Understanding the structure and essential elements of modern equipment is vital for ensuring smooth operations and effective maintenance. This section provides an in-depth look at the key mechanical components that drive reliable performance and durability.

Each element plays a crucial role in the overall function of the machine, from the engine to the supporting structures. A clear understanding of how these critical parts work together can help

Understanding the Wacker Neuson BS50 4S Components

In this section, we will explore the various elements that make up the core of a reliable construction tool. These essential components ensure the machine operates efficiently, providing the necessary force and functionality required for demanding tasks. Each part plays a crucial role in maintaining the performance and durability of the equipment over time.

Key Mechanical Elements

The mechanical structure is built to withstand heavy use. The core components include the engine, which powers the system, and the transmission, responsible for transferring energy. Additional elements like the fuel system and cooling mechanisms ensure the equipment runs smoothly and efficiently.

Supporting Systems

In addition to the mechanical aspects, supporting systems such as air filtration and vibration control enhance the tool’s longevity and operator comfort. These systems help minimize wear and tear, making sure the equipment remains in top condition during intensive use.

Key Features of the BS50 4S Model

This model is designed for efficiency and reliability, making it a standout option for various construction and compaction tasks. It delivers consistent performance in demanding environments, ensuring long-term use with minimal maintenance. The advanced engineering behind this machine enhances productivity while maintaining user comfort.

High-Performance Engine

Equipped with a powerful engine, this model ensures optimal fuel efficiency and reduced emissions. It is built to handle tough conditions without compromising on power or performance, providing reliable operation across various job sites.

Durability and Ease of Use

The robust construction of the machine ensures longevity, even in harsh working conditions. Additionally, the ergonomic design facilitates easy handling, reducing operator fatigue and improving overall work efficiency.

How to Identify Engine Parts

Understanding the various components within an engine is crucial for effective maintenance and repairs. Recognizing these elements can ensure smoother operation and help prevent major issues from occurring.

Key elements within the engine include several mechanical components that work together to generate power. Identifying these components requires basic knowledge of their function and location.

For example, many engines rely on a cylinder, piston, and valves for compression and combustion. Additionally, the crankshaft, which is connected to the piston, transforms linear motion into rotational force.

To properly identify engine components, it’s essential to have a clear understanding of how each part interacts and supports the overall engine operation.

Commonly Replaced Parts in the BS50 4S

Over time, regular maintenance of equipment becomes essential to ensure its optimal performance. Certain components are more prone to wear and tear due to continuous operation, requiring timely replacement. Identifying these key elements can help prolong the lifespan of your tool and avoid potential breakdowns.

Filters are often subject to frequent replacement, as they play a critical role in protecting the engine by keeping out dirt and debris. Keeping filters clean and replacing them when necessary ensures efficient operation.

Ignition systems are another commonly affected area, particularly the spark plug, which needs regular inspection and changing to maintain smooth starting and consistent performance.

Additionally, vibration dampeners tend to wear out over time due to constant exposure to stress, reducing the efficiency of the machine if not attended to. Regular checks and replacements are crucial to minimize excessive vibrations during use.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the durability and smooth operation of any equipment. Consistent maintenance not only extends the life of the machine but also helps to prevent unexpected breakdowns, keeping performance at its peak.

Regular Inspection

Performing routine checks is one of the most effective ways to maintain longevity. Pay close attention to any signs of wear and tear and address issues immediately to avoid further complications.

- Check for oil leaks and fluid levels regularly.

- Ensure that all bolts and screws are properly tightened.

- Look for any abnormal vibrations or noises during operation.

Cleaning and Lubrication

Keeping components clean and well-lubricated is crucial for minimizing friction and preventing overheating. Dirt and debris can cause parts to deteriorate quickly, while lubrication reduces wear between moving parts.

- Remove dirt, dust, and debris after each use.

