In the world of construction, efficiency and durability of machinery play a crucial role in getting the job done right. When working on large-scale projects, having the right machine for mixing materials can greatly impact both time and quality. It’s essential to be familiar with the inner workings of such equipment, as it ensures proper maintenance and optimal performance over time.

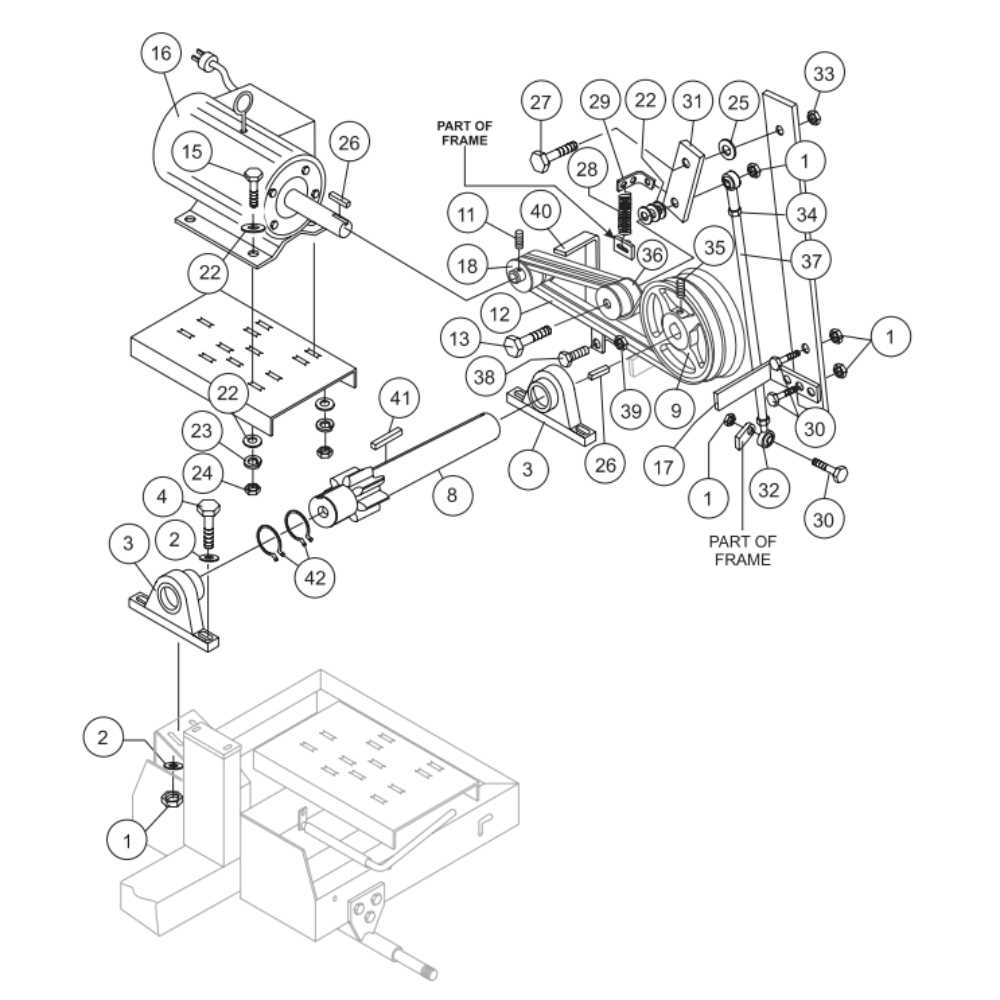

Every piece of construction machinery is made up of various interconnected elements that contribute to its overall function. Knowing how these elements fit together allows for easier troubleshooting when something goes wrong. This knowledge also empowers operators to replace or repair worn-out elements with minimal downtime, keeping the machine running smoothly on the job site.

