Maintaining your refrigeration unit’s functionality relies on a clear grasp of its individual elements. This section explores the various components that contribute to efficient operation. Knowing the roles and arrangements of these elements can greatly enhance your understanding and troubleshooting skills.

Identifying the essential mechanisms involved in producing frozen treats is crucial for anyone aiming to ensure optimal performance. Each component works in harmony, and understanding their interactions can aid in both repairs and upgrades. This knowledge empowers users to make informed decisions when addressing potential issues.

With a detailed exploration of the specific elements, you will gain insights into the configuration and function of each unit. Whether you’re a novice or an experienced user, familiarizing yourself with these components will lead to improved maintenance practices and a better overall experience.

Understanding U-Line Ice Maker Components

This section provides an overview of the essential elements involved in the functioning of a popular appliance designed for producing frozen water cubes. Each component plays a crucial role in ensuring the efficient operation and reliability of the system, contributing to its overall performance.

The assembly typically includes a reservoir for storing water, a refrigeration unit responsible for lowering the temperature, and a mechanism for regulating the freezing cycle. Additionally, sensors monitor various parameters, ensuring the process runs smoothly and effectively. Knowledge of these components is vital for troubleshooting and maintenance, enabling users to address any potential issues that may arise.

Moreover, understanding how these elements interact can lead to more efficient use of the appliance, helping users maximize its lifespan and functionality. Proper care and timely replacements of specific parts can enhance performance and prevent unexpected breakdowns, making familiarity with the system’s layout beneficial for every owner.

Key Parts of Ice Maker Systems

Understanding the essential components of a freezing appliance is crucial for effective maintenance and operation. Each element plays a vital role in the overall functionality, contributing to the seamless production of frozen products. By familiarizing oneself with these critical components, users can troubleshoot issues and ensure optimal performance.

Compressor

The compressor serves as the heart of the cooling system, responsible for circulating refrigerant and maintaining the necessary temperature for freezing. This component compresses the refrigerant gas, raising its pressure and temperature before sending it to the condenser.

Evaporator

The evaporator is where the actual freezing occurs. As the refrigerant absorbs heat from the surrounding area, it changes from a liquid to a gas, thereby cooling the environment inside the unit. This process is essential for producing frozen products efficiently.

Functionality of Ice Maker Elements

This section explores the essential components involved in the process of producing frozen water. Understanding how each element operates contributes to a better grasp of the overall system efficiency and performance.

Key Components and Their Roles

The functionality of the various components plays a critical role in the efficient production of frozen water. Each element has a specific task that contributes to the smooth operation of the system. Below is a brief overview of the main components:

| Component | Function |

|---|---|

| Water Reservoir | Stores the liquid until it is ready to be frozen. |

| Freezing Plate | Forms the frozen blocks or shapes through temperature regulation. |

| Heating Element | Gently warms the freezing plate to facilitate the removal of frozen shapes. |

| Water Inlet Valve | Controls the flow of water into the reservoir based on system needs. |

| Control Board | Manages the overall operation and timing of the various components. |

Importance of Maintenance

Regular upkeep of these components ensures optimal functionality and extends the lifespan of the unit. Neglecting maintenance can lead to reduced efficiency and potential breakdowns, highlighting the necessity of attentive care.

Common Issues with Ice Maker Parts

When dealing with the components of a freezing appliance, several common problems may arise that can hinder its performance. Understanding these issues can help identify the root causes and facilitate timely repairs or replacements, ensuring optimal functionality.

Frequent Malfunctions

Several typical malfunctions can affect the overall efficiency of a freezing unit. These can range from minor inconveniences to major operational failures, often stemming from wear and tear or environmental factors.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Water Supply Blockage | No water filling or slow production | Check water line for kinks or clogs; replace filters if necessary. |

| Temperature Fluctuations | Inconsistent freezing; melting and refreezing | Verify thermostat settings; clean condenser coils to improve airflow. |

| No Production | Complete lack of output | Inspect electrical connections; reset the unit or consult a technician. |

| Excessive Noise | Unusual sounds during operation | Examine motor and fan for obstructions; lubricate moving parts. |

Maintenance Tips

Regular upkeep can prevent many of the issues associated with freezing devices. Performing routine inspections and cleaning can significantly enhance their lifespan and performance.

Maintenance Tips for Ice Makers

Regular upkeep is essential to ensure optimal performance and longevity of your freezing appliance. By adhering to a few simple practices, you can significantly enhance efficiency and prevent potential malfunctions. These guidelines cover various aspects, from cleaning routines to component checks, ensuring your unit operates smoothly.

Cleaning and Sanitizing

Maintaining cleanliness is crucial for the functionality of your equipment. Regularly sanitize the interior and exterior surfaces to prevent buildup that can affect performance. Use a gentle cleaning solution and a soft cloth to wipe down surfaces, and ensure to rinse thoroughly to avoid any residue. Pay special attention to areas prone to moisture accumulation, as these can harbor bacteria and mold.

