In the world of small engines, having a thorough understanding of their essential elements is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, and familiarity with these parts can greatly enhance efficiency. This section aims to provide insights into the various elements that contribute to the seamless operation of your machinery.

Properly identifying and comprehending these elements not only simplifies troubleshooting but also aids in making informed decisions during repairs and upgrades. By exploring the intricacies of these systems, users can ensure longevity and reliability, thus maximizing the utility of their equipment. A detailed overview will serve as a valuable resource for both novices and seasoned enthusiasts alike.

As we delve into the specifics, attention will be given to the arrangement and interaction of components. Understanding how each part fits into the larger framework will empower users to tackle maintenance tasks with confidence. Whether you are looking to replace a worn-out element or simply wish to expand your knowledge, this guide offers a structured approach to mastering the essentials.

Zama RB-K93 Overview

This section provides an insightful look into a specific model that is widely used in gardening and landscaping. It serves as a crucial component in various equipment, ensuring efficient operation and reliability.

Key Features

- Enhanced performance and fuel efficiency

- Durable materials for prolonged lifespan

- Compatibility with various models and brands

Applications

- Used in lawn mowers

- Essential for trimmers and blowers

- Supports various outdoor power tools

Understanding the RB-K93 Model

This section explores the intricacies of a specific model within a range of tools designed for precision and efficiency. Each component plays a crucial role in the overall functionality, contributing to the performance and reliability of the unit.

Familiarizing oneself with the individual elements is essential for maintenance and optimal operation. Here are key aspects to consider:

- Design Features: The model incorporates innovative design principles that enhance usability.

- Component Interaction: Understanding how each part interacts can prevent operational issues.

- Maintenance Tips: Regular upkeep is vital for longevity and performance efficiency.

By delving into the specifics, users can ensure they are maximizing the potential of their equipment. Consider the following when examining the unit:

- Identify the main components and their functions.

- Learn about the assembly and disassembly processes for troubleshooting.

- Utilize resources for acquiring replacement parts or upgrades.

A comprehensive understanding of these elements will empower users to achieve the best possible results in their tasks, ultimately leading to enhanced productivity and satisfaction.