Focusing on the key elements of your equipment provides a deeper understanding of how each piece functions in relation to the whole. By identifying the individual sections, users can make informed decisions about repair or replacement when needed, ensuring long-term operational success and reli

Understanding the Parts of a Whiteman Mortar Mixer

When it comes to machines used for heavy-duty tasks, each component plays a crucial role in ensuring smooth and efficient operation. These machines rely on various elements working together to achieve their intended function. Recognizing how each piece fits into the overall system helps users maintain and troubleshoot them more effectively.

Engine: The core of the equipment, responsible for powering the entire system. Its performance directly influences how well the machine handles the workload, making it a vital component to monitor regularly.

Blades: These rotating elements are designed to blend materials thoroughly. Their specific shape and movement ensure that the substances are mixed uniformly, which is essential for consistent results.

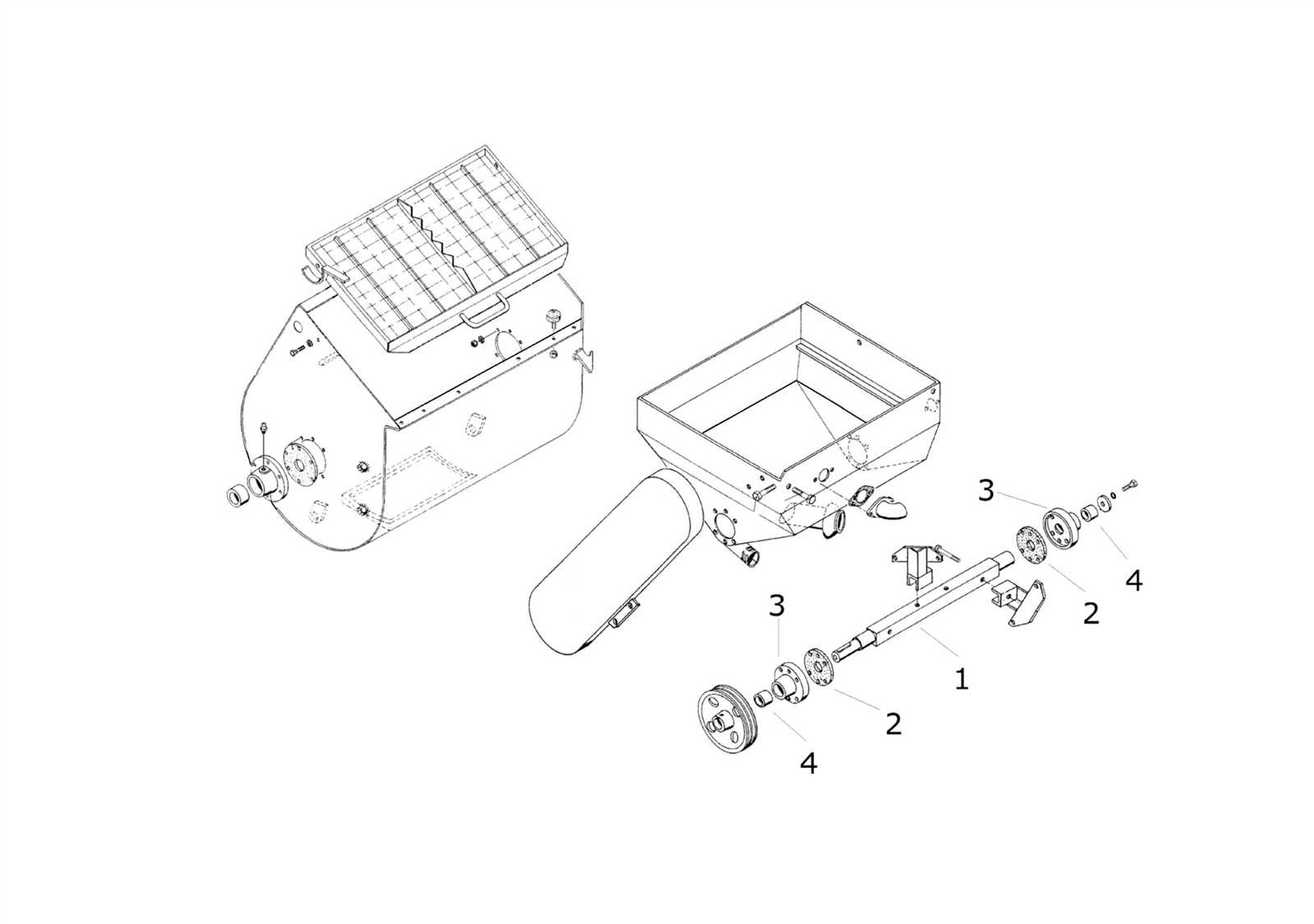

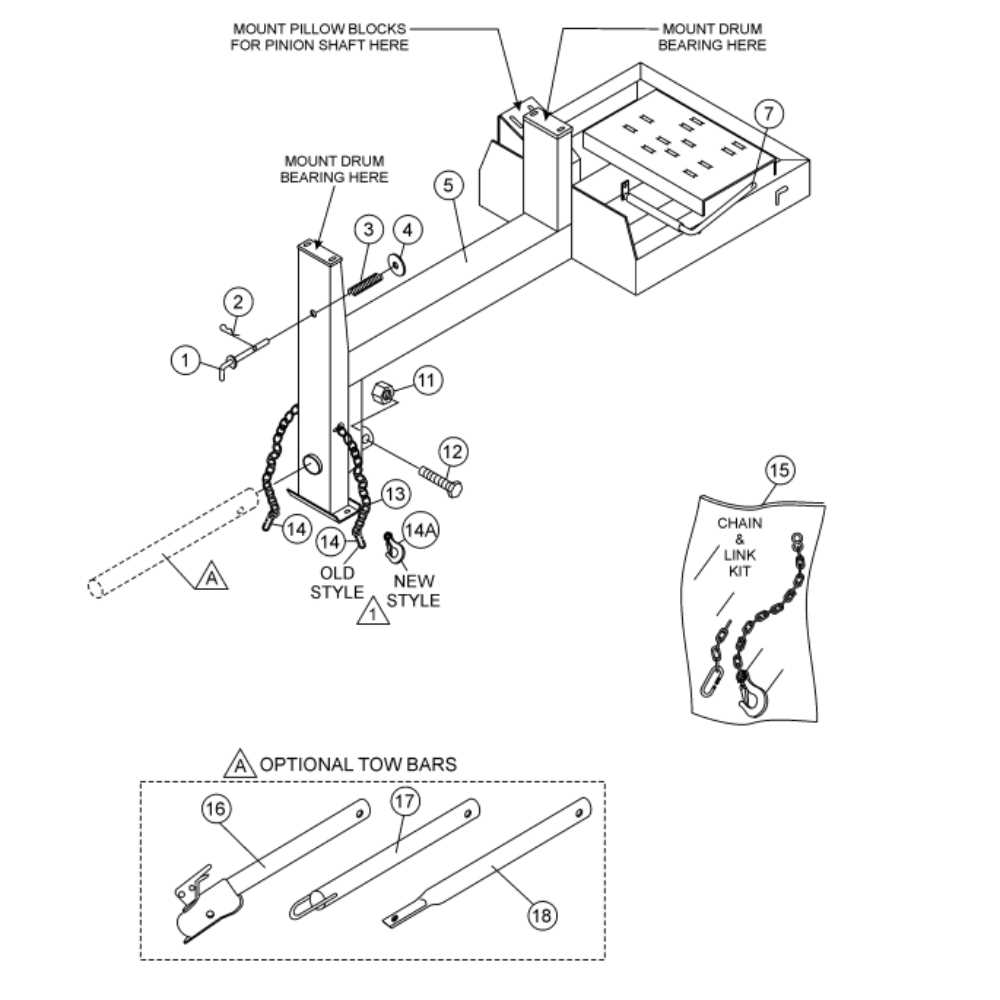

Drum: This rotating vessel holds the materials being processed. Its size and orientation are critical in maintaining balance and efficiency, allowing for optimal processing during operation.