Regular Inspections

Conducting periodic inspections can help identify any issues before they escalate. Check for signs of wear or damage in essential components such as seals and filters. Replacing these parts promptly can save time and prevent further complications. Additionally, monitoring the unit’s temperature and performance can help you catch irregularities early on, ensuring optimal operation.

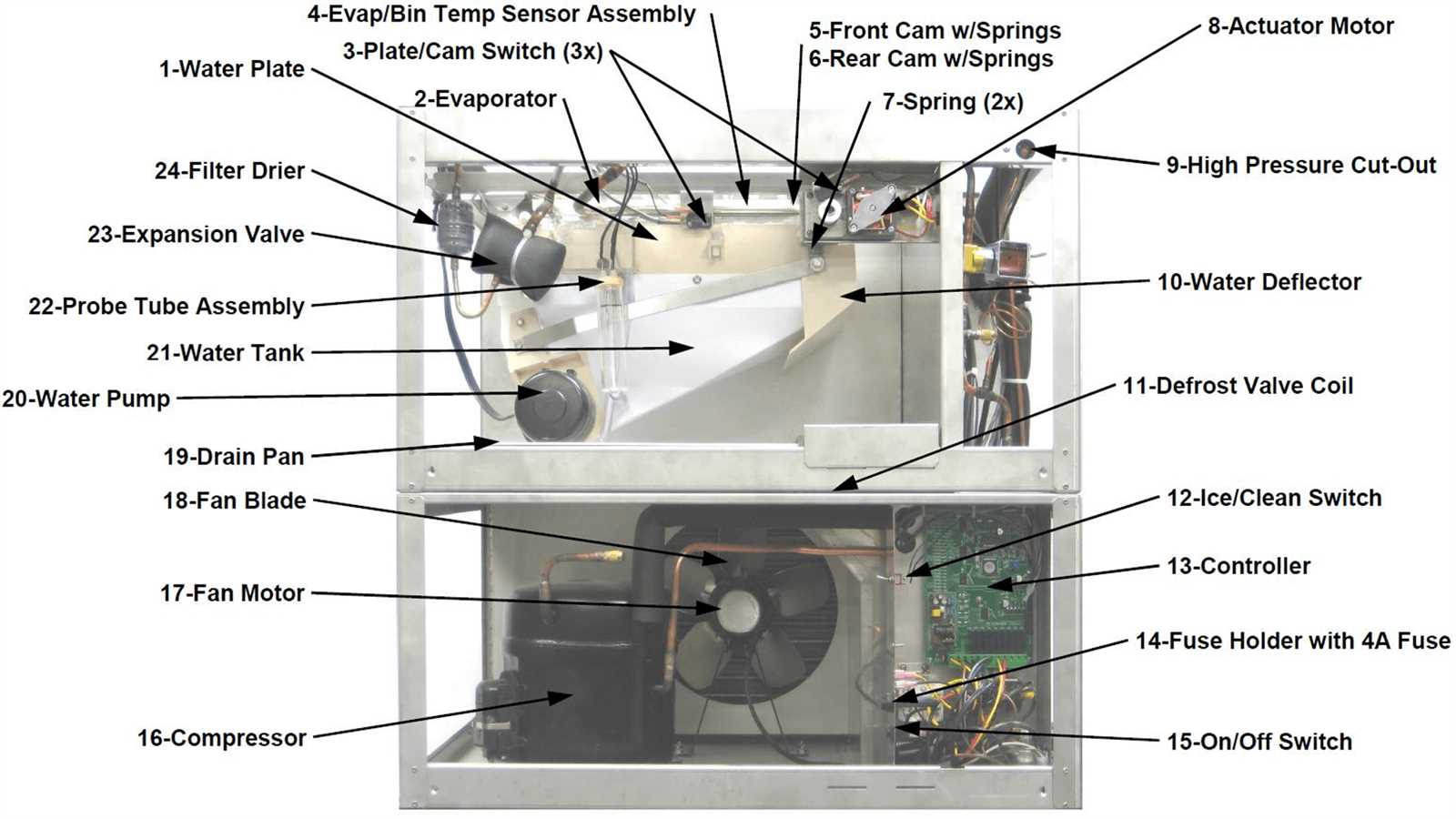

Identifying Parts in Diagrams

Understanding the components depicted in technical illustrations is crucial for effective maintenance and troubleshooting. By recognizing these elements, users can streamline the repair process and ensure optimal functionality of their equipment. Each component plays a specific role, and familiarity with their layout enhances the ability to identify issues quickly.

