In the realm of machinery and equipment, comprehending the arrangement and functionality of various elements is crucial for efficient operation and maintenance. An organized illustration can greatly aid in visualizing how different components interact within a system, providing clarity to both experienced professionals and newcomers alike.

Such a representation not only enhances understanding but also serves as a valuable reference during repairs and modifications. By identifying each element and its purpose, users can ensure that any adjustments made are precise and beneficial, ultimately improving overall performance.

As we delve deeper into this subject, we will explore the intricacies of these illustrations, examining how they facilitate a better grasp of assembly and disassembly processes. Mastering this knowledge empowers users to take control of their equipment, leading to enhanced productivity and reduced downtime.

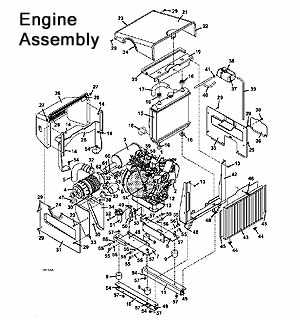

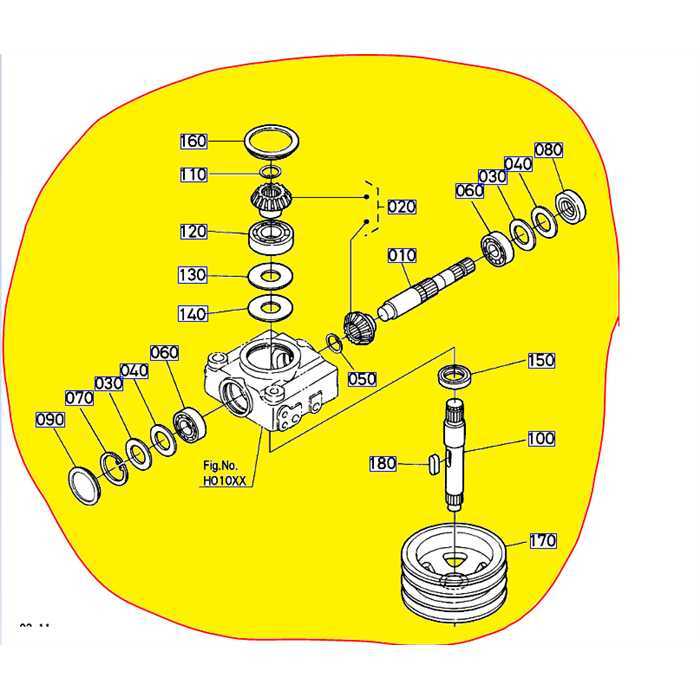

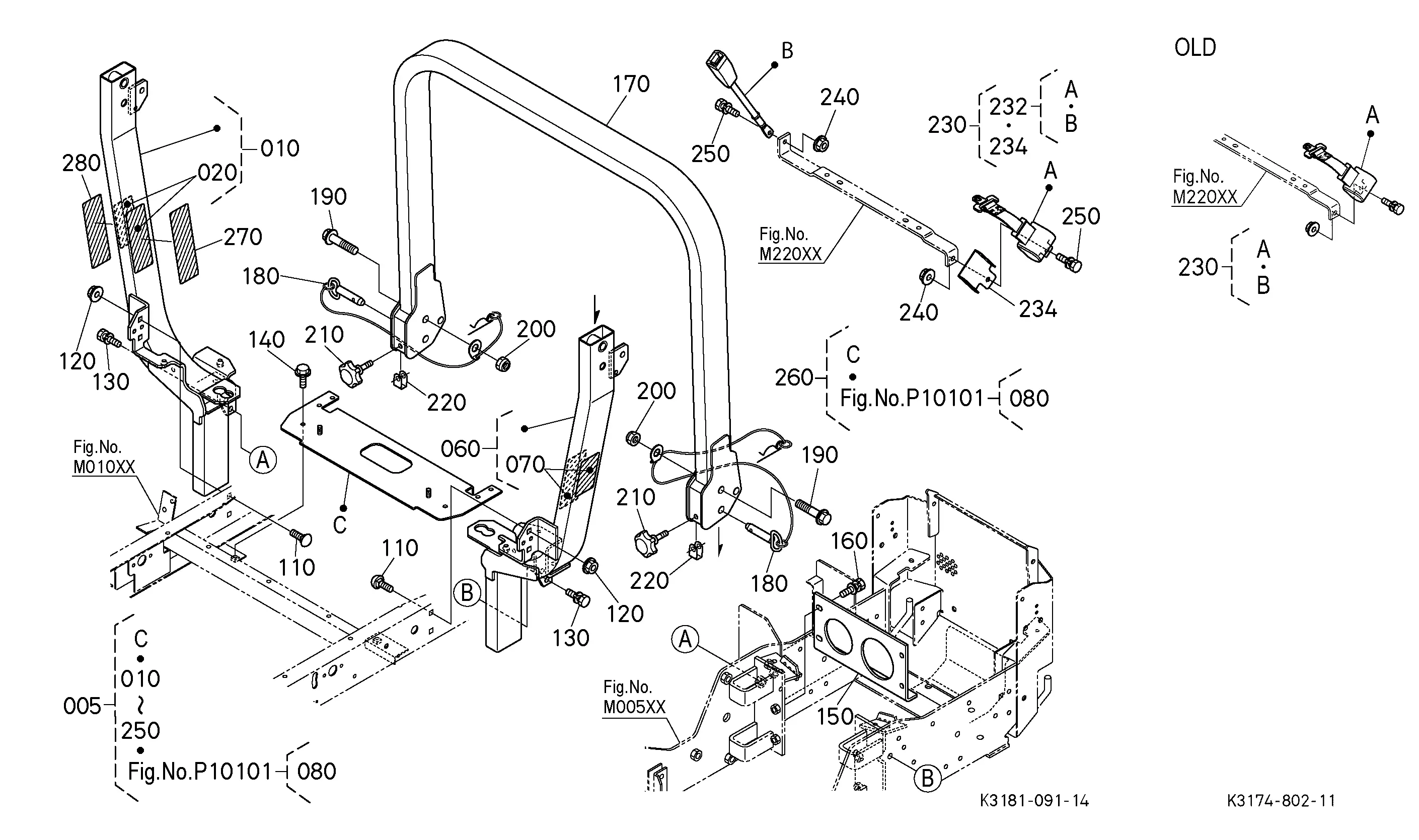

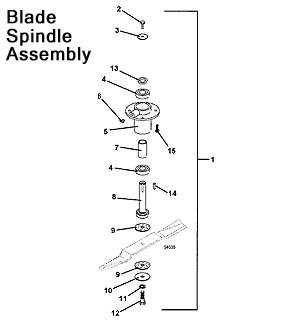

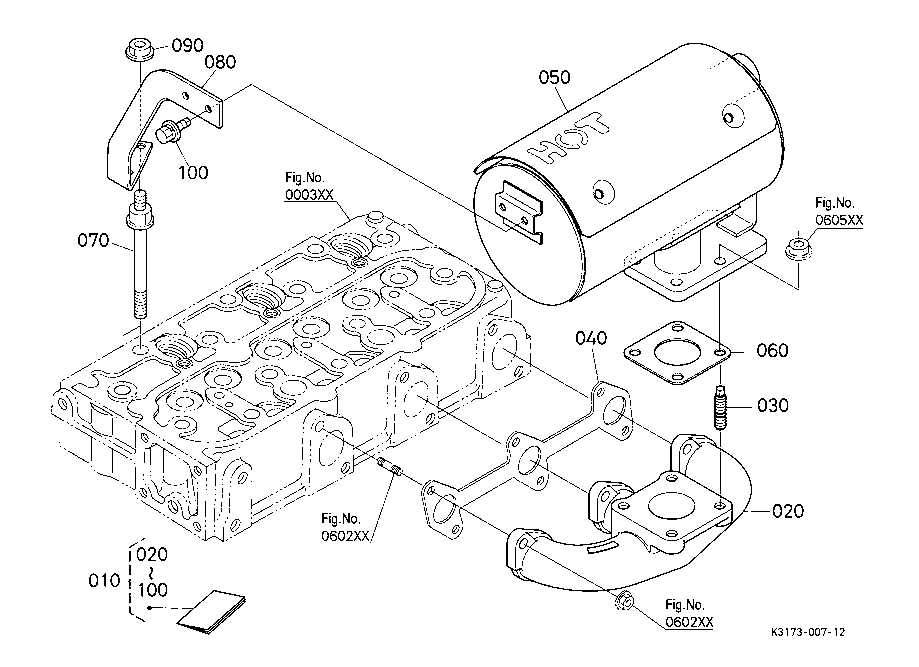

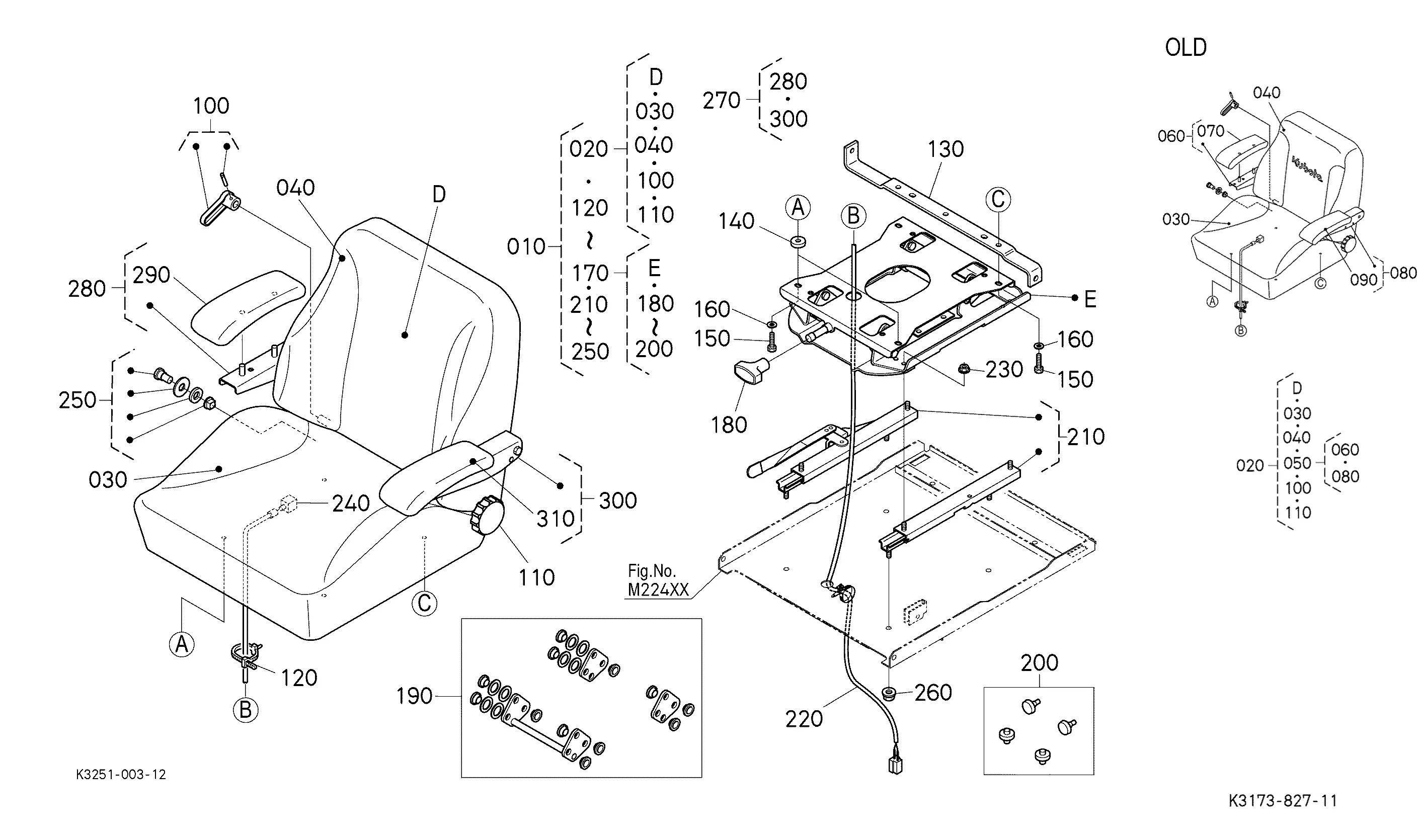

Understanding the Zd331 Components

Exploring the various elements that comprise a particular device is crucial for grasping its overall functionality and performance. Each component plays a distinct role, contributing to the seamless operation and reliability of the system. By examining these individual parts, users can gain insights into how they interact and support one another.

The assembly features a combination of mechanical and electronic elements that work together to achieve optimal results. Mechanical components ensure structural integrity and durability, while electronic parts manage the system’s processing and control functions. This synergy between the different types of components is essential for achieving the desired outcomes.