Frame: The sturdy support structure that holds everything

Key Components of a Mortar Mixer

Every machine used for blending building materials relies on a variety of core elements to ensure proper function and durability. These essential components work together to handle tough workloads and provide efficient mixing, making the equipment reliable for continuous use in construction settings.

Engine and Power Source

The engine serves as the driving force behind the operation, converting energy into motion. It powers the machine to rotate and mix materials effectively. Some units are powered by gas, while others may rely on electric motors for quieter, more eco-friendly operation.

Drum and Mixing Blades

The drum is a large cylindrical container where materials are loaded. Inside, durable blades spin to create the perfect consistency. The angle and design of these blades are critical for achieving smooth and uniform blending of different components.

-

How the Drum Functions in Mixing

The rotating container plays a crucial role in blending materials, ensuring a consistent and even mixture. Its movement, combined with the specific shape of the inner surface, helps combine components efficiently. By continuously rotating, the drum prevents settling and clumping, promoting a smooth consistency.

Rotation for Consistency

The continuous turning of the drum is essential to ensure all ingredients are evenly mixed. As it spins, the materials inside are lifted and dropped, creating a repetitive cycle of movement. This process enhances the distribution of different elements, reducing the risk of uneven results.

Optimized Interior Design

The inner surface of the drum often includes ridges or specialized features that assist in the blending process. These design elements help to scrape and fold the mixture, allowing it to be properly combined with minimal effort. This structure ensures the contents remain in motion, avoiding any stagnation or separation

The Role of the Engine in Mortar Mixing

The engine serves as the driving force behind the smooth and efficient operation of concrete blending machines. Its power output directly influences the speed and consistency of the blend, ensuring that materials are thoroughly mixed to the required standards. Without a reliable motor, achieving optimal performance would be difficult, making the engine a critical component in the entire process.

Power and Efficiency

At the heart of the mixing process is the engine’s ability to deliver consistent energy. A well-functioning motor ensures that the rotation speed remains steady, providing an even blend of materials. The efficiency of the engine also determines fuel consumption, making it vital for both performance and cost management.

Maintenance and Longevity

Proper care of the engine is essential for extending its lifespan and ensuring uninterrupted operation. Regular maintenance, including timely oil changes and inspections, helps prevent mechanical failures and keeps the motor running

Identifying and Replacing Worn Mixer Blades

Over time, the working components responsible for blending materials can wear down, reducing efficiency and potentially causing other mechanical issues. Recognizing the signs of wear early is key to maintaining optimal performance, ensuring smoother operation, and avoiding costly repairs. In this section, we will explore how to spot these signs and provide guidance on the replacement process.

Common Signs of Blade Wear

Blades that have been in use for an extended period often show visible signs of deterioration, such as dull edges, cracks, or deformation. Reduced blending effectiveness is another clear indicator. If the consistency of the material being processed is uneven, it’s likely time to inspect the working elements for wear and tear.

Steps to Replace Worn Blades

Replacing these components requires careful attention to detail and the right tools. Ensure that you have the correct replacement parts on hand. Follow the manufacturer’s

