When exploring the intricate designs of machinery, gaining insight into the layout of various elements is essential. These configurations not only serve functional purposes but also enhance the overall efficiency of the system. By examining how each piece interacts, one can uncover the ultimate effectiveness of the entire assembly.

Furthermore, a well-structured overview can illuminate the relationships between different components, providing clarity for maintenance and repair tasks. Understanding these connections is crucial for anyone looking to delve deeper into the mechanics at play. This knowledge empowers users to make informed decisions regarding their equipment.

As we navigate through the specifics, it becomes apparent that familiarity with these layouts contributes to better troubleshooting and operational performance. Emphasizing the importance of each element within the greater system can ultimately lead to enhanced reliability and longevity of the machinery.

Understanding the Ut33600a Parts Diagram

Grasping the intricate details of a technical schematic is essential for effective maintenance and troubleshooting. This visual representation allows users to identify individual components and their relationships within a complex system, ultimately enhancing operational efficiency.

Key Components and Their Functions

Every element depicted plays a crucial role in the overall functionality. Familiarizing oneself with these parts not only aids in repairs but also fosters a deeper understanding of how the system operates as a whole.

Navigating the Visual Representation

To effectively utilize the schematic, it’s important to know how to interpret symbols and notations. This knowledge empowers users to pinpoint issues swiftly and ensure that each segment works harmoniously.

Importance of Parts Diagrams

Understanding the intricate assembly of components is crucial for effective maintenance and repair. Visual representations serve as essential tools that enhance comprehension and facilitate accurate identification of individual elements within a larger system. By simplifying complex structures, these illustrations provide clarity and aid in efficient troubleshooting.

Benefits of Visual Representations

- Enhanced Clarity: Visual aids break down complicated systems into manageable parts, making it easier to grasp their functions.

- Efficient Troubleshooting: Quick identification of issues allows for timely repairs, minimizing downtime.

- Improved Communication: Standardized visuals promote better understanding among technicians and stakeholders.

Facilitating Maintenance Procedures

- Step-by-Step Guidance: Clear visuals provide a structured approach for maintenance tasks, ensuring nothing is overlooked.

- Accurate Reassembly: Reference materials help in the correct placement of components, reducing the risk of errors.

- Training and Onboarding: New personnel can quickly learn about system layouts and functionalities through these resources.

Key Components of Ut33600a

This section highlights the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these crucial components is vital for optimal performance and maintenance.

- Power Supply: Provides the necessary energy for operation.

- Control Unit: Manages operations and settings.

- Sensor System: Detects various parameters to ensure accuracy.

- Display Interface: Presents data and operational status to the user.

- Housing: Protects internal components from external elements.

Each of these elements plays a significant role in the overall performance, ensuring that the device operates smoothly and reliably.

