Insulators: Specially engineered insulating

Maintaining the Efficiency of TRS27

To ensure optimal functionality and longevity of any device, regular care and attention are essential. This involves a combination of proper usage, timely inspections, and routine maintenance practices. By focusing on these key areas, users can enhance performance and prevent unnecessary complications.

Regular Cleaning: Keeping components clean is crucial for smooth operation. Dust and debris can accumulate, leading to inefficiencies. Regularly wipe surfaces and ensure that all openings are free from obstructions.

Routine Checks: Conducting periodic assessments allows for the early detection of wear or damage. By identifying potential issues before they escalate, users can avoid costly repairs and maintain high performance.

Utilizing Quality Materials: When replacing any elements, always opt for high-quality substitutes. Using inferior materials can compromise overall functionality and lead to frequent breakdowns.

Adhering to Guidelines: Following manufacturer recommendations for usage and maintenance is paramount. These guidelines provide valuable insights on optimal performance and can significantly extend the lifespan of the equipment.

By implementing these practices, users can significantly improve efficiency and ensure reliable operation over time.

Safety Considerations for TRS27 Systems

When working with complex electronic systems, ensuring the safety of both users and equipment is paramount. Awareness of potential hazards and proper precautionary measures can significantly reduce risks associated with operation and maintenance. This section outlines key safety aspects that should be considered when dealing with such systems.

Firstly, it is crucial to adhere to established safety protocols. Following these guidelines helps to minimize risks and ensures that systems operate efficiently. Key practices include:

- Regularly inspecting components for wear and damage.

- Ensuring that all connections are secure to prevent electrical faults.

- Using appropriate personal protective equipment (PPE) during maintenance tasks.

Moreover, users should be informed about emergency procedures in case of unforeseen incidents. This includes:

- Understanding how to safely power down the system.

- Knowing the location of emergency shut-off switches.

- Being familiar with first aid procedures for electrical shocks.

Lastly, regular training and education for personnel can greatly enhance safety awareness. Engaging in workshops and drills ensures that everyone is prepared to handle emergencies effectively. By prioritizing safety, the reliability and longevity of the system can be maintained, creating a secure working environment.

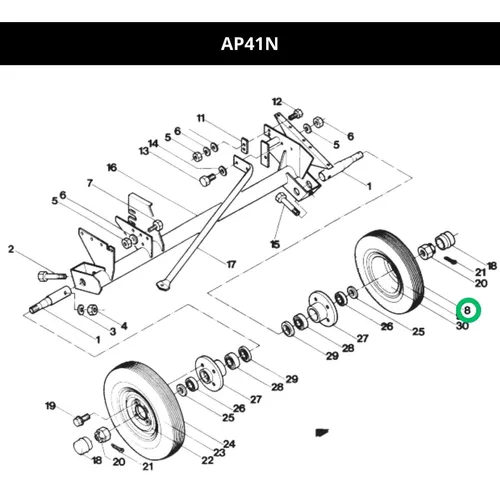

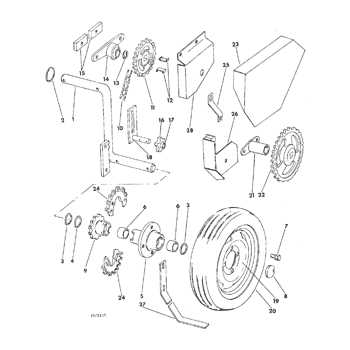

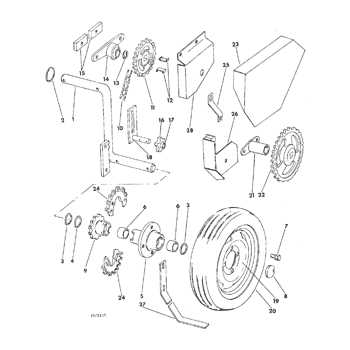

Overview of TRS27 Mechanical Layout

This section provides a comprehensive look at the structural arrangement of the device. Understanding this layout is crucial for grasping the functionality and interconnectivity of its components. It offers insights into the spatial organization that facilitates optimal performance.