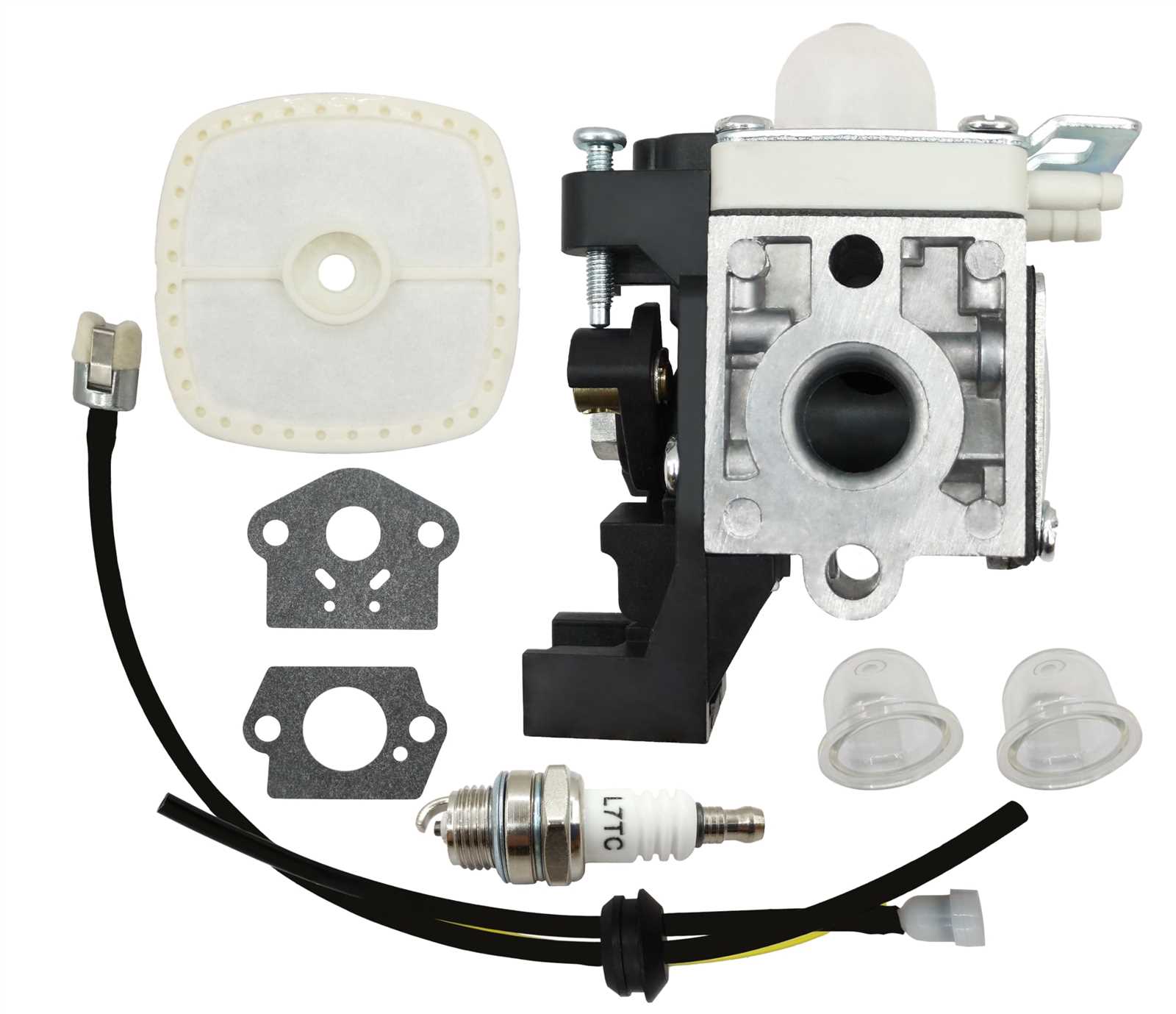

Components of the Zama RB-K93

This section explores the essential elements that contribute to the functionality of a specific type of equipment. Understanding these components is crucial for effective maintenance and optimization.

The housing serves as the protective outer shell, safeguarding internal mechanisms while providing a secure structure. Within this casing lies the diaphragm, which plays a pivotal role in regulating fuel flow, ensuring efficiency during operation.

Another critical element is the needle valve, which meticulously controls the fuel supply, directly influencing performance and responsiveness. Complementing this is the float chamber, responsible for maintaining an optimal fuel level, thereby enhancing stability.

Furthermore, the gasket seals components together, preventing leaks and ensuring a tight fit. Lastly, the spring provides necessary tension, aiding in the precise functioning of various parts, all of which are integral to the overall system’s effectiveness.

