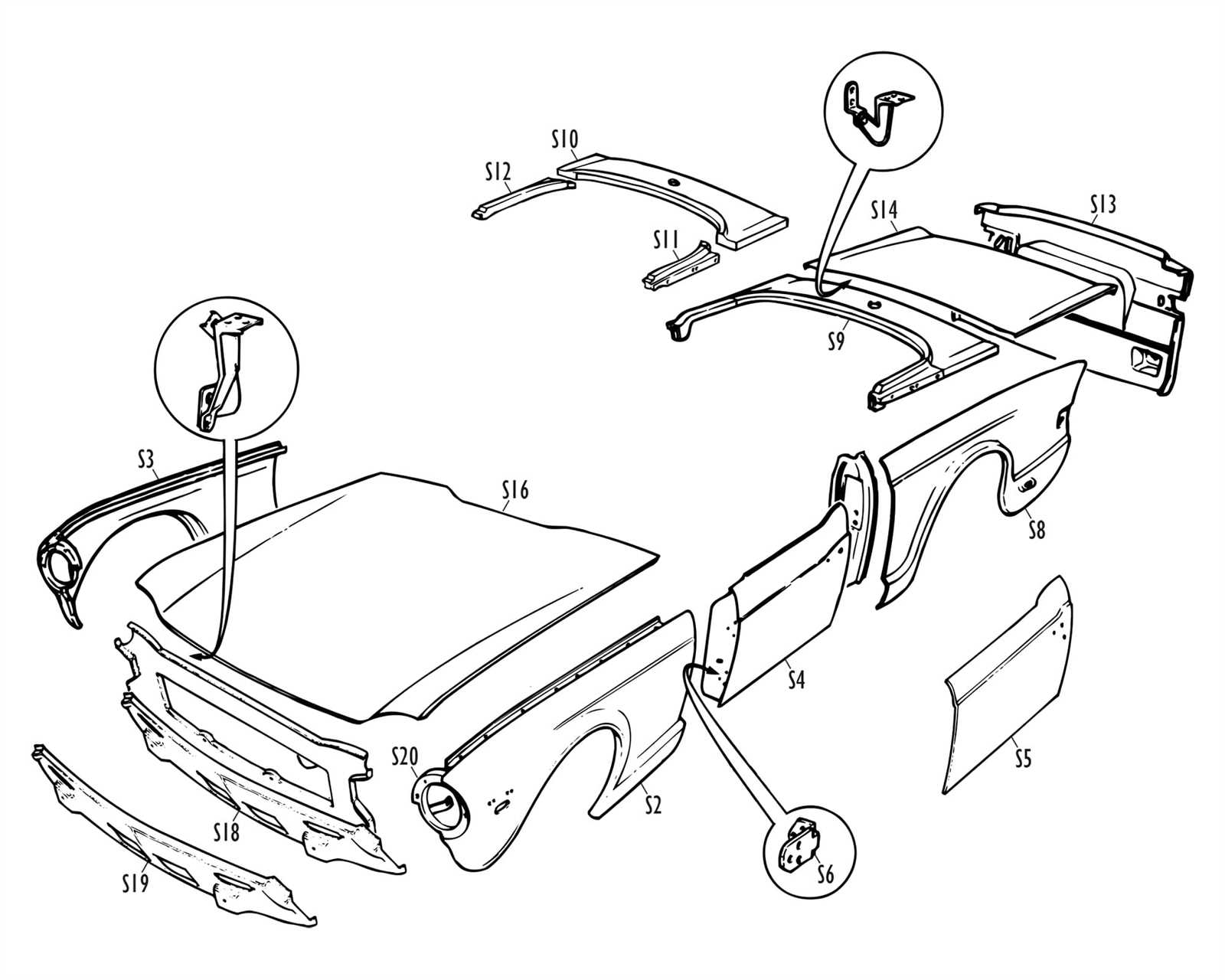

Key Sections of a Triumph Diagram

When exploring a visual layout of a mechanical system, it’s essential to understand how various components interact and are organized. Each area within this visual guide serves a specific purpose, helping to identify the relationships between individual units and offering insights into their functionality.

