In the realm of outdoor maintenance, efficient machinery plays a pivotal role in streamlining tasks. Among these devices, a certain type of equipment stands out for its ability to transform large organic material into manageable pieces. Grasping the intricacies of this machinery can enhance both its operation and longevity, ensuring optimal performance for various applications.

The functionality of this device relies heavily on its individual elements, each designed to contribute to the overall effectiveness of the machine. A comprehensive examination of these components reveals how they interact to facilitate the processing of bulky materials into finer shreds. By understanding the role of each segment, users can make informed decisions about maintenance and troubleshooting.

Whether you’re a seasoned professional or a newcomer to outdoor equipment, recognizing the significance of these integral parts is essential. From the feeding mechanism to the cutting tools, each piece plays a vital role in achieving desired results. A detailed look at these elements will empower users to maximize the potential of their machinery.

Understanding Wood Chipper Components

The mechanism responsible for breaking down organic materials into smaller pieces consists of several essential elements. Each part of this system plays a critical role in ensuring efficient operation and processing. Understanding how these elements work together helps to maintain optimal performance and prevents malfunctions.

Main Structural Elements

- Cutting Mechanism: The core element that slices through material, breaking it into manageable sizes.

- Feeding System: This section ensures smooth and consistent delivery of material to the cutting area.

- Discharge System: After the material is processed, this component directs it to the designated

Overview of Wood Chipper Functionality

The operation of a shredding device relies on a well-coordinated mechanism designed to reduce large natural materials into smaller fragments. The core components work together efficiently, ensuring that the device performs its task smoothly and effectively.

Key aspects of its functionality include:

- Feeding system: Materials are introduced into the device, where they are pulled in for processing.

- Cutting mechanism: The primary process takes place here, as sharp blades or other cutting elements slice through the material.

- Output control: Processed fragments are expelled through an exit chute, and the size of the fragments can often be controlled based on user preferences.

This system ensures that raw materials

Key Parts of a Wood Chipper

Understanding the essential components of this machine is crucial for maintaining its efficiency and ensuring its smooth operation. Each section plays a specific role in transforming large pieces of material into smaller fragments, contributing to the overall functionality and durability of the device.

Engine and Power Source

The engine, often powered by fuel or electricity, serves as the driving force behind the machine. It delivers the necessary energy to the system, allowing it to process material efficiently. A well-maintained power source is key to reliable performance and longevity.