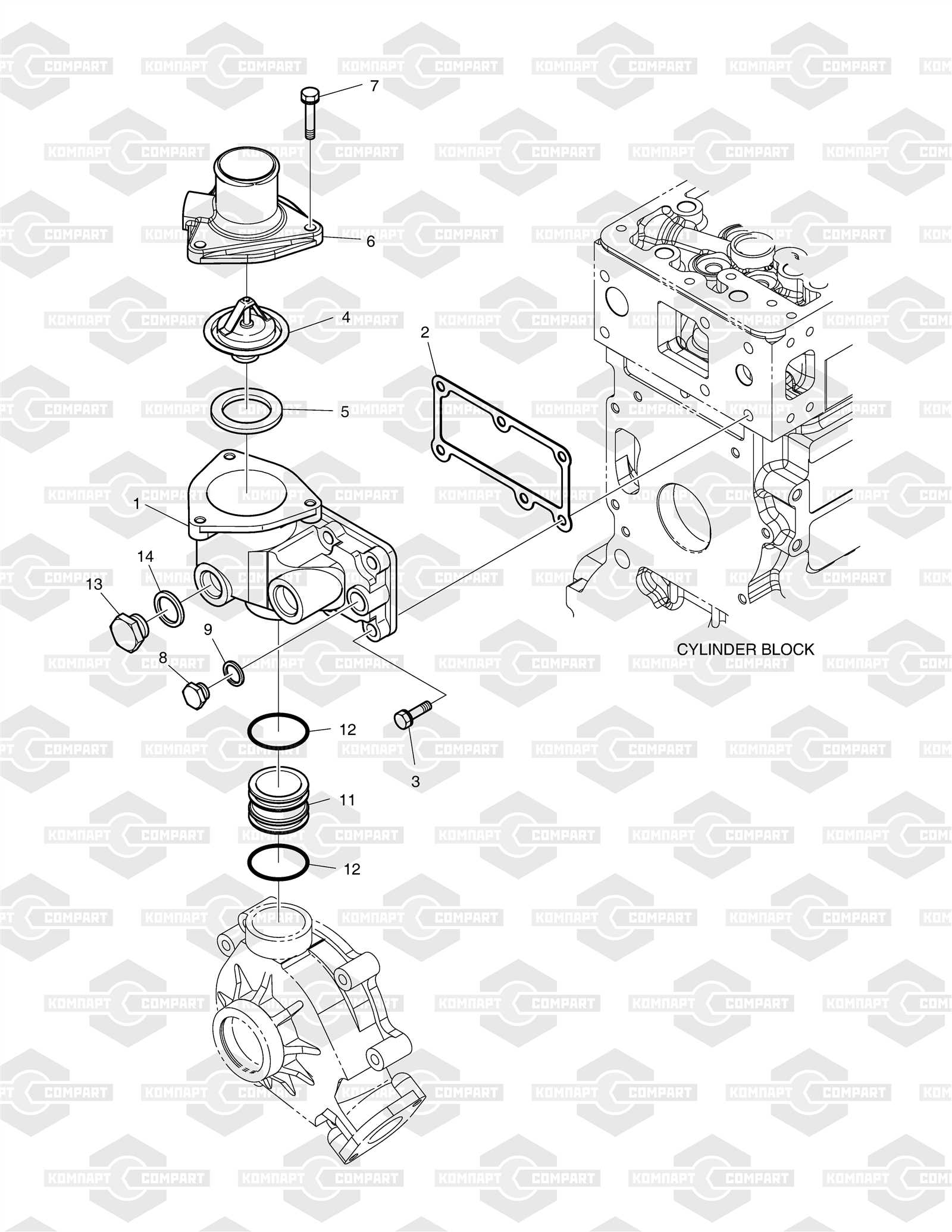

Importance of Parts Diagrams

Understanding the intricate components of a machine is essential for effective maintenance and repair. Visual representations serve as crucial tools for technicians, enabling them to identify, locate, and comprehend the various elements involved in a system. This clarity ultimately leads to enhanced efficiency and reduced downtime.

Facilitating Troubleshooting

Visual aids assist in quickly diagnosing issues by providing a clear overview of how each element interacts within the assembly. This efficiency is invaluable in minimizing operational disruptions.

Streamlining Maintenance

Having a comprehensive visual reference can significantly simplify the maintenance process. It empowers users to understand the assembly better, ensuring that replacements and repairs are conducted accurately and timely, thus preserving the longevity of the equipment.

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear overview of the various elements involved in a mechanical assembly, allowing users to identify and locate individual pieces easily.

First and foremost, familiarize yourself with the overall layout. Typically, these visuals will arrange parts in a logical sequence, often reflecting their physical configuration within the assembly. Take a moment to observe how the components are grouped and how they interact with one another.

Next, pay attention to the labeling system. Each item is usually marked with a unique identifier, which may correspond to a list or key. This allows for straightforward referencing when sourcing replacements or troubleshooting issues. Ensure to cross-reference these labels with any accompanying documentation to gain a deeper understanding of each component’s function.

Additionally, look for any notes or legends provided with the illustration. These annotations can offer valuable insights into specific features or special instructions regarding the components. They often highlight critical elements that may not be immediately obvious, enhancing your comprehension.

Lastly, practice makes perfect. The more you engage with these visual tools, the more intuitive reading them will become. Regularly referencing these materials during maintenance activities will enhance your confidence and efficiency in working with complex assemblies.

Common Issues with RB-K93 Parts

Understanding frequent challenges associated with components in small engine applications is essential for optimal performance. Various factors can lead to inefficiencies or malfunctions, impacting overall functionality.

Typical Problems

- Clogged Filters: Dirt and debris can accumulate, obstructing airflow and fuel flow.

- Worn Seals: Over time, seals may deteriorate, leading to leaks and pressure loss.

- Faulty Gaskets: Poor sealing can result in air leaks, affecting combustion efficiency.

Preventive Measures

- Regular Maintenance: Periodic cleaning and inspection can prevent many issues.

- Quality Replacement: Using high-quality components ensures better longevity and performance.

- Timely Repairs: Addressing problems quickly helps maintain efficiency and prevent further damage.

Identifying Genuine Zama Components

Recognizing authentic elements in equipment is essential for optimal performance and longevity. Counterfeit or substandard items can lead to inefficiency and increased maintenance costs. This section explores key features that help differentiate original components from imitations.

Key Features to Consider

- Quality of Materials: Authentic items are made from high-grade materials, ensuring durability.

- Branding and Markings: Look for consistent logos and part numbers that match official documentation.

- Packaging: Genuine components often come in branded packaging, which is professionally designed.

Verification Methods

- Consult official manuals for reference.

- Check with authorized dealers for confirmation.

- Examine reviews and feedback from other users.

Maintenance Tips for the RB-K93

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following some straightforward guidelines, you can maintain its efficiency and prevent potential issues that may arise from neglect. Here are key practices to consider for effective maintenance.

1. Clean After Use: Always remove any debris and residue after each operation. This helps prevent clogs and maintains the functionality of the components.

2. Check Seals and Gaskets: Inspect seals and gaskets for wear and tear regularly. Replacing damaged seals promptly can prevent leaks and improve overall efficiency.

3. Lubrication: Apply appropriate lubricants to moving parts as recommended in the user manual. Proper lubrication reduces friction and wear, enhancing the lifespan of the unit.