Structural Overview

This section focuses on the core framework, which often includes the primary supports and foundational elements. It provides an overview of how the central pieces fit together, offering a map of the key mechanical areas.

Connection Points and Fasteners

The diagram also highlights essential junctions and attachment points. Understanding these areas is crucial for assembling or disassembling different segments, ensuring stability and proper alignment. This section often features bolts, screws, and other fastening mechanisms.

Section Function Identifying Engine Parts on a Diagram

Understanding the layout of components within a motor is crucial for effective maintenance and repairs. By studying the visual representation of these elements, one can gain a better grasp of their positioning and function. Each component is connected to others in specific ways, and knowing how to locate them visually is a key skill for any technician.

Starting with the core structures, it’s essential to recognize how different elements like the crankshaft, valves, and cylinders interact. Their arrangement within the motor determines the overall efficiency and performance of the machine. Recognizing these main components can simplify the process of addressing common issues or conducting upgrades.

Additionally, smaller details like fasteners, gaskets, and belts, though less prominent, play an equally important role in the overall system. Being able to pinpoint their location on a

Frame and Bodywork Components Explained

The structure and exterior elements of a motorcycle play a crucial role in its overall performance, aesthetics, and rider experience. Understanding these components helps enthusiasts appreciate the engineering behind their machines, as well as assists in maintenance and modifications. This section delves into the various elements that contribute to a motorcycle’s framework and outer design.

Chassis Structure

The chassis serves as the foundation of the vehicle, supporting various systems and components. Typically constructed from high-strength materials, the frame must endure various stresses and strains while maintaining rigidity and stability. The design can significantly affect handling characteristics, making it essential for riders to choose a layout that suits their preferences and riding style.

Body Panels and Fairings

Body panels and fairings enhance the motorcycle’s aerodynamics while providing protection to the internal components. These elements can vary greatly in design and materials, ranging from lightweight plastics to robust composites. They not only contribute to the visual appeal but also play a critical role in reducing drag and improving fuel efficiency.

