In modern sanitation systems, effective waste management is crucial for maintaining hygiene and functionality. The intricate components of these systems work together to ensure optimal performance and reliability. Each element plays a distinct role, contributing to the overall efficiency and effectiveness of the setup.

By examining the configuration of these individual components, one can gain valuable insights into their functions and interactions. A comprehensive overview of these elements can aid in troubleshooting and maintenance, ensuring that the entire system operates seamlessly. Knowledge of how each piece integrates within the larger framework enhances the user’s ability to manage and care for their sanitation needs.

Moreover, understanding the layout and relationships among the components can facilitate informed decision-making when it comes to repairs or upgrades. A clear representation of the arrangement not only serves as a guide for technicians but also empowers users to engage more effectively with their sanitation systems.

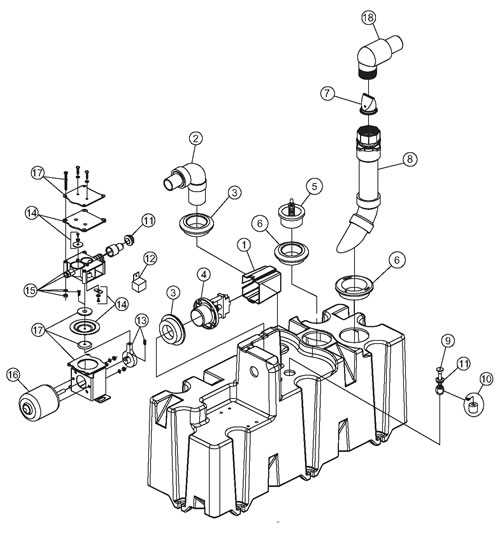

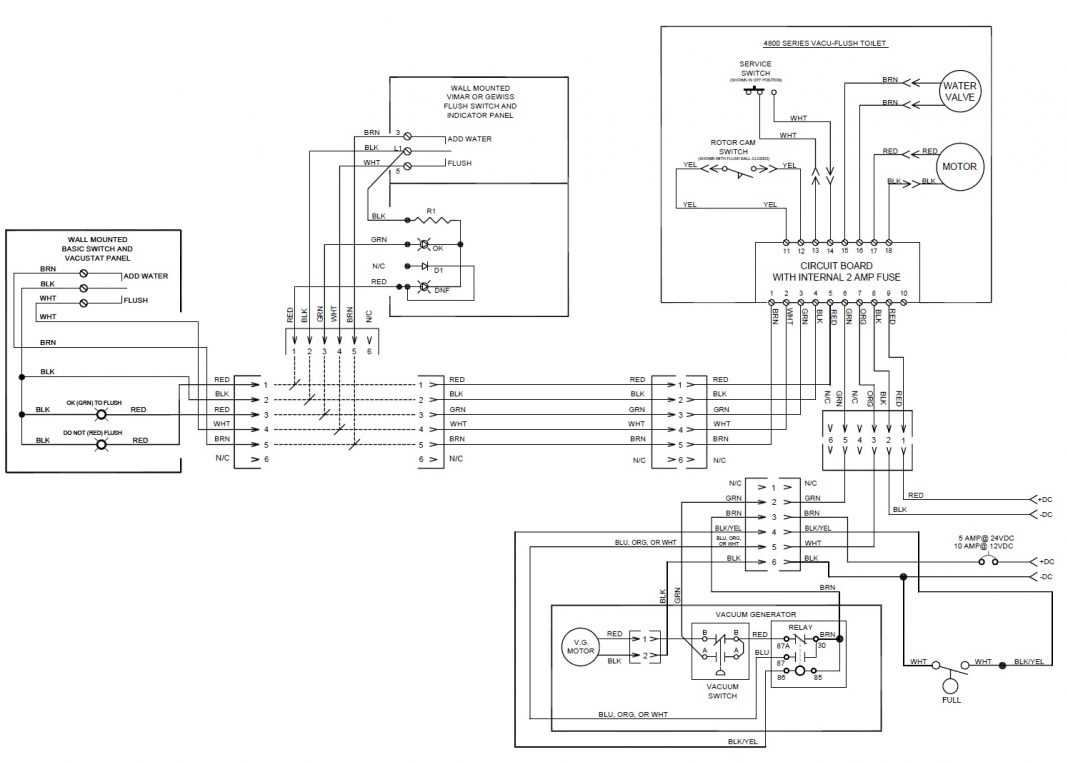

Understanding the Vacuflush System

This innovative waste management solution operates on the principles of suction and vacuum pressure, effectively transporting waste to a holding tank with minimal water usage. Its design prioritizes efficiency and environmental considerations, making it a preferred choice in various applications.

