In modern marine systems, the use of auxiliary mechanisms to enhance navigation and control has become essential. These specialized devices help improve maneuverability, making them invaluable for various vessels. Understanding how these systems are assembled and interconnected can greatly improve operational efficiency and maintenance practices.

This guide explores the main elements of such systems, focusing on their structure and functionality. By examining each component, we can gain a clearer picture of how the overall mechanism works together to provide precise control. Whether for routine upkeep or troubleshooting, knowing the layout of these crucial elements is an important part of ensuring smooth operation.

With this information, you can develop a better understanding of how these essential mechanisms are designed and how each element plays a role in their overall performance. This knowledge will prove helpful for anyone seeking to maintain or repair these systems efficiently.

Understanding the Vetus Bow Thruster

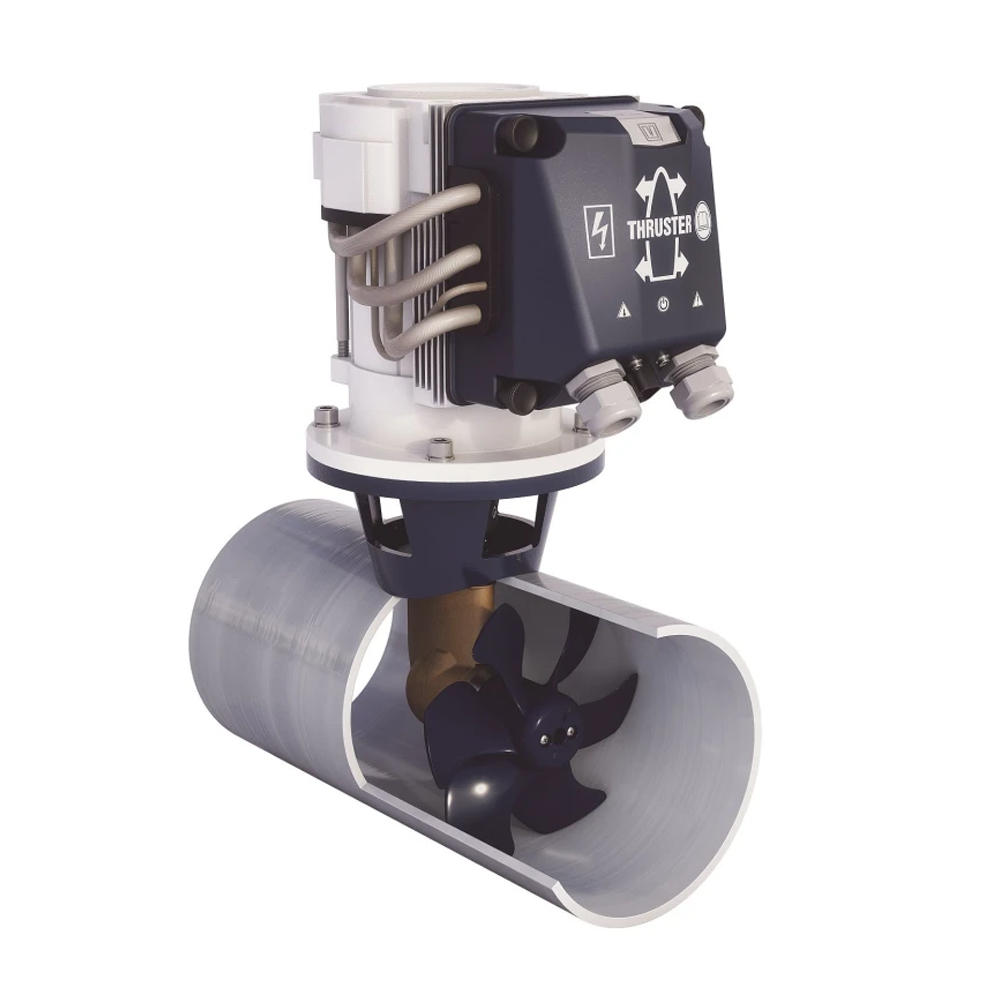

Mastering the use of a marine propulsion assist system is essential for enhancing the maneuverability of a vessel in tight spaces. This system provides precise control, allowing for easier docking and navigating through confined areas. Understanding how each component works together ensures a smoother and more reliable operation.