Understanding the significance of each element allows for more informed maintenance and troubleshooting practices. Recognizing how these components influence one another can help users identify potential issues and implement effective solutions. Knowledge of the assembly not only enhances operational efficiency but also empowers users to make modifications or upgrades as needed.

Key Features of Zd331 Equipment

The equipment in question is designed with a focus on efficiency and reliability, making it an essential tool in various applications. Its innovative design integrates advanced technology, ensuring that users can achieve optimal performance while maintaining ease of use.

Advanced Technology Integration

- Utilizes cutting-edge components for enhanced functionality.

- Features user-friendly interfaces for seamless operation.

- Equipped with smart sensors that provide real-time feedback.

Durability and Reliability

- Constructed from high-quality materials that withstand harsh conditions.

- Engineered for longevity, reducing the need for frequent maintenance.

- Offers robust performance in various operational environments.

Overall, this equipment combines modern features with durability, making it an invaluable asset for professionals seeking reliable solutions.

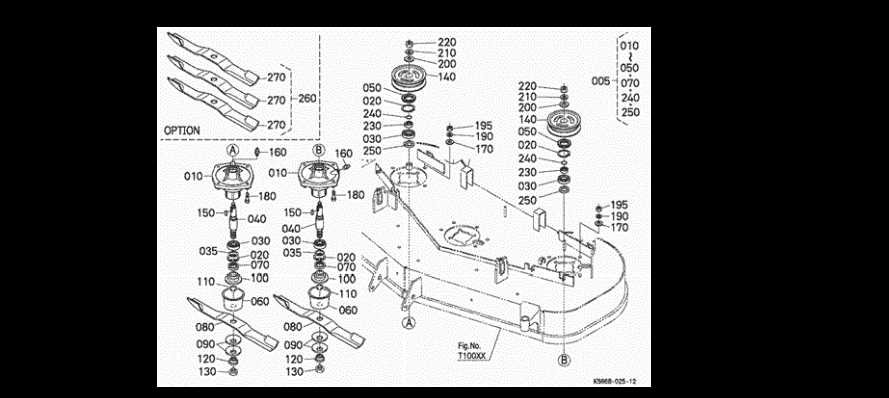

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective assembly, maintenance, and repair. These illustrations provide users with a clear understanding of how each element fits together, ensuring optimal performance and functionality of the entire system. A well-detailed image can greatly reduce errors and enhance efficiency during various processes.

Enhancing Efficiency and Reducing Errors

Accurate visual aids significantly streamline the workflow by offering clarity and guidance. When individuals can easily identify the correct components and their placements, the likelihood of mistakes decreases. This not only saves time but also minimizes the risk of costly damages that can arise from incorrect assembly.

Facilitating Communication and Training

Clear visual documentation serves as an essential tool for communication among team members and during training sessions. It allows novices to quickly grasp the layout and function of each component, fostering a better learning environment. Moreover, these visuals help experienced technicians share their knowledge effectively, ensuring everyone is on the same page.