The system consists of key components that work in unison to create a reliable and hygienic method of waste disposal. By utilizing a network of tubes and valves, it ensures quick evacuation of waste while minimizing odors and preventing leaks.

Understanding the functionality of each element is crucial for maintaining optimal performance. Regular inspections and knowledge of the assembly can help users troubleshoot common issues and enhance the system’s longevity.

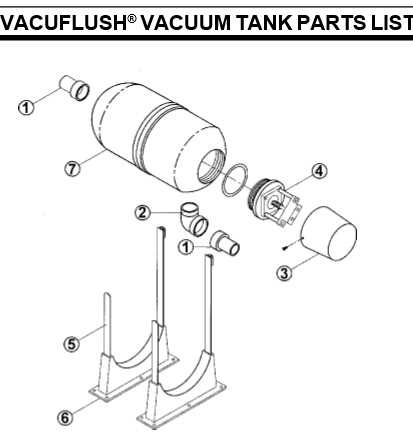

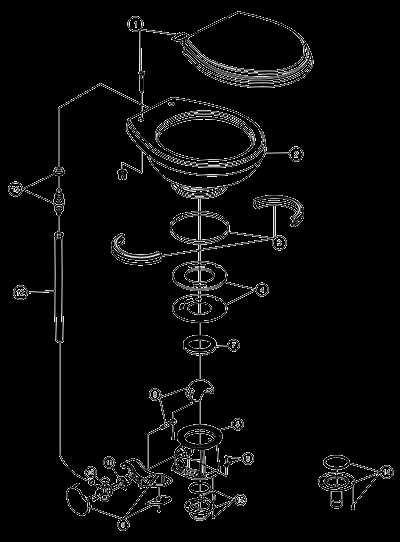

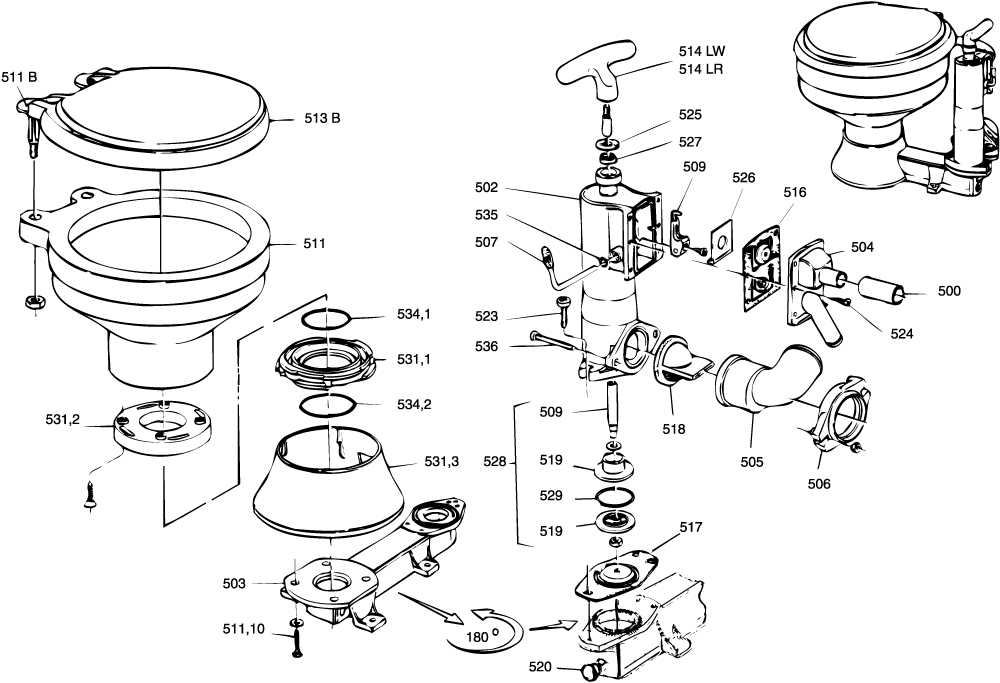

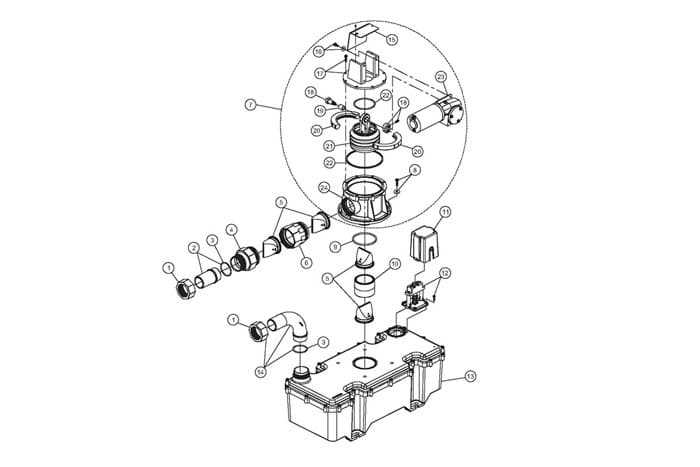

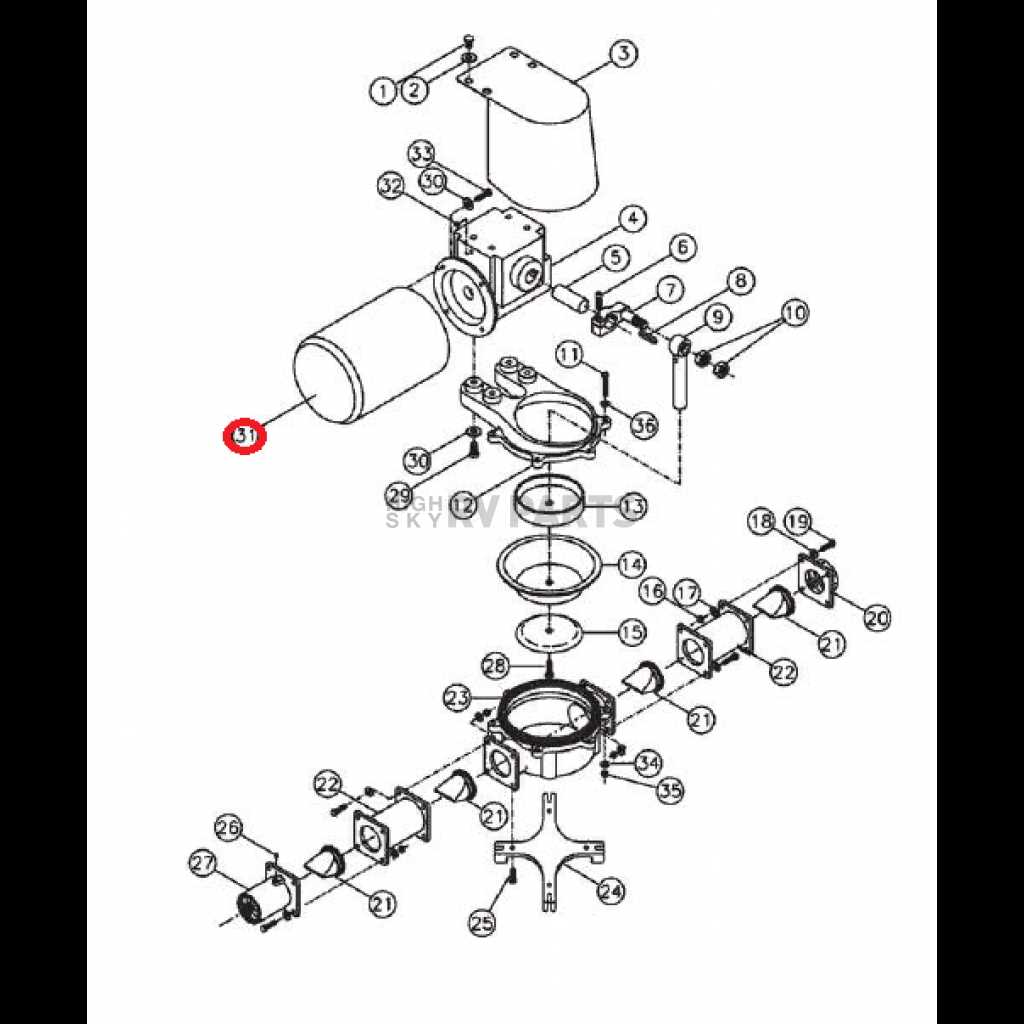

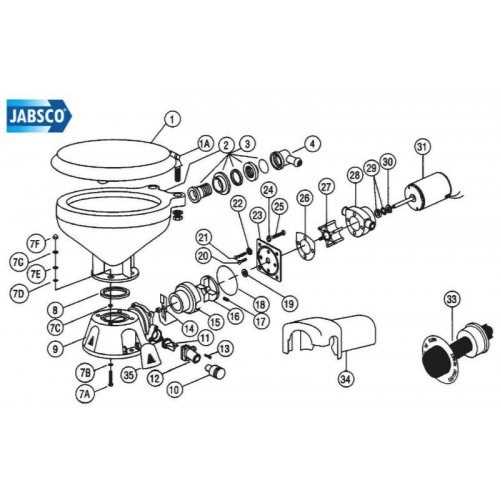

Components of a Vacuflush System

The system designed for efficient waste management in various settings comprises several essential elements. Each component plays a vital role in ensuring smooth operation and reliability, contributing to the overall functionality of the unit. Understanding these elements helps users maintain and troubleshoot the system effectively.

| Component | Description |

|---|---|

| Compressor | Generates the necessary vacuum pressure to transport waste effectively. |

| Tank | Stores waste until it can be pumped out, designed to prevent leaks and odors. |

| Control Unit | Regulates the system’s operations, ensuring efficient waste removal and management. |