4. Regular Inspections: Conduct periodic checks on all parts to identify signs of wear or damage. Early detection of issues can save time and costs associated with more significant repairs.

5. Store Properly: When not in use, store the equipment in a dry and safe environment. Protecting it from extreme temperatures and moisture will help maintain its condition.

6. Follow Manufacturer’s Guidelines: Always adhere to the maintenance schedule and instructions provided by the manufacturer. This ensures that you are performing the correct procedures at the right intervals.

By implementing these maintenance practices, you can ensure your equipment operates efficiently and remains in good condition for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process with the right resources. Several avenues can lead you to reliable suppliers, ensuring that you keep your device in optimal working condition.

Online Retailers

Numerous online platforms specialize in offering a wide range of replacements for various models. Sites like Amazon and eBay provide user reviews and competitive pricing, making them excellent starting points.

Local Dealers and Repair Shops

Visiting authorized distributors or local repair centers can also yield quality alternatives. These establishments often carry genuine items or can assist in sourcing what you need, ensuring compatibility and reliability.

Compatibility with Other Models

Understanding how components from one device can be utilized in another is crucial for enhancing functionality and efficiency. Compatibility among various models can lead to greater versatility and reduce the need for specific replacements. This is especially beneficial for users seeking cost-effective solutions.

Many parts designed for one model may also fit others, allowing for easy substitutions. For example, certain features like fuel systems or carburetors might be interchangeable, which can save time during repairs. It’s essential to consult compatibility charts or guides to ensure seamless integration and optimal performance.

Furthermore, exploring cross-model compatibility can reveal alternatives that may offer improved durability or performance. Users should always verify specifications before making any modifications, as this ensures that the equipment remains reliable and efficient in its operation.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is essential for efficient and effective work. Proper tools not only streamline the repair process but also ensure safety and accuracy, minimizing the risk of damage to components. Whether you are performing minor adjustments or more extensive overhauls, a well-equipped toolkit is crucial.

To begin, a set of basic hand tools is indispensable. This includes screwdrivers of various sizes, wrenches, and pliers, which will allow you to easily access and manipulate different elements. Additionally, a torque wrench can be particularly useful for ensuring that fasteners are tightened to the manufacturer’s specifications, which is vital for maintaining the integrity of the assembly.

For more intricate tasks, specialized tools may be necessary. Items such as a multimeter for electrical testing or a feeler gauge for precise measurements can enhance your repair capabilities. Furthermore, having a workbench and proper lighting will create a conducive environment for detailed work, enabling you to focus on the task at hand without distractions.

Lastly, consider investing in safety equipment such as gloves and goggles. Protecting yourself during repairs is just as important as having the right tools, as it helps prevent injuries and ensures a safer working environment. With the right combination of tools and safety measures, you can tackle any repair job with confidence.

Step-by-Step Repair Process

This section outlines a comprehensive method for addressing issues related to fuel delivery systems commonly found in small engines. Following these steps will help ensure efficient troubleshooting and effective resolution of problems.

- Preparation

- Gather necessary tools: screwdrivers, wrenches, and cleaning supplies.

- Ensure you have a clean workspace to avoid contamination.

- Review safety protocols, including using gloves and goggles.

- Disassembly

- Carefully remove the outer casing and any protective covers.

- Take note of the arrangement of components for easier reassembly.

- Keep screws and small parts organized to prevent loss.

- Inspection

- Check for visible wear and tear on components.

- Inspect seals and gaskets for signs of damage or degradation.

- Examine connections and hoses for leaks or blockages.

- Cleaning

- Use a suitable solvent to clean all parts thoroughly.

- Remove any debris or residue that may affect performance.

- Ensure all passages are free from obstructions.

- Replacement

- Identify any damaged components that need replacement.

- Install new parts, ensuring they are properly fitted.

- Follow manufacturer specifications for installation torque and alignment.

- Reassembly

- Reassemble the unit in reverse order of disassembly.

- Double-check that all screws and connections are secure.

- Ensure all protective covers are reattached correctly.

- Testing

- Start the engine and observe its operation.

- Check for any unusual sounds or leaks during operation.

- Perform adjustments as necessary to optimize performance.

By adhering to this structured approach, you can effectively diagnose and repair issues, enhancing the longevity and efficiency of the equipment.

FAQs about Zama RB-K93 Parts

This section addresses common inquiries related to components and their functionalities. Understanding these elements can enhance the maintenance and performance of your equipment, ensuring optimal operation and longevity.

Common Questions

- What are the key components of the equipment?

- How can I identify a faulty element?

- Are replacement pieces readily available?

- What tools are needed for component replacement?

Maintenance Tips

- Regularly inspect components for wear and tear.

- Use manufacturer-recommended lubricants for moving parts.

- Ensure all connections are tight to prevent leaks.

- Keep the equipment clean to avoid debris buildup.