Engines are intricate machines that rely on a harmonious interplay of various elements to function optimally. Each component plays a vital role in ensuring performance, efficiency, and longevity. For enthusiasts and technicians alike, grasping the layout and interaction of these parts is essential for maintenance and repair.

In this exploration, we will delve into the intricacies of a specific 16 horsepower engine configuration, focusing on the critical elements that define its structure and operation. By breaking down the essential components, we aim to provide clarity on how they contribute to the overall functionality of the engine.

Whether you are a seasoned mechanic or a curious learner, this guide serves as the ultimate resource to navigate the complexities of engine assembly. Understanding these components not only enhances your technical skills but also empowers you to tackle repairs with confidence.

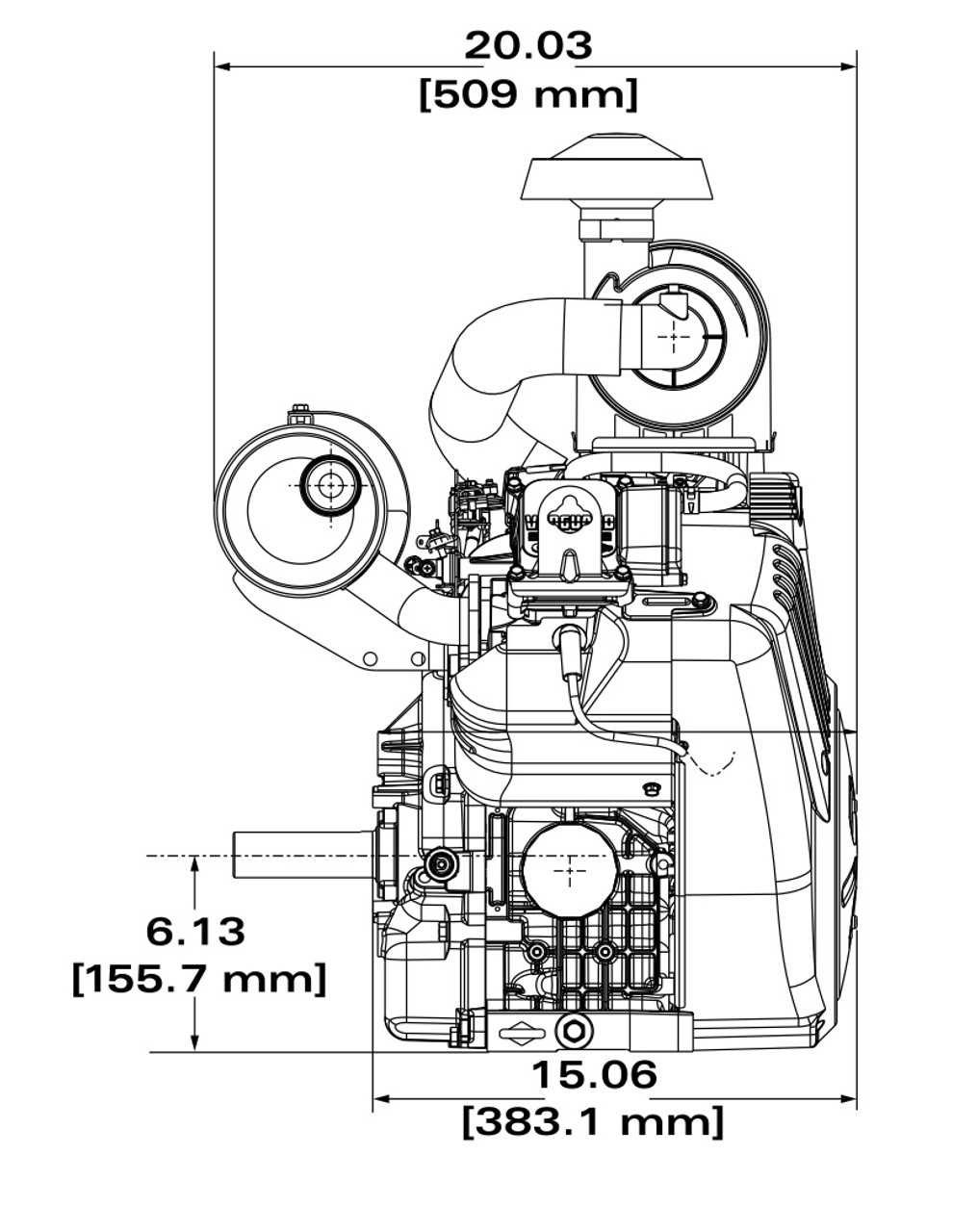

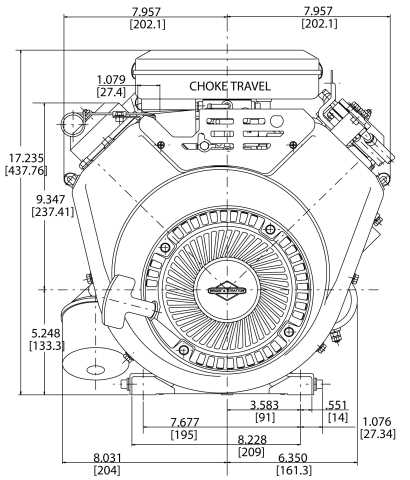

Understanding Vanguard 16 HP V-Twin Engine

This section explores the intricacies of a specific power unit known for its performance and reliability in various applications. By examining its design and functionality, we can gain insights into how it delivers efficient energy output while ensuring durability and ease of maintenance.