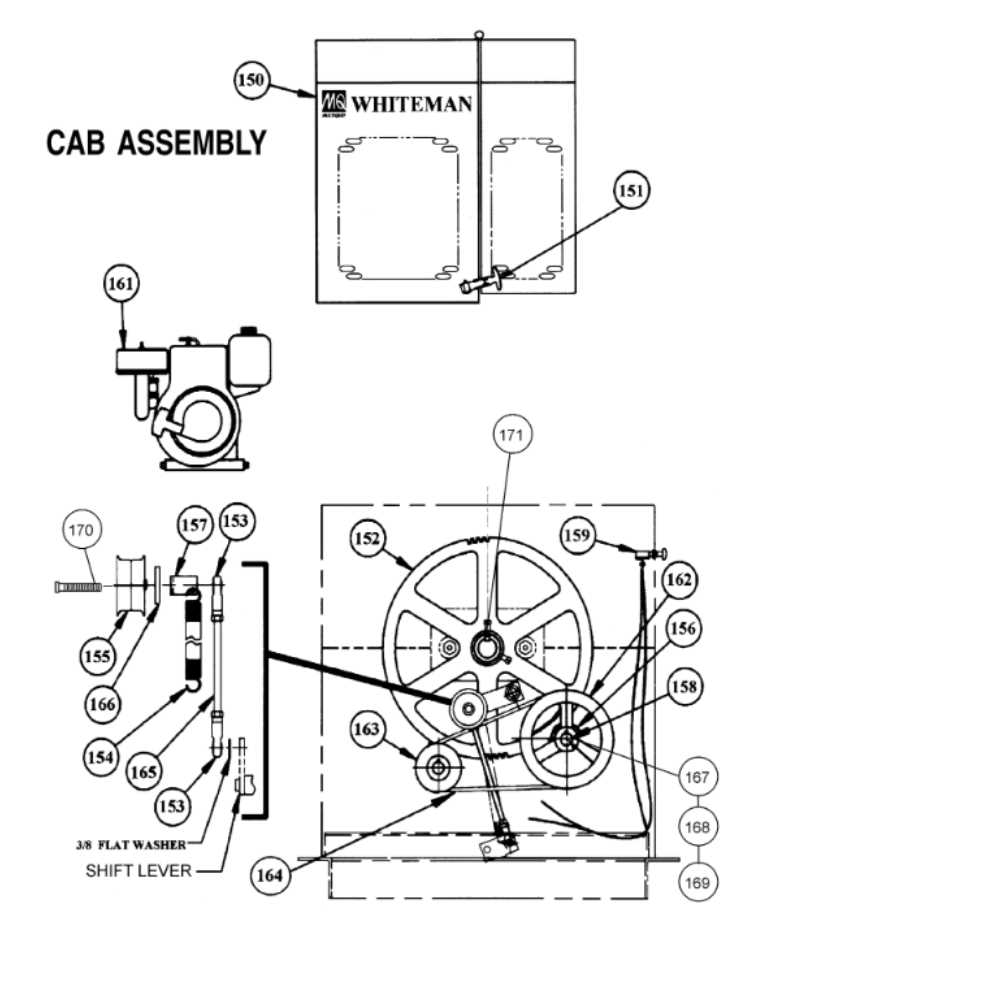

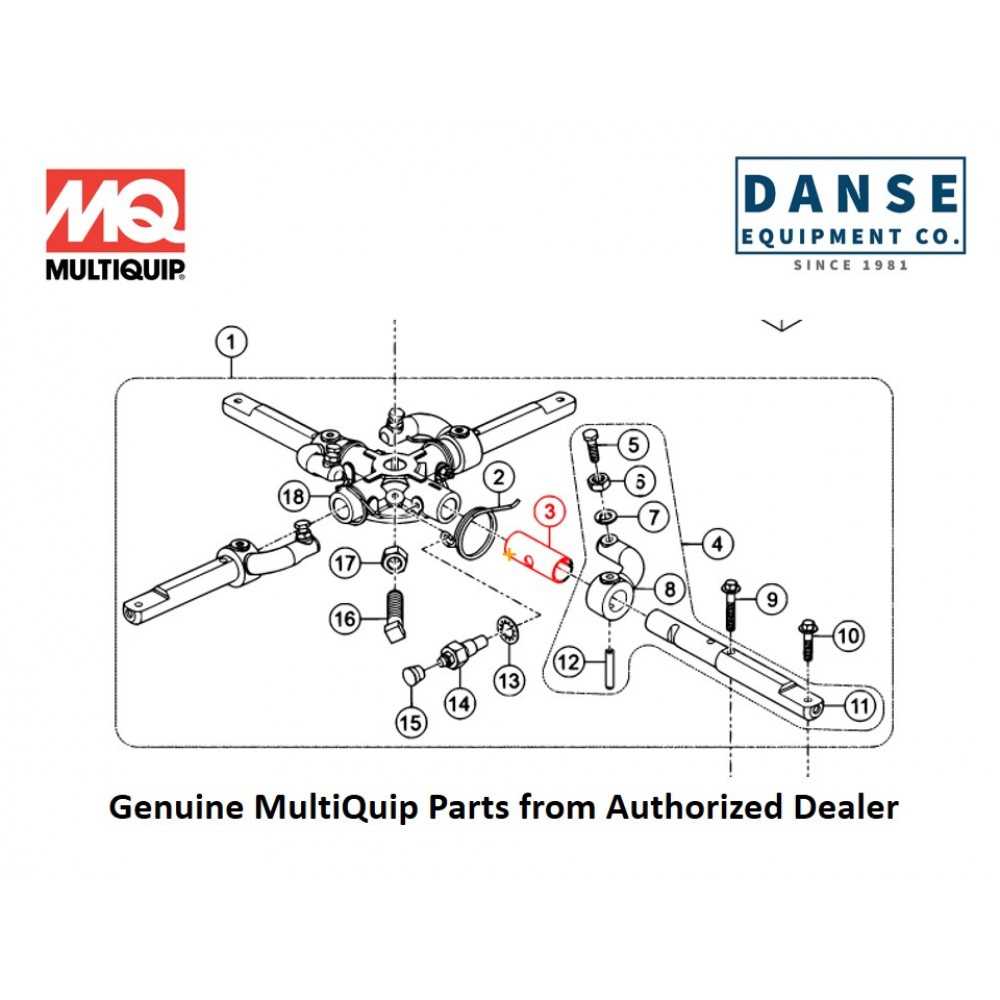

Clutch Mechanism: Ensuring Smooth Operation

The clutch mechanism plays a pivotal role in the functionality of various equipment by facilitating the seamless transfer of power between different components. This intricate system is designed to engage and disengage various parts, ensuring efficient operation during use. A well-functioning clutch is essential for maintaining optimal performance and prolonging the lifespan of the machinery.

Components of the Clutch System

Understanding the main elements of the clutch system helps in recognizing its importance. Key components include:

- Pressure Plate: This component applies force to the friction disc, ensuring a secure connection when engaged.

- Friction Disc: Responsible for transmitting power, it grips the flywheel to initiate movement.

- Release Bearing: Facilitates the disengagement of the clutch, allowing for smooth shifts between different operational modes.

- Clutch Fork: This part aids in the mechanical action required to engage or disengage the system.

Importance of Regular Maintenance

To ensure longevity and optimal performance, routine inspections and maintenance of the clutch mechanism are crucial. Regular checks can prevent potential issues such as:

- Excessive wear on components, which may lead to failure.

- Improper engagement or disengagement, affecting overall performance.

- Fluid leaks that may compromise the system’s efficiency.

