When it comes to mastering construction machinery, a thorough comprehension of its inner workings is essential. This knowledge empowers operators to maintain and troubleshoot equipment effectively, ensuring optimal performance in various tasks.

Exploring the intricate layout of each unit reveals a symbiotic relationship between components, showcasing how they work together to achieve stability and efficiency. By delving into the structural aspects, users can uncover the ultimate secrets to effective operation.

Whether you’re a seasoned professional or a novice, grasping the arrangement and function of each element is crucial for successful machinery management. This guide aims to provide insight into the essential features that contribute to overall functionality.

Overview of Wacker BS50-2 Parts

This section aims to provide a comprehensive understanding of the various components that make up the machinery. Each element plays a crucial role in ensuring optimal performance and reliability, contributing to the overall functionality of the equipment. Familiarity with these components can assist in maintenance and troubleshooting, enhancing operational efficiency.

Key Components

The following table outlines some of the essential elements that are integral to the effective operation of the machine:

| Component | Description |

|---|---|

| Engine | Power source that drives the equipment, providing necessary energy for operation. |

| Vibrating Plate | The main working surface that compacts material through vibrations. |

| Handle | Control mechanism that allows the operator to maneuver and direct the machine. |

| Fuel Tank | Reservoir that holds the fuel needed for engine operation. |

| Rubber Mat | Provides cushioning and reduces vibrations transferred to the operator. |

Importance of Understanding Components

Knowledge of these critical elements aids in effective maintenance practices and facilitates the identification of issues that may arise during operation. A well-informed operator is better equipped to perform repairs and ensure longevity of the equipment.