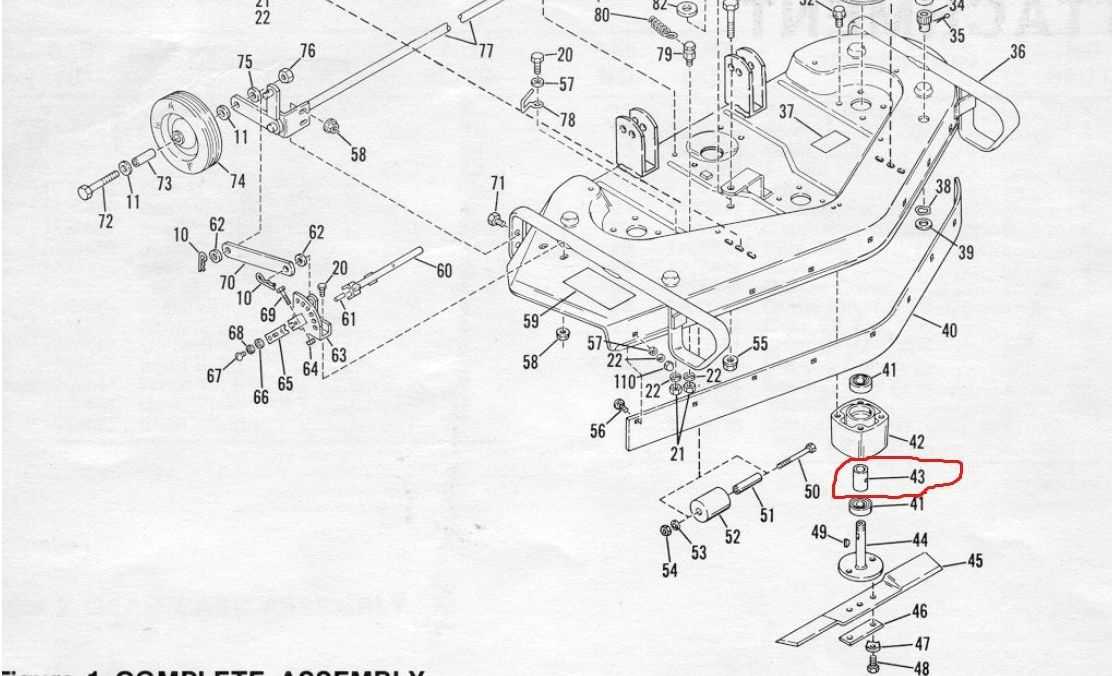

Common Issues with Zd331 Parts

In the world of machinery, certain components often exhibit recurring problems that can hinder overall performance. Understanding these common issues can help users identify and address them effectively, ensuring smoother operation and extended lifespan of the equipment. By recognizing these challenges, maintenance can be prioritized, minimizing downtime and enhancing efficiency.

Frequent Wear and Tear

Component degradation is a prevalent concern, as constant use can lead to reduced functionality. Factors such as exposure to harsh environments, excessive loads, and lack of lubrication contribute to accelerated wear. Regular inspections and timely replacements are essential to mitigate these effects.

Improper Installation

Another issue arises from incorrect assembly, which can result in misalignments and malfunctions. This can be attributed to inadequate guidance during the installation process or the use of incompatible components. Ensuring that all elements are installed according to specifications is crucial for optimal performance.

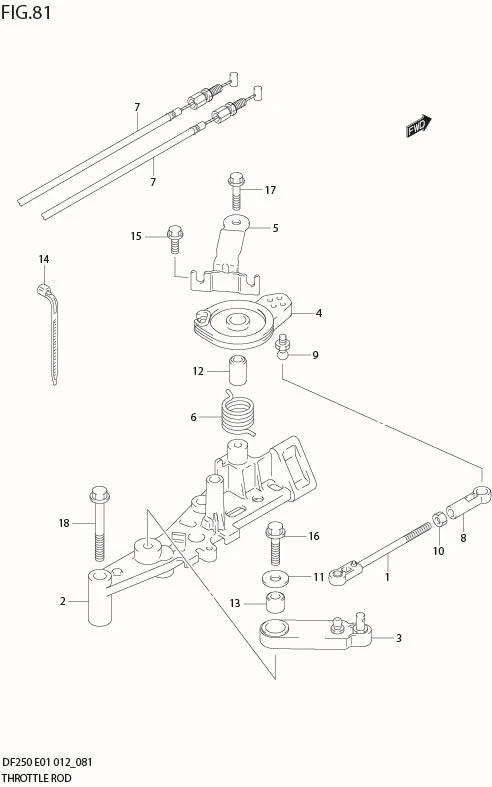

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone looking to effectively assemble, repair, or maintain machinery. These illustrations provide a clear overview of various elements, their arrangement, and how they interconnect within the overall system. Familiarizing yourself with these visuals can greatly enhance your efficiency in identifying parts and troubleshooting issues.

To successfully interpret these graphics, it’s important to recognize certain key features:

| Feature | Description |

|---|---|

| Labels | Most illustrations include identifiers for each element, often accompanied by reference numbers or codes. |

| Connections | Lines or arrows typically indicate how components are linked, showcasing the flow of operation. |

| Grouping | Elements may be organized into clusters, indicating their functionality or relationship within a subsystem. |

| Scale | Understanding the size and proportions depicted is crucial for accurate assembly or replacement of components. |

By keeping these aspects in mind, you can effectively navigate and utilize visual representations, leading to improved comprehension and successful handling of various equipment tasks.

Comparing Zd331 with Similar Models

When evaluating various models within the same category, it is essential to consider their distinct features and overall performance. This comparison highlights similarities and differences that can significantly impact user experience and functionality.