| Piping | Connects components and facilitates the movement of waste through the system. |

| Valves | Control the flow of waste and air within the system, maintaining optimal pressure. |

Functionality of Each Component

This section explores the roles and interactions of various elements within a vacuum sanitation system. Understanding how each component operates is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Pump | Generates suction to facilitate waste removal through the system. |

| Compressor | Maintains optimal pressure levels, ensuring efficient operation. |

| Control Panel | Allows users to manage system settings and monitor performance. |

| Valves | Regulate the flow of waste and air within the system. |

| Hoses | Transport waste and air between different system components. |

| Tank | Stores waste until it is ready to be disposed of properly. |

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and optimal performance of any system. Implementing a few straightforward practices can significantly extend the life of your equipment, preventing costly repairs and enhancing functionality.

Regular Inspections

Conduct frequent evaluations to identify potential issues before they escalate. Look for signs of wear, leaks, or unusual sounds that may indicate a need for attention. Early detection is key to avoiding more significant problems down the line.

Cleaning and Lubrication

Keep all components clean and free from debris. Regular cleaning helps maintain efficiency and reduces the risk of blockages. Additionally, applying suitable lubricants to moving parts ensures smooth operation and minimizes friction, which can lead to premature wear.

Emphasizing these maintenance strategies will not only enhance performance but also promote longevity, allowing for a more reliable and efficient experience.

Common Issues and Troubleshooting

When operating a vacuum-based waste management system, users may encounter a variety of challenges that can disrupt functionality. Understanding these common problems and their solutions can enhance performance and ensure longevity.

1. Clogs and Blockages

One of the most frequent issues is the formation of clogs within the system. These obstructions can occur due to debris, improper waste disposal, or the buildup of materials over time. To resolve this, regularly inspect the system for blockages and employ appropriate cleaning methods, such as using specialized tools or flushing with water.

2. Poor Performance

Another concern is diminished efficiency, which may manifest as weak suction or frequent cycling. This can be attributed to low power supply, air leaks, or worn components. Conduct a thorough examination of the system’s connections, seals, and power source. Replacing any worn parts and ensuring a secure assembly will help restore optimal operation.

