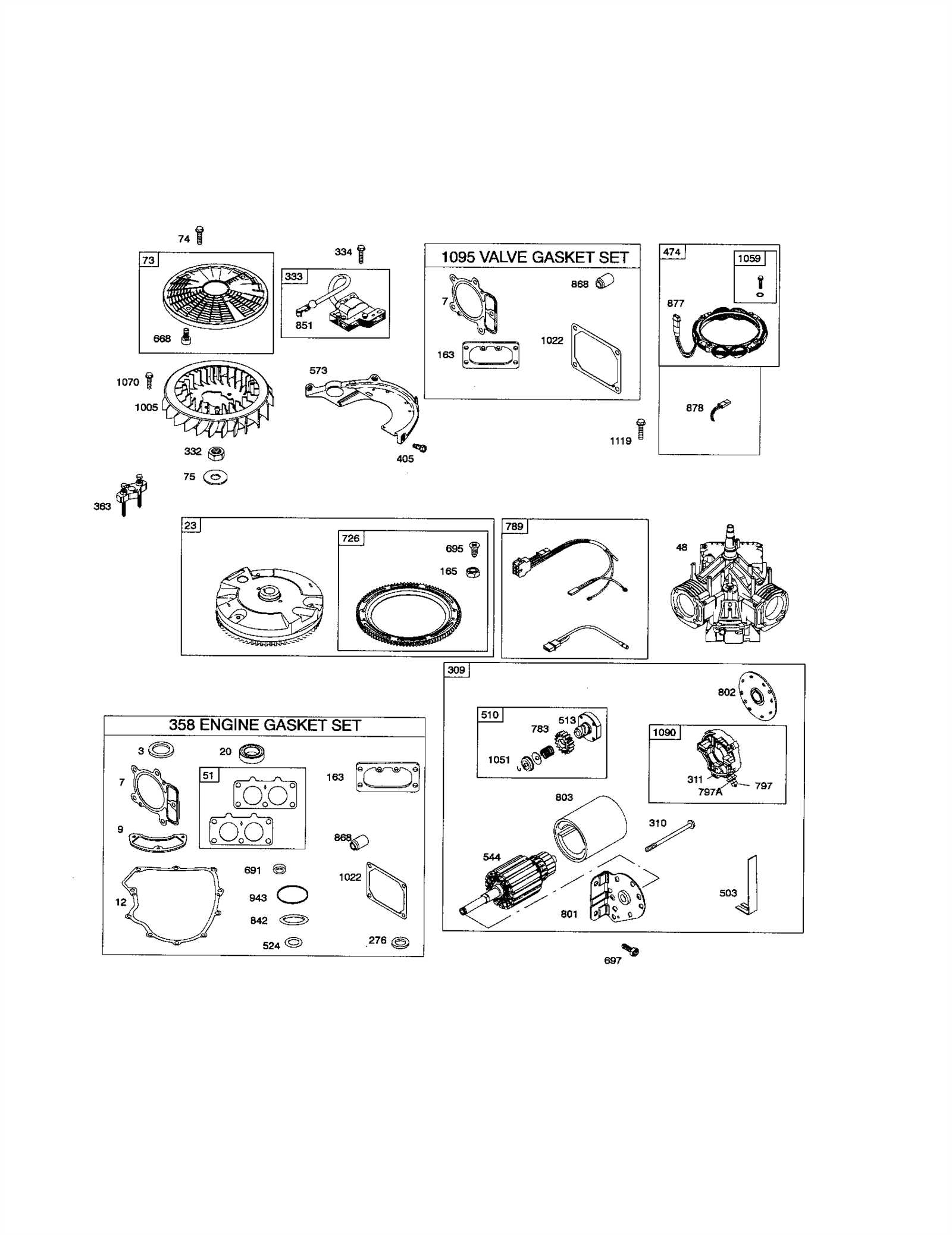

| Exploring the Engine Assembly Layout

The engine assembly is a critical component of any machine, with each element meticulously organized to ensure optimal performance and functionality. Understanding how the various elements interact can provide valuable insights into the overall mechanics and maintenance of the system. In this section, we will examine the arrangement of key components and how their placement contributes to the smooth operation of the engine as a whole.