Key Features

This engine model is distinguished by its robust construction and advanced engineering. It incorporates dual cylinders that enhance power delivery, making it suitable for a range of tasks, from lawn care to heavy-duty equipment. The careful arrangement of components contributes to smoother operation and reduced vibrations.

Maintenance Considerations

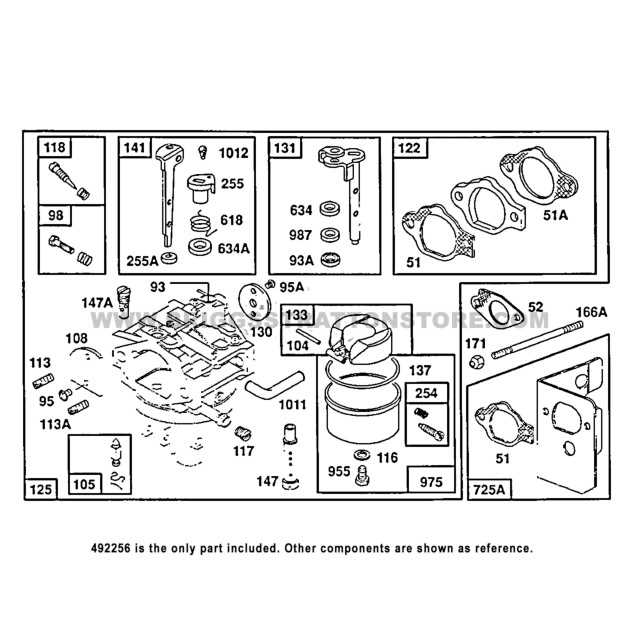

Key Components of the Engine

Understanding the essential elements of an engine is crucial for effective maintenance and performance optimization. Each component plays a significant role in the overall functionality, contributing to the engine’s efficiency and longevity.

Cylinders and Pistons

The cylinders house the pistons, which are vital for converting fuel into mechanical energy. Their movement generates power, making them integral to the engine’s operation.

Crumple System and Crankshaft

The crumple system facilitates the transfer of power from the pistons to the crankshaft. This connection is essential for translating linear motion into rotational energy, enabling the engine to drive various applications effectively.