Cutter Mechanism

The cutting mechanism is the core

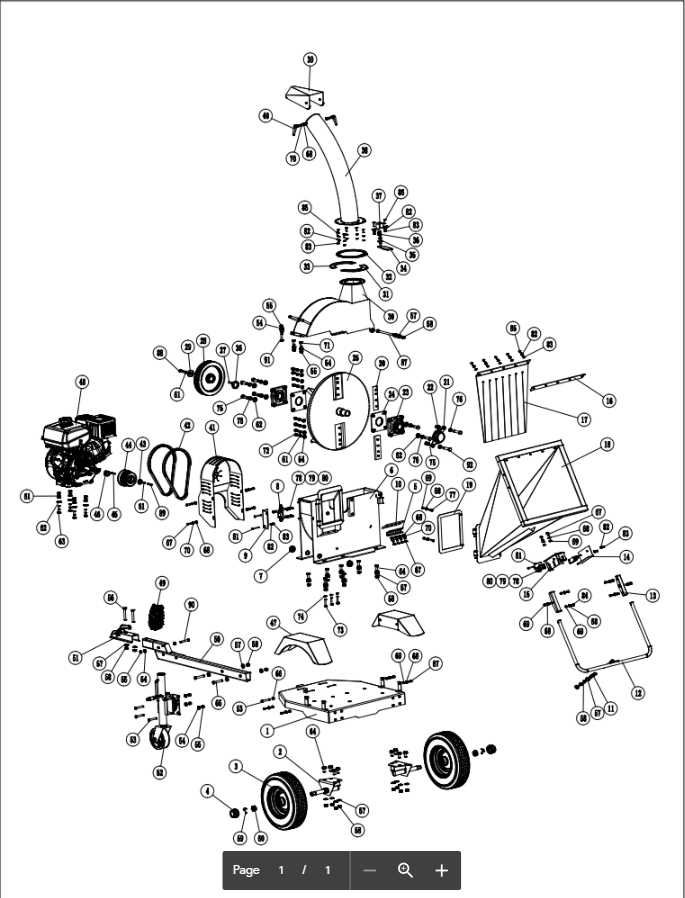

Diagram Analysis for Effective Repairs

Understanding the structure and layout of a mechanical system is crucial when performing repairs. By carefully studying visual representations of the device’s components, you can identify connections between elements and detect potential problem areas. This approach enables more efficient troubleshooting and prevents further damage during maintenance.

When analyzing these visual guides, it’s important to break down each section systematically. Start by identifying major assemblies and their relationships with smaller components. This method allows you to focus on key areas that may require attention, ensuring repairs are done accurately and swiftly.

Effective use of technical diagrams also helps in predicting future issues. Recognizing wear points or misaligned elements early can extend the life of

Identifying Common Issues in Chippers

Mechanical shredders, like any complex equipment, can face operational challenges over time. Recognizing and addressing these problems early helps maintain performance and avoid costly repairs. By understanding the most frequent malfunctions, users can prolong the lifespan of their equipment and ensure smooth operation.

One typical issue is related to dull or damaged blades. When cutting components lose sharpness, the machine may struggle to process material efficiently, leading to blockages or incomplete shredding. Regular maintenance of these key elements is crucial to prevent downtime.

Another common problem involves the engine or motor. Overheating or

Importance of Regular Maintenance Practices

Keeping equipment in optimal condition is crucial for ensuring its longevity and performance. Regular inspections and upkeep prevent malfunctions, reduce the need for costly repairs, and enhance safety during operation. A well-maintained machine operates smoothly and efficiently, minimizing downtime and improving overall productivity.

Preventing Unexpected Failures

Routine maintenance helps identify potential issues before they escalate into significant problems. By addressing wear and tear early, you can avoid unexpected breakdowns that could disrupt work schedules and result in extended repair times.

Maximizing Performance and Efficiency

Consistent care not only extends the lifespan of the equipment but also ensures it continues to operate at peak efficiency. Lubrication, cleaning, and timely replacement of consumable

Choosing Quality Replacement Parts

When maintaining equipment, selecting high-quality replacement components is essential to ensure long-lasting performance and efficiency. Identifying the right items can prevent future breakdowns, saving both time and money.

Compatibility plays a crucial role in finding the proper components. It is important to verify that the selected items are suited to the specific make and model of your machinery.

Durability should also be a priority. Opt for materials known for their strength and resistance to wear, ensuring that the components will endure under heavy use.

Additionally, consider the manufacturer’s reputation. Parts from trusted brands often come with warranties and better customer support, offering greater reliability and peace of mind.

Safety Features in Wood Chippers

Operating heavy-duty machines requires careful attention to built-in safeguards designed to protect the user. These protective measures ensure the operator’s safety and prevent accidents during operation. Understanding and utilizing these features is essential for efficient and secure use of the machinery.

Automatic Shutdown Mechanisms

Many modern machines are equipped with automatic shutdown systems that activate when any abnormal conditions are detected. These systems help to prevent serious malfunctions or potential hazards by halting the operation immediately when necessary.

Emergency Stop Buttons

Another crucial feature is the emergency stop button, often strategically placed for quick access. In case of unexpected issues, the user can press this button to immediately