At the core of the engine, various mechanisms are positioned to work in harmony, enabling the machine to operate efficiently. The placement of each element, from the power generation system to the supporting structures, is carefully designed to ensure balance and reliability. By analyzing the layout, we can gain a deeper understanding of how the assembly works to deliver consistent performance over time.

Understanding the Transmission System Diagram

The transmission system plays a crucial role in ensuring the smooth and efficient operation of machinery. By examining the layout and structure of its components, one can gain valuable insights into how power is transferred and regulated throughout the system. This section offers a comprehensive overview of the key elements involved in this process.

Main Components Overview

Each element within the transmission system has a specific function that contributes to the overall performance. Understanding these components is essential for maintenance and troubleshooting.

- Drive Assembly: Responsible for transmitting power from the engine to the operational mechanisms.

- Gears and Shafts: Control the speed and direction of movement, allowing for adjustments as needed.

- Clutches and Couplings: Enable smooth engagement and disengagement of power transmission.

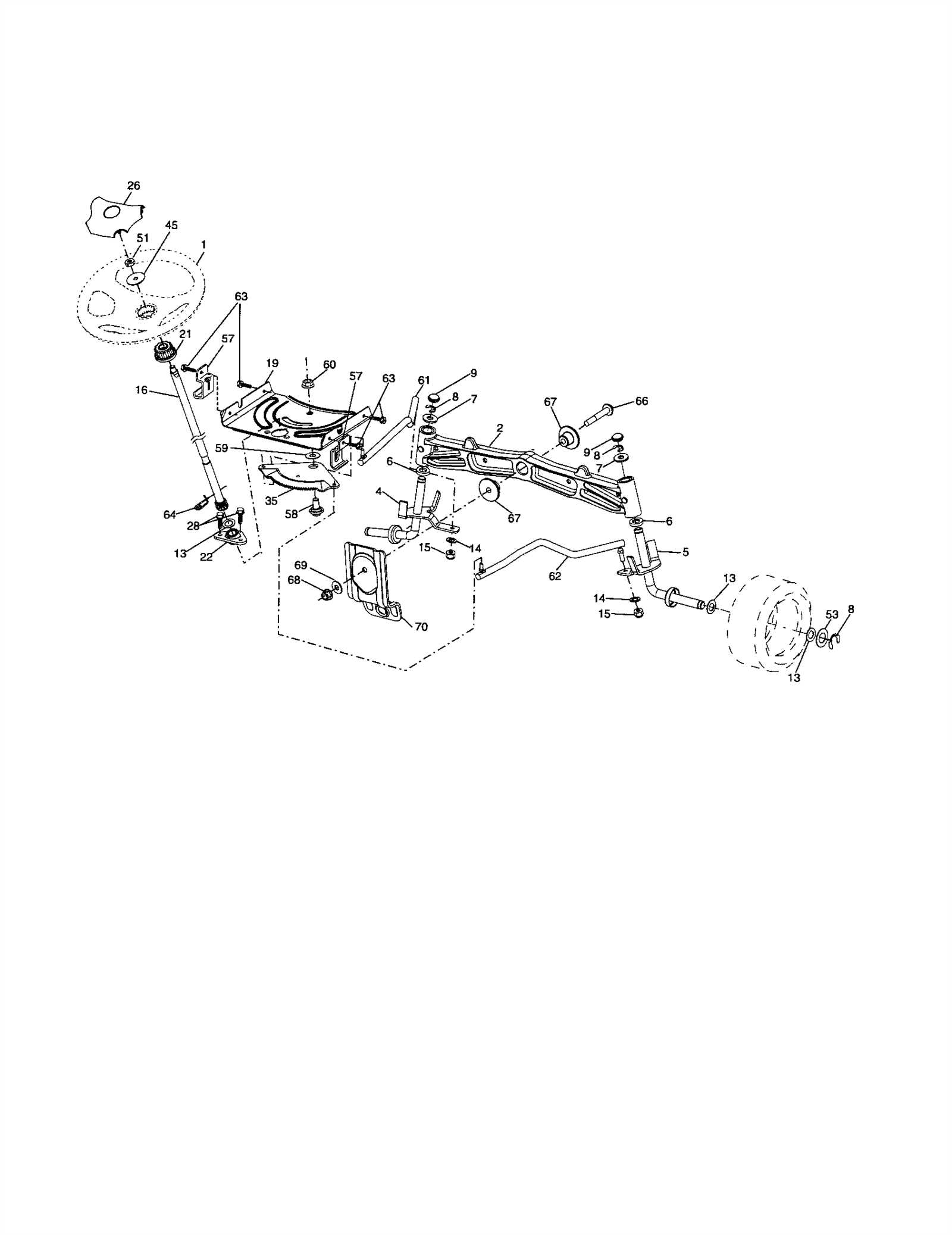

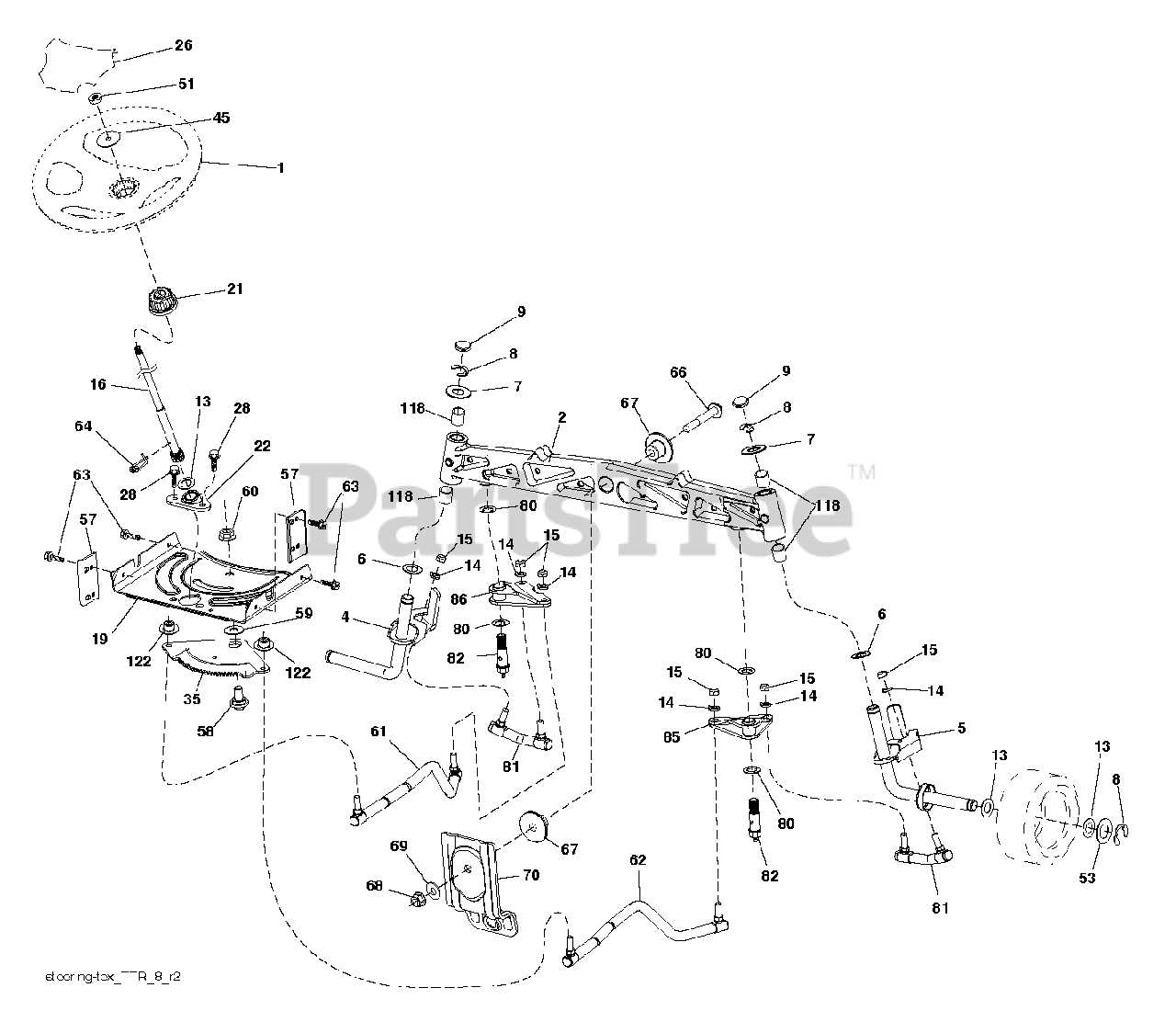

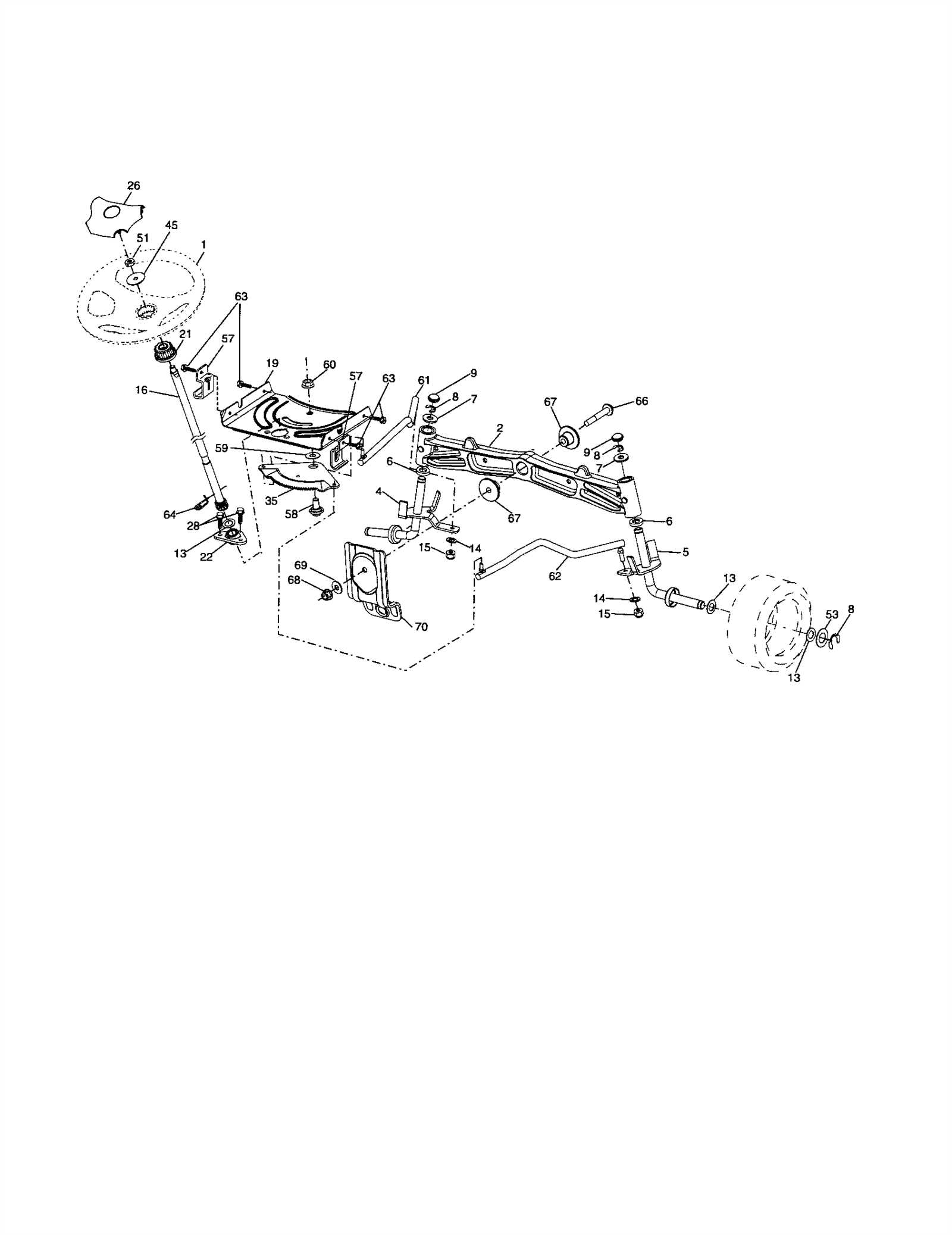

