In the realm of machinery maintenance, comprehending the structure and functionality of various elements is essential. This knowledge facilitates efficient repairs and ensures optimal performance. Detailed representations of these components serve as invaluable resources for technicians and operators alike.

Each machine consists of numerous interconnected pieces, each playing a vital role in the overall operation. Familiarizing oneself with these layouts can significantly enhance troubleshooting capabilities and streamline maintenance procedures. Furthermore, these visual aids assist in identifying wear and tear, enabling timely interventions.

By exploring the intricate configurations of machinery, users can gain insights into the best practices for upkeep and repair. This understanding not only extends the lifespan of equipment but also promotes safety and efficiency in operations. Embracing this approach empowers users to tackle challenges confidently and effectively.

Overview of Vermeer BC1500 Components

This section provides a comprehensive look at the various elements that contribute to the functionality of a specific equipment model. Understanding these components is crucial for effective operation, maintenance, and troubleshooting. Each part plays a significant role in the overall performance and reliability of the machine.

The following table outlines the key components, their functions, and common specifications:

| Component | Function | Specifications |

|---|---|---|

| Engine | Powers the entire system | 25 HP, Diesel |

| Chassis | Provides structural support and stability | Heavy-duty steel construction |

| Hydraulic System | Operates various functions, including feeding and chipping | Hydraulic fluid capacity: 10 gallons |

| Feeding Mechanism | Guides material into the cutting area | Variable speed control |

| Chipper Blades | Shred and chip the material | High-carbon steel, replaceable |

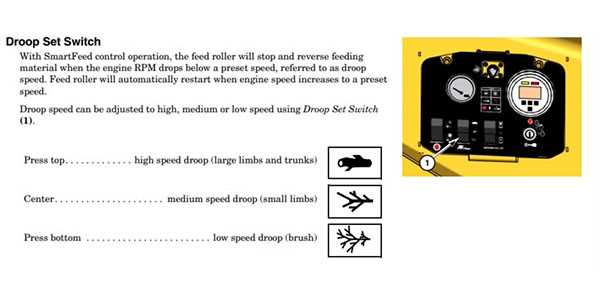

| Control Panel | Allows operator to manage machine functions | Ergonomically designed with easy access |

Each of these elements is vital for optimal operation and longevity. Proper knowledge of their functions can aid users in performing maintenance tasks efficiently.