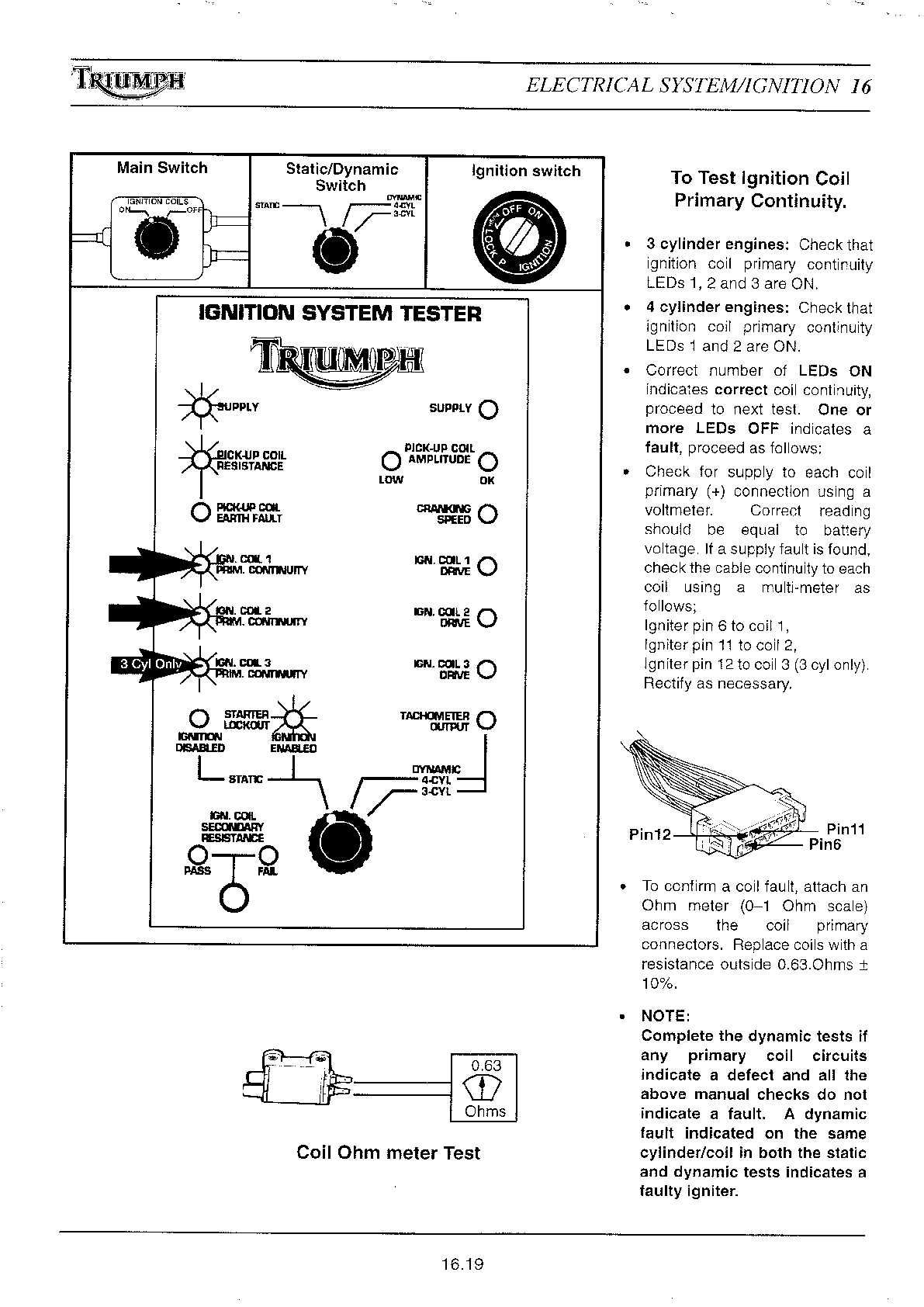

Locating Electrical System Parts

Understanding the arrangement and function of various components within the electrical framework is essential for effective troubleshooting and maintenance. By familiarizing oneself with the layout and specific roles of each element, one can streamline repair processes and enhance overall efficiency.

Key Components of the Electrical Framework

The electrical framework comprises several crucial components, each serving a distinct purpose. These elements work together to ensure the smooth operation of the vehicle’s electrical systems. Here are some of the primary components to be aware of:

Component Function Battery Supplies electrical energy to the system, especially during startup. Alternator Generates electrical power to recharge the battery while the engine runs. Starter Motor Engages the engine during the initial ignition process. Fuses Protect circuits by breaking the connection in case of overloads. Relays Act as switches that control high-current circuits with low-current signals. Identifying Locations and Access Points

To efficiently access and inspect the electrical components, one must know their locations. Typically, the battery is found in the engine compartment, while the alternator is positioned near the front of the engine. The starter motor is usually mounted on the transmission, and the fuses can often be located in a dedicated fuse box inside the vehicle’s cabin. Consulting the vehicle’s service manual can provide additional guidance on specific locations.

Using Diagrams for Maintenance and Repair

Visual representations play a crucial role in the upkeep and restoration of mechanical systems. They provide a clear overview of the components and their interconnections, allowing technicians to understand complex assemblies quickly. By utilizing these illustrations, users can enhance their ability to troubleshoot issues effectively, ensuring a more efficient repair process.

Incorporating graphical resources not only simplifies the identification of individual elements but also aids in comprehending their functions within the entire structure. This facilitates a systematic approach to maintenance, helping to prevent errors and ensuring that every aspect of the system is addressed.