Key components of this system include the motor, which generates the necessary force, and the propeller, responsible for delivering the movement. By coordinating these elements, the system can provide lateral motion, giving the operator more control in challenging conditions.

- Motor: Powers the entire system, converting electrical energy into mechanical motion.

- Propeller: Transfers the energy into directed movement, assisting with turning and positioning.

- Control unit: Allows the operator to adjust the intensity and direction of the movement.

Key Components of a Bow Thruster

A modern marine propulsion system is designed to enhance vessel maneuverability and control, particularly in tight spaces. It consists of several essential elements that work in harmony to provide lateral movement. These parts are built to optimize performance, minimize noise, and ensure reliable operation even in challenging conditions.

Primary Elements

- Propeller: This vital element is responsible for generating the lateral force. The blades are shaped to maximize efficiency, offering a balance between power and smooth operation.

- Motor: A high-torque electric or hydraulic unit powers the system, converting electrical energy into mechanical force.

- Control Unit: This interface allows the operator to activate and control the system. It typically includes switches or joysticks for precision control.

Additional Components

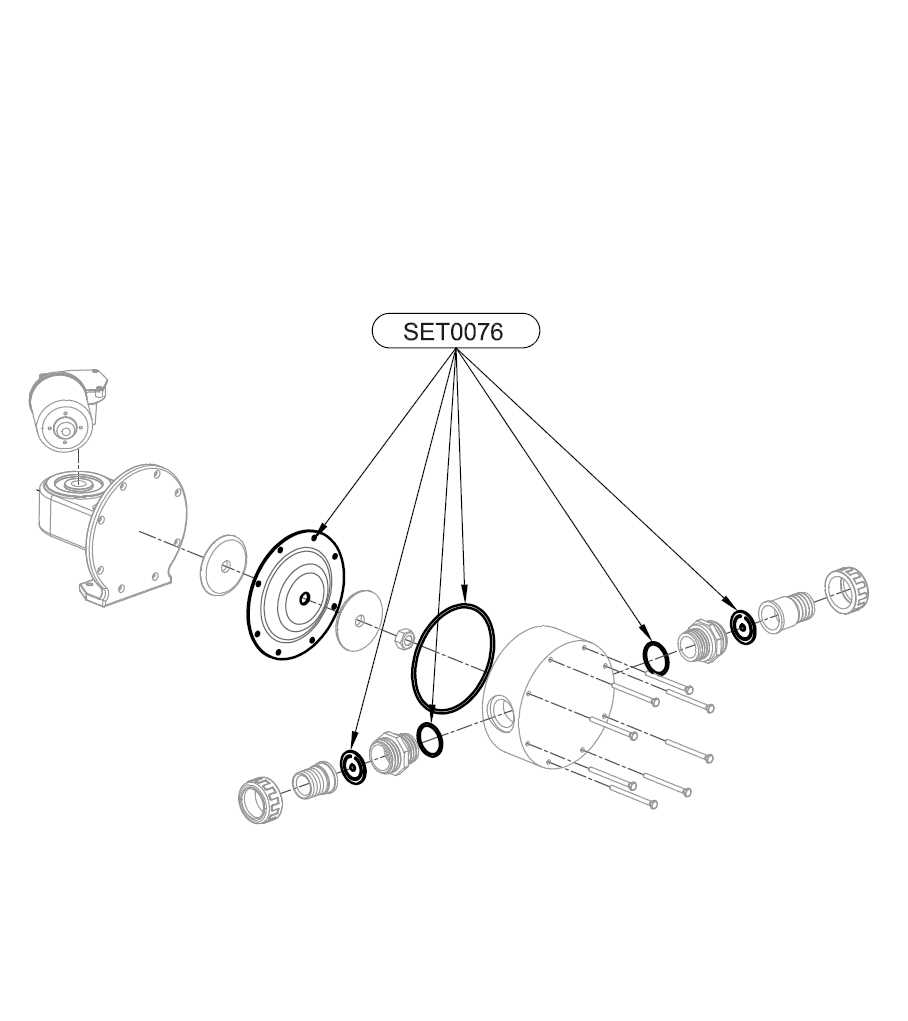

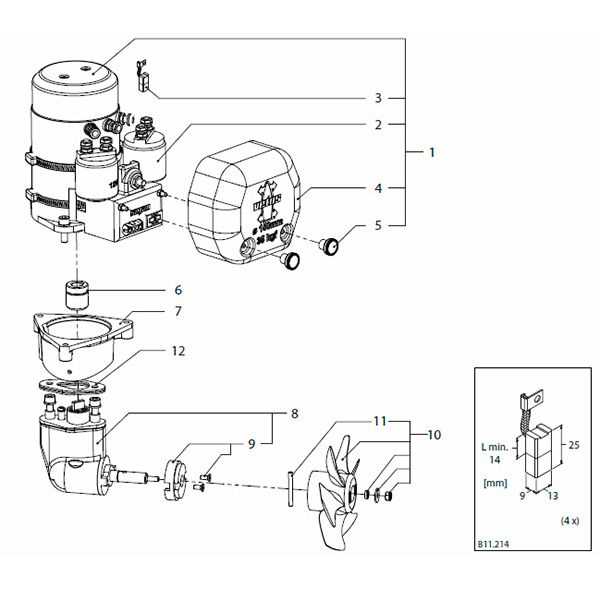

Diagram Overview for Installation