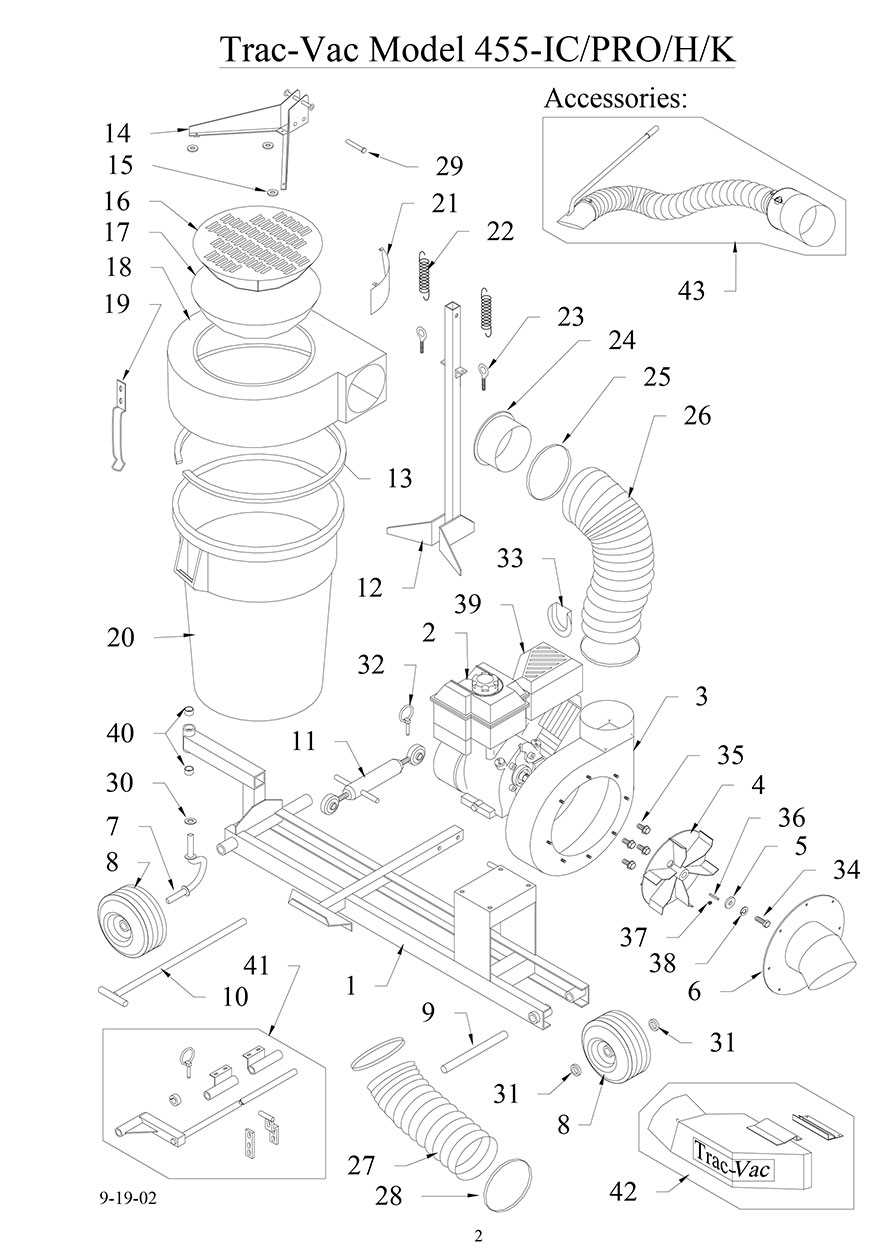

Importance of Parts Schematics

Understanding the layout and components of machinery through detailed visual aids plays a crucial role in efficient maintenance and repair practices. These diagrams serve as comprehensive guides, illustrating the intricate interplay of various elements within the equipment.

Enhanced Maintenance Precision

- Facilitates precise identification of components

- Aids in targeted troubleshooting efforts

- Ensures accurate part replacement

Operational Efficiency and Safety

- Promotes proactive maintenance schedules

- Reduces downtime through expedited repairs

- Enhances workplace safety by promoting informed handling of equipment

Overall, the utility of these detailed schematics extends beyond mere identification; they empower technicians with the knowledge needed to maintain machinery at optimal levels of performance and reliability.

Key Features of the BC1500

The model in question is designed with a range of innovative characteristics that enhance its efficiency and usability. It is tailored to meet the demands of various tasks, providing operators with robust performance and reliability in challenging environments.

Robust Build Quality

This equipment is constructed from high-quality materials, ensuring durability and resistance to wear. Its rugged design allows for consistent operation even in tough conditions, making it a dependable choice for professionals.

Advanced Operational Efficiency

- Powerful engine that delivers exceptional performance.

- Efficient fuel consumption, reducing operational costs.

- Streamlined controls for easy handling and maneuverability.

These standout features contribute to an effective and user-friendly experience, enabling users to achieve optimal results in their projects.