-

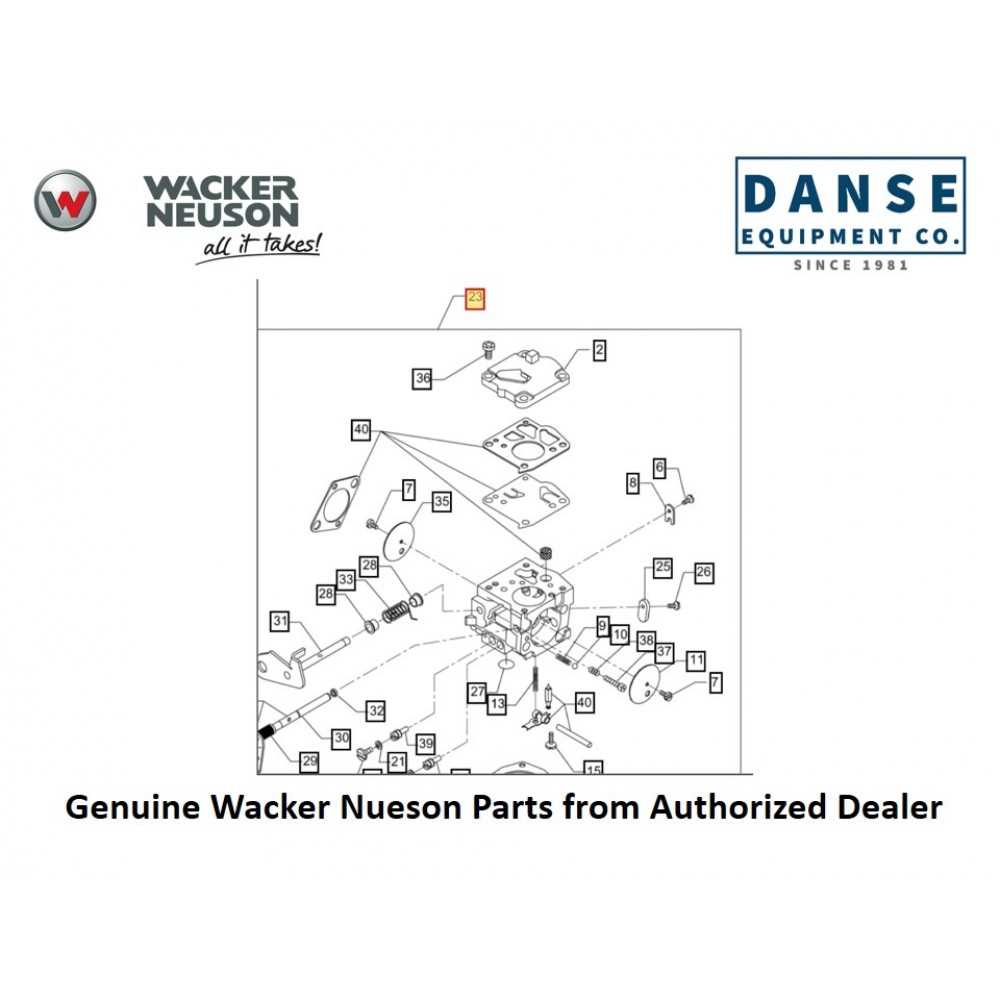

Fuel System Overview and Diagram

The fuel system is a critical component of any engine, responsible for delivering the necessary energy to ensure optimal performance. This section provides a comprehensive look at the various elements involved in the fuel delivery process, as well as a visual representation of these components.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel until it is needed for combustion.

- Fuel Pump: Moves fuel from the tank to the engine at the required pressure.

- Fuel Filter: Cleans the fuel by removing impurities and contaminants.

- Fuel Injectors: Atomize the fuel for efficient combustion in the engine’s cylinders.

- Fuel Lines: Transport fuel between the tank, pump, filter, and injectors.