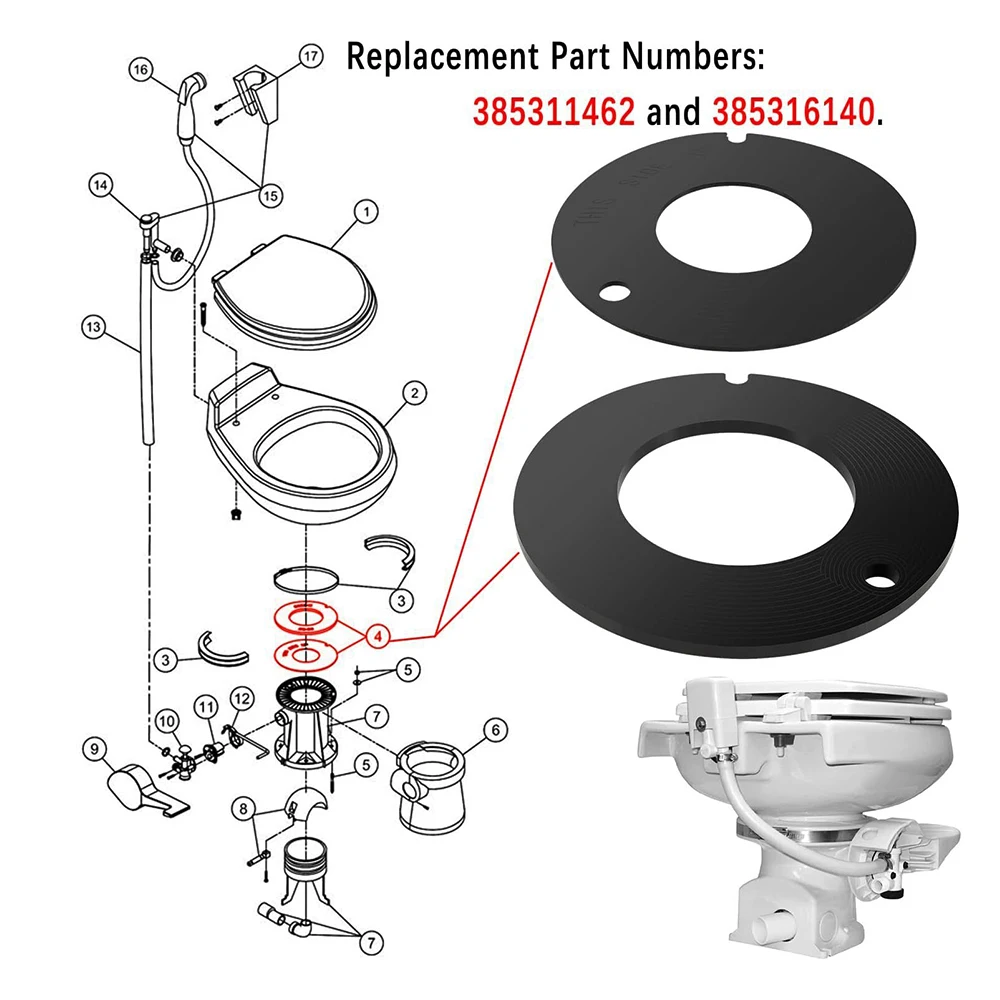

Replacing Vacuflush Parts Safely

Ensuring the integrity of your system while performing replacements is crucial for maintaining efficiency and preventing potential hazards. This guide outlines essential steps to safely carry out the task, promoting a seamless and secure experience.

- Before starting, gather all necessary tools and components.

- Always disconnect the power supply to avoid electrical hazards.

- Ensure the area is well-ventilated to reduce exposure to fumes or odors.

Follow these steps to ensure a smooth process:

- Identify the components that require replacement.

- Carefully remove the existing items, taking note of their arrangement.

- Install the new items, ensuring proper alignment and secure fittings.

- Double-check all connections before restoring power.

After installation, perform a thorough inspection to verify functionality and check for leaks. Regular maintenance can prevent future issues and enhance longevity.