By understanding the clutch mechanism and its components, operators can ensure that their machinery operates smoothly and reliably.

Understanding the Importance of the Gearbox

The gearbox plays a crucial role in the efficiency and functionality of construction machinery. This component is essential for converting the motor’s power into usable torque and speed, enabling the equipment to perform various tasks effectively. Understanding its significance can help users maintain optimal performance and extend the lifespan of their machinery.

Key Functions of the Gearbox

- Power Conversion: The gearbox modifies the engine’s output to suit specific operational requirements, ensuring the machinery runs smoothly under different loads.

- Speed Regulation: It allows for adjustments in rotational speed, facilitating precise control during operation.

- Torque Amplification: This component can enhance the torque produced by the motor, which is vital for handling heavy materials.

Maintenance Tips

- Regularly check for leaks and ensure that the gearbox is properly lubricated.

- Inspect the seals and gaskets for wear and replace them as necessary.

- Monitor the temperature of the gearbox to prevent overheating, which can lead to damage.

Maintaining the Belt System for Optimal Performance

Proper upkeep of the belt mechanism is crucial for ensuring smooth operation and longevity of equipment. A well-maintained belt system not only enhances efficiency but also reduces the likelihood of unexpected breakdowns. Regular inspections and timely interventions can significantly impact overall productivity.