Understanding the Flow of Fuel

The flow of fuel through the system is essential for maintaining engine efficiency. It begins at the tank, where the fuel is drawn by the pump. The pump then pushes the fuel through the filter, ensuring that any debris is removed before it reaches the injectors. Finally, the fuel injectors deliver the precise amount of fuel into the engine’s cylinders, allowing for optimal combustion and power generation.

Exhaust System Components Breakdown

The exhaust system plays a crucial role in the overall functionality and efficiency of any combustion engine. Understanding its various elements is essential for maintenance and troubleshooting. Each component contributes to the effective expulsion of gases, ensuring optimal performance and compliance with environmental regulations.

Key Elements of the Exhaust System

Among the vital parts of the exhaust system are the manifold, catalytic converter, and muffler. The manifold collects exhaust gases from the engine cylinders and directs them into the exhaust pathway. Following this, the catalytic converter reduces harmful emissions before the gases reach the atmosphere. Lastly, the muffler minimizes noise produced during the gas expulsion process, ensuring a quieter operation.

Maintenance Considerations

Regular inspections of these components are necessary to prevent leaks and maintain efficiency. Signs of wear, such as rust or unusual noises, can indicate potential issues that require immediate attention. Proper maintenance not only prolongs the life of the exhaust system but also enhances the overall performance of the engine.

Vibration System Parts Explained

The vibration system is a crucial component of machinery designed to enhance efficiency and performance. Understanding the individual elements that contribute to this system allows for better maintenance and optimization, leading to improved operational results.

Vibration Motor: This is the heart of the system, generating oscillations that facilitate effective operation. The motor’s performance directly impacts the overall functionality of the machinery.

Mounts: These components serve to isolate vibrations from the machine’s frame, ensuring stability and reducing wear on surrounding parts. Properly functioning mounts enhance longevity and minimize maintenance requirements.

Weights: Often adjustable, these elements help regulate the amplitude and frequency of vibrations. By fine-tuning the weights, operators can achieve desired performance levels tailored to specific tasks.

Bearings: Essential for smooth operation, bearings reduce friction between moving parts, contributing to the overall efficiency of the vibration system. Regular inspection and replacement are vital to prevent breakdowns.

Control Mechanisms: These systems allow operators to adjust settings based on operational needs. By managing the vibration output, they can enhance performance and adapt to various working conditions.

Air Filtration System and Key Elements

The air filtration system is a crucial component that ensures optimal performance and longevity of machinery. It serves the purpose of trapping dust, debris, and other contaminants, preventing them from entering the engine and causing damage. By maintaining clean air intake, this system contributes significantly to the overall efficiency and reliability of the equipment.

Key elements of an effective air filtration setup include the air filter, pre-cleaner, and housing. The air filter itself is designed to capture fine particles, while a pre-cleaner may be utilized to remove larger debris before it reaches the main filter. Proper sealing and installation of these components are essential to prevent any bypass of unfiltered air, ensuring that only clean air enters the engine.

Regular maintenance and replacement of the air filter are vital practices to uphold performance standards. Neglecting these aspects can lead to reduced engine efficiency, increased fuel consumption, and potential operational failures. Therefore, understanding the importance of the air filtration system and its key components is essential for effective machinery management.

Drive Mechanism Components and Functions

The drive mechanism is a critical assembly that converts energy into motion, enabling various machines to perform efficiently. Understanding its components and their respective roles is essential for ensuring optimal operation and maintenance.

- Engine: The heart of the mechanism, providing the necessary power to initiate movement.

- Transmission: This component transmits power from the engine to the wheels or other moving parts, allowing for speed and torque adjustments.

- Clutch: It connects and disconnects the engine from the transmission, enabling smooth gear changes and preventing stalling.

- Drive Shaft: A crucial link that transfers power from the transmission to the wheels, facilitating movement.

- Bearings: These reduce friction between moving parts, enhancing efficiency and prolonging component life.

- Gears: They adjust the torque and speed of the machine, allowing for versatile performance across different tasks.

Each component plays a vital role in the drive mechanism’s overall functionality, contributing to the machine’s effectiveness and reliability.