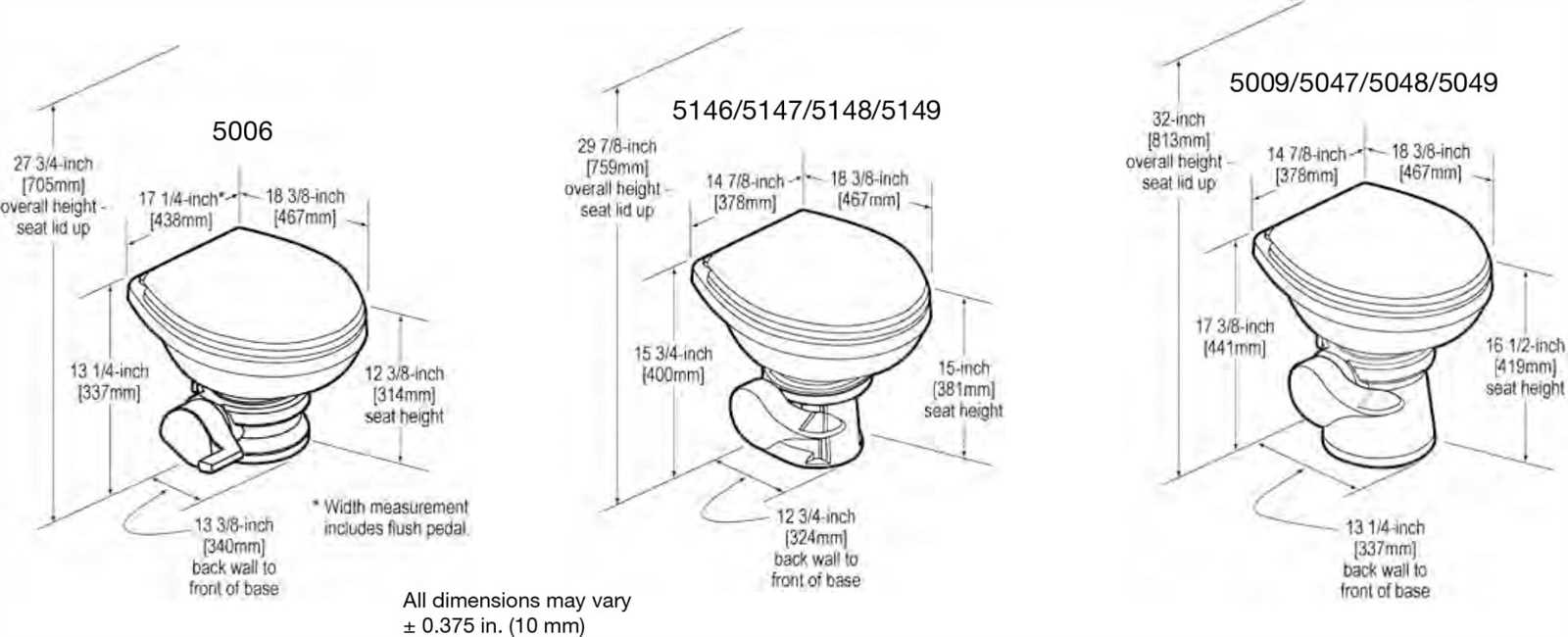

Installation Guide for New Parts

When it comes to replacing or upgrading components, proper installation is crucial to ensure smooth operation. This guide outlines the steps to follow for a successful installation of new elements in your system. Careful attention to detail during the process will prevent potential issues and ensure long-term efficiency.

Below is a step-by-step approach to help you navigate the assembly and integration of the fresh components:

- Prepare the working area by ensuring it is clean and free of any obstructions.

- Gather all necessary tools and ensure that the replacement pieces are compatible with your setup.

- Carefully remove any existing components that need replacing. Disconnect any connections with caution to avoid damage.

- Position the new component in place, aligning it with the appropriate connectors or mounting points.

- Secure the element using

Importance of Regular Inspections

Conducting routine evaluations of essential systems is crucial for maintaining optimal performance and ensuring longevity. These assessments help identify potential issues before they escalate, thereby saving time and resources in the long run.

Preventive Maintenance

Regular check-ups allow for the timely detection of wear and tear. By addressing minor concerns early, one can prevent major failures that could lead to costly repairs or replacements.

Safety Assurance

Consistent inspections contribute significantly to safety. By ensuring all components function properly, the risk of accidents or malfunctions is greatly reduced, providing peace of mind for users.

Choosing Quality Replacement Parts

When it comes to maintaining your system, selecting high-quality components is essential for optimal performance and longevity. Opting for superior alternatives ensures reliability and efficiency, reducing the likelihood of future complications.

Researching Manufacturers: Start by investigating reputable manufacturers known for their durable offerings. Look for brands with a solid track record in the industry, as this can significantly influence the quality of the items you choose.

Compatibility Matters: Ensure that the components you select are compatible with your system. This prevents installation issues and guarantees that everything functions seamlessly together.

Reading Reviews: Pay attention to customer feedback and reviews. Insights from other users can provide valuable information regarding the performance and reliability of specific alternatives.

Warranties and Guarantees: Consider components that come with warranties or guarantees. This not only reflects the manufacturer’s confidence in their products but also offers peace of mind for your investment.

Price vs. Quality: While it may be tempting to choose cheaper options, remember that investing in quality often pays off in the long run. Durable components can save you from frequent replacements and repairs, making them a worthwhile choice.