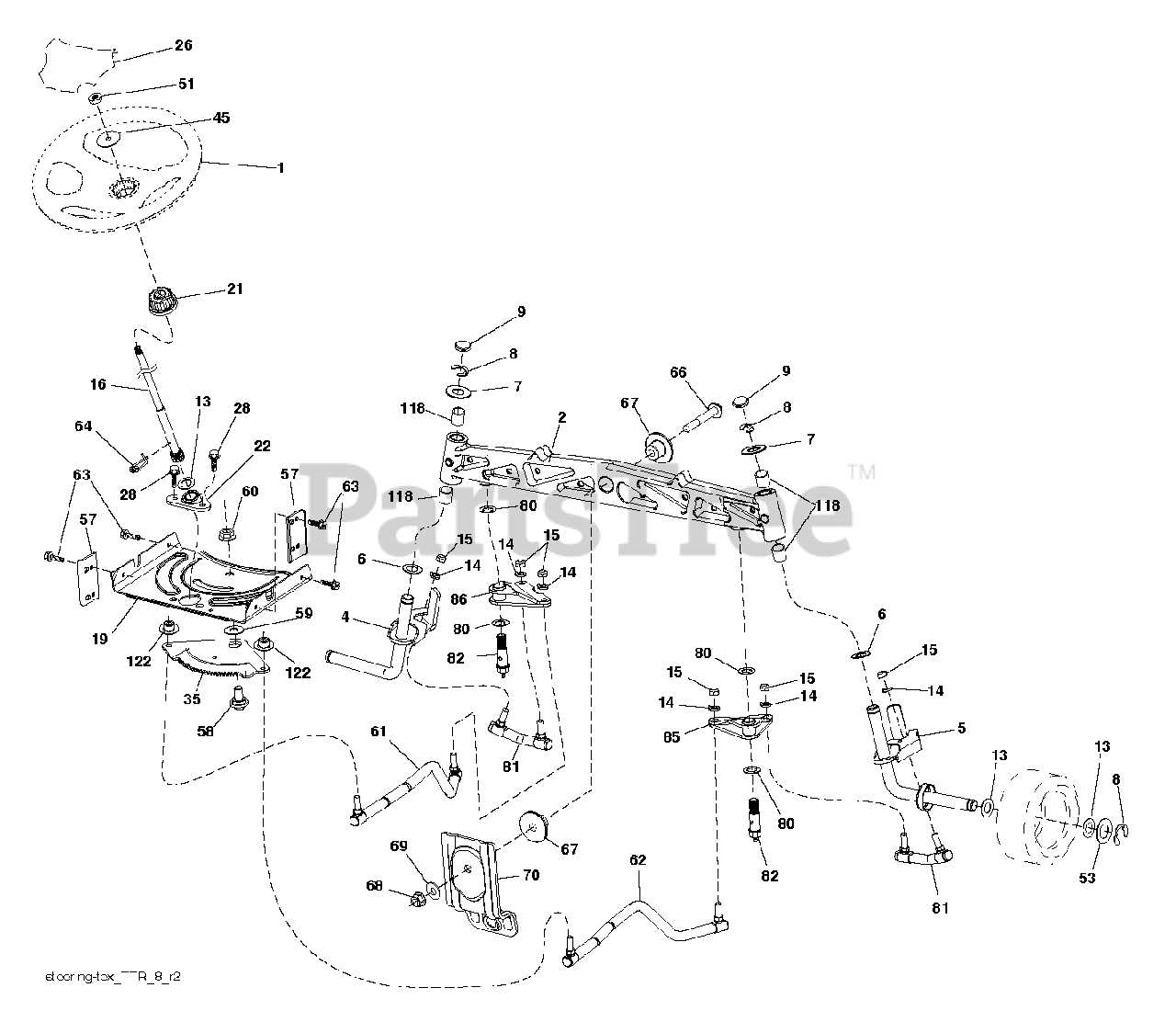

Detailed View of Steering Mechanism

The steering system is a crucial component that ensures precise control and maneuverability of the equipment. This section provides an overview of how the steering works, highlighting the interconnected elements that allow for smooth direction changes. Understanding the structure and function of this system helps in maintaining optimal performance and identifying potential issues early on.