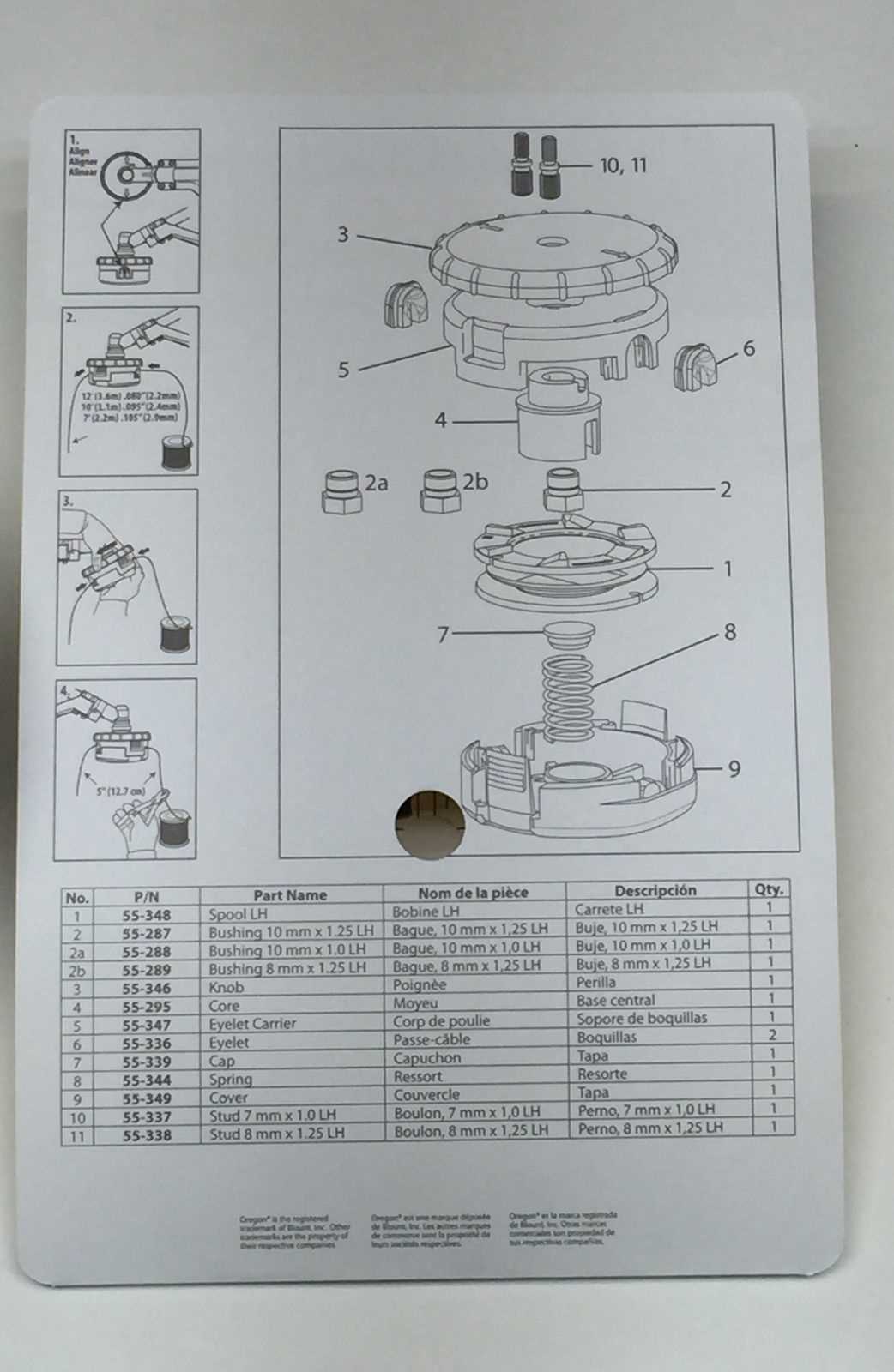

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and assembly. This guide will help you grasp the key elements that make these illustrations useful, ensuring you can easily locate and identify individual elements.

Understanding Symbols and Notations

Each illustration employs unique symbols and notations to convey information about various components. Familiarize yourself with these icons, as they serve as visual shorthand for identifying specific items and their relationships within the assembly.

Reading Layout and Orientation

Pay attention to the layout and orientation of elements in the illustration. Components are typically arranged to show their connectivity and positioning. Note the direction of arrows and labels that indicate how parts interact, guiding you in the assembly or repair process.

Common Issues with Ut33600a Parts

Understanding the frequent complications associated with specific components can greatly enhance troubleshooting efficiency. Users often encounter various challenges that can affect functionality and overall performance. Identifying these issues early is crucial for effective maintenance and longevity of the equipment.

Wear and Tear

One of the primary concerns is the gradual deterioration that occurs due to regular use. Components may exhibit signs of wear, leading to decreased efficiency. Regular inspection can help mitigate unexpected failures and ensure optimal operation.

Compatibility Problems

Another common issue arises from the incompatibility of certain elements with different systems. Ensuring proper alignment and compatibility can prevent significant malfunctions and enhance overall performance. Always verify specifications before making replacements.

Where to Find the Diagram

Locating detailed visual guides for mechanical components can significantly streamline your repair and maintenance efforts. These resources are essential for understanding the assembly and functionality of various units.

Online Resources

- Manufacturer’s Website: Often provides official documentation.

- Technical Forums: Community-driven discussions can lead to shared resources.

- DIY Websites: Many platforms specialize in repair guides and visual aids.

Physical Locations

- Local Repair Shops: Staff may have printed guides available.

- Trade Schools: Educational institutions may have reference materials.

- Library Archives: Public libraries often keep technical manuals on file.

Maintenance Tips for Ut33600a

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Adopting effective strategies can help prevent issues and enhance overall efficiency.

1. Routine Inspections: Conduct frequent checks to identify any wear or damage. Look for signs of rust, leaks, or unusual noises that may indicate underlying problems.

2. Cleanliness: Keep your machinery clean to avoid dirt accumulation, which can lead to malfunctions. Use appropriate cleaning agents and tools for safe maintenance.

3. Lubrication: Regularly apply suitable lubricants to moving parts to minimize friction and reduce wear. Ensure you follow the manufacturer’s recommendations for the best results.

4. Calibration: Periodically calibrate your equipment to maintain accuracy and precision. This helps in achieving the desired performance standards consistently.

5. Proper Storage: When not in use, store your equipment in a dry, sheltered location to protect it from environmental damage. This can significantly extend its life.

6. Follow the Manual: Always refer to the user manual for specific maintenance instructions and guidelines. Adhering to these recommendations is crucial for safe and effective operation.