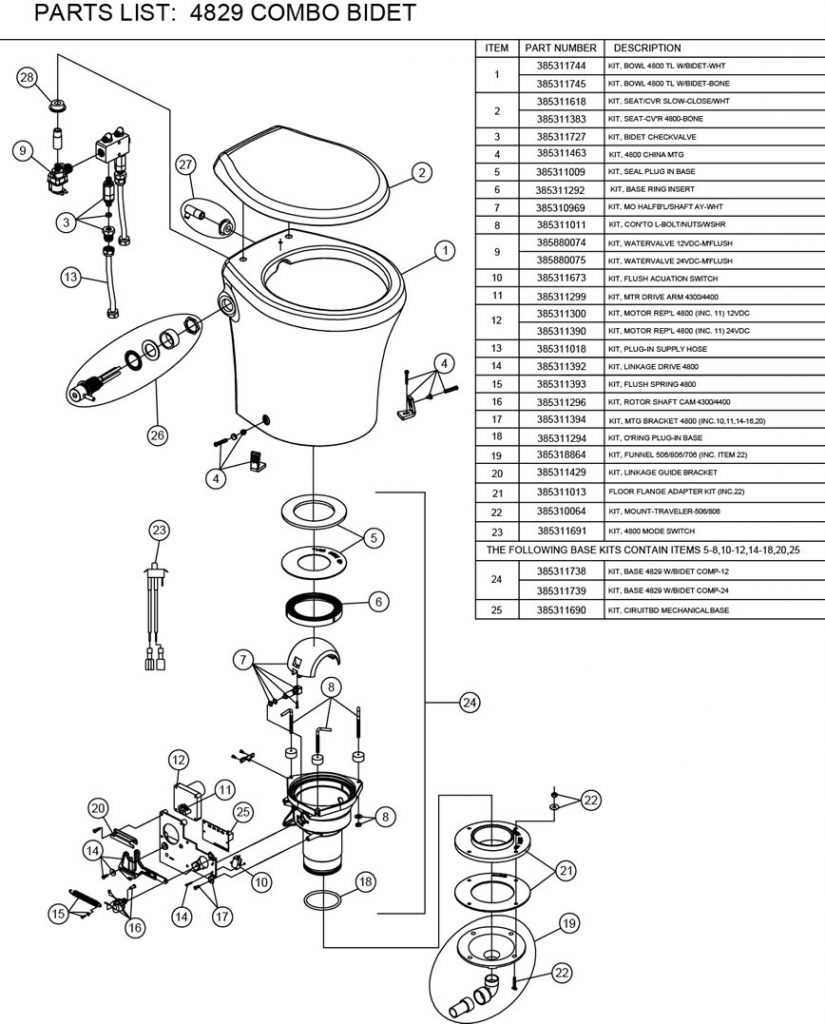

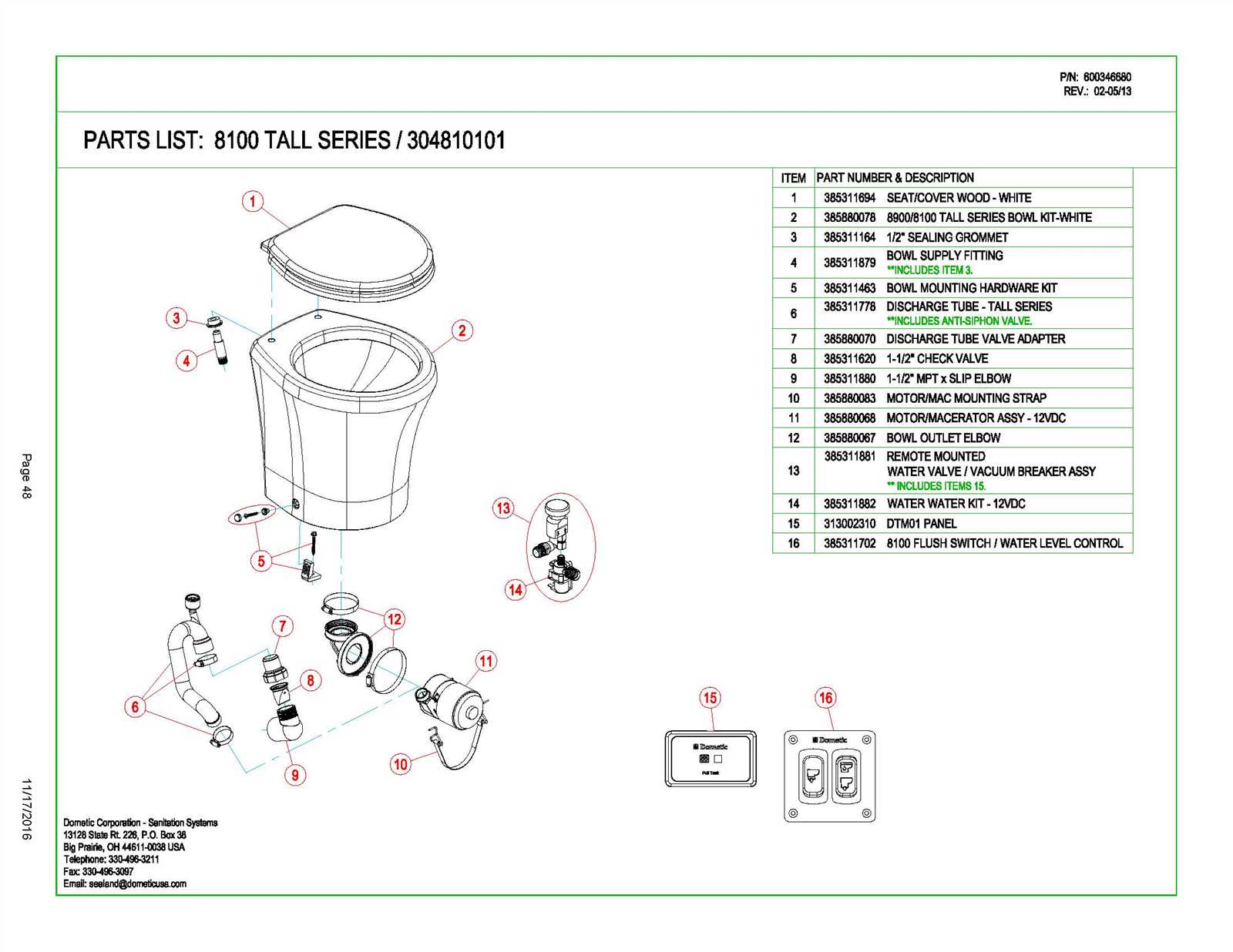

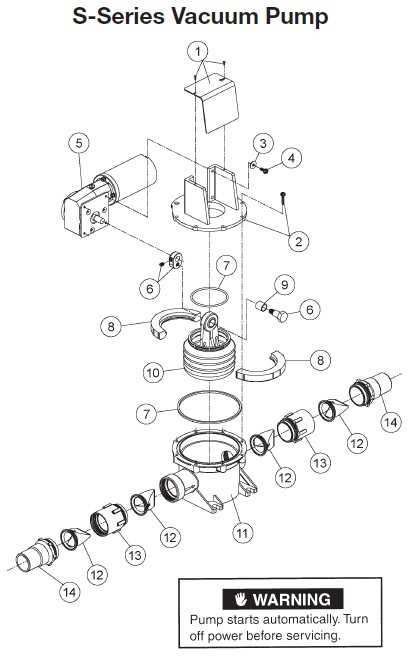

Vacuflush Diagrams Explained

Understanding the inner workings of modern marine sanitation systems is crucial for efficient maintenance and troubleshooting. These systems operate through a combination of advanced mechanisms that manage waste and ensure smooth functioning. By visualizing how various components are interconnected, users can gain valuable insights into optimizing their system’s performance.

Component Function Control Valve Regulates the pressure within the system to ensure proper operation. Pump Assembly Creates the necessary vacuum to transport waste through the system efficiently. Waste Tank Stores waste securely until disposal is performed. Seals and Gaskets Ensure airtight connections to prevent leaks and maintain system integrity. Upgrading Your System

Improving the performance and reliability of your sanitation system can significantly enhance its overall efficiency. Regular enhancements help ensure smooth operation, minimize maintenance, and extend the lifespan of the entire setup. Whether you’re adding new features or replacing outdated components, making the right upgrades can optimize both function and comfort.

Choosing the Right Enhancements

When selecting new components, it’s essential to prioritize compatibility and quality. Look for advanced options designed to handle modern demands while reducing power consumption and improving flow management. Opting for robust materials ensures that your system can withstand continuous use and harsh environments.

Installation Tips

During the upgrade process, proper installation is key to maintaining seamless functionality. Following manufacturer guidelines and performing regular checks can prevent issues such as leaks or clogs. If you’re unsure about the process, consulting a professional can ensure that the installation is done efficiently and correctly.

Frequently Asked Questions

In this section, we will address common inquiries regarding the maintenance and functionality of specific systems. These answers are designed to provide clarity on how to ensure long-lasting use and troubleshoot potential challenges. Whether you’re dealing with routine checks or technical adjustments, these responses will guide you through effective solutions.

How often should routine inspections be performed?

Regular inspections are recommended to ensure that everything is working optimally. It is advised to carry out these checks at least every few months to identify any signs of wear or possible malfunctions before they become significant issues.

What should I do if I notice unusual performance?

When you detect any irregularities in the operation, such as decreased efficiency or odd noises, it’s important to inspect the main components immediately. If issues persist after a basic check, consult the relevant manual or contact professional support for further assistance.