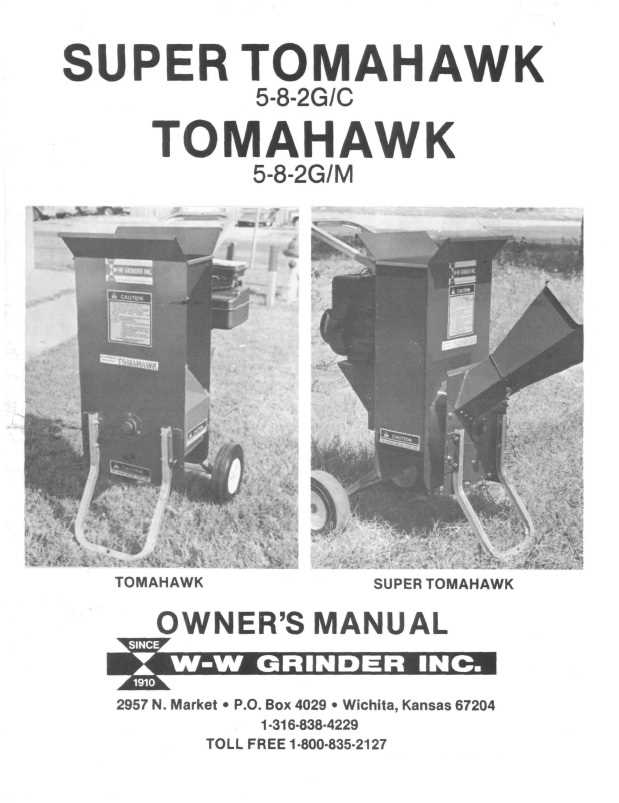

Comparing Different Wood Chipper Models

When evaluating various outdoor equipment for processing garden debris, it’s essential to consider the differences in power, efficiency, and ease of use. These factors play a key role in determining which machine best suits your needs, whether for smaller tasks or heavy-duty requirements.

Engine power is a significant factor in differentiating models. Larger units generally feature more robust motors, capable of handling denser materials. On the other hand, compact devices offer portability and are perfect for light yard maintenance.

Hopper size is another critical aspect. Models with wider entry points allow users to feed larger branches and leaves, improving overall efficiency. Smaller devices often

Assembly Instructions for Wood Chipper Parts

When putting together the various components of your outdoor equipment, it’s important to follow each step methodically to ensure proper function and safety. This guide will help you organize the assembly process in a clear and efficient manner, outlining key steps without overwhelming technical details.

- Begin by laying out all the necessary pieces. Make sure you have everything listed in the instruction manual before starting the assembly.

- Attach the main unit to the base, ensuring all fasteners are tightened securely. Use appropriate tools for this step to avoid damage to the equipment.

- Next, install the cutting mechanism, carefully aligning it with the housing to ensure smooth operation. Double-check that it is positioned correctly before securing it in place.

- Connect the feeding chute, ensuring it is firmly attached

Tips for Efficient Operation

To maximize productivity and ensure safe use of your equipment, it is essential to follow best practices during operation. Understanding the nuances of efficient handling can greatly enhance performance and reduce the risk of malfunctions.

Regular Maintenance

Frequent upkeep is vital for optimal functionality. Ensure that all components are in good condition, and replace worn-out parts promptly. This not only prolongs the lifespan of the machine but also prevents unexpected breakdowns.

Proper Loading Techniques

Loading material correctly can significantly impact the effectiveness of the process. Avoid overloading, as it can lead to jams and decreased efficiency. Instead, feed material gradually and evenly to maintain a steady workflow.

Tip Description Check Fluid Levels Regularly inspect oil and fuel levels to ensure optimal operation. Wear Safety Gear Always wear protective equipment to minimize risks during use. Follow Manufacturer Instructions Refer to the manual for specific guidelines to ensure safe handling. Resources for Wood Chipper Owners

Maintaining and operating machinery effectively requires access to reliable information and tools. This section aims to provide valuable resources for individuals managing these types of equipment, ensuring they have the necessary knowledge and support for optimal performance and longevity.

Online Communities

Engaging with online forums and social media groups can be an excellent way to connect with fellow enthusiasts and experts. These platforms often feature discussions on troubleshooting, maintenance tips, and shared experiences, fostering a sense of community among users.

Manufacturer Support

Many manufacturers offer extensive resources on their websites, including manuals, FAQs, and instructional videos. Utilizing these materials can enhance understanding of the machinery and assist in resolving any issues that may arise.

Proactive maintenance and staying informed about best practices can significantly enhance the efficiency and safety of your equipment. Whether through community support or manufacturer resources, having access to accurate information is essential.