Understanding Maintenance Procedures

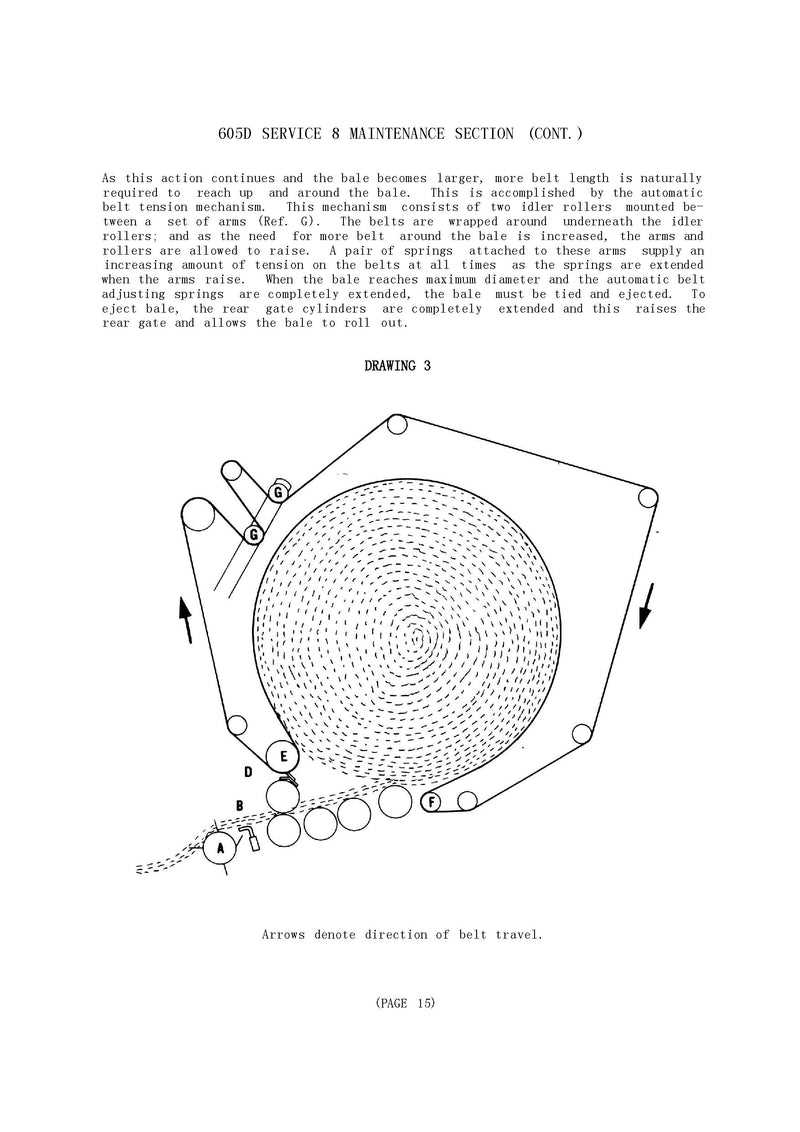

Effective upkeep is essential for ensuring the longevity and optimal performance of any machinery. Regular inspections and systematic procedures contribute significantly to reducing downtime and preventing unexpected failures. This section will explore various strategies to maintain equipment efficiently.

Key Maintenance Strategies

- Routine Inspections: Conducting frequent assessments allows operators to identify wear and tear before it leads to major issues.

- Cleaning and Lubrication: Keeping components clean and well-lubricated reduces friction and wear, enhancing performance.

- Replacement of Worn Parts: Timely replacement of aged or damaged components ensures smooth operation and safety.

Documentation and Record-Keeping

Maintaining accurate records of all maintenance activities is crucial. Documenting each procedure helps in tracking the history of repairs and replacements, allowing for informed decision-making regarding future actions. This practice also aids in compliance with safety regulations and standards.

By implementing these practices, operators can ensure their machinery remains efficient and reliable, ultimately leading to improved productivity and reduced operational costs.

Common Issues with BC1500 Parts

In this section, we explore the typical challenges encountered with components of the BC1500 equipment. Understanding these issues is crucial for effective maintenance and troubleshooting.

1. Common Malfunctions

Various components of the BC1500 machinery may experience frequent malfunctions during operation. These problems often arise from wear and tear, improper maintenance practices, or environmental factors affecting component integrity.

2. Performance Degradation

Over time, certain parts of the BC1500 can exhibit diminished performance, affecting overall operational efficiency. Identifying and addressing these performance issues promptly can extend the lifespan of the equipment and reduce downtime.

How to Identify Faulty Components

In troubleshooting equipment like the Vermeer BC1500, understanding how to pinpoint defective parts is crucial for efficient repairs and maintenance. Identifying malfunctioning elements involves meticulous inspection and testing of various system components. Begin by examining each section for signs of wear, damage, or irregular performance indicators.

Visual Inspection

Start with a visual assessment to detect visible signs of wear, such as cracks, discoloration, or loose connections. Look for components that appear different from their usual condition, indicating potential issues that require further investigation.