Benefit Description Enhanced Clarity Illustrations clarify the arrangement and relationship between components, reducing confusion. Efficient Troubleshooting Visual aids assist in identifying issues swiftly, minimizing downtime during repairs. Improved Understanding Diagrams provide insight into how systems operate, fostering a deeper comprehension of mechanical principles. Systematic Maintenance Step-by-step visuals guide users through the maintenance process, ensuring thoroughness. Choosing the Correct Parts for Triumph

When it comes to maintaining your vehicle, selecting the right components is crucial for ensuring optimal performance and longevity. Understanding the specifics of what you need can significantly enhance your driving experience.

Assessing Compatibility is the first step in this process. It’s important to consult reliable resources that outline the specifications of your model. This will help you avoid mismatches and ensure that the new components fit seamlessly.

Next, consider quality and reliability. Opting for well-regarded manufacturers can make a substantial difference in the durability of the items you choose. High-quality components are often designed to meet or exceed the original standards, providing peace of mind for the owner.

Finally, don’t underestimate the value of expert advice. Engaging with knowledgeable professionals or enthusiasts can provide insights that may not be readily apparent. Their experience can guide you in making informed decisions, ultimately leading to a smoother operation of your vehicle.

Upgrading Triumph with Compatible Parts

Enhancing your motorcycle experience often involves selecting components that elevate performance, style, and comfort. The journey of improvement can lead to significant changes, ensuring that the bike meets the evolving demands of the rider. This section explores options for optimizing your machine with suitable alternatives that complement its design and functionality.

Benefits of Upgrading Components

- Improved Performance: Upgrading certain elements can lead to better handling, acceleration, and overall ride quality.

- Enhanced Comfort: Choosing compatible alternatives can significantly increase rider comfort during long journeys.

- Personalized Aesthetics: Modifications allow for a unique look that reflects individual style and preferences.

- Increased Reliability: Selecting high-quality substitutes can enhance the longevity and durability of your vehicle.

Popular Upgrades to Consider

- Suspension Systems: Upgrading to advanced shock absorbers can provide superior handling and ride comfort.

- Exhaust Systems: Consider performance exhausts that improve sound and increase horsepower.

- Brake Components: Enhanced brake kits offer better stopping power and responsiveness.

- Tires: Opting for high-performance tires can improve grip and stability on various surfaces.

Where to Find Detailed Diagrams

Accessing comprehensive visual representations is crucial for anyone looking to understand the intricate components of their vehicle. These illustrations offer clarity on assembly, functionality, and maintenance, ensuring that users can easily identify and manage the necessary elements.

Online Resources

The internet hosts a plethora of platforms where you can find accurate illustrations. Here are some recommended sources:

- Manufacturer Websites: Official sites often provide extensive libraries of technical materials.

- Online Forums: Enthusiast communities frequently share valuable resources and insights.

- Specialized Retailers: Websites dedicated to automotive parts often feature detailed guides and images.

Printed Manuals and Guides

In addition to digital resources, printed materials remain a reliable option. Consider the following:

- Service Manuals: These are typically published by manufacturers and include comprehensive breakdowns.

- Repair Guides: Books available at bookstores or libraries can offer step-by-step instructions alongside visuals.

- Workshop Manuals: Often used by professionals, these manuals provide an in-depth look at vehicle components.

Common Issues Found in Parts Diagrams

In technical illustrations related to vehicle components, several frequent challenges may arise, impacting the clarity and utility of the information presented. Understanding these issues is crucial for effective maintenance and repair.

One prevalent problem is the inaccuracy of representations, where certain elements may not accurately reflect their real-world counterparts. This discrepancy can lead to confusion during the assembly or disassembly processes.

Additionally, incomplete details often hinder users from fully grasping the necessary steps for repairs. Missing components or unclear labels can result in significant delays and errors, affecting the overall efficiency of the task.

Another challenge is ambiguity in part identification. When similar components are depicted without distinct markers, it becomes difficult to discern the correct item needed for a specific task. This can cause frustration and lead to incorrect installations.

Finally, outdated information can pose significant issues. As models evolve, illustrations may not be updated to reflect changes, leading users to rely on obsolete data. Keeping diagrams current is essential for effective troubleshooting and maintenance.