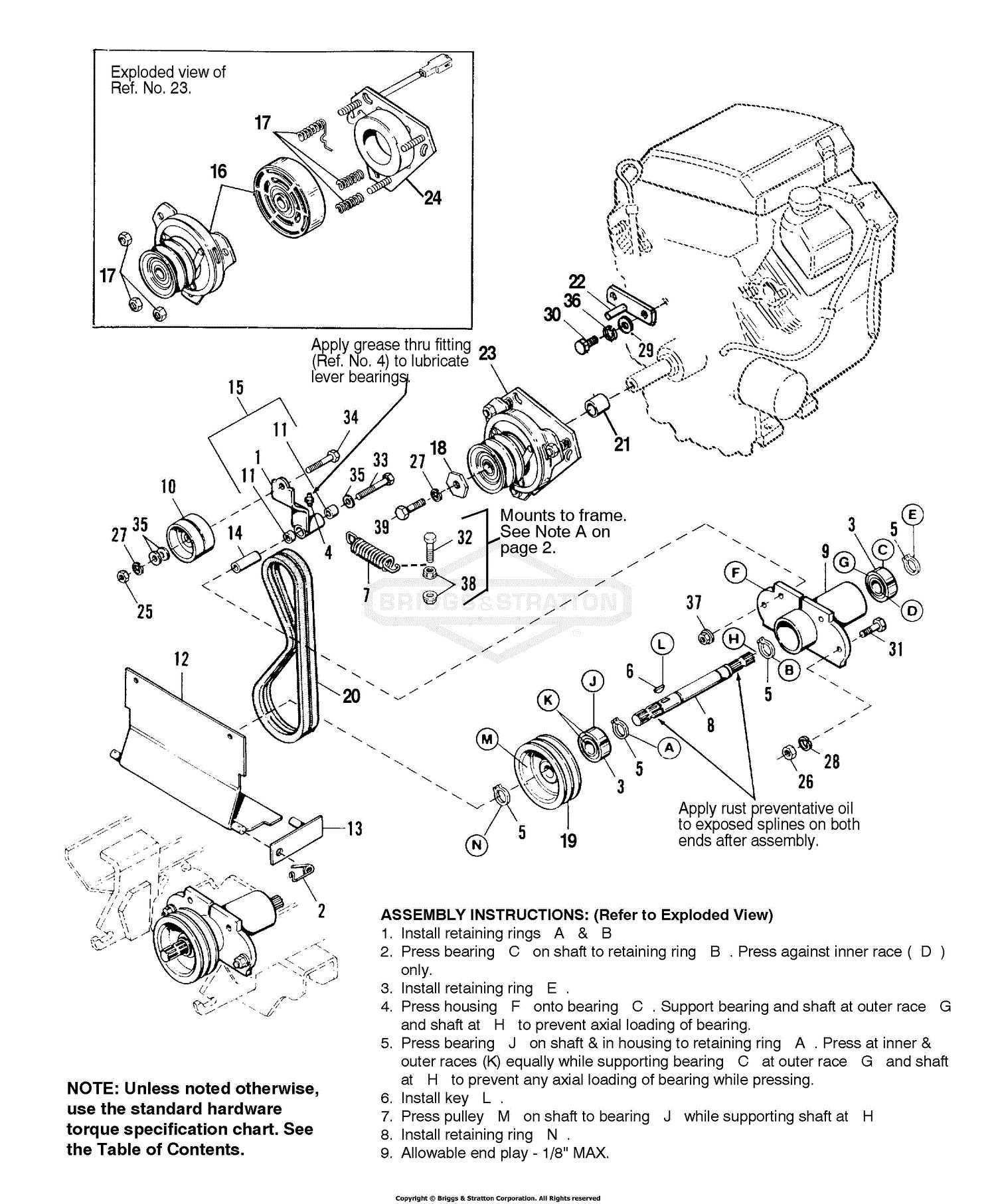

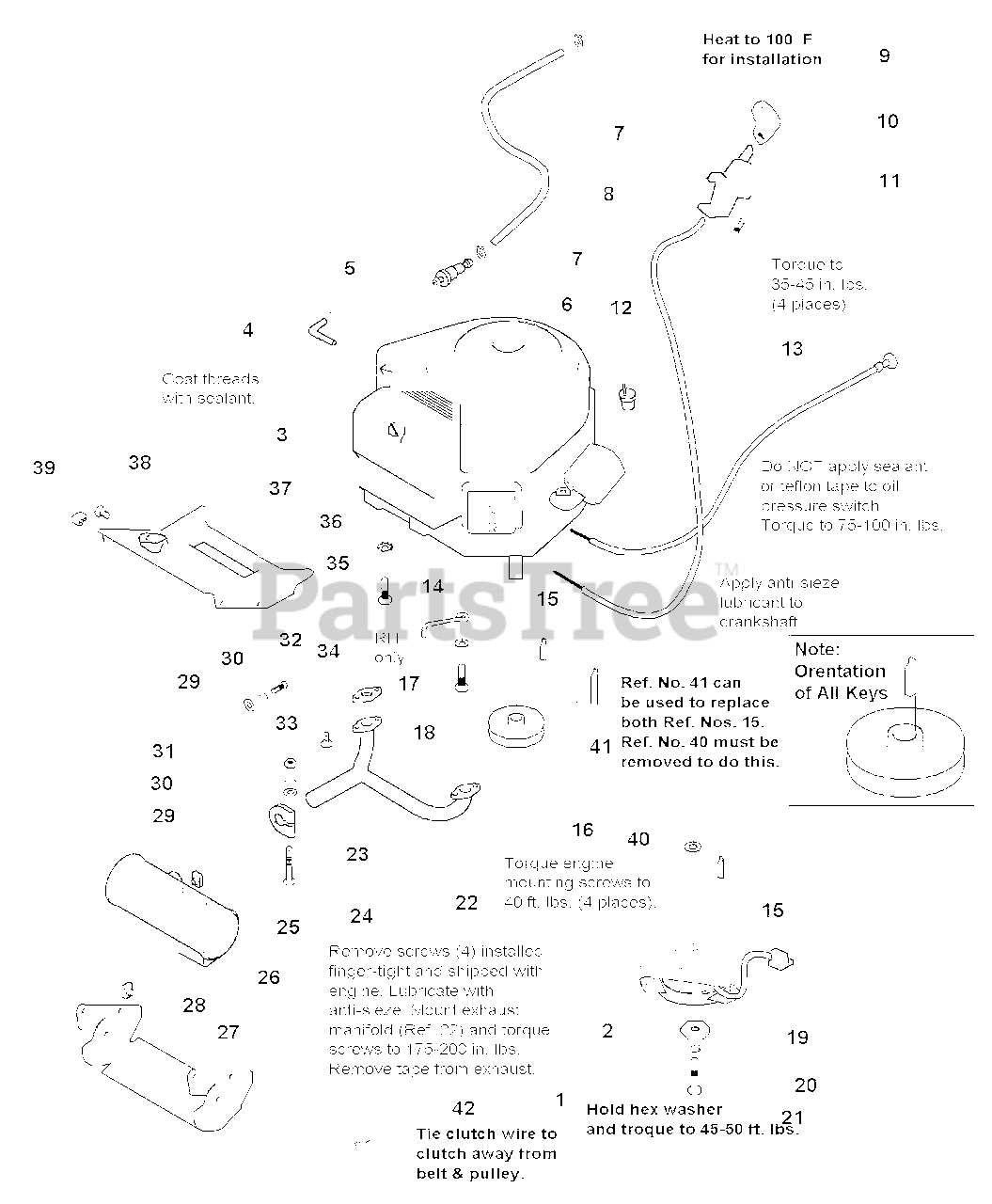

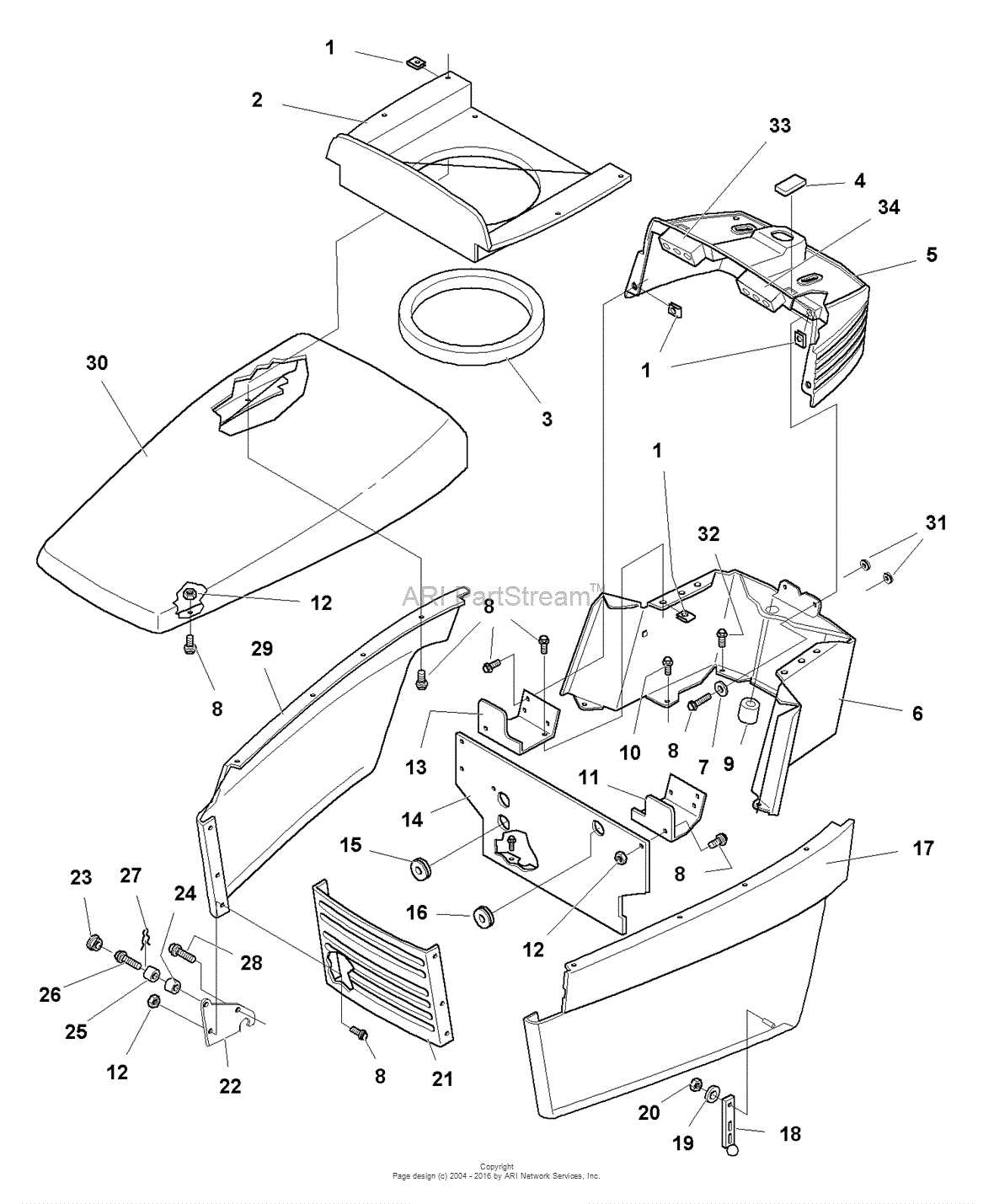

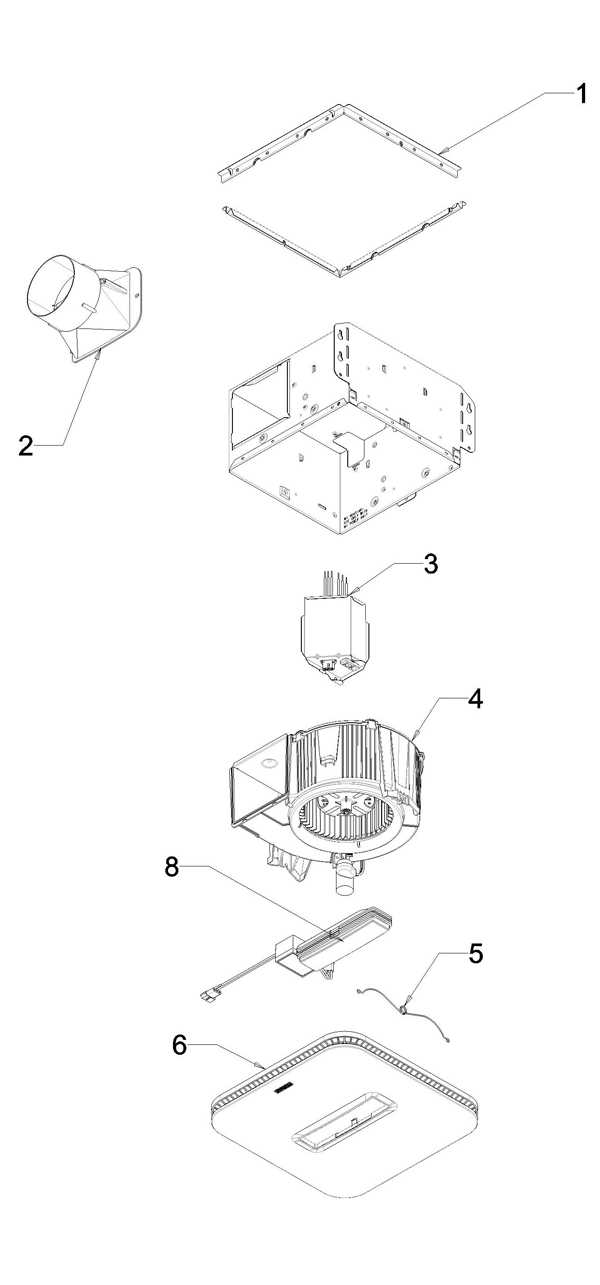

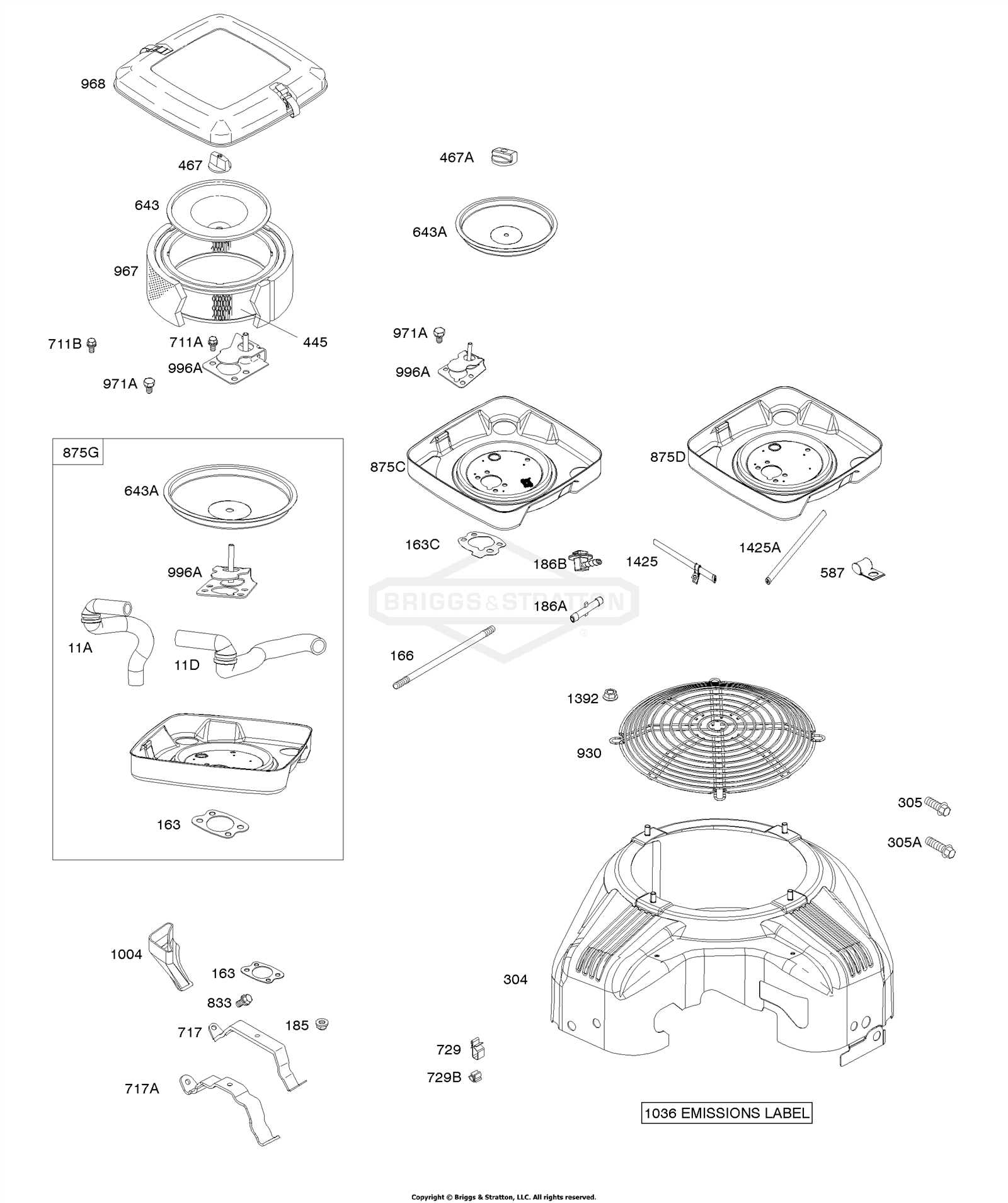

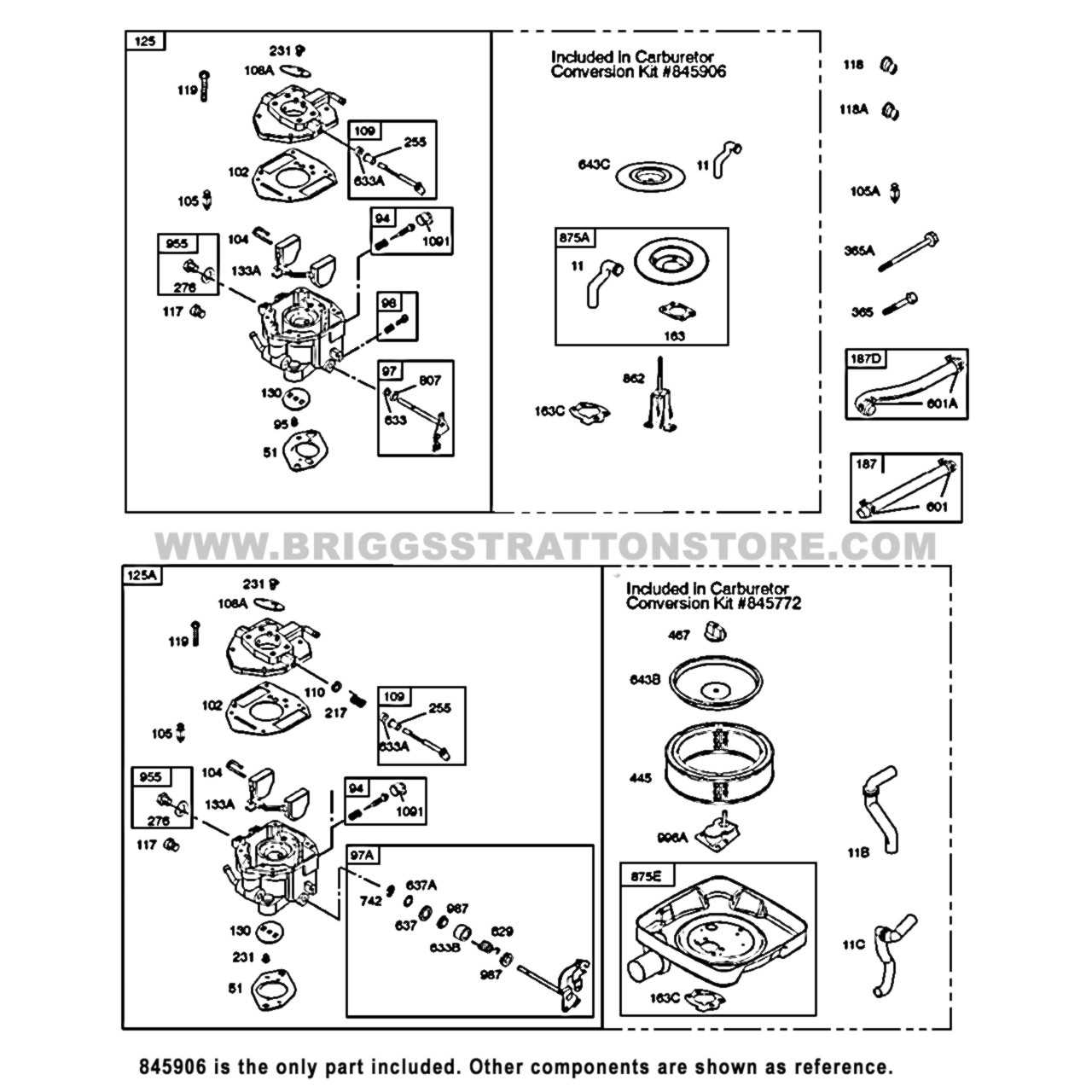

Importance of Parts Diagram

Understanding the layout and components of a mechanical system is crucial for effective maintenance and repair. A visual representation of the various elements involved serves as a valuable resource for technicians and enthusiasts alike. It enables users to identify, locate, and comprehend the functions of each individual component.

Efficiency is greatly enhanced when one can quickly refer to a visual guide. It eliminates confusion and streamlines the troubleshooting process, allowing for faster diagnostics and resolution of issues. This is particularly important in complex machinery where components may be intricately connected.