Functional Testing

Proceed with functional tests to evaluate the performance of critical parts. Utilize diagnostic tools and meters to measure electrical outputs, pressures, or mechanical movements. Compare obtained readings with standard operational parameters to identify deviations that could point to faulty components.

Ordering Replacement Parts Efficiently

Ensuring uninterrupted equipment operation relies heavily on timely replacement components. Streamlining the procurement process involves identifying compatible items swiftly and accurately.

Efficiently sourcing necessary replacements requires understanding equipment specifications and functionalities. This knowledge aids in selecting suitable alternatives promptly.

Utilizing comprehensive parts catalogs facilitates quick identification and ordering of needed components. Familiarizing oneself with terminology commonly used in equipment maintenance expedites the search for compatible replacements.

Collaborating closely with suppliers who specialize in industrial machinery parts ensures access to genuine components tailored to specific operational requirements.

Maintaining detailed records of equipment configurations simplifies the process of reordering components, promoting operational continuity and reducing downtime.

Tips for Effective Repairs

When it comes to maintaining and fixing machinery, having a strategic approach can make all the difference. Understanding the components and how they interact is crucial for ensuring that repairs are not only effective but also long-lasting. Here are some essential tips to consider when undertaking repairs.

Firstly, always begin by assessing the condition of the equipment. A thorough inspection will help identify any obvious issues and give insight into potential problems that may arise in the future. This step can save time and resources by addressing multiple concerns at once.

Secondly, gather all necessary tools and materials before starting the repair process. Having everything on hand eliminates unnecessary interruptions and allows for a more efficient workflow. Additionally, keeping a well-organized workspace can enhance productivity and reduce the risk of errors.

Furthermore, following the manufacturer’s guidelines can provide valuable insights into the repair process. These instructions often contain specific details that can simplify complex tasks and ensure that everything is done correctly. If available, consulting a repair manual can be extremely helpful.

Lastly, don’t hesitate to seek assistance or advice from experienced individuals. Learning from others’ experiences can provide new perspectives and techniques that may improve your repair skills. Engaging with a community of knowledgeable peers can also lead to valuable insights and resources.

Comparison with Other Chipper Models

When evaluating different wood shredders, it is essential to consider how various models stack up against each other in terms of performance, efficiency, and features. This comparison helps potential buyers identify which equipment best suits their specific needs, whether for personal or commercial use. Understanding these differences can lead to more informed purchasing decisions, ensuring that users select a machine that aligns with their expectations and requirements.

Key Features

Different shredders offer varying features that can enhance their usability and efficiency. Factors such as engine power, chipper size, and maintenance requirements play significant roles in determining the suitability of each model for different tasks.

Performance Comparison

| Model | Engine Power (HP) | Chipping Capacity (inches) | Weight (lbs) |

|---|---|---|---|

| Model A | 15 | 6 | 800 |

| Model B | 20 | 8 | 1200 |

| Model C | 18 | 7 | 950 |

By comparing the specifications and features of these various models, users can better understand their capabilities and how they align with specific needs, whether for light yard work or heavy-duty commercial applications.

Best Practices for Equipment Care

Proper maintenance and attention to machinery are crucial for ensuring optimal performance and longevity. By adhering to effective care strategies, operators can minimize downtime, reduce repair costs, and enhance overall efficiency.

Regular inspections and timely servicing play a significant role in identifying potential issues before they escalate. Operators should be diligent in monitoring key components and performing routine checks as recommended by the manufacturer.

| Care Practice | Description | Frequency |

|---|---|---|

| Clean Equipment | Remove dirt, debris, and contaminants from surfaces and components. | After each use |

| Check Fluid Levels | Ensure that oil, coolant, and other fluids are at appropriate levels. | Weekly |

| Inspect Belts and Hoses | Look for signs of wear, cracks, or fraying to prevent breakdowns. | Monthly |

| Lubricate Moving Parts | Apply lubricant to bearings and joints to reduce friction. | As needed |

| Review Safety Features | Check that all safety devices are functioning properly. | Monthly |

Following these best practices fosters a proactive approach to equipment management, ensuring reliability and extending the service life of essential machinery.