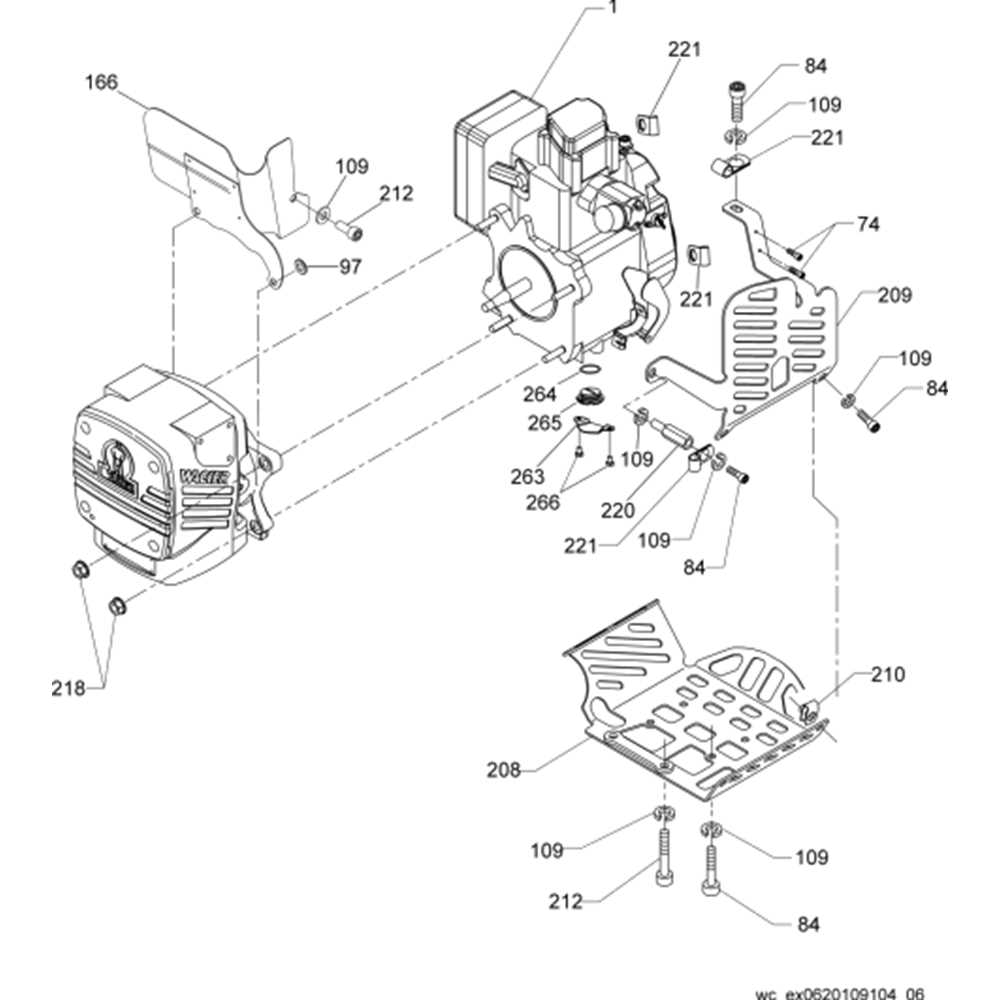

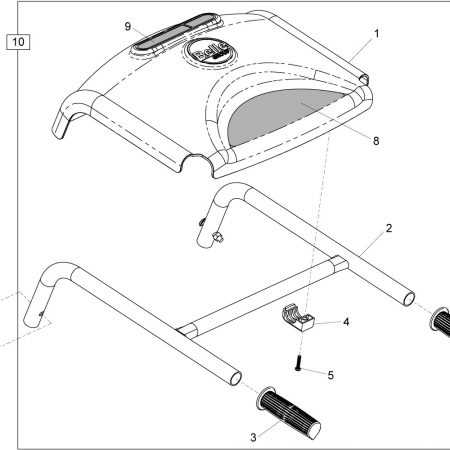

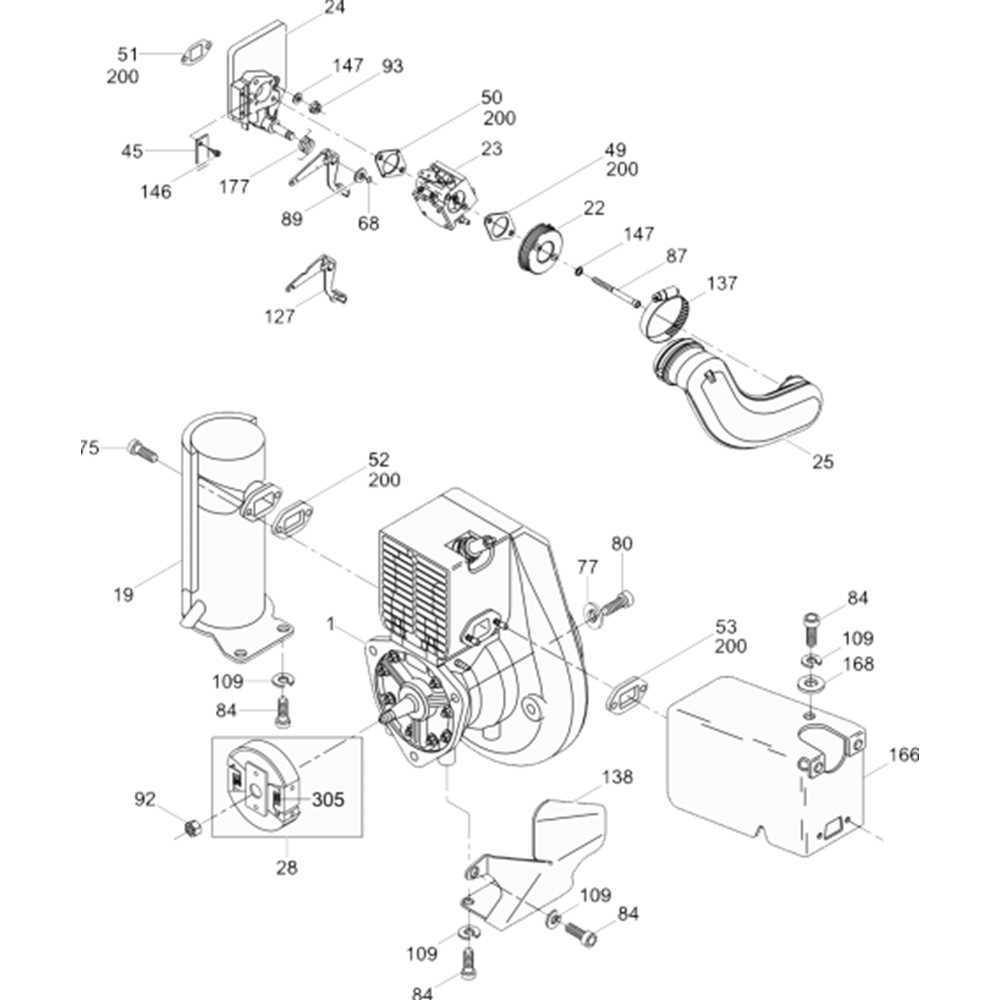

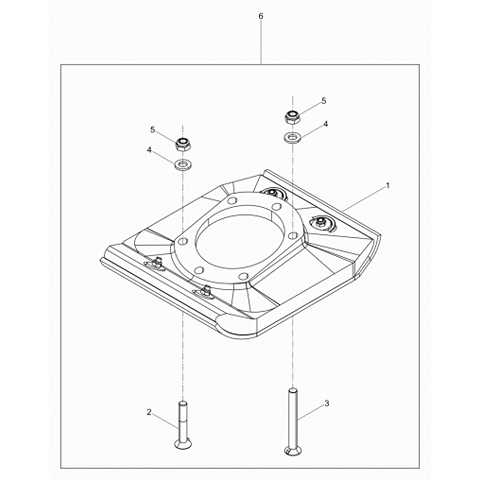

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and troubleshooting of machinery. A visual representation serves as a crucial tool, helping users identify and locate individual elements within the equipment. This structured illustration not only simplifies the assembly process but also enhances understanding of how different pieces interact with one another.