Key Components of the Steering Assembly

The steering assembly consists of several elements that work together to transmit the movement from the control wheel to the wheels. These include mechanical linkages, rotating shafts, and joints that allow flexible motion. Each part plays a vital role in converting the operator’s input into effective direction adjustments, ensuring stability during operation.

Functionality and Maintenance

The operation of the steering system relies on the seamless interaction between its components. Regular inspections are necessary to ensure that all elements remain in good working condition. Lubrication, tightening of bolts, and replacement of worn-out parts can extend the lifespan of the system, reducing the risk of malfunction and improving overall usability.

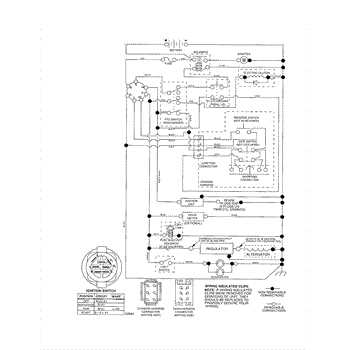

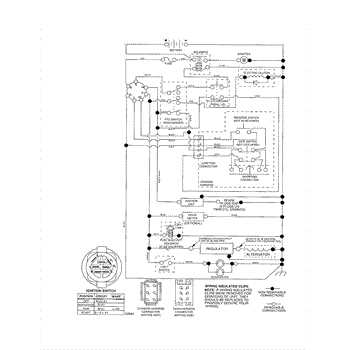

Analyzing the Electrical Wiring Path

The electrical system plays a crucial role in ensuring the smooth operation of any machinery. Understanding the routing of wires and connections is essential for maintaining the functionality of various components. By carefully examining the electrical paths, one can ensure proper power distribution and avoid potential issues related to misconnection or failure of electrical circuits.

Understanding the Wiring Layout

To thoroughly assess the system, it’s important to follow the flow of the wiring from the power source to individual components. Each section of wiring should be traced, ensuring connections are secure and that no breaks or worn areas are present. Identifying the start and end points of each wire helps in maintaining overall system integrity.

Steps for Inspection

- Begin by locating the main power supply and tracing the wires to the primary components.