Key Features and Specifications

One of the primary aspects to analyze is the specification set that each model offers. While some may excel in energy efficiency, others might provide superior durability or enhanced user-friendly interfaces. Evaluating these factors can guide potential users in making informed choices based on their specific needs.

Performance and Reliability

Performance metrics play a crucial role in determining the effectiveness of each model. Analyzing user feedback and expert reviews reveals how various units operate under similar conditions. Additionally, assessing reliability over time can offer insights into maintenance requirements and longevity, which are vital for any consumer investment.

Maintenance Tips for Zd331 Systems

Regular upkeep of complex systems is crucial to ensure optimal performance and longevity. Implementing a proactive maintenance strategy can prevent potential issues and enhance reliability. Here are some essential tips to consider for maintaining these systems effectively.

Routine Inspections

Conducting frequent checks is vital for identifying wear and tear early on. Look for signs of damage or deterioration in components and connections. Establish a schedule for these inspections to ensure no critical areas are overlooked.

Proper Cleaning Procedures

Keeping the system clean is essential to prevent dust and debris from affecting performance. Utilize appropriate cleaning agents and techniques to avoid damaging sensitive parts. Regularly remove any buildup that could impede functionality.

Remember, a well-maintained system not only performs better but also saves costs on repairs in the long run. Adopting these maintenance practices will help prolong the lifespan of your equipment.

Upgrading Your Zd331 Equipment

Enhancing your machinery can significantly improve performance and efficiency. By investing in modern components and technology, you can ensure that your system operates at optimal levels. This section discusses various strategies for upgrading your equipment, focusing on essential enhancements that lead to better functionality and longevity.

Benefits of Upgrading

Upgrading your system offers numerous advantages, including increased reliability, improved energy efficiency, and enhanced capabilities. Incorporating the latest technology not only boosts performance but also helps to meet evolving industry standards. Additionally, newer components often come with better support and warranties, providing peace of mind for operators.

Key Components to Consider

When planning an upgrade, it’s crucial to identify which elements will yield the most significant impact. Below is a table outlining some critical components that can enhance your equipment:

| Component | Benefit |

|---|---|

| Control Systems | Improved precision and automation capabilities |

| Power Supply | Increased efficiency and reduced energy costs |

| Monitoring Sensors | Enhanced data collection for better decision-making |

| Cooling Systems | Prevention of overheating and extended equipment lifespan |

By carefully selecting the right components for your upgrade, you can significantly enhance the overall performance and reliability of your machinery. Consider conducting a thorough assessment to identify specific needs and determine the best course of action for improvements.

Parts Availability for Zd331 Models

This section delves into the accessibility of components for various models, focusing on the essentials required for maintenance and repairs. Understanding the availability of these components is crucial for ensuring the optimal functionality of the equipment.

Sources for Component Procurement

- Authorized Distributors

- Online Marketplaces

- Specialty Retailers

- Manufacturer’s Websites

Factors Influencing Component Accessibility

- Production Volume: Higher production often leads to better availability.

- Age of Model: Older versions may have limited stock.

- Market Demand: Popular models tend to have more readily available supplies.

- Geographical Location: Availability can vary based on region.

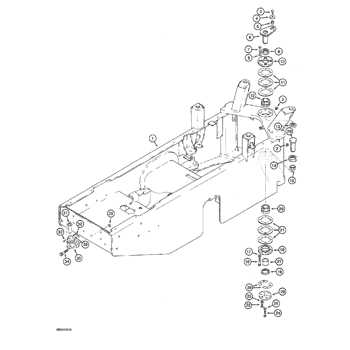

Installation Guidelines for Zd331 Components

This section outlines essential procedures for the proper setup of various components associated with the system. Adhering to these instructions will ensure optimal performance and longevity of the equipment.

Preparation Steps

- Gather all necessary tools and components before starting the installation.

- Review the manufacturer’s specifications to familiarize yourself with the requirements.

- Ensure a clean workspace to avoid contamination of parts.

Installation Process

- Begin by securing the base unit in a stable position.

- Carefully connect the components according to the established layout.

- Use appropriate fasteners to secure each element, ensuring they are tight but not over-torqued.

- Verify all connections and configurations before powering on the system.

- Conduct a functional test to confirm that everything operates as intended.

Following these guidelines will help maintain the efficiency and reliability of the setup, leading to successful operation in various applications.