Furthermore, such illustrations foster a deeper understanding of the entire system, promoting better decision-making when it comes to repairs or upgrades. Users can visualize how changes to one part may impact others, leading to more informed choices that can prolong the lifespan of the equipment.

In addition, a well-crafted visual reference aids in communication between team members. It provides a common language that can bridge gaps in technical knowledge, ensuring everyone is on the same page when discussing repairs or modifications.

Common Issues with Vanguard Engines

Engines of this type are known for their durability and reliability, but like any machinery, they can encounter a range of problems over time. Understanding these common issues can help users maintain optimal performance and prolong the engine’s lifespan.

- Overheating: Excessive heat can lead to serious damage. This can be caused by:

- Low coolant levels

- Clogged cooling fins

- Faulty thermostats

- Fuel System Problems: Issues with fuel delivery can affect performance. Common causes include:

- Clogged fuel filters

- Dirty carburetors

- Poor quality fuel

- Oil Leaks: Leaking oil can create significant issues. Possible sources are:

- Worn gaskets

- Damaged seals

- Poorly fitted components

- Starting Difficulties: Trouble starting can be frustrating. This may stem from:

- Weak batteries

- Faulty ignition systems

- Dirty spark plugs

- Vibration Issues: Excessive shaking can indicate imbalances. Common reasons include:

- Misaligned components

- Worn engine mounts

- Unbalanced rotating parts

lessCopy code

By being aware of these frequent challenges, users can take proactive measures to ensure their engines operate smoothly and efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your engine requires consistent care and attention. By following a few key practices, you can significantly extend the lifespan of your machinery while maintaining optimal performance. Regular upkeep not only prevents unexpected failures but also enhances the overall reliability of your equipment.

Regular Oil Changes

Changing the oil at regular intervals is crucial for keeping the internal components lubricated and functioning smoothly. Fresh oil helps to reduce friction and wear, preventing damage over time. Always refer to the manufacturer’s recommendations for the appropriate type and frequency of oil changes to maximize the benefits.