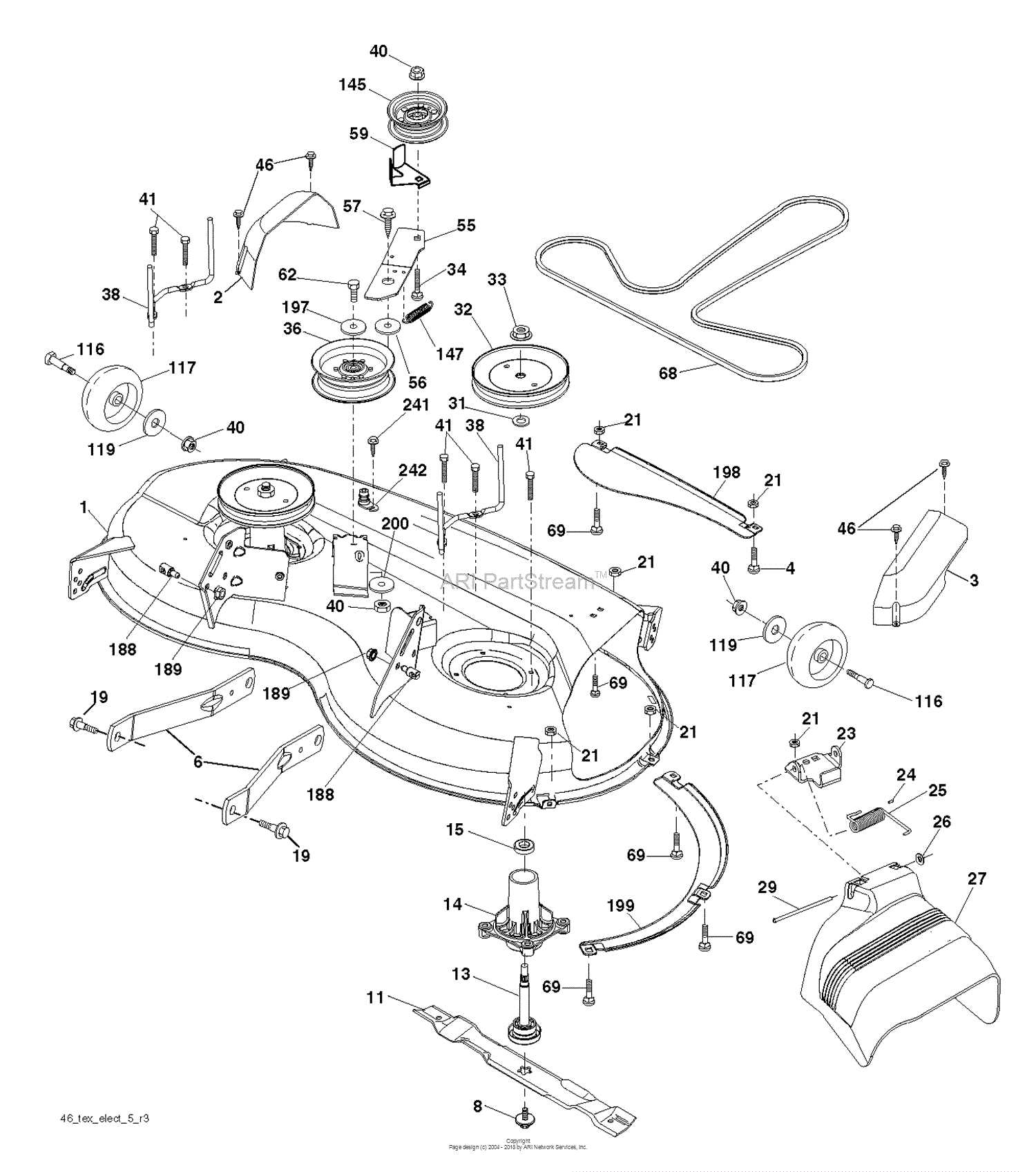

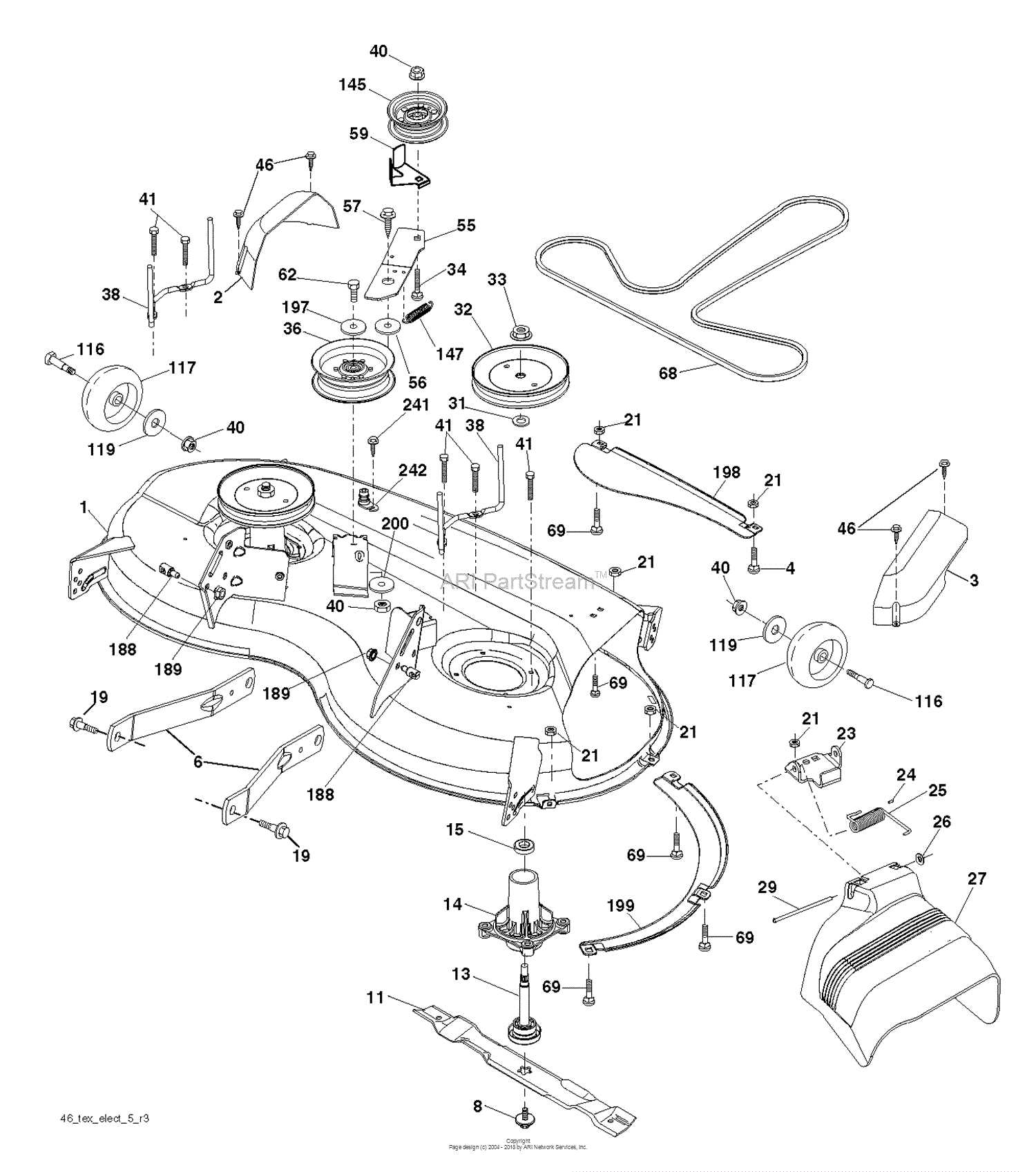

Breakdown of the Mower Deck Structure

The mower deck is a crucial component of any lawn care machine, serving as the foundation for cutting performance and overall efficiency. Understanding its construction and the various elements that comprise it can greatly enhance maintenance and operation. This section delves into the essential features and layout of the deck, providing insight into its functionality and design.

At the core of the deck lies the housing, designed to securely contain the cutting blades while facilitating the flow of grass clippings. This robust framework is typically constructed from durable materials, ensuring longevity even under rigorous conditions. The design incorporates a series of attachment points for securing the blades, allowing for easy replacement and adjustments.

Additionally, the mower deck is equipped with anti-scalping wheels, which play a vital role in preventing damage to the lawn surface during operation. These wheels maintain a consistent cutting height, allowing the machine to glide smoothly over uneven terrain. The integration of adjustable height settings further enhances the versatility of the deck, enabling users to achieve the desired grass length with ease.

Another important aspect is the discharge system, which is engineered to efficiently direct clippings away from the cutting area. This not only promotes a clean finish but also reduces the likelihood of clogging. Understanding these components helps users appreciate the thoughtful engineering behind the mower deck and its impact on performance.

Inspecting the Fuel System Connections