Common Elements to Recognize

Several key components frequently appear in these visual representations. Familiarizing oneself with their shapes and functions can significantly aid in diagnostics. Below is a list of typical features you might encounter:

| Component Name | Description |

|---|---|

| Compressor | Responsible for circulating refrigerant through the system to maintain cold temperatures. |

| Condenser Coil | Transfers heat from the refrigerant to the surrounding air, helping to cool the system. |

| Evaporator Coil | Absorbs heat from the environment, allowing the refrigerant to vaporize and cool the area. |

| Water Inlet Valve | Controls the flow of water into the system, ensuring proper filling during operation. |

Practical Tips for Component Identification

To effectively identify elements within these illustrations, consider the following strategies: examine the labels accompanying each component, use a magnifying glass for small details, and refer to manufacturer guides that may offer further clarification. This practice will not only facilitate a better understanding of the system but also enhance overall operational efficiency.

Replacement Parts for U-Line Models

When it comes to maintaining and repairing your appliance, understanding the various components available for different models is essential. This section highlights essential replacement elements that ensure optimal performance and longevity of your unit.

Here are some common replacement components you might consider:

- Compressor: Vital for the cooling process, ensuring efficiency and functionality.

- Thermostat: Regulates temperature, playing a crucial role in maintaining desired settings.

- Water pump: Responsible for circulating water, crucial for production and operation.

- Fan assembly: Helps in air circulation, promoting consistent temperature and performance.

- Hoses and fittings: Important for water delivery and drainage, ensuring proper operation.

- Electrical connections: Key for powering various functions and maintaining safety.

When seeking these components, it is advisable to verify compatibility with your specific model to avoid any operational issues. Regular maintenance and timely replacements can greatly enhance the functionality of your appliance.

Installation Guidelines for Ice Makers

Proper installation of refrigeration units designed for producing frozen water is crucial for optimal performance and longevity. Following systematic procedures ensures efficient operation while minimizing potential issues.

Before beginning the setup process, it is essential to prepare the designated area. Ensure that the location has adequate ventilation and is near a reliable power source. Additionally, check for the availability of necessary water supply connections.

| Step | Action |

|---|---|

| 1 | Unpack the unit and verify that all components are included as per the manufacturer’s instructions. |

| 2 | Position the equipment on a stable and level surface to prevent operational disturbances. |

| 3 | Connect the water line, ensuring secure fittings to avoid leaks. |

| 4 | Plug the unit into an appropriate electrical outlet, confirming that voltage matches specifications. |

| 5 | Test the system by running it through a complete cycle to ensure all functions operate smoothly. |

Regular maintenance and periodic inspections will enhance the reliability of the unit, ensuring it meets performance expectations over time. Adhering to these guidelines will facilitate a successful setup experience.

Upgrading Ice Maker Components

Improving the efficiency and performance of a freezing appliance can significantly enhance its functionality and longevity. This process often involves replacing outdated or malfunctioning components with advanced alternatives. By investing in quality upgrades, users can achieve better output, energy efficiency, and overall reliability.

One of the first steps in this enhancement journey is evaluating existing components for wear and tear. Common upgrades include high-efficiency motors, advanced control boards, and improved insulation materials. These modifications can lead to faster production cycles and reduced energy consumption.

Additionally, it is crucial to consider compatibility when selecting new components. Ensuring that replacements fit seamlessly with the existing system is vital for optimal operation. Researching specific models and brands will aid in making informed decisions, allowing for a successful transition to more efficient parts.

Finally, routine maintenance of upgraded components is essential to maintain performance and prevent future issues. Regular inspections and cleaning can prolong the lifespan of enhancements, ensuring that the unit remains in peak condition.

Ice Production and Efficiency Factors

The process of producing frozen water requires careful consideration of various elements that influence the overall output and performance of the unit. Understanding these factors can significantly enhance the effectiveness of the freezing mechanism and ensure optimal results.

Temperature Control: Maintaining the right temperature is crucial for achieving maximum efficiency. Lower temperatures facilitate quicker freezing, while fluctuations can lead to inconsistent results.

Water Quality: The quality of the liquid used plays a vital role in the freezing process. Impurities can affect the clarity and texture of the finished product, impacting both aesthetics and functionality.

Design and Configuration: The layout and design of the equipment can greatly influence productivity. Efficient flow patterns and strategic component placement allow for enhanced performance and reduced energy consumption.

Maintenance Practices: Regular upkeep and cleaning are essential to prevent buildup that can hinder efficiency. A well-maintained system operates at its best, leading to improved output and longevity.

Energy Consumption: Understanding energy usage can help optimize operational costs. Implementing energy-efficient technologies can reduce waste and lower overall expenses while maintaining high production levels.

Safety Considerations for Ice Makers

Ensuring the secure operation of freezing appliances is crucial for preventing accidents and maintaining efficiency. Proper attention to safety measures can significantly reduce risks associated with these devices.

- Regular Maintenance: Schedule consistent check-ups to identify and resolve potential issues before they escalate.

- Electrical Safety: Verify that the unit is properly grounded and that all electrical connections are secure to prevent short circuits.

- Water Quality: Use clean, potable water to minimize contamination and maintain hygiene standards.

- Ventilation: Ensure adequate airflow around the unit to avoid overheating and enhance performance.

Adhering to these precautions can promote safe and efficient operation, contributing to a longer lifespan and better performance of the appliance.