Routine Inspections

Conducting frequent checks on belts, filters, and air intakes can help identify potential issues before they escalate. Look for signs of wear or damage and replace parts as needed. Clean air filters ensure that the engine receives adequate airflow, contributing to efficient operation and longevity.

Where to Find Replacement Parts

When your equipment requires new components, locating reliable sources for quality replacements is essential. Various options are available for those seeking to restore functionality and ensure optimal performance. Understanding where to look can save time and provide peace of mind.

Here are some common sources for acquiring necessary components:

| Source | Description |

|---|---|

| Authorized Dealers | Official vendors often offer a wide range of original items and can provide expert advice on selection. |

| Online Retailers | Numerous e-commerce websites feature extensive catalogs, allowing for easy comparison of prices and availability. |

| Local Repair Shops | Many repair shops stock essential items and can assist with installation or troubleshooting. |

| Salvage Yards | These places may have used components at a lower cost, perfect for budget-conscious individuals. |

Regardless of the source chosen, verifying the quality and compatibility of items is crucial for achieving the best results. With the right approach, restoring your equipment can be straightforward and efficient.

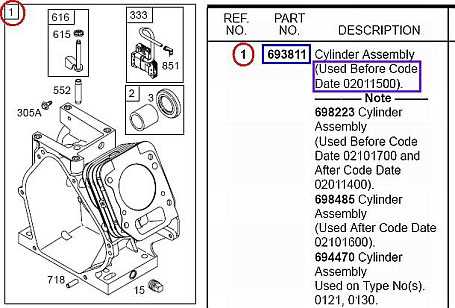

Benefits of Using Genuine Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These original items are specifically engineered to meet precise specifications, which enhances overall functionality and reliability.

One significant advantage of using genuine components is the assurance of compatibility. These pieces work seamlessly together, minimizing the risk of malfunction or damage. Additionally, they often come with manufacturer warranties, providing extra peace of mind.

Furthermore, original items tend to offer superior durability compared to aftermarket alternatives. This means reduced maintenance costs and less frequent replacements, leading to greater savings in the long run. Investing in authentic components ultimately supports the efficiency and effectiveness of your equipment.