To achieve optimal performance, consider the following maintenance practices:

- Conduct regular visual inspections to check for signs of wear or damage.

- Ensure proper tension is maintained to prevent slippage and premature wear.

- Lubricate pulleys and other moving parts to minimize friction.

- Clean debris from the belt and surrounding areas to prevent contamination.

- Replace worn or damaged belts promptly to maintain operational integrity.

By adhering to these guidelines, operators can ensure that the belt system remains in peak condition, facilitating seamless functionality and prolonging the lifespan of the equipment.

How to Troubleshoot the Mixer’s Electrical System

Ensuring the functionality of the electrical components in your machine is essential for optimal operation. Addressing issues related to the power supply, wiring, and control mechanisms can prevent costly repairs and downtime. This section provides a systematic approach to identify and resolve common electrical challenges.

Identifying Power Supply Issues

The first step in diagnosing electrical troubles is checking the power source. A consistent and sufficient supply is crucial for proper operation. Use the following table to guide your checks:

Check Action Voltage Levels Use a multimeter to ensure voltage matches specifications. Power Connections Inspect for loose or damaged wires and tighten as necessary. Fuse Integrity Replace any blown fuses and check for recurring issues. Troubleshooting Wiring and Controls

If the power supply appears normal, the next step is to examine the internal wiring and control systems. Faulty connections or malfunctioning components can hinder performance:

Check Action Wiring Inspection Look for frayed wires and ensure all connections are secure. Switch Functionality Test all switches and buttons for proper operation. Motor Condition Examine the motor for unusual sounds or overheating. Drum Rotation and Its Impact on Mixing Quality

The way a container spins plays a crucial role in achieving optimal blending results. Proper rotation ensures that the materials inside are thoroughly combined, which can significantly enhance the consistency and performance of the final mixture. Understanding how rotation affects the blending process can help operators fine-tune their methods for superior outcomes.

Importance of Speed and Direction

The speed at which the drum rotates influences how effectively the components mix. A slower rotation may allow for gentle blending, which is suitable for more delicate materials, while a faster spin can lead to vigorous agitation, ensuring that all elements are uniformly incorporated. Additionally, the direction of rotation can affect the flow dynamics within the drum, impacting how the ingredients interact with one another.

Uniformity and Quality Control

Consistent rotation promotes uniformity in the mixture, which is vital for achieving the desired properties in the end product. If the blending is uneven, it may result in areas of excess or deficiency, leading to subpar quality. Regularly monitoring the rotation settings allows for adjustments that maintain high standards and minimize waste.

Importance of Regular Maintenance for Mixer Longevity

Ensuring the longevity of essential equipment relies heavily on consistent upkeep. Regularly caring for these machines not only maximizes their efficiency but also prevents unexpected breakdowns, which can lead to costly repairs and downtime. A proactive approach to maintenance extends the lifespan of the equipment and enhances overall performance.

Here are key benefits of regular maintenance:

- Improved Performance: Routine checks and adjustments help maintain optimal operation, ensuring that equipment functions at peak capacity.

- Reduced Downtime: Addressing minor issues before they escalate prevents major malfunctions, allowing for continuous operation.

- Cost Savings: Investing time in regular inspections can save money by avoiding expensive repairs and replacements down the line.

- Enhanced Safety: Well-maintained machinery reduces the risk of accidents, protecting operators and ensuring a safer working environment.

- Better Resale Value: Equipment that is regularly serviced often holds its value better, making it more attractive to potential buyers.

In summary, maintaining equipment through regular servicing is crucial for ensuring its reliability, performance, and safety. By committing to a routine maintenance schedule, operators can enjoy increased productivity and longevity from their machines.