This section provides a general layout for the correct placement and alignment of components during the assembly process. The visual representation simplifies the understanding of how various elements connect, ensuring that the installation proceeds efficiently and accurately. By following the provided illustration, users can easily identify where each part fits within the system, reducing the potential for errors.

Key Connection Points: The illustration highlights essential connection points that must be securely fastened during the setup. Ensuring tight and precise connections is vital for the overall performance and reliability of the system.

Orientation and Positioning: Proper orientation is crucial for smooth functionality. The diagram outlines the recommended positioning of each component, helping users to ensure everything is aligned according to the technical specifications.

How to Identify Each Part

Understanding the various components of a marine propulsion system is essential for effective maintenance and troubleshooting. By familiarizing yourself with the individual elements, you can ensure smoother operation and timely repairs when necessary. Each section of the system plays a vital role, and recognizing them will help in achieving optimal performance.

Recognizing Key Mechanical Elements

Start by examining the central assembly, which is often the most complex part of the system. Look for the larger metallic structure, typically connected to several auxiliary components. This core segment houses important mechanisms that drive functionality. Pay attention to the surrounding seals, couplings, and fasteners that hold everything together, ensuring a tight and secure fit.

Locating Electrical Components

Electrical elements are crucial for controlling the entire system. These parts are usually smaller and are connected through wiring that links to a control interface. Inspect the wiring harnesses, relays,