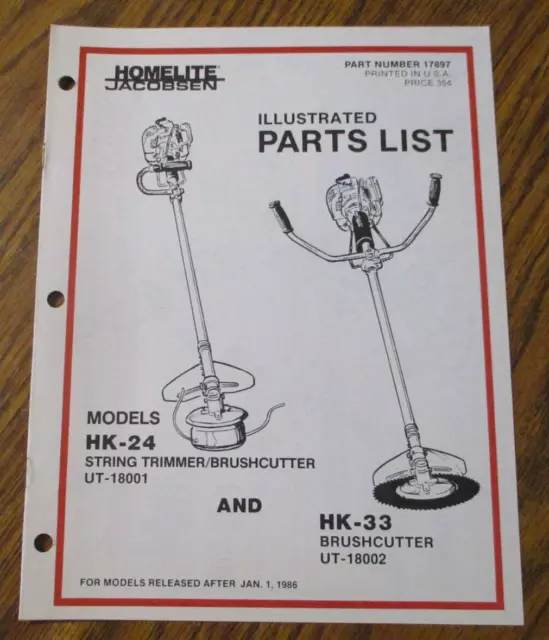

Comparing Parts with Other Models

This section explores the relationships and differences among various components across different machinery. Understanding these similarities and distinctions can enhance maintenance practices and improve efficiency in repairs.

Identifying Common Elements

Many devices share foundational features that can simplify repairs. By examining these common elements, one can determine the best alternatives when specific items are unavailable. This approach not only saves time but also reduces costs.

Evaluating Compatibility

Compatibility is crucial when substituting elements from different models. Careful consideration of specifications and design can lead to effective cross-referencing, ensuring optimal performance. Ultimately, this practice promotes sustainability through resourcefulness.

Assembly and Disassembly Guidance

This section provides essential instructions for efficiently putting together and taking apart the components of your equipment. Proper handling during these processes is crucial to ensure both functionality and longevity.

Preparation: Before you begin, gather all necessary tools and ensure your workspace is clean and organized. This will help prevent any unnecessary mishaps and allow for a smoother workflow.

Step-by-step Assembly: Start by identifying each component clearly. Follow the sequence of connections as indicated in the provided reference material. Pay close attention to the alignment and orientation of parts to avoid complications later on. Secure each piece firmly, but be cautious not to overtighten, which may lead to damage.

Disassembly Process: When taking the equipment apart, reverse the assembly steps carefully. Make sure to document the order of components if needed. This will simplify reassembly in the future. Use appropriate tools to avoid stripping screws or damaging other parts.

Final Checks: After assembly, inspect all connections to ensure everything is in place. For disassembled items, store parts in labeled containers to keep them organized. Following these guidelines will enhance your experience and maintain the integrity of your equipment.

Aftermarket Parts for Ut33600a

Exploring alternatives for essential components can significantly enhance performance and longevity. Many users seek replacements that not only match original specifications but also offer improved durability and cost-effectiveness. This section focuses on various options available in the market that cater to diverse needs.

- Compatibility with existing systems

- Enhanced materials for better resilience

- Cost advantages compared to original components

- Wider availability and sourcing options

When considering substitutes, it’s crucial to evaluate quality and reliability. Here are some common alternatives:

- High-performance variants that offer superior functionality

- Upgraded versions featuring advanced technology

- Reconditioned items that meet stringent testing standards

By choosing aftermarket solutions, users can achieve a balance between efficiency and budget, ensuring that their equipment remains operational and effective.

Visual Identification of Components

Understanding the various elements within a mechanical assembly is crucial for effective maintenance and repair. By recognizing distinct features and characteristics, individuals can ensure proper functionality and troubleshooting of equipment.

Key Features to Observe

- Shape and Size: Different components often have unique geometrical attributes.

- Color Coding: Manufacturers frequently use specific colors to differentiate parts.

- Material Composition: The texture and material can provide clues about a component’s purpose.

Identification Process

- Familiarize yourself with the general layout of the assembly.

- Use reference materials to compare known components.

- Take notes on any discrepancies or unique identifiers.

Updating Your Parts List

Maintaining an accurate inventory is crucial for efficient operations. Regularly revising your list of components ensures you have the necessary items on hand, minimizes delays, and enhances overall productivity. This section provides insights on how to effectively update your inventory documentation.

Steps to Revise Your Inventory

To keep your list current, follow these systematic steps:

| Step | Description |

|---|---|

| 1 | Review existing items and check for any discrepancies. |

| 2 | Identify new additions that need to be included. |

| 3 | Remove outdated or obsolete items from the list. |

| 4 | Verify quantities and reorder levels for each item. |

| 5 | Document changes and communicate updates to relevant teams. |

Benefits of Regular Updates

Keeping your documentation refreshed brings multiple advantages. It reduces the risk of stock shortages, enhances planning accuracy, and ultimately leads to more streamlined operations. By adopting a routine of regular reviews, you can ensure that your inventory aligns with current needs and trends.

Resources for Further Learning

Expanding your knowledge in any technical field requires access to a variety of resources. These materials can enhance your understanding and provide deeper insights into specific components and their functionalities. Below are several recommended avenues for further exploration.

- Online Courses: Platforms like Coursera, Udemy, and edX offer a plethora of courses that cover foundational and advanced topics.

- Books and Manuals: Comprehensive guides and textbooks can serve as excellent references for detailed information.

- Webinars and Workshops: Participate in live sessions to engage with experts and ask questions in real-time.

- Technical Forums: Join communities such as Stack Overflow or specialized discussion boards to connect with fellow learners and professionals.

Utilizing these resources can significantly bolster your understanding and help you stay updated with the latest advancements in the field.