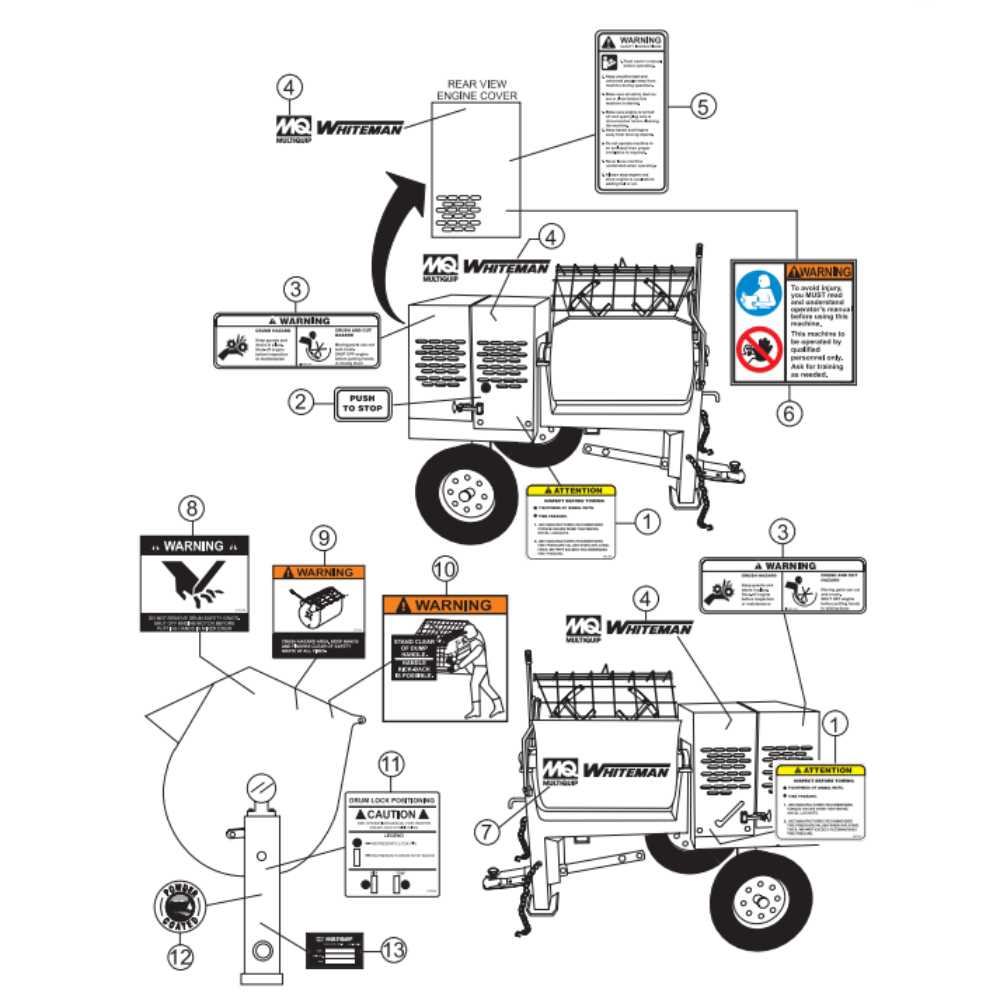

Finding Genuine Replacement Parts for Whiteman Mixers

When it comes to maintaining the longevity of your construction equipment, securing authentic components is crucial. Using original elements ensures optimal performance, safety, and durability, allowing operators to work efficiently without unnecessary interruptions.

Here are some essential tips for sourcing genuine components:

- Research Authorized Dealers: Start by identifying certified distributors who specialize in construction machinery. These vendors often carry a comprehensive selection of original elements.

- Check Online Platforms: Numerous reputable websites offer genuine components. Look for platforms with customer reviews and ratings to ensure reliability.

- Contact Manufacturer Support: Reach out directly to the manufacturer for recommendations on where to purchase authentic components. They can guide you to trusted sources.

- Utilize Local Suppliers: Many local hardware and construction supply stores maintain inventories of authentic elements. Building relationships with these suppliers can lead to better deals and timely availability.

By prioritizing the acquisition of genuine components, users can ensure their equipment functions effectively, minimizing downtime and enhancing productivity on the job site.