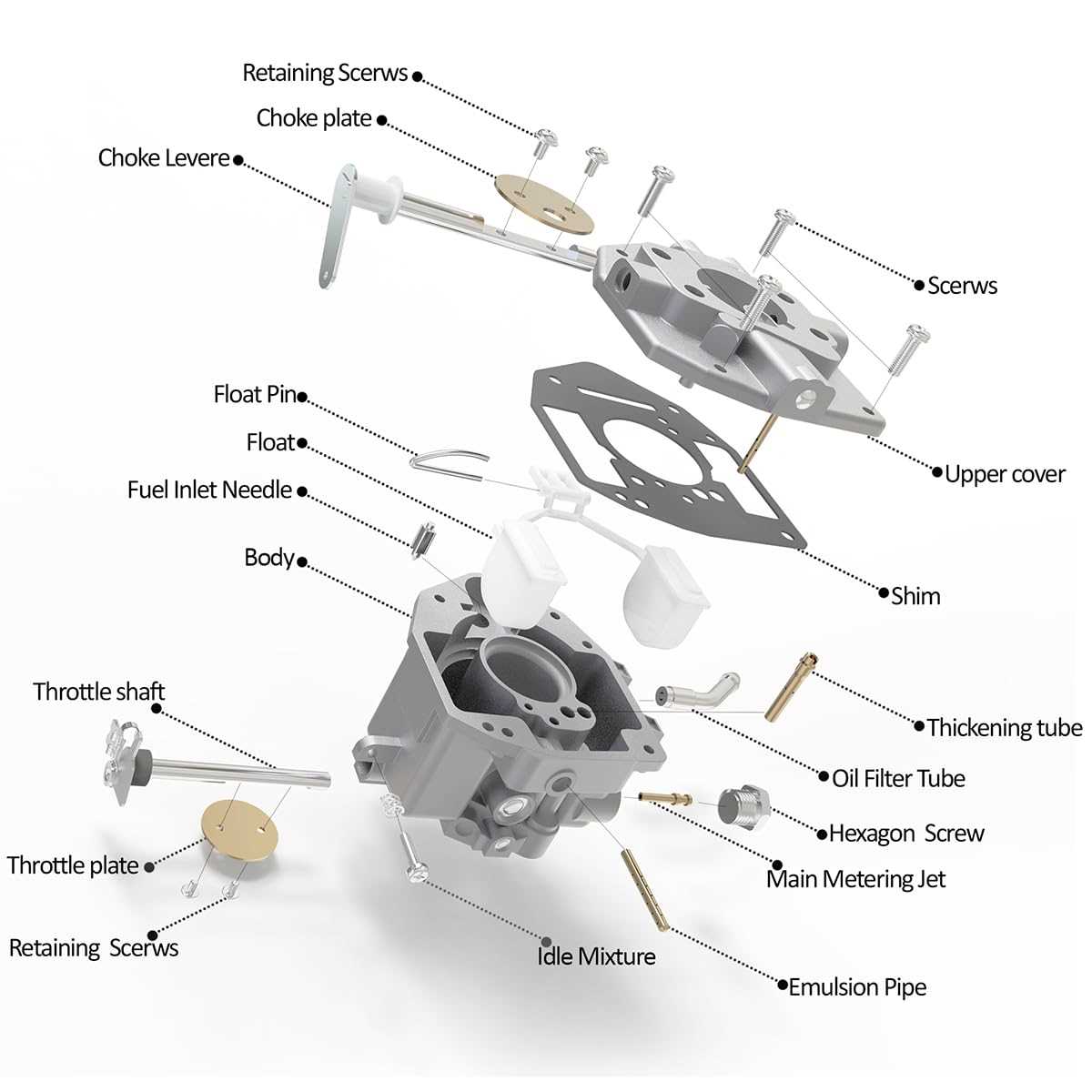

How to Read a Parts Diagram

Understanding an illustration that depicts components can significantly enhance your ability to maintain and repair machinery. Such visuals serve as a roadmap, guiding users through the various elements and their relationships within the system. This section will help you navigate and interpret these informative representations with ease.

Identifying Components

Each element in the illustration is typically labeled with a unique identifier, often a number or letter. Familiarize yourself with this coding system as it allows you to cross-reference with accompanying documentation, such as manuals or lists. Pay close attention to the shapes and sizes, as they can provide insight into how the parts fit together.

Understanding Connections

It’s essential to grasp how the components interact. Lines or arrows may indicate the connections between parts, showing how they are linked or how they function together. Noting these connections helps in visualizing the overall assembly, enabling you to approach repairs or replacements with confidence.

Popular Upgrades for Performance

Enhancing the efficiency and power of small engines can significantly improve their functionality and longevity. Many enthusiasts explore various modifications to achieve better performance, whether for lawn equipment, generators, or other applications. This section outlines some of the most sought-after upgrades that can elevate the overall capability of your engine.

1. High-Performance Air Filter: Upgrading to a high-flow air filter allows for improved air intake, which can boost combustion efficiency. Cleaner air can lead to enhanced horsepower and torque.

2. Exhaust System Modification: Replacing the stock exhaust with a performance-oriented system can reduce back pressure and improve exhaust flow. This modification not only increases power but can also create a more pleasing sound.

3. Carburetor Tuning: Adjusting or replacing the carburetor can optimize fuel delivery, resulting in better throttle response and overall performance. A properly tuned carburetor ensures that the engine runs smoothly under various conditions.

4. Performance Spark Plugs: Installing high-quality spark plugs can lead to improved ignition and more efficient fuel burning. This simple change can enhance starting and acceleration.

5. Upgrade Ignition System: A more advanced ignition system can deliver a stronger spark, improving engine performance and efficiency. This upgrade is particularly beneficial in high-stress conditions.

Implementing these modifications can make a noticeable difference in the overall performance of your engine. Careful consideration and proper installation of these upgrades can result in a more powerful and reliable machine.

Comparing Vanguard V-Twin Models

This section explores the distinctions and similarities among various engine models, focusing on their performance characteristics, applications, and design features. By examining these elements, users can make informed decisions based on their specific requirements and preferences.

Performance Features

The engines in question are renowned for their power output and efficiency. Each model has unique specifications that cater to different usage scenarios. Here’s a comparison of key performance metrics:

| Model | Power Output (HP) | Torque (ft-lb) | Displacement (cc) |

|---|---|---|---|

| Model A | 16 | 25 | 500 |

| Model B | 18 | 30 | 550 |

| Model C | 20 | 35 | 600 |

Applications and Usability

Different engine types serve various purposes, from residential lawn care to heavy-duty industrial tasks. Understanding the intended application can significantly influence the choice of model. Here’s a brief overview of common applications:

| Model | Common Use Cases |

|---|---|

| Model A | Residential mowing and gardening |

| Model B | Commercial landscaping and light construction |

| Model C | Heavy-duty machinery and large commercial projects |

Resources for Repair Assistance

When tackling maintenance or repair tasks, having the right resources at your disposal can make a significant difference. Access to comprehensive guides, community forums, and expert advice enhances your ability to effectively address any issues that arise.

Online Forums: Engaging with dedicated communities online allows for the exchange of knowledge and experiences. These platforms often provide invaluable insights from fellow enthusiasts who have faced similar challenges.

Video Tutorials: Visual aids can be immensely helpful. Platforms like YouTube feature a plethora of instructional videos that guide you through various repair processes step-by-step.

Manufacturer’s Manuals: Official documentation is a vital resource. These manuals typically include detailed instructions, troubleshooting tips, and essential specifications to ensure proper handling.

Local Workshops: Don’t overlook local repair shops. Many offer assistance and can provide expert guidance, ensuring your tasks are completed efficiently.

By utilizing these resources, you can delve deeper into your repair projects, ultimately enhancing your skills and confidence in maintaining your equipment.

Safety Precautions During Repairs

When performing maintenance or troubleshooting on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adopting proper safety measures can significantly reduce risks and ensure a smooth repair process. Below are key precautions to consider before starting any work.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure that the work area is clean and free from clutter to avoid tripping hazards.

- Keep fire extinguishers nearby and ensure they are in good working order.

- Use tools and equipment according to the manufacturer’s instructions to prevent misuse.

Electrical Safety

- Disconnect the power supply before starting any electrical repairs.

- Check for any exposed wires or damaged components that could pose a shock hazard.

- Use insulated tools when working with electrical systems.

By following these safety precautions, you can create a safer environment and mitigate potential hazards during repair activities.