Ensuring the integrity of the fuel delivery system is essential for optimal engine performance. This section focuses on examining the connections within the fuel system to prevent leaks and ensure proper flow. A thorough inspection can help identify any issues that might hinder the efficiency of the engine.

Visual Examination

Begin by visually inspecting all fuel lines and connectors for signs of wear, corrosion, or damage. Look for any cracks or fraying in the hoses that could lead to fuel leaks. Additionally, check for loose connections that may not provide a secure seal, as these can also cause issues in the fuel flow.

Testing for Leaks

After the visual inspection, it is important to test the connections for leaks. You can do this by applying a small amount of soapy water to the areas where connections are made. If bubbles form, this indicates a leak that needs to be addressed. Taking the time to ensure all connections are secure will enhance the overall functionality of the engine.

Guide to

This section serves as a comprehensive resource aimed at enhancing your understanding of mechanical components and their organization within various machinery. It offers valuable insights into the essential elements that contribute to the efficient functioning of equipment, facilitating smoother operations and maintenance procedures.

Understanding Component Layout

Grasping the arrangement of different elements is crucial for troubleshooting and repairs. Familiarizing yourself with how these pieces fit together can greatly simplify the process of identifying issues and implementing effective solutions.

Maintenance Tips

Regular upkeep is vital for the longevity of any mechanical system. By knowing the key components and their functions, you can ensure proper care, thus preventing potential malfunctions and extending the lifespan of your machinery.

|