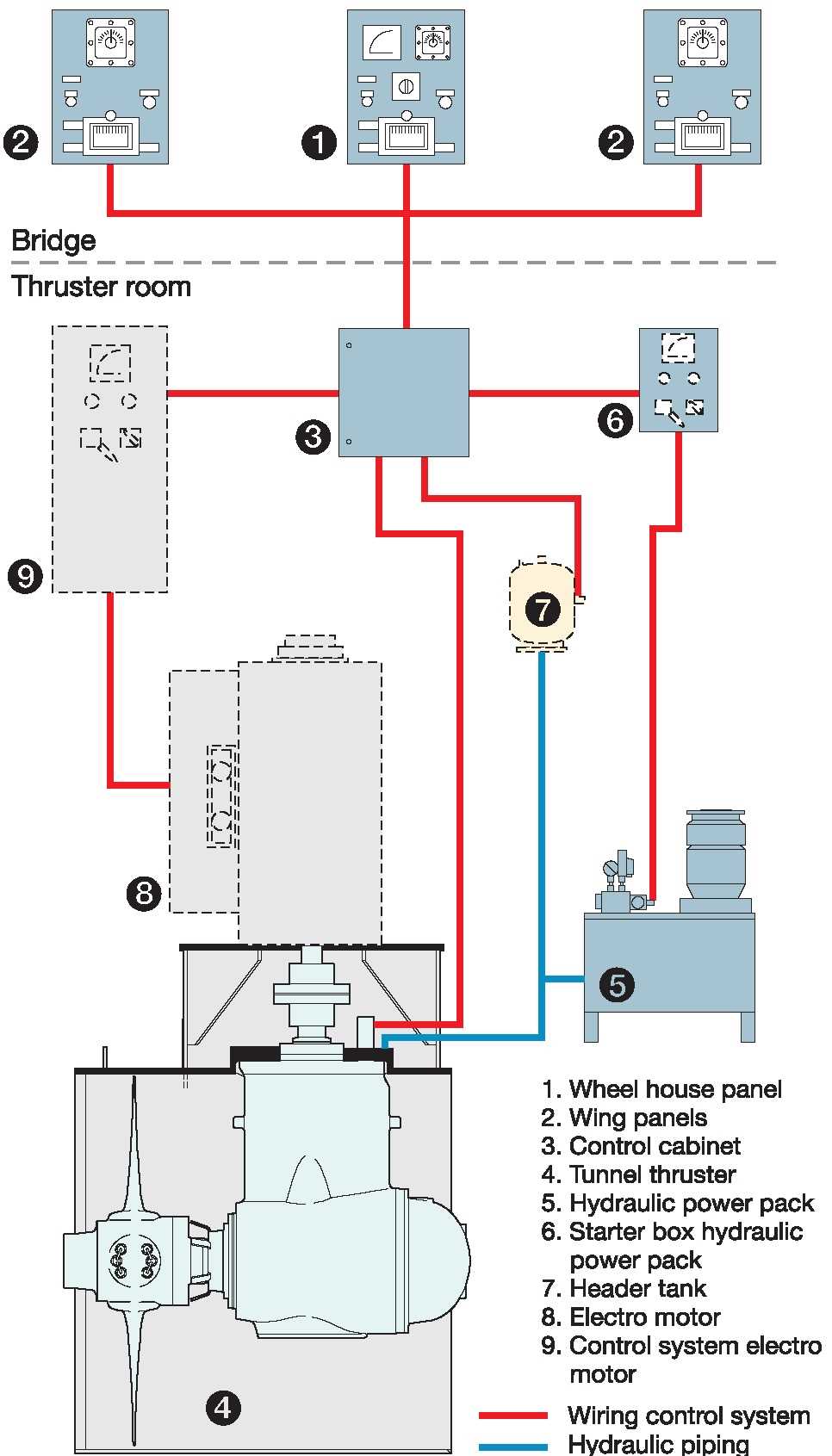

Electrical Connections in the System

The electrical infrastructure of any marine maneuvering equipment is critical for its optimal functionality. To ensure smooth and efficient performance, understanding the wiring layout and how components interact is essential. This section provides insights into the key electrical linkages within such systems.

Main Power Supply

The central power source must be properly connected to supply energy to the motor unit. This typically involves connecting the positive and negative terminals to ensure a stable current flow. Securing the wiring and avoiding loose connections helps prevent malfunctions during operation.

- Ensure cables are of the appropriate gauge for the current load.

- Use marine-grade connectors to resist corrosion.

- Regularly inspect terminals for signs of wear or damage.