When examining the visual layout, it’s important to recognize that each section corresponds to a specific function or role within the overall system. Familiarity with these functions can significantly improve operational efficiency. Furthermore, knowing where each part fits can aid in timely replacements and repairs, reducing downtime and ensuring optimal performance.

Ultimately, having a clear grasp of the components’ arrangement empowers users to maintain their equipment proactively, leading to a more reliable and effective workflow. Engaging with such representations allows for a deeper appreciation of the machinery’s design and operational integrity.

Key Components of Wacker BS50-2

This section explores the essential elements that contribute to the functionality and efficiency of this compact vibratory machine. Understanding these components can help users maintain and operate the equipment effectively.

Main Features

- Engine: Provides the necessary power for operation.

- Vibration System: Enhances soil compaction through effective oscillation.

- Base Plate: Ensures stability and effective ground contact.

Supporting Elements

- Handle: Facilitates maneuverability and control.

- Fuel Tank: Stores the energy source for operation.

- Safety Features: Includes guards and emergency shut-off mechanisms.

Importance of Accurate Diagrams

Precise visual representations are crucial in any technical field, serving as a foundational tool for understanding complex machinery. They facilitate communication, enhance learning, and ensure proper maintenance and assembly processes.

Benefits of Clarity

- Improved comprehension of intricate systems.

- Minimized errors during repairs and assembly.

- Enhanced training for new personnel.

Impact on Efficiency

- Streamlined troubleshooting procedures.

- Reduced downtime due to faster problem identification.

- Increased overall operational effectiveness.

Common Issues with Wacker BS50-2

This section highlights frequent problems encountered with a specific type of vibratory plate compactor, which can hinder performance and efficiency. Understanding these issues is essential for maintenance and operational longevity.

- Starting Difficulties:

Many operators face challenges when attempting to start the machine. This may result from:

- Fuel issues, such as contamination or old fuel.

- Electrical problems, including battery failure.

- Blocked air filters.

- Vibration Irregularities:

Inconsistent vibration can affect compaction effectiveness. Common causes include:

- Worn or damaged isolation mounts.

- Imbalanced or broken exciter assembly.

- Excessive Noise:

Unusual loud sounds during operation can indicate:

- Loose components or fasteners.

- Worn bearings or bushings.

- Hydraulic Issues:

For models equipped with hydraulic systems, look out for:

- Leaks in hoses or connections.

- Low fluid levels.

- Faulty hydraulic pumps.

- Wear and Tear:

Components may wear out over time, leading to:

- Decreased performance.

- Need for frequent replacements.

Addressing these common issues promptly can ensure optimal performance and extend the lifespan of the equipment.

How to Read the Parts Diagram

Understanding an illustration that outlines components can be crucial for effective maintenance and repair. This guide will help you navigate through the various sections and labels, allowing for a clearer comprehension of how each element interacts within the assembly.

Identifying Components

Each item is usually labeled with a unique identifier. Locate these labels on the visual to connect them with the corresponding list of specifications. This step is vital for ordering the correct replacements or recognizing what needs attention during inspections.

Interpreting Relationships

Pay attention to how the elements are arranged. The layout often indicates their physical relationships, such as connections and alignments. Understanding these relationships can assist in troubleshooting issues and ensuring all parts function seamlessly together.

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery requires consistent care and attention. By implementing regular maintenance practices, users can prevent potential issues and enhance performance efficiency over time.

Regular Inspections: Schedule frequent evaluations to identify wear and tear. Early detection of problems can save time and costs.

Cleanliness: Keep the equipment free from dirt and debris. Regular cleaning helps maintain functionality and prevents corrosion.

Lubrication: Apply appropriate lubricants to moving parts. This minimizes friction and extends the life of components.

Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures. This ensures optimal performance and warranty compliance.

Store Properly: When not in use, store equipment in a dry, protected environment. Proper storage conditions prevent damage from environmental factors.

By integrating these practices, users can significantly enhance the durability and effectiveness of their machinery, ensuring it operates at its best for years to come.

Where to Find Replacement Parts

When it comes to sourcing components for your machinery, various avenues can provide the necessary resources. Whether you’re looking to replace worn-out items or enhance performance, knowing where to search is crucial.

- Authorized Dealers: These outlets guarantee genuine components that meet manufacturer standards.

- Online Retailers: Websites specializing in machinery parts offer a vast selection with user-friendly navigation.