Key Structural Elements

The configuration encompasses various essential elements that play a vital role in the overall operation. Each segment is strategically placed to ensure efficiency and ease of access during assembly and maintenance.

Arrangement Details

The following table outlines the specific features and their corresponding descriptions:

| Feature |

Description |

| Base Unit |

Foundation providing stability and support for all components. |

| Mounting Points |

Locations for securing additional parts or accessories. |

| Access Panels |

Facilitate easy access for maintenance or modifications. |

| Connection Ports |

Interfaces for external devices and power sources. |

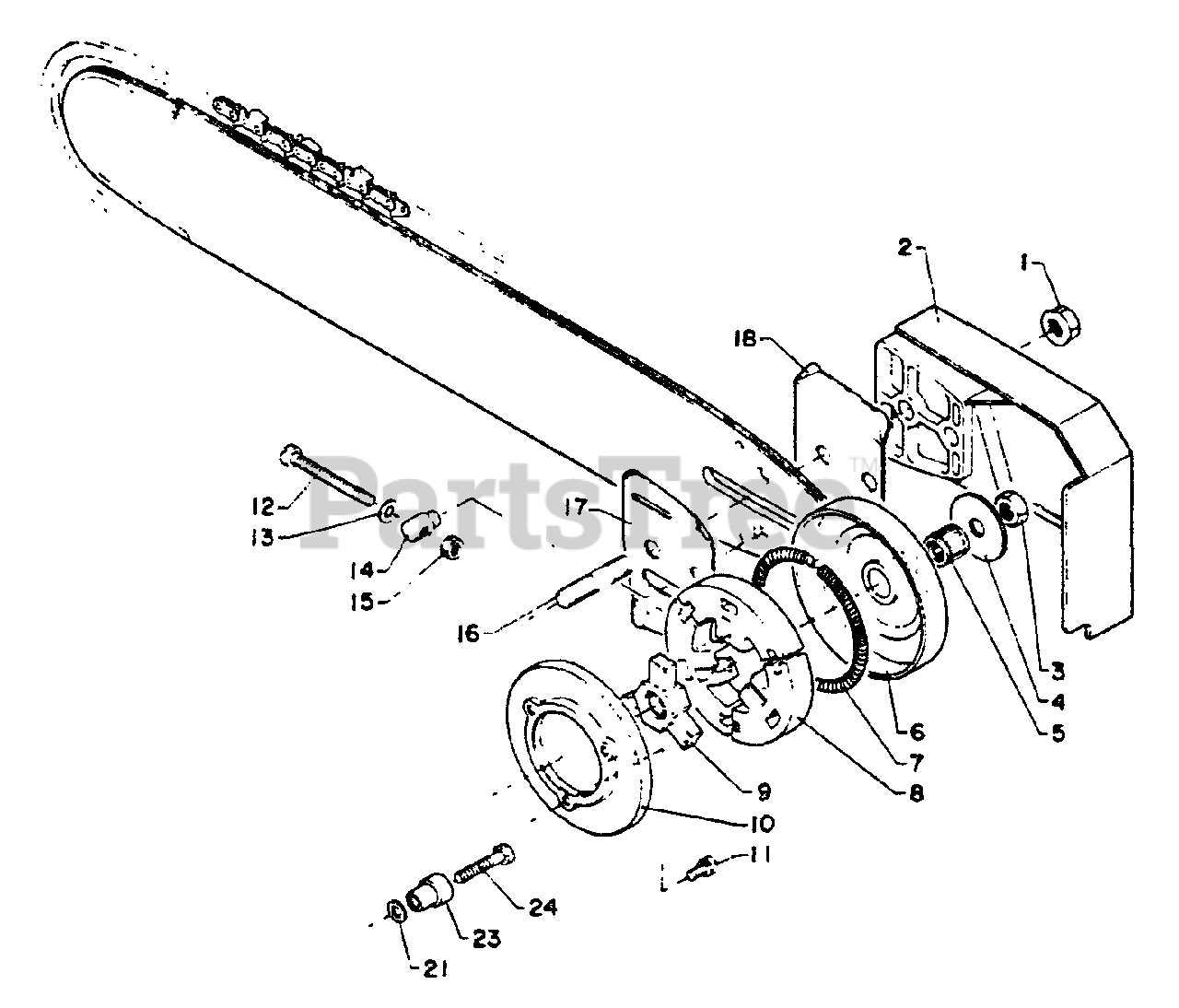

Electrical Connections in the TRS27 Diagram

Understanding the layout of electrical linkages is crucial for effective implementation and troubleshooting. Each connection plays a vital role in ensuring the system operates smoothly. By examining the interrelations and functionality, one can appreciate the significance of proper integration.

In this setup, various elements connect to facilitate the flow of current. The arrangement illustrates how components interact to achieve the desired outcome. Each line and junction serves a specific purpose, contributing to the overall performance of the system.

It is important to ensure that all connections are secure and properly configured to avoid potential issues. Incorrect linkages can lead to malfunctions or inefficiencies. Regular inspection and maintenance of these connections will enhance reliability and longevity.

By grasping the significance of each electrical linkage, one can better understand the complexities involved in the operation. This knowledge not only aids in installation but also in future modifications or enhancements.

Tools Required for TRS27 Repair

When undertaking the repair of any electronic device, having the right tools is essential for a successful outcome. The correct instruments not only facilitate the process but also ensure that components are handled with care, minimizing the risk of damage. Below is a list of necessary items to effectively perform maintenance on the device.

Screwdrivers: A variety of screwdrivers, including Phillips and flathead types, are crucial for opening the casing and accessing internal components. These tools allow for the removal of screws without stripping them, ensuring that all parts can be secured properly upon reassembly.

Multimeter: This device is indispensable for diagnosing electrical issues. It can measure voltage, current, and resistance, helping to pinpoint faulty components or connections that may need attention.