Control Interface Wiring

The control panel, usually located at the helm, is wired to the primary unit through dedicated

Maintenance Tips for Long-Term Performance

To ensure optimal functionality and longevity of your marine propulsion system, regular upkeep is essential. By following a structured maintenance routine, you can prevent common issues and enhance the reliability of your equipment. Below are some key recommendations to consider for preserving performance over time.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect electrical connections | Monthly | Check for corrosion and secure connections to prevent power loss. |

| Clean intake and outlet vents | Every 3 months | Remove debris to ensure efficient airflow and cooling. |

| Check fluid levels | Every season | Maintain appropriate levels of hydraulic fluid for smooth operation. |

| Inspect seals and gaskets | Annually | Look for wear or leaks that could affect performance. |

| Test operational functionality | Before each use | Run a brief test to ensure the system responds correctly. |

Adhering to these maintenance practices will help you achieve a dependable performance from your equipment, reducing the likelihood of unexpected repairs and enhancing overall efficiency. Make maintenance a priority to enjoy uninterrupted use throughout the operational season.

Propeller and Motor Functionality

The efficiency of a propulsion system relies heavily on the interaction between the rotating blades and the driving mechanism. This combination plays a crucial role in maneuvering vessels, enabling precise movements and stability in the water. Understanding how these components operate together is essential for optimizing performance and ensuring reliable navigation.

The motor is responsible for generating the rotational force necessary to drive the propeller. This force translates into thrust, which propels the vessel in the desired direction. The design and efficiency of both elements directly influence the system’s overall effectiveness. Below is a table summarizing the key characteristics and functions of the propeller and motor:

| Component | Function | Key Characteristics |

|---|---|---|

| Propeller | Converts rotational motion into thrust | Blade shape, size, pitch |

| Motor | Generates rotational force | Power output, speed, torque |

By carefully considering the specifications and compatibility of both the rotating blades and the driving unit, users can enhance maneuverability and responsiveness. Regular maintenance and inspections ensure that these components function optimally, contributing to safe and efficient operations on the water.

Detailed View of Control Units

The control units play a crucial role in managing the operation of maneuvering systems on vessels. These components are designed to provide precise handling and response to various navigational needs, ensuring efficient movement and positioning in tight spaces. Understanding the structure and functionality of these units is essential for optimal performance.

Each control unit is typically equipped with several key features that enhance usability. Controls often include joysticks or switches, allowing the operator to direct movement with ease. Additionally, indicator lights provide real-time feedback on system status, alerting the user to any potential issues or the readiness of the unit.

Power supply connections are also an integral part of these systems, ensuring that control units receive the necessary energy to function effectively. Proper wiring and connections are essential for reliable operation, as any disruption can lead to performance failures. Regular inspections and maintenance of these components are recommended to prevent unexpected downtime.

Moreover, advancements in technology have led to the incorporation of digital interfaces in some control units. These interfaces can offer enhanced functionality, including programmable settings and compatibility with various navigational systems. As a result, operators can customize their experience, making maneuvers more intuitive and responsive.

Hydraulic Systems in Thruster Operations

Hydraulic mechanisms play a crucial role in the functionality of marine propulsion systems. These systems utilize fluid power to achieve the desired movement and maneuverability of watercraft. By employing pressurized fluids, operators can control various components, allowing for precise adjustments and improved handling in different maritime conditions.

Components of Hydraulic Systems

The effectiveness of hydraulic operations relies on several key elements. Hydraulic pumps generate the necessary pressure, while valves regulate the flow of fluid to different parts of the mechanism. Actuators convert hydraulic energy into mechanical motion, enabling swift and reliable movements. Understanding the interplay between these components is essential for maintaining optimal performance and ensuring safety during operations.

Advantages of Hydraulic Mechanisms

One of the primary benefits of hydraulic systems is their ability to transmit power efficiently over significant distances. This capability allows for compact designs that do not compromise on strength or responsiveness. Additionally, hydraulic systems are less susceptible to wear and tear compared to mechanical alternatives, leading to reduced maintenance needs and longer service life. As a result, these systems are highly valued in modern marine applications, providing enhanced control and flexibility on the water.

Troubleshooting Common Component Issues

When dealing with issues in propulsion systems, identifying and resolving common problems can greatly enhance performance and reliability. Understanding the typical malfunctions and their symptoms can help in quick diagnosis and repair, ensuring smooth operation.