- Local Distributors: Check regional suppliers who might have stock on hand, reducing wait times for delivery.

- Second-Hand Market: Explore platforms like eBay or specialized forums for used components in good condition.

Always compare prices and read reviews to ensure quality before making a purchase.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures for assembling and disassembling the equipment efficiently and safely. Proper techniques not only ensure optimal functionality but also prolong the lifespan of the machine.

Preparation Steps

- Gather necessary tools such as wrenches, screwdrivers, and safety gear.

- Ensure the work area is clean and free of any obstructions.

- Review the manufacturer’s manual for specific instructions and safety precautions.

Assembly Procedure

- Begin by aligning the main components according to the designated layout.

- Secure each part using the appropriate fasteners, ensuring they are tightened to the recommended torque settings.

- Connect any electrical or hydraulic lines as specified, checking for proper connections.

- Conduct a thorough inspection to verify that all components are securely attached and aligned correctly.

Disassembly Procedure

- Disconnect any power sources and remove safety guards.

- Loosen and remove fasteners in the reverse order of assembly to prevent damage.

- Carefully detach components, ensuring not to force any parts apart.

- Organize all removed items for easier reassembly later.

Following these guidelines will facilitate a smooth process, allowing for effective maintenance and repair of the equipment when needed.

Cost of Wacker BS50-2 Components

The expense associated with essential elements of construction machinery can significantly impact overall project budgets. Understanding the financial implications of acquiring various components is crucial for both operators and contractors. This section delves into the pricing landscape of individual units, offering insights into what to expect when sourcing replacements or upgrades.

When considering the cost of these specific machine components, factors such as brand reputation, material quality, and availability come into play. Generally, prices can vary widely based on these elements, with some units being more accessible due to higher production volumes, while others might command a premium due to their specialized nature.

In addition, the market dynamics, including supply chain conditions and regional demand, influence pricing trends. For instance, fluctuations in raw material costs can directly affect the final price tag of crucial components, making it important for buyers to stay informed about current market conditions.

Ultimately, investing time in researching and comparing prices from various suppliers can lead to cost savings. A thorough understanding of the financial landscape associated with these essential components can empower users to make informed purchasing decisions and optimize their operational efficiency.

Compatibility with Other Models

Understanding the interoperability of different machinery components is essential for ensuring optimal performance and maintenance. Certain models may share similarities in design and function, allowing for cross-compatibility that can be beneficial for users seeking replacements or upgrades.

Similar Models

Several machines exhibit design traits that align closely with each other. Here are some examples:

- Model A: Known for its robust engine and similar operational specifications.

- Model B: Shares many internal features, making it a viable option for parts interchangeability.

- Model C: Designed for comparable applications, often using the same type of components.

Benefits of Compatibility

Utilizing interchangeable components can yield several advantages:

- Cost-effectiveness: Users can often find more affordable replacement options.

- Availability: Some components may be easier to source from different models.

- Versatility: Enhanced flexibility in machinery configurations and setups.

By exploring compatibility among different models, operators can ensure their equipment remains efficient and reliable, while also minimizing downtime. Always consult specifications to verify compatibility before proceeding with any part exchanges.

FAQs About Wacker BS50-2 Parts

This section aims to address common inquiries regarding components and accessories associated with a specific vibratory plate model. Understanding these elements can help users make informed decisions and maintain optimal performance.

-

What are the essential components of this equipment?

The main elements include the base plate, engine, and vibration mechanism. Each plays a crucial role in ensuring effective operation.

-

How can I identify a defective part?

Look for signs such as unusual noises, reduced vibration efficiency, or visible wear and tear. Regular inspection is recommended.

-

Where can I purchase replacement items?

Authorized dealers, online marketplaces, and specialized equipment retailers are good sources for genuine components.

-

Are there maintenance tips for these components?

Regular cleaning, lubrication, and timely replacement of worn items will extend the lifespan of the machinery.

-

Can I use aftermarket components?

While aftermarket options may be available, it’s essential to ensure compatibility and quality to avoid operational issues.

Customer Reviews and Experiences

This section explores the insights and feedback from users regarding their interactions with a particular model of construction equipment. Many individuals share their experiences, highlighting both the strengths and challenges they faced while operating the machinery. The aim is to provide a comprehensive overview of customer satisfaction and real-world performance.

Users often emphasize the durability and reliability of the device, noting how it stands up to rigorous job site demands. Additionally, several reviews mention the ease of use, making it accessible for both seasoned professionals and newcomers alike. However, some feedback points to a need for improvement in certain functionalities, prompting discussions on possible enhancements.

Ultimately, these reviews serve as valuable resources for potential buyers, allowing them to delve deeper into the practical applications and performance metrics of the equipment. By understanding firsthand accounts, customers can make informed decisions that align with their project requirements.