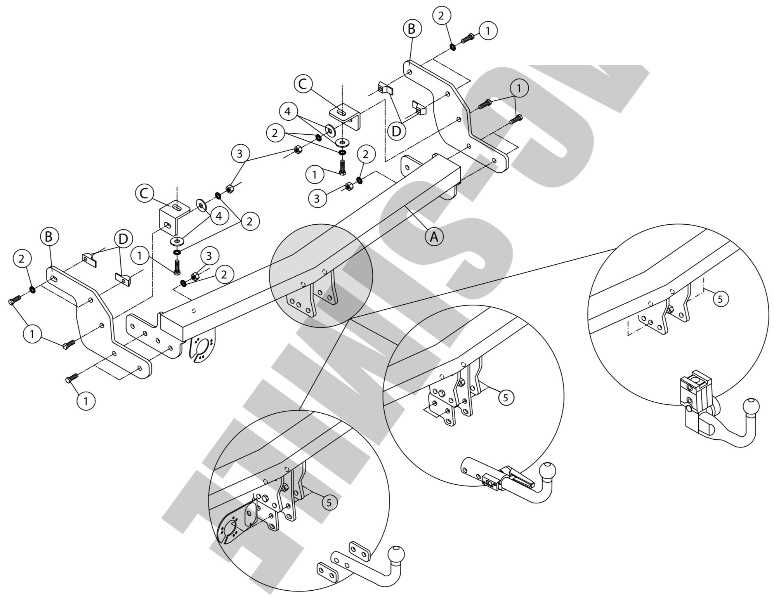

Safety Precautions During Repairs

When undertaking any maintenance task, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation and awareness of the risks involved can significantly enhance the safety of the work environment. Familiarizing oneself with potential hazards and implementing necessary precautions is essential for a successful and secure repair process.

Before starting any repair, ensure that you have the appropriate tools and protective equipment on hand. This may include gloves, goggles, and other safety gear tailored to the specific task at hand. Additionally, working in a well-ventilated area is important to avoid inhaling harmful fumes or dust.

It is advisable to disconnect power sources and secure any movable components to prevent unexpected movements during repairs. Always follow the manufacturer’s guidelines and recommendations when disassembling or reassembling equipment. Keeping the workspace organized and free from clutter can also help reduce the risk of accidents.

Be mindful of the materials you are working with, as some may be hazardous or require special handling. In case of any spills or leaks, know the proper procedures for managing them safely. Lastly, never hesitate to ask for assistance or consult professionals if you are unsure about any step in the process.

Resources for Zd331 Troubleshooting

Effective resolution of technical issues often relies on comprehensive resources that provide valuable information. Accessing the right materials can significantly enhance the troubleshooting process, offering guidance on various challenges. Utilizing manuals, online forums, and technical documents can streamline the identification of problems and potential solutions.

Here are some useful resources that can assist in troubleshooting:

| Resource Type | Description | Link |

|---|---|---|

| User Manual | Detailed instructions and specifications for operation and maintenance. | User Manual |

| Online Forums | A community of users sharing experiences and solutions to common issues. | Forums |

| Technical Support | Direct assistance from professionals to address specific inquiries. | Technical Support |

| Video Tutorials | Step-by-step visual guides demonstrating troubleshooting techniques. | Video Tutorials |

Enhancing Performance of Zd331 Systems

Improving the functionality of specific systems involves a multifaceted approach that considers various components and their interactions. By focusing on optimizing key elements, users can achieve greater efficiency and reliability. Understanding how these parts work together is essential for maximizing overall performance.

Regular Maintenance is crucial for ensuring that every element operates smoothly. Frequent inspections and timely replacements can prevent minor issues from escalating into major problems. Establishing a routine maintenance schedule helps identify wear and tear early on, allowing for prompt interventions.

Another significant aspect is the upgrade of critical components. Utilizing advanced materials and technologies can enhance durability and performance. Investing in high-quality replacements can lead to significant improvements in efficiency and longevity.

Calibration and fine-tuning play a vital role in optimizing system performance. Adjusting settings and configurations to align with operational requirements can yield substantial benefits. Regularly revisiting these parameters ensures that the system adapts to changing demands effectively.

Moreover, integrating monitoring tools can provide valuable insights into performance metrics. Utilizing technology to track system functionality helps in making informed decisions about necessary adjustments or upgrades, ultimately leading to enhanced efficiency.