Soldering Iron: A soldering iron is essential for repairing or replacing damaged electronic parts. It allows for precise soldering, ensuring that connections are strong and reliable.

Wire Cutters and Strippers: These tools are necessary for preparing wires for connections. They enable the technician to cut wires to the required length and strip insulation from them without damaging the conductor.

Antistatic Wrist Strap: To prevent static discharge from damaging sensitive electronic components, an antistatic wrist strap should be used. This safety measure protects both the technician and the equipment during repairs.

Having these essential tools on hand will significantly enhance the efficiency and effectiveness of the repair process, leading to better results and prolonged device longevity.

Best Practices for TRS27 Maintenance

Ensuring the longevity and optimal performance of any device requires a systematic approach to care and upkeep. Regular maintenance not only enhances functionality but also prevents potential issues that could arise from neglect. Here are some key strategies to maintain your equipment effectively.

Regular Cleaning

Keeping the equipment clean is essential for its operation. Dust and debris can accumulate over time, impacting performance. Consider the following steps:

- Use a soft cloth to wipe surfaces regularly.

- Avoid harsh chemicals that can damage finishes.

- Pay special attention to ventilation areas to prevent overheating.

Routine Inspections

Conducting regular checks can help identify wear and tear before they become major problems. Follow these guidelines:

- Inspect connections and interfaces for any signs of damage.

- Test all functions periodically to ensure they operate correctly.

- Replace any worn components promptly to avoid further issues.

Optimizing the Performance of TRS27

Enhancing the efficiency and functionality of your system requires a thorough understanding of its components. By focusing on specific strategies, one can achieve better reliability and overall performance. This section highlights essential practices to ensure that your setup operates at its best.

Understanding System Configuration

Evaluating the configuration of each element is crucial. Proper alignment and integration of parts can significantly impact the operational effectiveness. Ensure that connections are secure and components are compatible to minimize issues and enhance responsiveness.

Regular Maintenance and Updates

Consistent upkeep is vital for sustaining optimal performance. This includes routine checks, cleaning, and updating software or firmware as necessary. Implementing these practices not only prolongs the lifespan of your components but also ensures that they function seamlessly together.