Here are some frequent issues to consider:

- Electrical Failures: Check for loose connections, damaged wiring, or blown fuses that may prevent proper function.

- Hydraulic Problems: Inspect hydraulic fluid levels and look for leaks that could affect system pressure.

- Mechanical Wear: Examine components for signs of wear or corrosion that may hinder movement and efficiency.

- Noise and Vibrations: Unusual sounds may indicate misalignment or loose parts; conduct a thorough check to pinpoint the source.

To effectively troubleshoot these issues, follow these steps:

- Conduct a visual inspection of the entire system.

- Refer to manufacturer documentation for specific operational guidelines.

- Test electrical connections using a multimeter to ensure proper voltage levels.

- Monitor performance during operation to identify any irregularities.

- Replace any worn or damaged components as necessary.

By systematically addressing these common issues, operators can maintain the functionality and longevity of their propulsion systems, ensuring a safe and enjoyable experience.

Choosing the Right Replacement Parts

Selecting suitable components for marine propulsion systems is crucial for maintaining performance and safety. Proper replacement ensures that your equipment operates efficiently, reducing the risk of malfunctions and extending its lifespan.

When looking for new components, consider compatibility with your existing system, the quality of materials, and the reputation of the manufacturer. Here are some key factors to keep in mind:

| Factor | Description |

|---|---|

| Compatibility | Ensure that the new components are designed to fit with your current setup to avoid issues during installation. |

| Quality | Opt for high-quality materials that can withstand marine environments, ensuring durability and reliability. |

| Manufacturer Reputation | Research the manufacturer’s track record for producing dependable components. Trusted brands often provide warranties and customer support. |

| Price | Compare prices but avoid compromising on quality for cost. Investing in reliable components can save you money in the long run. |

| Availability | Check the availability of the components from suppliers to ensure timely replacement without significant downtime. |

By carefully evaluating these factors, you can make informed decisions that enhance the efficiency and safety of your marine operations.

Integration with Other Boat Systems

Effective navigation and maneuvering require seamless communication between various systems onboard. When these components are interconnected, they enhance overall vessel performance, ensuring smoother operations and greater control in diverse marine conditions.

When considering the integration of maneuvering devices, several key systems must be taken into account:

- Steering System: The interaction between the maneuvering unit and the steering mechanism is crucial for coordinated movement, allowing for precise directional control.

- Electrical System: A reliable power supply is essential for optimal functionality. Proper integration ensures that electrical connections are secure and able to handle the required load.

- Engine Controls: Synchronizing with propulsion systems enables more effective use of power, allowing for responsive handling during various maneuvers.

- Navigation Systems: Linking with navigation aids enhances situational awareness, enabling better decision-making while maneuvering in tight spaces.

- Safety Systems: Integration with safety features, such as alarms and monitoring systems, ensures immediate response to potential issues, safeguarding both the vessel and crew.

Proper installation and configuration are vital to achieving successful integration. Regular maintenance checks can help identify potential issues before they escalate, ensuring the reliability of interconnected systems.

Upgrading to a More Powerful Unit

Enhancing your vessel’s maneuverability and control can be achieved by opting for a more robust model. This improvement not only boosts performance but also contributes to a smoother sailing experience, especially in challenging conditions.

When considering an upgrade, it’s essential to evaluate several factors to ensure the new unit meets your requirements effectively:

- Power Rating: Assess the power output needed for your vessel’s size and type of use.

- Installation Requirements: Determine if the new unit fits within the existing space and connections.

- Weight Considerations: Ensure that the added weight will not adversely affect the boat’s balance.

- Control Systems: Verify compatibility with your current control mechanisms for seamless operation.

- Durability and Reliability: Choose a unit that promises longevity and dependable performance in various conditions.

Consulting with professionals or reviewing user feedback can also provide insights into the best options available. Making an informed choice will enhance your vessel’s capabilities and ensure a safer, more enjoyable experience on the water.